TABLE OF CONTENTS

3

TABLE OF CONTENTS

TO OUR CUSTOMER ................................................... 1

TABLE OF CONTENTS ................................................ 3

SAFETY ........................................................................ 5

MACHINE PURPOSE ............................................... 5

PERSONAL SAFETY INSTRUCTIONS.................... 5

MAKING YOUR TRACTOR A SAFE VEHICLE......... 6

How to Maintain Safety ......................................... 6

FOR SAFE OPERATION .......................................... 7

How to be a Safe Operator ................................... 7

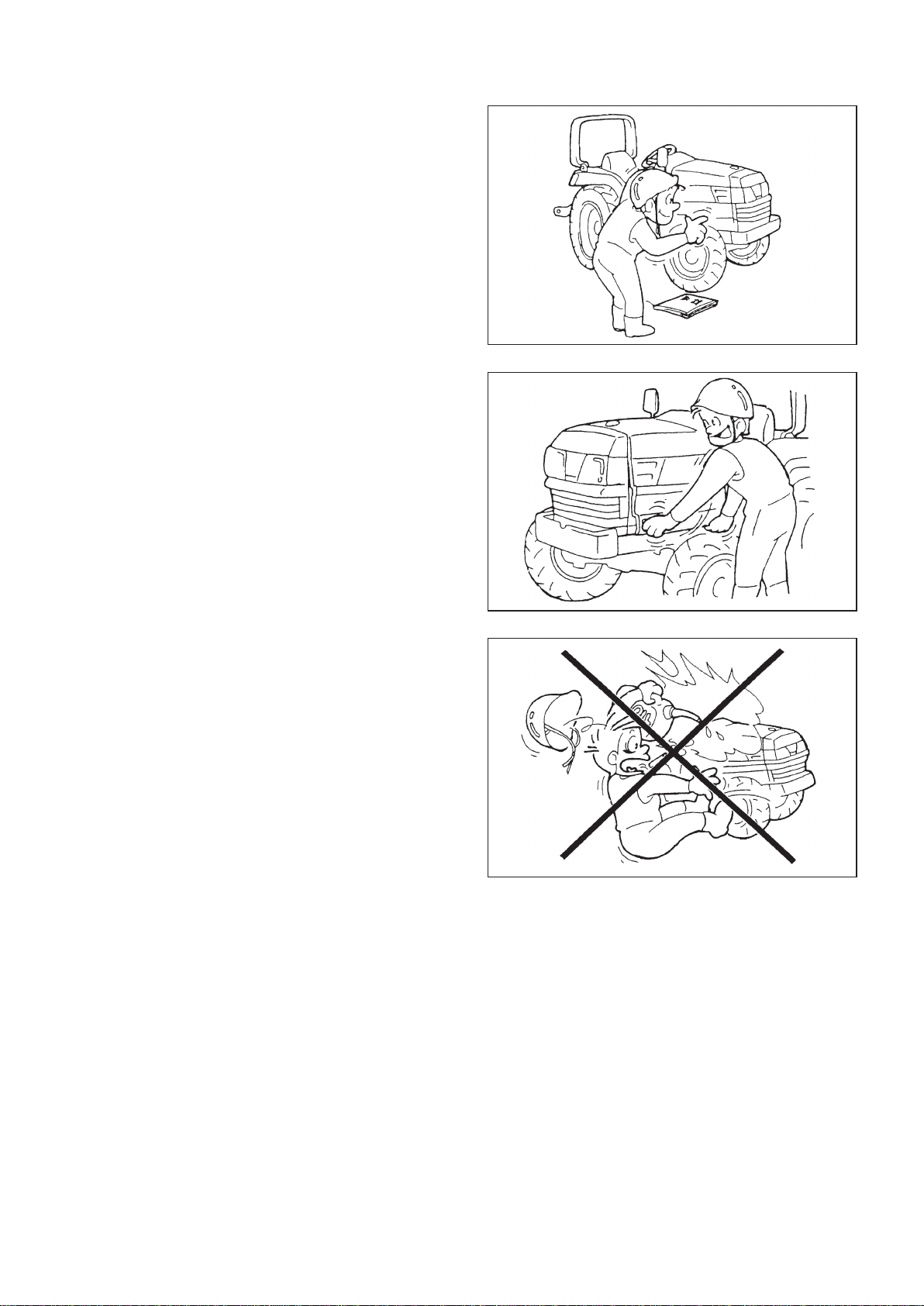

When Another Person Operates Your Machine .... 7

Before Operation................................................... 8

Starting Engine and Operating Tractor ................. 9

When Traveling ..................................................... 9

Loading onto or Unloading from a Truck............. 11

During Operation................................................. 12

Inspection and Maintenance ............................... 13

Storage ............................................................... 14

Dismantling and Disposal ................................... 14

MAINTENANCE OF THE ELECTRIC SYSTEM ..... 15

To Maintain Electric Wiring.................................. 15

To Handle the Battery ......................................... 15

To Handle Booster Cables .................................. 16

SAFETY DECALS................................................... 17

Maintenance of Safety Decals ............................ 19

Location of Safety Decals ................................... 20

INTRODUCTION......................................................... 21

TRACTOR IDENTIFICATION ..................................... 22

STATUTORY PLATE .............................................. 22

MODEL / SERIAL NUMBER ................................... 22

MODEL TYPE DESIGNATION................................ 23

MAJOR COMPONENTS............................................. 24

OPERATION ............................................................... 25

INSTRUMENT PANEL ............................................ 26

Main Switch......................................................... 26

Indicator Light Array ............................................ 27

Tachometer & Engine Hourmeter........................ 28

Coolant Temperature Gauge............................... 28

Fuel Gauge ......................................................... 28

Switches ............................................................. 29

CLUTCH PEDAL..................................................... 30

BRAKE .................................................................... 30

Brake Pedals....................................................... 30

Parking Brake Lever ........................................... 30

BREAK-IN PERIOD ................................................ 31

STARTING .............................................................. 31

Pre-Start Inspection ............................................ 31

Normal Starting ................................................... 32

Restarting Warm Engine..................................... 33

Cold Weather Starting......................................... 33

Warm-Up Period ................................................. 33

Operator Observations........................................ 34

Starting Circuit Operation.................................... 34

ENGINE SPEED CONTROLS ................................ 35

GROUND SPEED SELECTION.............................. 35

STOPPING TRACTOR ........................................... 37

DIFFERENTIAL LOCK OPERATION ...................... 38

4-WHEEL DRIVE .................................................... 38

POWER TAKE-OFF (PTO) ..................................... 39

Rear PTO Shaft .................................................. 39

PTO Operating Controls ..................................... 40

3-POINT HITCH ...................................................... 41

Hitch Controls ..................................................... 41

Rear Linkage....................................................... 42

Attaching Implements ......................................... 43

Using Position Control ........................................ 43

Detaching Implements ........................................ 44

EXTERNAL AUXILIARY HYDRAULICS (OPTION) 45

REAR HITCH .......................................................... 46

ROLL OVER PROTECTIVE STRUCTURE

(ROPS).................................................................... 47

How to Tilt ROPS ................................................ 47

SEAT & SUSPENSION ADJUSTMENT .................. 48

7 PINS SOCKET ..................................................... 49

BEACON ................................................................. 49

TOWING.................................................................. 49

FRONT LOADER FIXATION POINT....................... 49

FALLING OBJECTS PROTECTIVE STRUCTURE

(FOPS) & OPERATORS PROTECTION

STRUCTURE (OPS) FIXATION POINT.................. 50

JACKING................................................................. 50

LUBRICATION & PERIODIC MAINTENANCE .......... 51

SPECIFICATIONS & CAPACITIES ......................... 51

Engine Oil ........................................................... 51

Engine Coolant ................................................... 51

Fuel Tank ............................................................ 51

Transmission & Differential Housing

(Including Hydraulic System) .............................. 51

Front Axle............................................................ 51

Grease Fittings.................................................... 51

LUBRICATION / FILL POINTS................................ 52

PERIODIC MAINTENANCE SCHEDULE ............... 53

SERVICE ACCESS ................................................. 55

Opening / Closing Engine Hood ......................... 55

LUBRICATION DETAILS......................................... 56

Grease Fittings.................................................... 56

Engine Oil & Filter ............................................... 56

Transmission Oil & Filters ................................... 57

Front Axle Oil ...................................................... 58