CODE: GZ0000010348

October, 2005

© 2005 HORIBA, Ltd. For any question regarding this product, please contact your local agency, or inquire from the HORIBA

website (http://global.horiba.com/contact_e/index.htm).

Instruction Manual for pH Electrodes

Thank you for purchasing a HORIBA pH electrode. Read this manual carefully, before using the electrode.

Contents: Electrode …1 ・Instruction manual …1

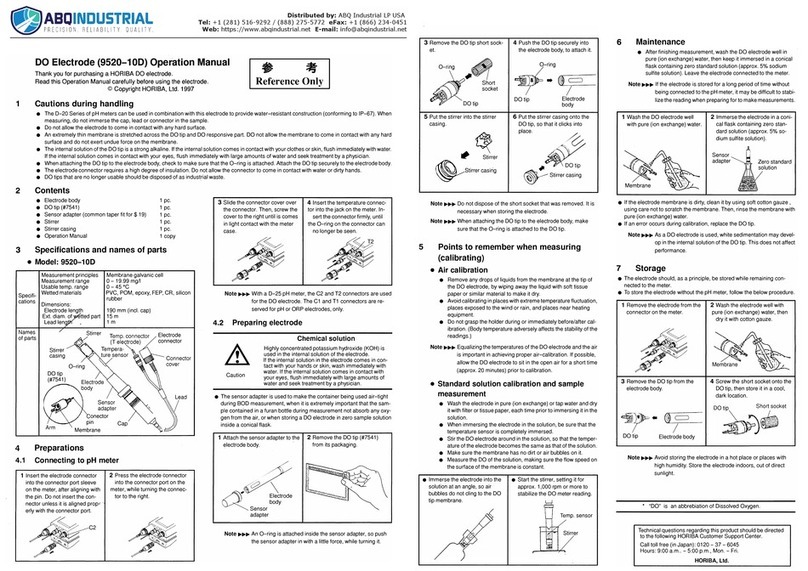

■Specifications and parts description

■Connecting to pH meter

5.Insert the electrode connector into the connector port sleeve on the meter, after aligning with the pin. Do not insert the connector unless it is aligned

properly with the connector port.

6.Press the electrode connector into the connector port on the meter, while turning the connector to the right.

7.Slide the connector cover over the connector. Then, push the cover in straight until it comes in light contact with the meter case. Do not turn the

cover.

8. Insert the temperature connector into the jack on the meter. Insert the connector firmly, until the O-ring on the connector can no longer be seen.

Note

Be sure to install the temperature connector. If not, accurate measurement cannot be performed.

■Preparation

Note

White crystal (KCl) can adhere to the internal solution filler port or protective cap. However, it will not cause any performance problem.

Wash away the white crystal with pure water.

●For first use or after long-term interval

■Measurement (calibration)

■Storage

• Do not dry the responsive glass membrane and liquid junction. If they are dry, replace the internal solution and immerse them in pure water for 12 hours

or longer. After these procedures, perform calibration. If calibration cannot be performed correctly, replace the electrode.

• Avoid storing the electrode in hot and humid locations. Store the electrode indoors, out of direct sunlight.

■Maintenance

Note

Do not use organic solvents (such as acetone or tetrahydrofuran) or strong acid or alkaline cleansing solutions. Using such chemicals may

damage the body of the electrode or cause a decline in performance.

• To maintain electrode performance, replace the internal solution approximately every two or three months. (Refer to " ■Preparation.")

• Dirt on the responsive glass membrane or liquid junction by the test solution may cause a decline in electrode response and sensitivity or measurement

error. If the electrode is very dirty and cannot be washed clean using pure water, perform cleansing.

●Cleansing of electrod

■For accurate measurement

For accurate measurement, refer to items below.

• Stir the sample with stirrer in measurement (calibration).

• Perform temperature compensation manually or automatically. (Refer to the instruction manual of pH meter.)

• Temperature of standard solution and sample should be the same.

• Immerse the responsive glass membrane and liquid junction in the sample completely. Make sure that the surface of the internal solution inside the

electrode is higher than the surface of the sample solution.

• Rinse the electrode with the sample before measurement.

• Perform calibration before measurement. If measurement is performed everyday, perform calibration once or more a day.

■Cautions for use

Caution

Chemical solution

The internal solution in the electrode uses potassium chloride (3.33

mol/L-KCI). If the internal material comes in contact with the hands

or skin, wash immediately with water. If the internal solution comes

in contact with the eyes, flush with a large amount of running water,

then seek medical advice.

Glass fragments

Glass fragments can cause injury.

The outer tube and tip of the electrode are made from glass.

Be careful not to break them.

Model/ Part name Specification Specification

●9678-10D

pH range: pH 0 to 14

Usable temp. range: 0ºC to 100ºC

Storage temp. range: 0ºC to 50ºC

Internal electrode: Silver/ silver chloride

Reference electrode internal solution:

3.33 mol/L-KCl solution (#300)

Liquid junction material: Porous ceramic

Wetted material: Glass, ceramic

Electrode length: 250 mm (including a cap)

Ext. diam. of wetted part: 7 mm

Wetted part height: Approx. 21 mm (from the tip of

electrode)

Lead length: 1 m

1. Loosen the knurled nut, then

remove the protective cap.

2. Remove the existing electrode

internal solution with a dropper.

3. Fill the electrode with new

internal solution

(#300) until the

solution level

gets close to

the filler port.

4. Wash the electrode tip well with

pure water,

then wipe

it dry with

filter

paper.

1. Open the internal solution filler

port. *1

2. If necessary, fill the electrode with

new internal solution until the

solution level gets close to the

filler port.

3. Wash the electrode with pure

water and dry it with filter paper,

prior to every immersion into

standard/sample solution.

4. When there are air bubbles inside

the responsive glass membrane,

stir it lightly to remove bubbles.

Liquid junction

Protective cap

Stem

Cap

Temp. connector

Electrode connector

Connector cover

Lead

Responsive glass

membrane

Internal solution filler port

(Slide cap)

Knurled nut

Protective cap

Knurled nut

②remove

①loosen

5. Immerse the responsive glass

membrane and liquid junction

in the sample completely.

Make sure that the surface of

the internal solution inside the

electrode is higher than the

surface of the sample solution.

6. Stir the electrode

lightly to remove

bubbles.

*1 Be sure to keep the internal solution filler port open

during measurement. If it is clogged with the solution,

accurate measurement cannot be performed. Wipe the

solution with cloth.

*2 For calibration/ measurement on pH meter, refer to the

instruction manual of pH meter.

1. Wash the electrode well with

pure water to

remove sample

completely.

2. Close the slide cap. 3. Wash the inside of the

protective cap with

pure water, then add

enough pure water to

soak the swab.

4. Attach the protective cap and

tighten the knurled nut.

1. Open the slide cap.

2. Immerse the responsive glass membrane and liquid

junction in cleansing agent for approximately one hour

until contamination is removed. The responsive glass

membrane can also be cleaned by wiping it with cotton

gauze containing cleansing agent.

3. Rinse the electrode with pure water completely.

4. Replace the internal solution.

(Refer to " ■Preparation.")

Note

Be sure to perform calibration prior to measurement after

cleansing the electrode.

Type of dirt Cleansing agent

General Diluted neutral cleansing agent

Oil Alcohol, or diluted neutral cleansing agent

Inorganic substance Inorganic substance Electrode cleaner (#220) or

Hydrochloric acid approx. 1 mol/L

Protein Cleansing agent including protein-cutting

enzyme

Liquid junction Electrode cleaner (#220)

• Do not shock the electrode.

• Do not use chapped or cracked electrode. Replace such electrode

with a new one.

• Do not allow the connector to come in contact with water or unclean

hands.

• Always use the #300 internal solution for reference electrode.

• If the responsive glass membrane or liquid junction is very dirty and

cannot be washed clean using pure water, cleanse it depending on dirt

condition. (Refer to " ■Maintenance.")

• Avoid continuous use of this electrode at acidic or alkaline

concentrations above 0.1 mol/L. Using the electrode under these

conditions may harm performance and shorten the life of the

electrode.

• Do not measure the solutions which contain fluoride ion, which may

corrode the glass electrode.

• Do not suddenly immerse the electrode in samples where the

temperature variation is 50ºC or more.

• Brown colored silver chloride can be detected inside the responsive

glass membrane. However, it will not cause any performance problem.

• Do not use the sensor in any place where usable temperature is out of

the specified range.

• White crystal can adhere to the internal solution filler port or protective

cap after storage of the electrode. However, it will not cause any

performance problem.

①attach

②tighten

Protective cap

Knurled nut