Airfield Lighting Systems UK Limited

Aviation House, Russell Gardens, Wickford

Essex SS11 8BF Tel +44 1702 547866

sales@alsukltd.co.uk www.alsukltd.co.uk

Table of Contents

1. Safety ............................................................................................................................ 1

1.1. Safety Symbols .................................................................................................. 1

1.2. Professional ....................................................................................................... 1

1.3. Introduction to safety ......................................................................................... 2

2. Equipment Information ................................................................................................. 4

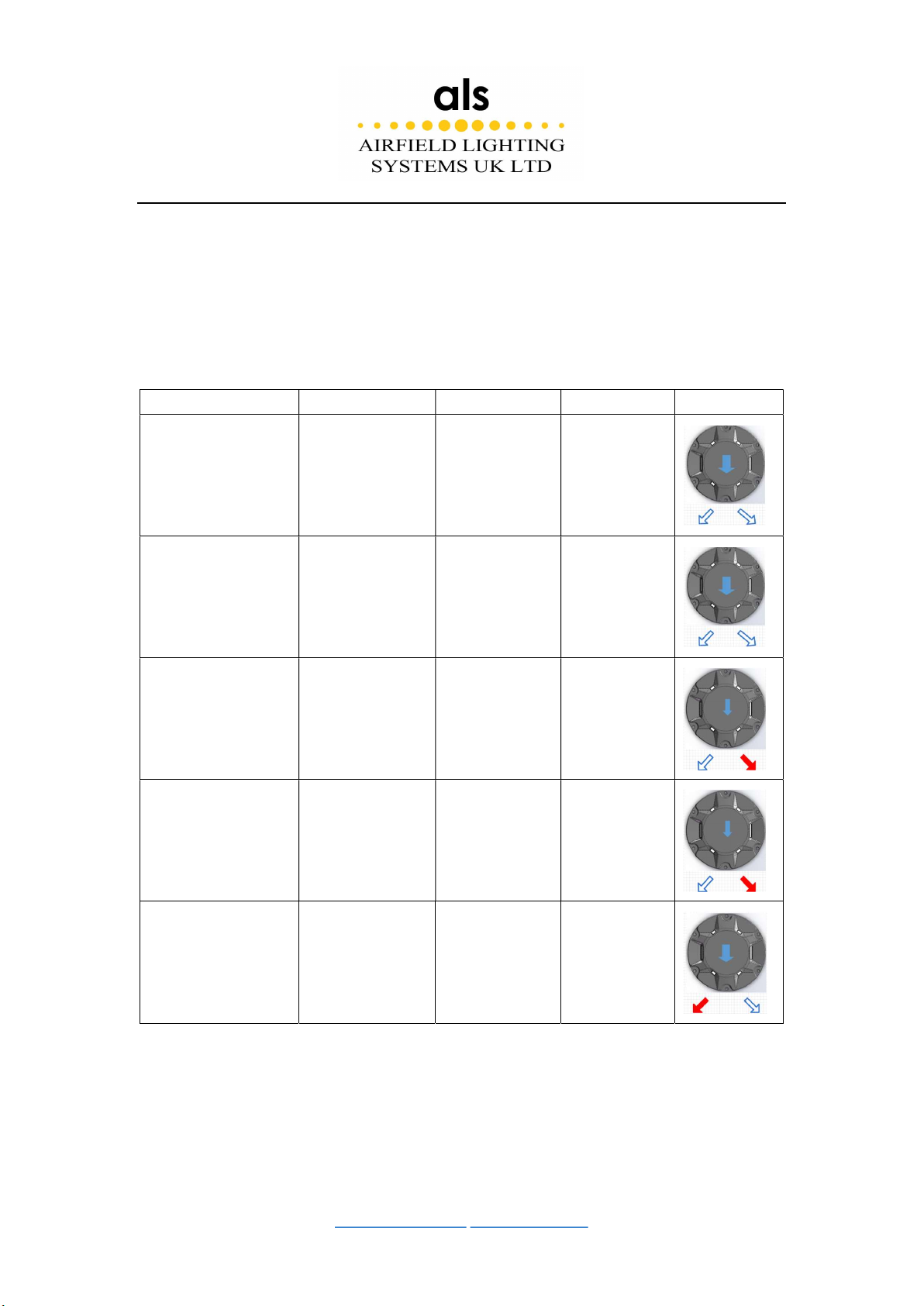

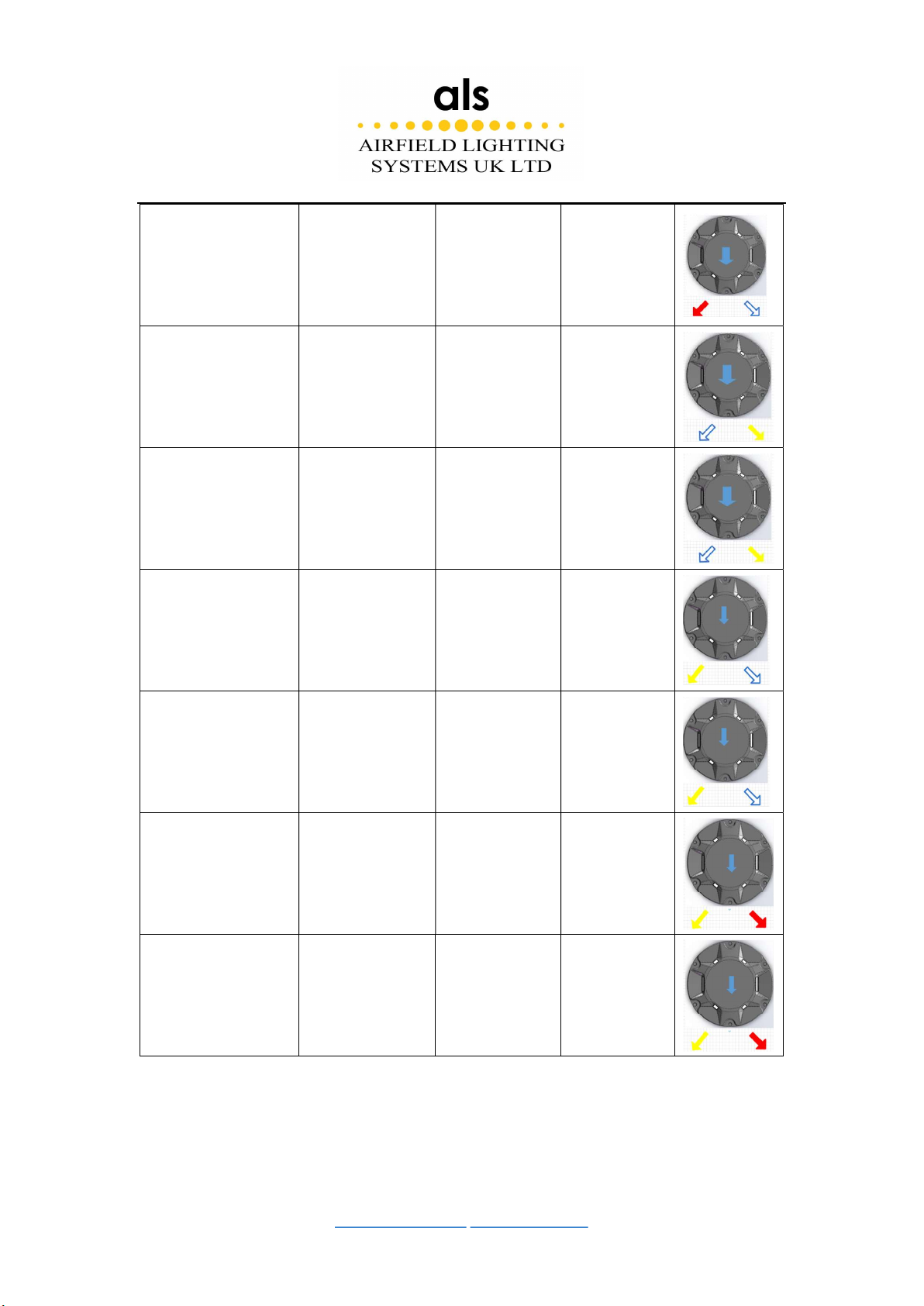

2.1. Fixtures in this manual ....................................................................................... 4

2.2. Compliance with standards ............................................................................... 6

2.3. Features ............................................................................................................. 6

2.4. Power and power factor..................................................................................... 7

2.5. Dimensions and Weight ..................................................................................... 8

3. Installation ..................................................................................................................... 9

3.1. Tools and Material ............................................................................................. 9

3.2. Installation steps ................................................................................................ 9

3.3 Installation Bolt Torque ......................................................................................... 11

3.4Top-Lock Installation Guidelines ........................................................................... 11

4. Maintenance ............................................................................................................... 13

4.1 Basic Maintenance Program ................................................................................ 13

4.2 Workshop Maintenance ........................................................................................ 14

4.2.1 Tools and accessories ....................................................................................... 14

4.2.2 Remove a light fixture from its base .................................................................. 15

4.2.3 Remove and replace light source ...................................................................... 16

4.2.4 Replace the prism and its sealing gasket ......................................................... 17

4.2.5 Waterproof test .................................................................................................. 18

5. Spare Parts ................................................................................................................. 19