Operating & Installation Instructions EN WV151-1/WV201-1/WV310-1 Date 15.10.2023 Version 7.0 3–48

Table of contents

1General .................................................................................................................... 5

1.1 Contents and purpose of this manual........................................................... 5

1.2 Explanation of symbols................................................................................. 5

1.3 Additional symbols........................................................................................ 6

1.4 Warranty ....................................................................................................... 7

1.5 Liability.......................................................................................................... 7

2Safety instructions................................................................................................. 8

2.1 General ......................................................................................................... 8

2.2 Intended use ................................................................................................. 8

2.3 Foreseeable misuse ..................................................................................... 9

2.4 Obligations of the operator and the personnel ............................................. 9

2.4.1 Follow these instructions ........................................................................ 9

2.4.2 Obligations of the operating company.................................................... 9

2.4.3 Obligations of the personnel ................................................................ 10

2.5 Personnel requirements ............................................................................. 10

2.5.1 Personnel qualification ......................................................................... 10

2.6 Personal protective equipment (PPE) ........................................................ 11

2.7 Changes and modifications ........................................................................ 11

2.8 General hazards / residual risks................................................................. 11

2.8.1 General hazards at the workplace ....................................................... 11

2.8.2 Danger due to electricity ...................................................................... 12

2.8.3 Mechanical hazards ............................................................................. 12

2.8.4 Danger due to alternating magnetic fields ........................................... 13

2.8.5 Noise hazards ...................................................................................... 13

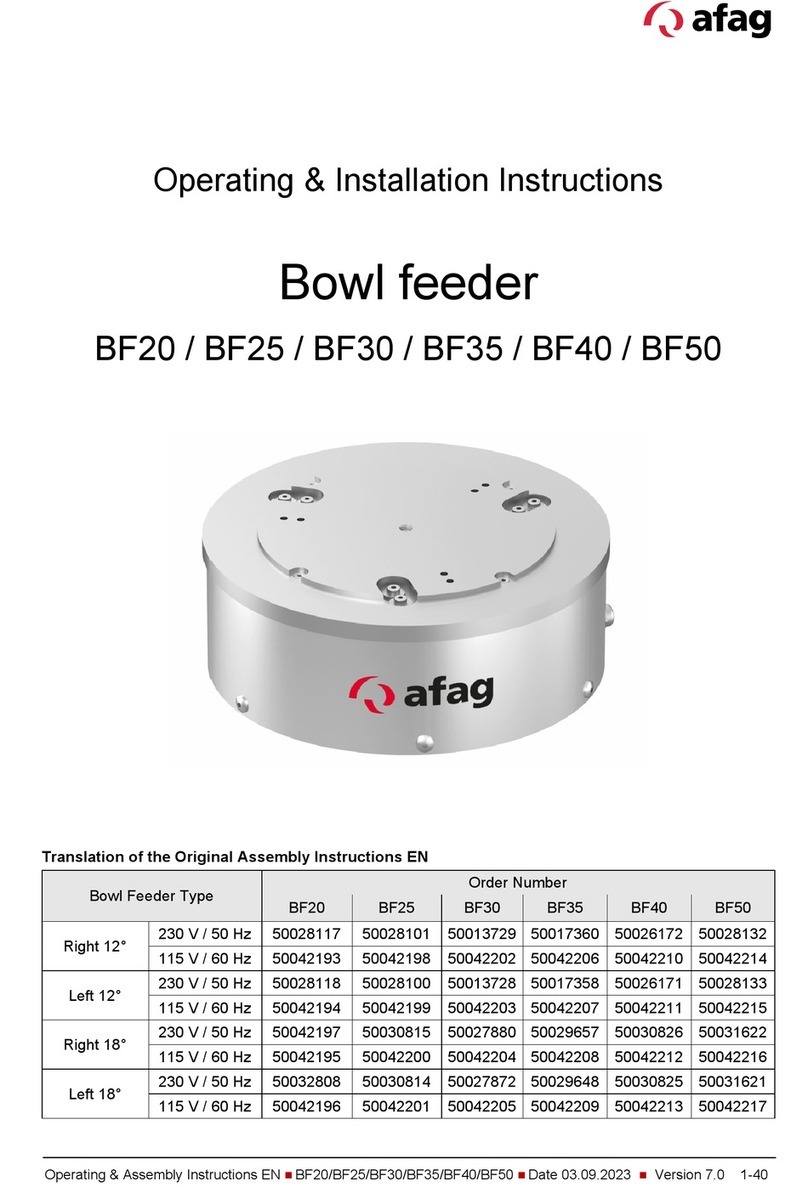

3Technical data ...................................................................................................... 14

3.1 Dimensional drawing WV151-1 - WV310-1................................................ 14

3.2 Technical data WV151-1 - WV310-1.......................................................... 15

3.3 Accessories ................................................................................................ 16

3.3.1 Mounting parts...................................................................................... 16

3.3.2 Controller.............................................................................................. 16

4Transport, packaging and storage ..................................................................... 17

4.1 Safety instructions ...................................................................................... 17

4.2 Scope of supply .......................................................................................... 17

4.3 Transport .................................................................................................... 18

4.4 Packaging ................................................................................................... 18

4.5 Storage ....................................................................................................... 18

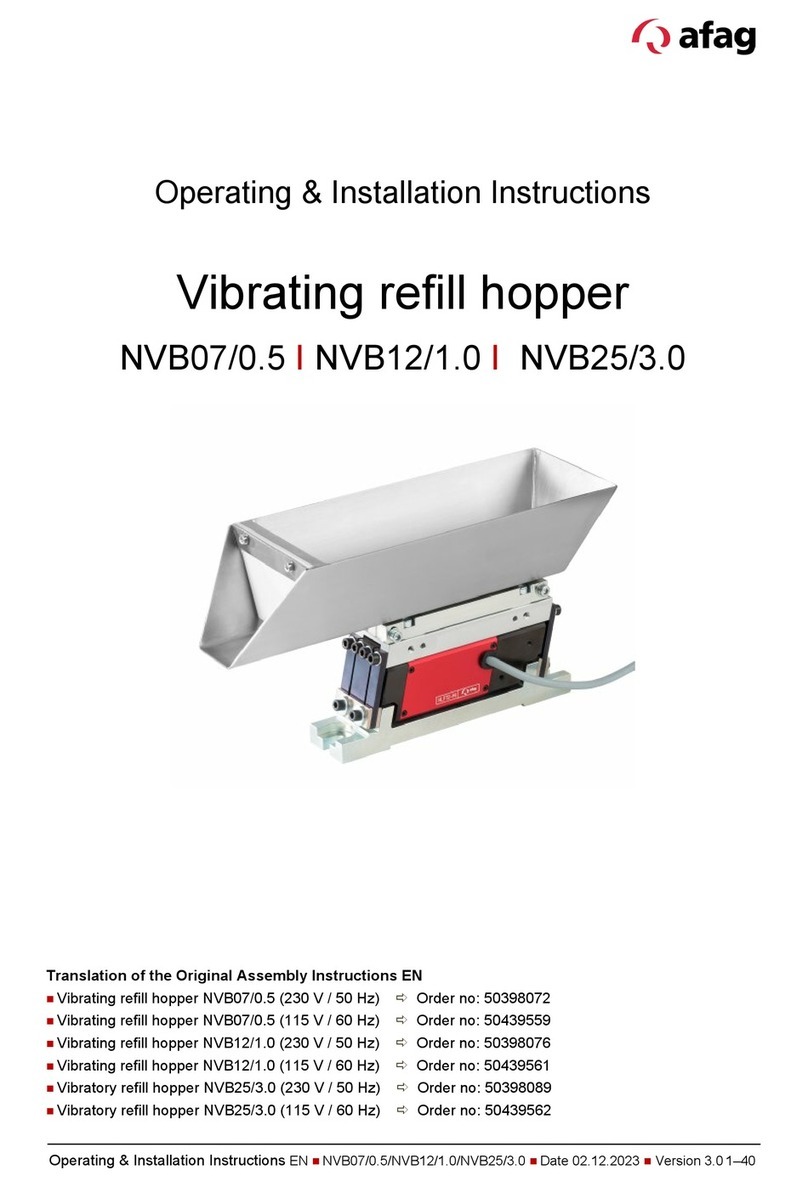

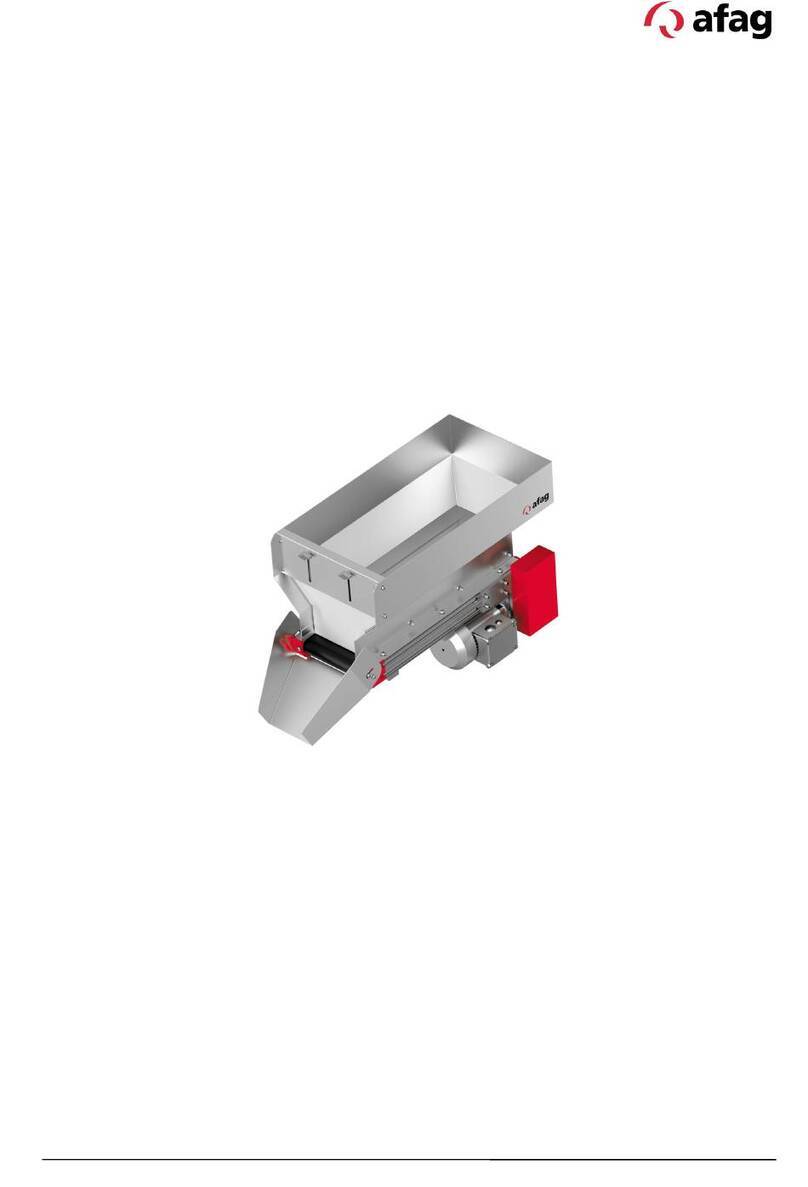

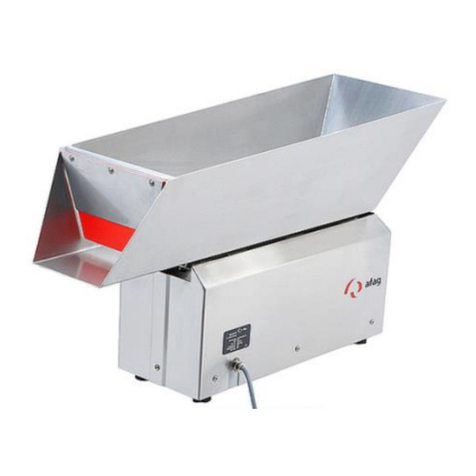

5Design and description ....................................................................................... 19

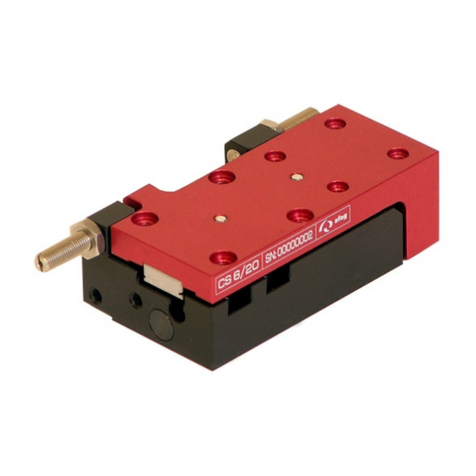

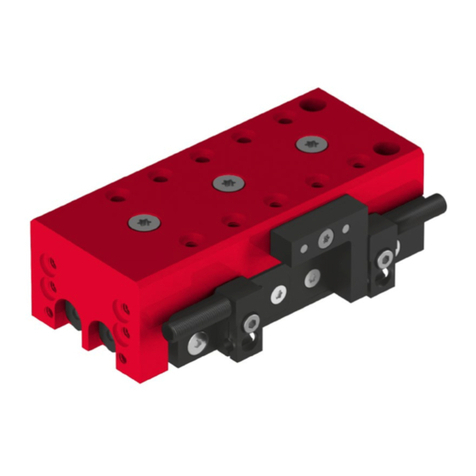

5.1 Structure of the WV151-1 - WV310-1......................................................... 19

5.2 Description of the bowl feeder WV ............................................................. 20