2 Eurovac HV

Contents

1This instruction manual............................................................................................4

1.1 Precautions ..................................................................................................4

1.2 Explanation of symbols and typeface ..........................................................4

2Safety ......................................................................................................................5

2.1 Intended use ................................................................................................5

2.2 Predictable incorrect application..................................................................6

2.3 Safe handling ...............................................................................................6

2.4 Staff qualification..........................................................................................6

2.5 Modifications to the product.........................................................................7

2.6 Usage of spare parts and accessories.........................................................7

2.7 Liability information ......................................................................................7

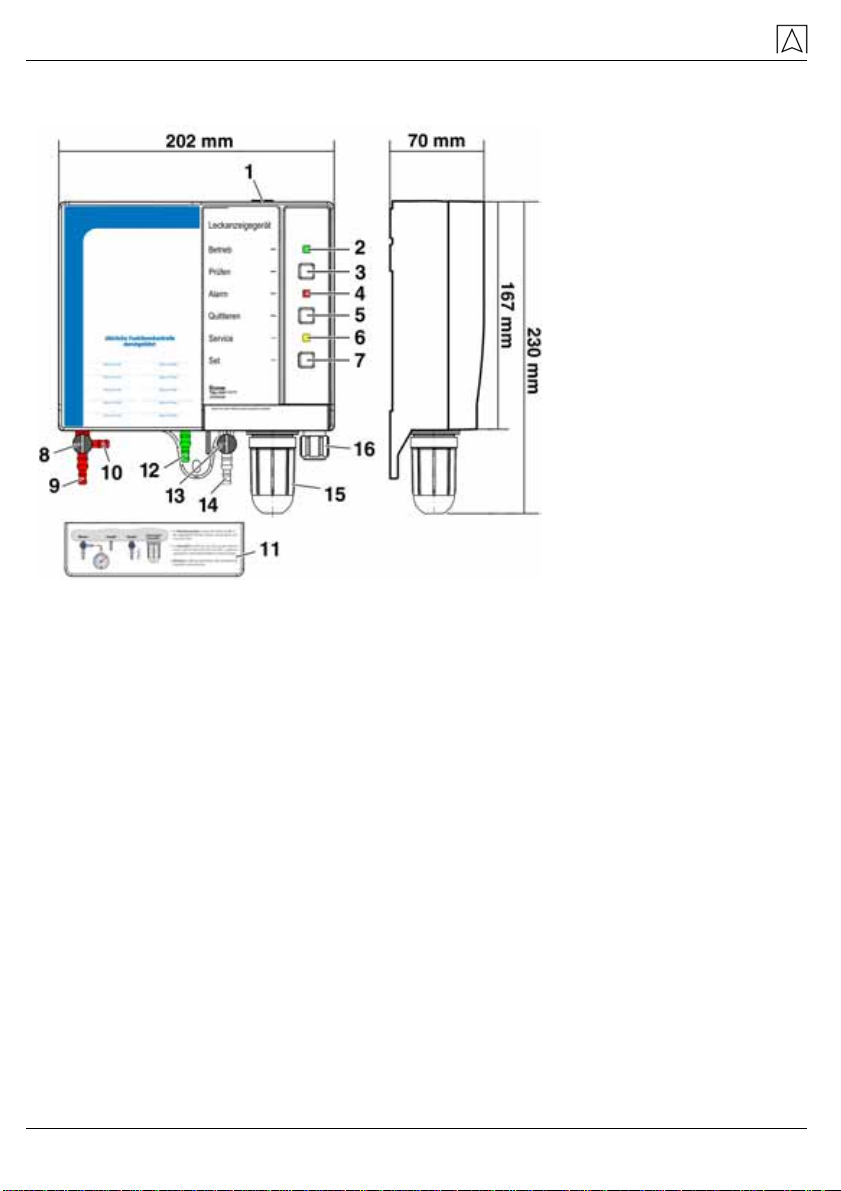

3Product description..................................................................................................8

3.1 Function........................................................................................................9

3.2 Operating modes..........................................................................................9

3.3 Application examples.................................................................................10

4Technical specifications.........................................................................................11

4.1 Approvals, tests and conformities..............................................................12

5Transport and storage...........................................................................................13

6Mounting and commissioning................................................................................13

6.1 Preparing the tank......................................................................................13

6.2 Preparing mounting....................................................................................14

6.3 Installation site ...........................................................................................15

6.4 Installing the leak detector .........................................................................15

6.5 Electrical connection..................................................................................16

6.6 Hose connections.......................................................................................18

6.7 Valve settings.............................................................................................20

6.8 Commissioning the device.........................................................................20

7Operation...............................................................................................................21

7.1 Alarm condition ..........................................................................................21

7.2 Function test...............................................................................................21

8Maintenance..........................................................................................................23

8.1 Service indication.......................................................................................23

8.2 Maintenance activities................................................................................24

9Troubleshooting.....................................................................................................25

9.1 Evaluation of the pump operating time ......................................................26

10 Shutting down, disposal ........................................................................................27

11 Spare parts and accessories.................................................................................27