MAWA-050A

Contents

ii

(2) -4-1. Improvement against a misfire ·············································2-11

(2) -5. Connecting the argon gas ························································ 2-12

(2) -6. Connecting the external input/output devices ······························· 2-13

(2) -7. Connecting the external communication device ···························· 2-14

(2) -8. Connection with the torch head for touch start ······························ 2-15

(2) -9. Connecting the step-down transformer (option) ···························· 2-16

(3) Interface·······························································································2-17

(3) -1. Explanation of external input/output signals ································· 2-17

(3) -1-1. Input connector (D-Sub 37-pin, female) ································ 2-17

(3) -1-2. Output connector (D-Sub 25-pin, female) ······························ 2-19

(3) -1-3. Option input/output connector (D-Sub 25-pin, male) ················ 2-21

(3) -1-4. Current/voltage monitor connector (D-Sub 15-pin, female)········ 2-23

(3) -2. Connection diagram of external input/output signals ······················ 2-24

(3) -2-1. Input connector (D-Sub 37-pin, female) ································ 2-24

(3) -2-2. Output connector (D-Sub 25-pin, female) ······························ 2-25

(3) -2-3. Option input/output connector (D-Sub 25-pin, male) ················ 2-26

(3) -3. External input/output signal table ··············································· 2-27

(3) -3-1. User input terminals·························································· 2-27

(3) -3-2. User output terminals ························································ 2-30

(3) -4. Input signal connecting method ················································· 2-33

3. Operating Unit

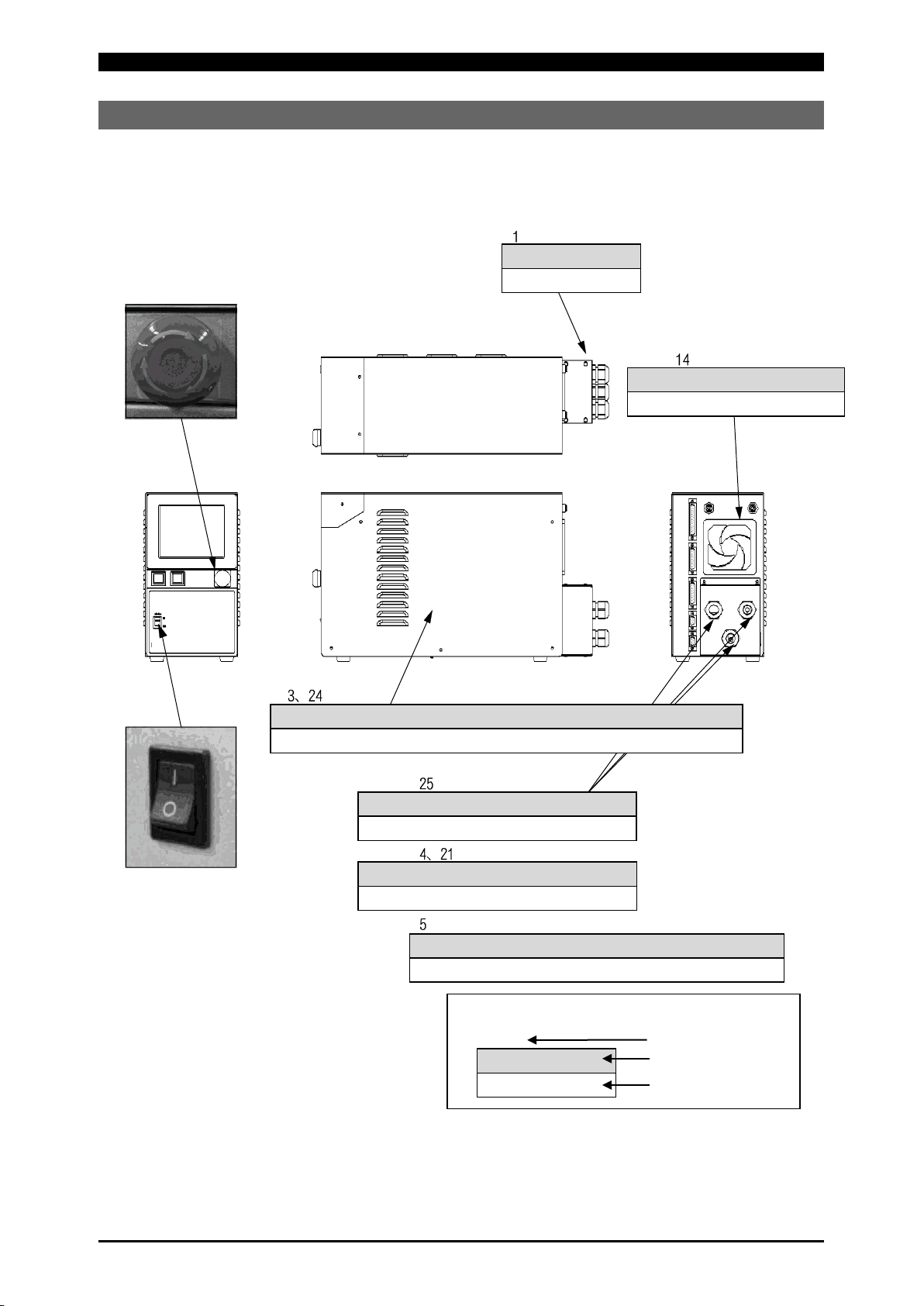

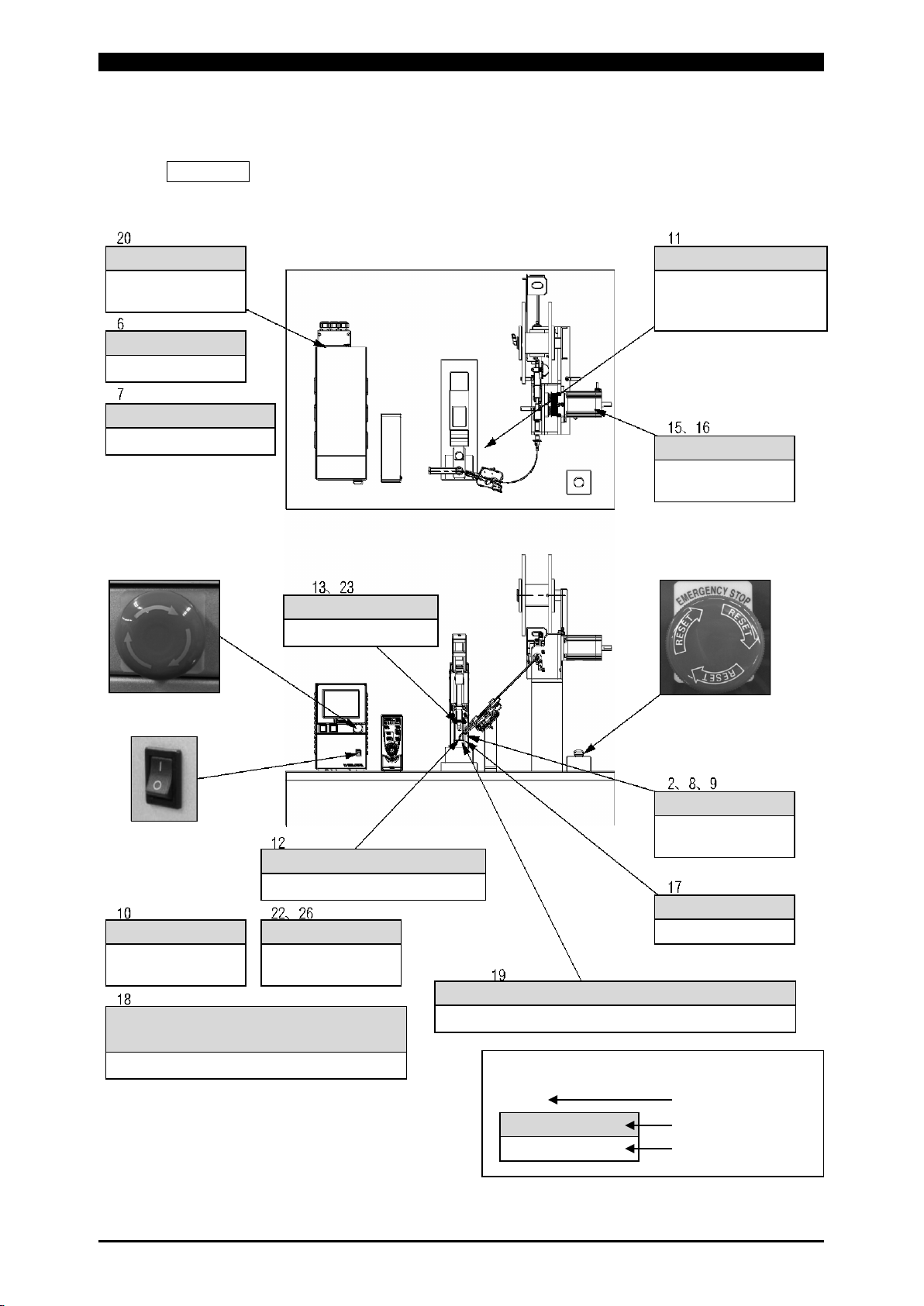

(1) Front Panel··························································································· 3-1

4. Explanation of Screens

(1) Screen Structure ···················································································· 4-1

(2) Menu Screen························································································· 4-3

(3) Monitor Screen ······················································································ 4-5

(4) Envelope Screen····················································································4-10

(5) Basic Setting Screen···············································································4-15

(6) Switch Select Screen ··············································································4-17

(7) Initialize Memory Screen··········································································4-21

(8) External I/O Setting Screen ······································································4-22

(9) Welding Condition Setting Screen······························································4-23

(10) Schedule Setting Screen··········································································4-27

(11) Monitor Select Screen ·············································································4-30

(12) Upper/Lower Limit Set Screen···································································4-32

(13) SCH Copy Screen ··················································································4-33

(14) External I/O Check Screen ·······································································4-36

(15) Count Setting Screen ··············································································4-39

(16) Error History Screen ···············································································4-40

(17) Password Setting Screen ·········································································4-41

(18) Maintenance Screen ···············································································4-42

(19) Set Values of Each Screen at Delivery from the Factory··································4-43

5. Welding

(1) Pre-Start Inspection ················································································ 5-1

(2) Turning on the Power Supply ···································································· 5-2

(3) Basic Function Setting············································································· 5-3

(3) -1. Common detail item setting ······················································· 5-4

(4) Welding Condition Setting ········································································ 5-5

(4) -1. Registering the welding conditions ·············································· 5-5