MD Series

Contents

1

Thank you for purchasing our MD Series, Transistor Welding Power Supply.

For correct use, read this Operation Manual carefully. After reading, save it properly for

future reference.

Contents

1. Special Precautions ........................................................................................................ 1-1

(1) Safety Precautions....................................................................................................... 1-1

(2) Precautions for Handling ............................................................................................. 1-4

(3) On Disposal ................................................................................................................. 1-4

(4) Function Difference Depending on Model ................................................................... 1-5

2. Features ........................................................................................................................... 2-1

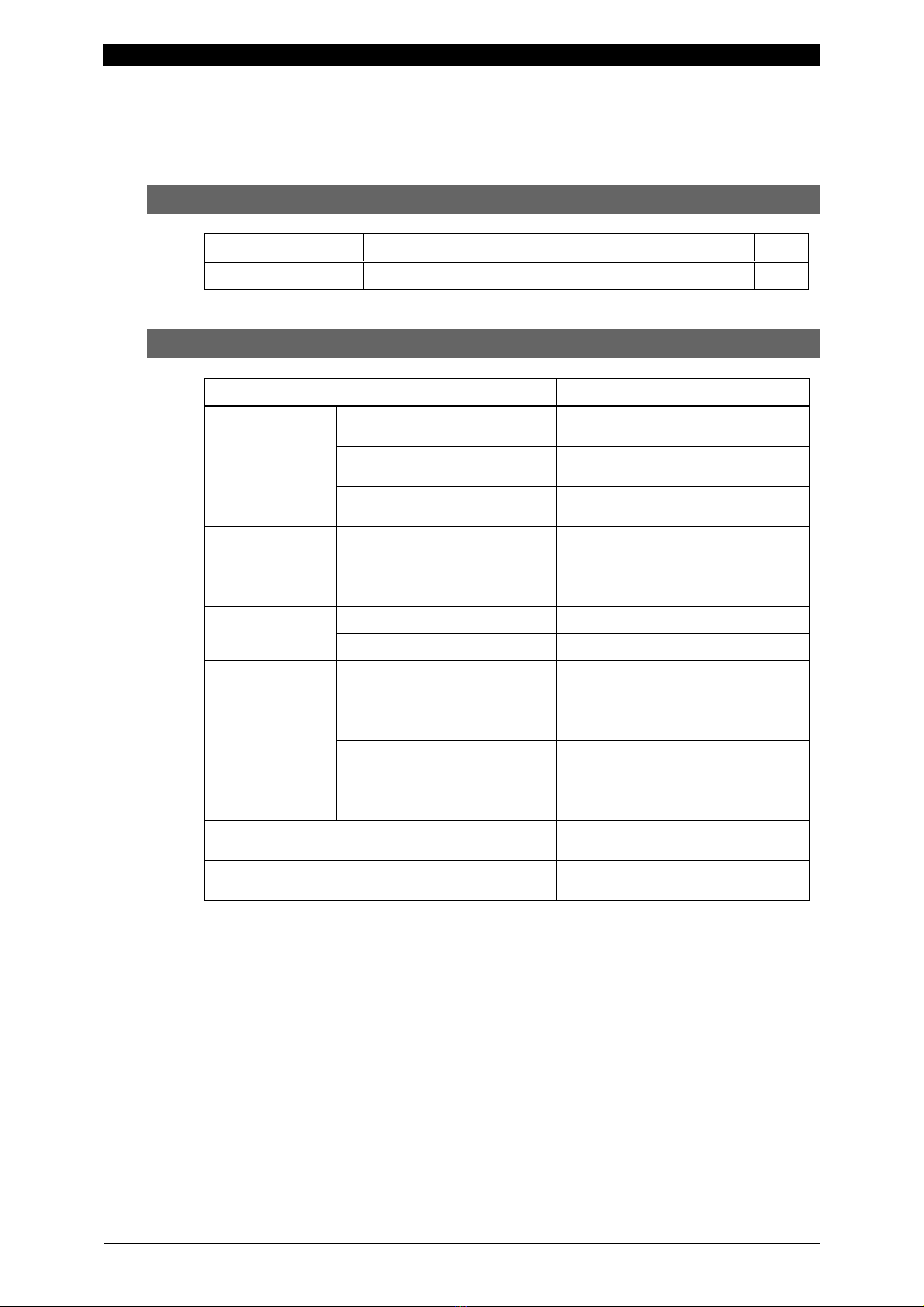

3. Packaging ........................................................................................................................ 3-1

(1) Accessories ................................................................................................................. 3-1

(2) Options ........................................................................................................................ 3-1

4. Name

and

Functions

of

Each

Section ............................................................................. 4-1

(1) Front Panel .................................................................................................................. 4-1

(2) Rear Panel................................................................................................................... 4-3

(3) Side Panel ................................................................................................................. 4-10

5. Connection....................................................................................................................... 5-1

(1) Basic Connection......................................................................................................... 5-1

(2) Connecting Contacts or NPN (Open Collector) Transistors ........................................ 5-2

(3) Connecting PNP (Source) Transistors......................................................................... 5-3

(4) Timing Chart ................................................................................................................ 5-4

6. Explanation of the Screen .............................................................................................. 6-1

(1) Menu Screen ............................................................................................................... 6-1

(2) Setting the Schedule (SCHEDULE Screen) ................................................................ 6-2

(3) Displaying the Measured Value (MONITOR Screen) .................................................. 6-4

(4) Setting Upper/Lower Limits for Judgment (COMPARATOR Screen) .......................... 6-6

(5) Setting the Precheck Welding (PRECHECK Screen).................................................. 6-8

(6) Changing the Initial Settings (STATUS Screen) ........................................................ 6-10

7. Basic Operation............................................................................................................... 7-1

8. Error Code........................................................................................................................ 8-1

9. External Communication Function................................................................................ 9-1

(1) Communication Specifications..................................................................................... 9-1

(2) Single-Directional Communication B Mode ................................................................. 9-2

(3) Single-Directional Communication C Mode ................................................................. 9-5

(4) Bi-Directional Communication Mode ........................................................................... 9-9

10. Specifications ................................................................................................................ 10-1

(1) Specifications............................................................................................................. 10-1

(2) Duty Cycle ................................................................................................................. 10-5

(3) Board List for Maintenance........................................................................................ 10-6