4 –62 Assembly instructions EN ◼PDZ-128 I PDZ-160 I PDZ-200 ◼Date 12.04.2023 ◼V4.1

3.4.1 Dimension drawing SE-Power .............................................................28

3.4.2 Technical data SE-Power.....................................................................29

4Transport, packaging and storage.....................................................................30

4.1 Safety instructions for transport..................................................................30

4.2 Scope of supply..........................................................................................31

4.3 Transport ....................................................................................................32

4.4 Packaging...................................................................................................32

4.5 Storage.......................................................................................................32

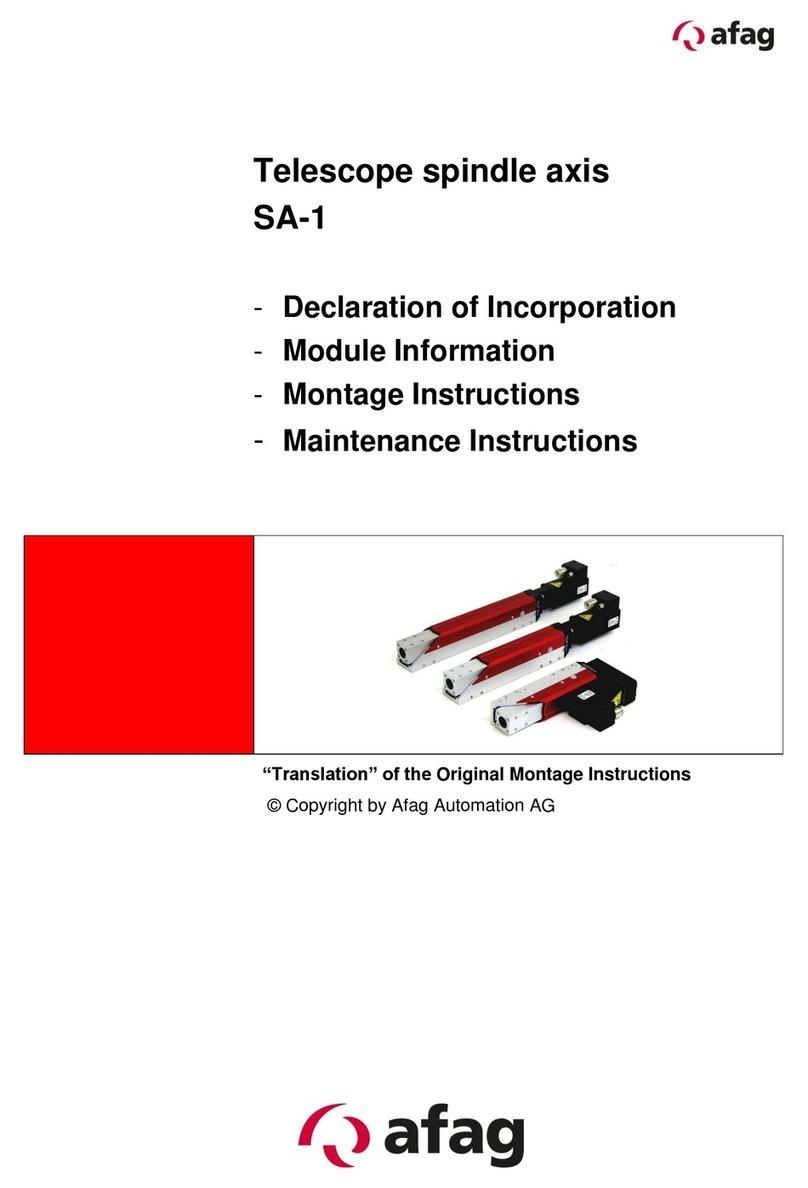

5Design and description .......................................................................................33

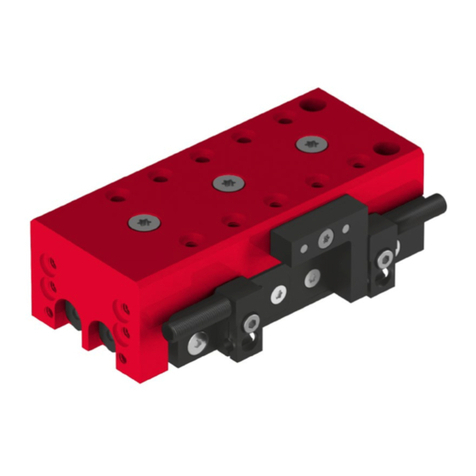

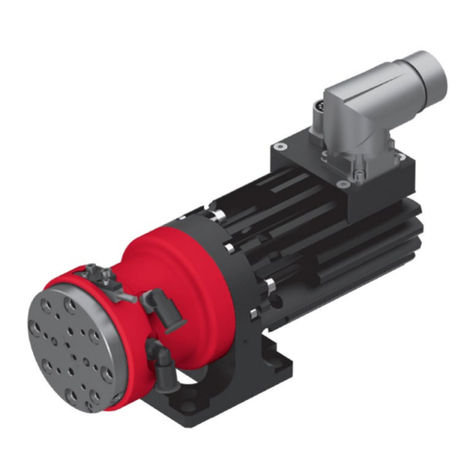

5.1 Structure of portal axis................................................................................33

5.2 Product description.....................................................................................33

5.3 Accessories ................................................................................................34

6Installation, assembly & setting .........................................................................36

6.1 Safety Instructions for Installation & Assembly ..........................................36

6.2 Assembly & attachment..............................................................................37

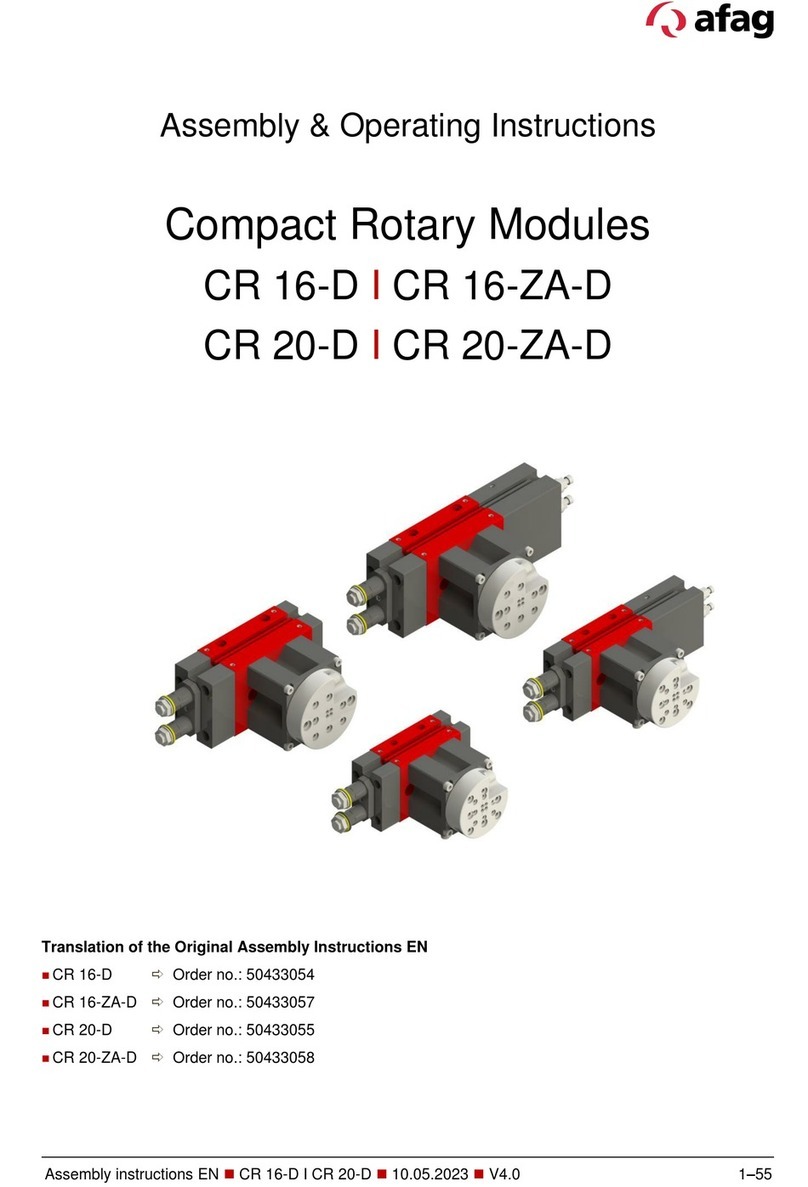

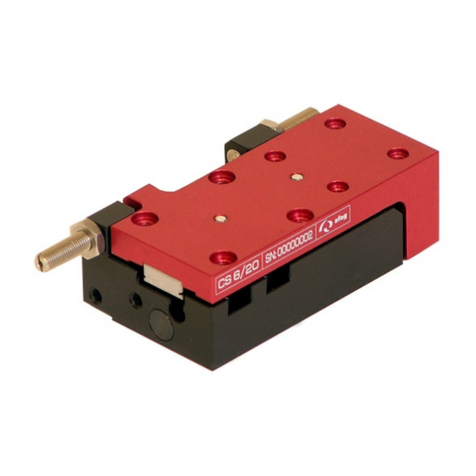

6.2.1 Overview of individual parts of the PDZ...............................................37

6.2.2 Mounting surfaces................................................................................37

6.2.3 Mounting options on the axle slide.......................................................38

6.2.4 Attachment grid and centering bushings..............................................38

6.2.5 Tightening torques................................................................................39

6.3 Installation in an assembly system.............................................................40

6.4 Motor gearbox combination........................................................................40

6.4.1 Electrical interfaces of the portal axis...................................................41

6.4.2 Changing the gearbox mounting side ..................................................42

6.4.3 Attachment of other gearboxes............................................................44

6.5 Programming the portal axis ......................................................................45

6.6 Add-on modules .........................................................................................45

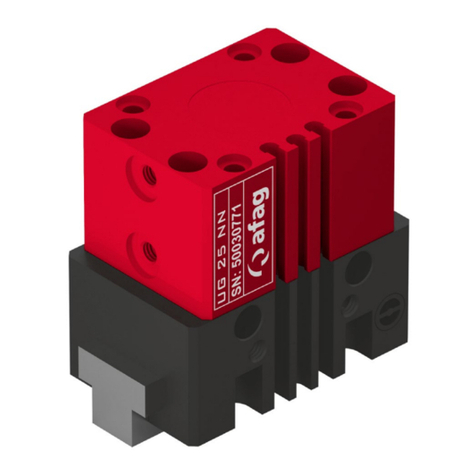

6.6.1 Servo motor..........................................................................................46

6.6.2 Mounting the transmission unit ............................................................47

6.6.3 Superstructures for portal axes............................................................48

6.6.1 Stroke limiter ........................................................................................48

6.6.2 Portal axis with double slide (special version) .....................................50

7Commissioning ....................................................................................................51

7.1 Safety instructions for commissioning........................................................51

7.2 Preparatory activities for commissioning....................................................51

7.3 Commissioning of the modules ..................................................................51

7.4 Setting up & retrofitting...............................................................................52

8Fault elimination...................................................................................................53

8.1 Safety instructions for troubleshooting .......................................................53

8.2 Fault causes and remedy...........................................................................54

8.2.1 A) Malfunctions during reference travel ...............................................54

8.2.2 Malfunction during operation................................................................55