•Stacked Basket Stop mechanism for 90°transfers

•Adjustable width machine to handle different width baskets

•Variable conveyor length to suit system requirements*

•Additional conveyors can be controlled from Bottom-up

Stacker panel

•Variable speed lift*

•Pre-Stacker available to provide higher per minute stacking rate

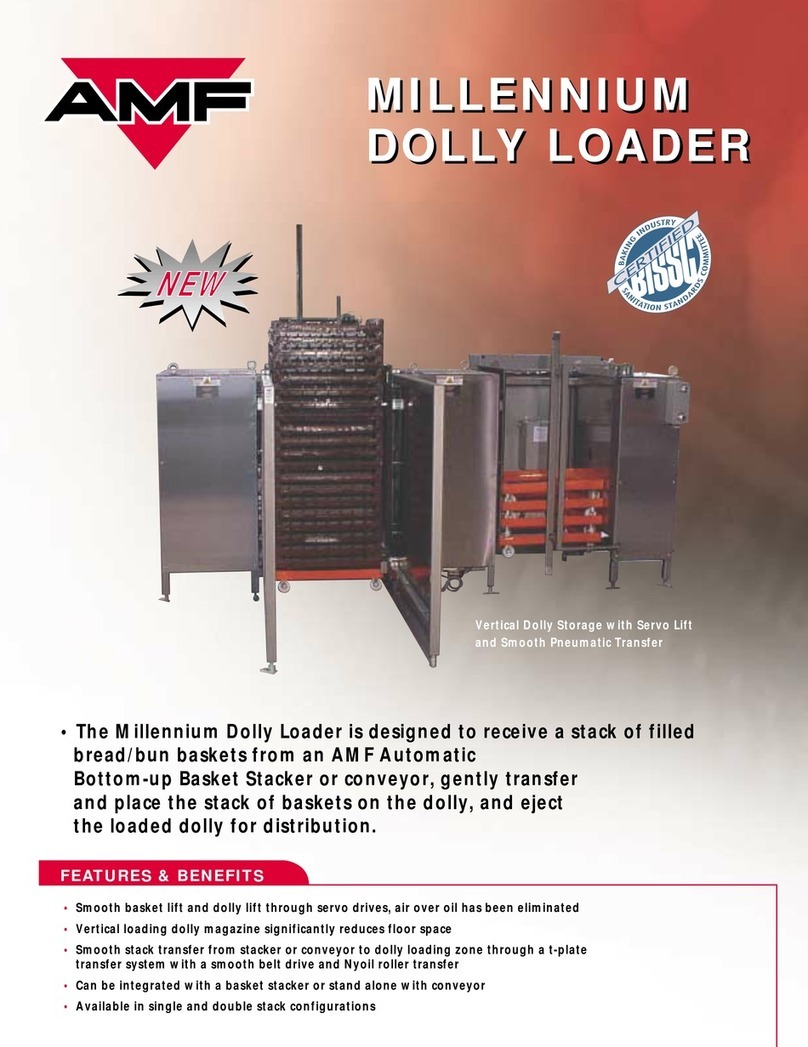

•Dolly Loader / Double Dolly Loader

•Operator control upgrade to Allen Bradley PanelView 550 and

Allen Bradley SLC 5/04 PLC for system control integration

•Gravity or powered discharge conveyors available to suit

your needs

•Stainless Steel Frame

•Double Long Stacker Avalaible for ultra Hi Speed (50 BPM)

*Subject to engineering approval

BASKET STACKER

Specifications

Options

Max Basket

Height Max Rate

(Baskets/min.)

Low

Speed

Medium

High

7”

7”

5”

12

20

28

Exit, Basket Stacker

(Capacity - 8 ft. / 2 m)

Electrical Requirements

1 SCFM (472 cm3/sec.

230/460volts, 3 phase, 60 hertz

Air Requirements: Clean dry air at 80 PSI (5.6 kg/cm2)

Total Connected Load: 5 KVA

Approx. Shipping Weight:

Stacker 1600 lbs. (726 kg)

Dolly Loader 425 lbs. (193 kg)

Approximate Dimensions

169’’ X 68’’ X 51’’ (4290 mm X 1720 mm X 1290 mm)

BASKET STACKER

•Designed and manufactured in accordance with BISSC

sanitation standards

•Heavy duty tabletop chain on conveyors

•Mild steel painted frame

•Low, Medium, and High speed units available*

* Subject to engineering approval

Mechanical

Features

Electrical

Features

Basket Stacker Detail

Basket Lifting Detail

* Specify RH or LH Configuration for Location

of Panel, Operator Interface & Motors

The Bottom-Up Basket Stacker is equipment with the

following control elements:

•Allen Bradley PV-300 Operator Interface

•Allen Bradley Pushbuttons for:

-Two-button start

-Stop

-Emergency stop

SS NEMA 4 Machine Mounted Enclosure with:

- Operation Status Light

- AC Inverters

- Allen Bradley Micrologix PLC

- 24 volts Pneumatic valves

Contact your AMF representative for more

informtion about our complete line of:

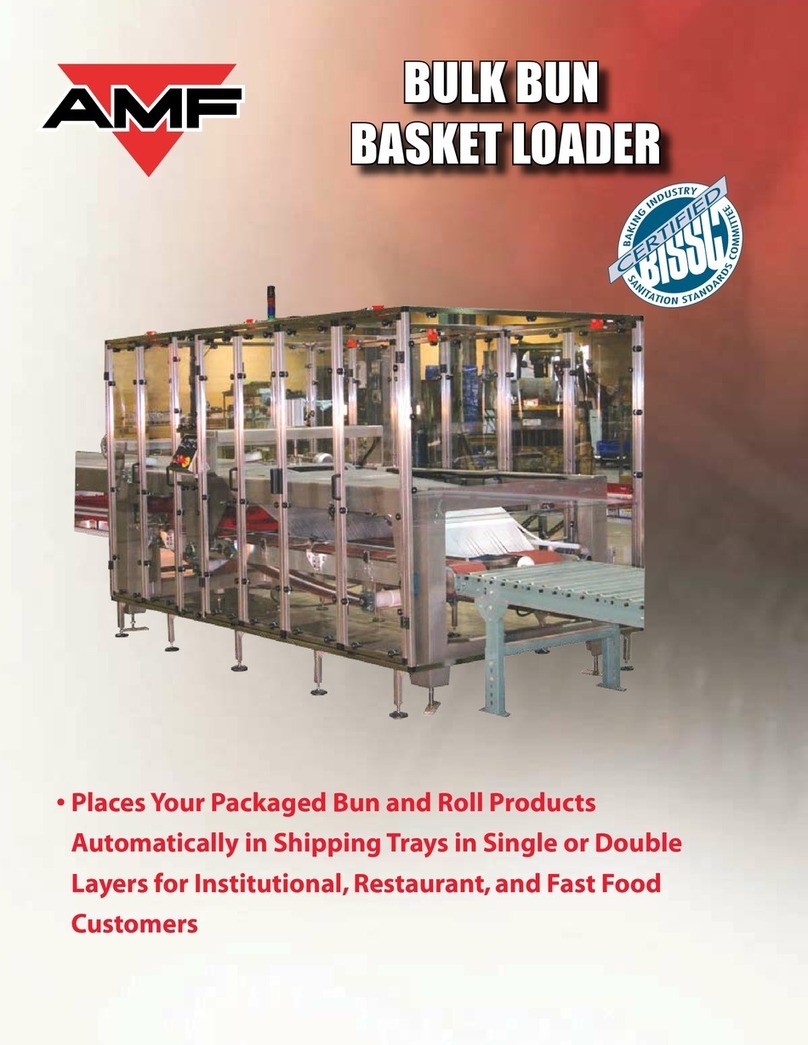

•Basket and Tray Loaders

•Basket Un-Stackers

•Pan Stackers & Un-Stackers

•Pre-Stackers, Separators

•Cross Nested Un-stackers

•Orientors and Turners

•Basket and Pan Conveyors

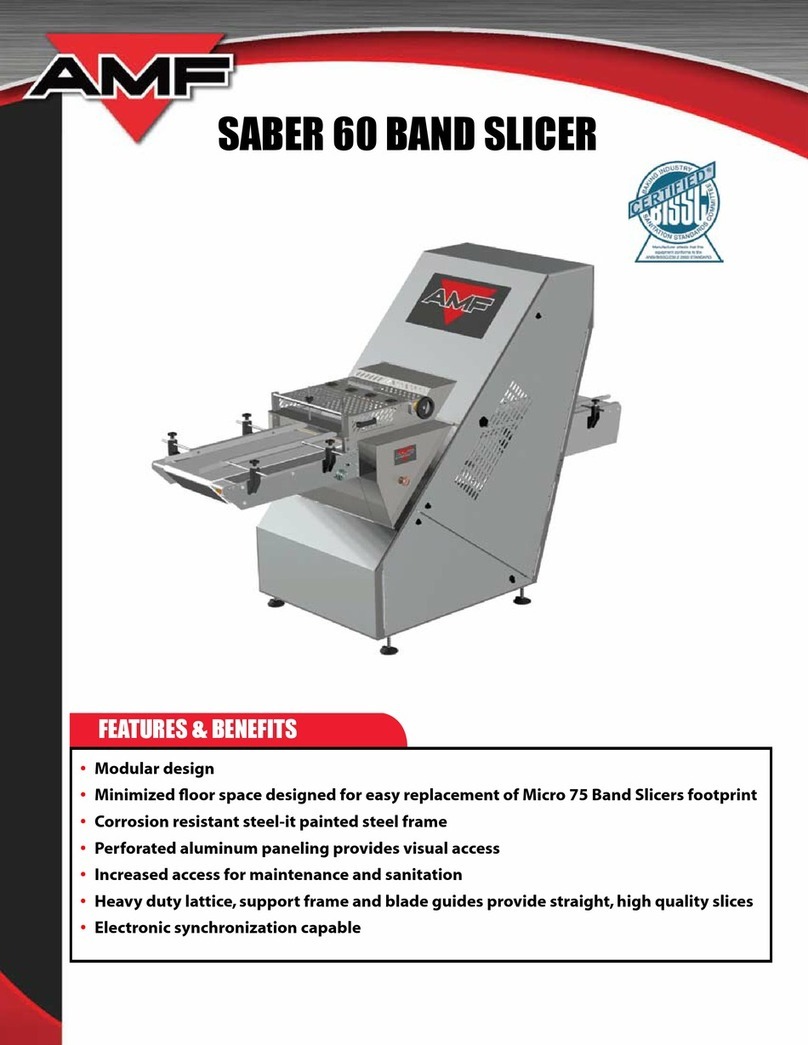

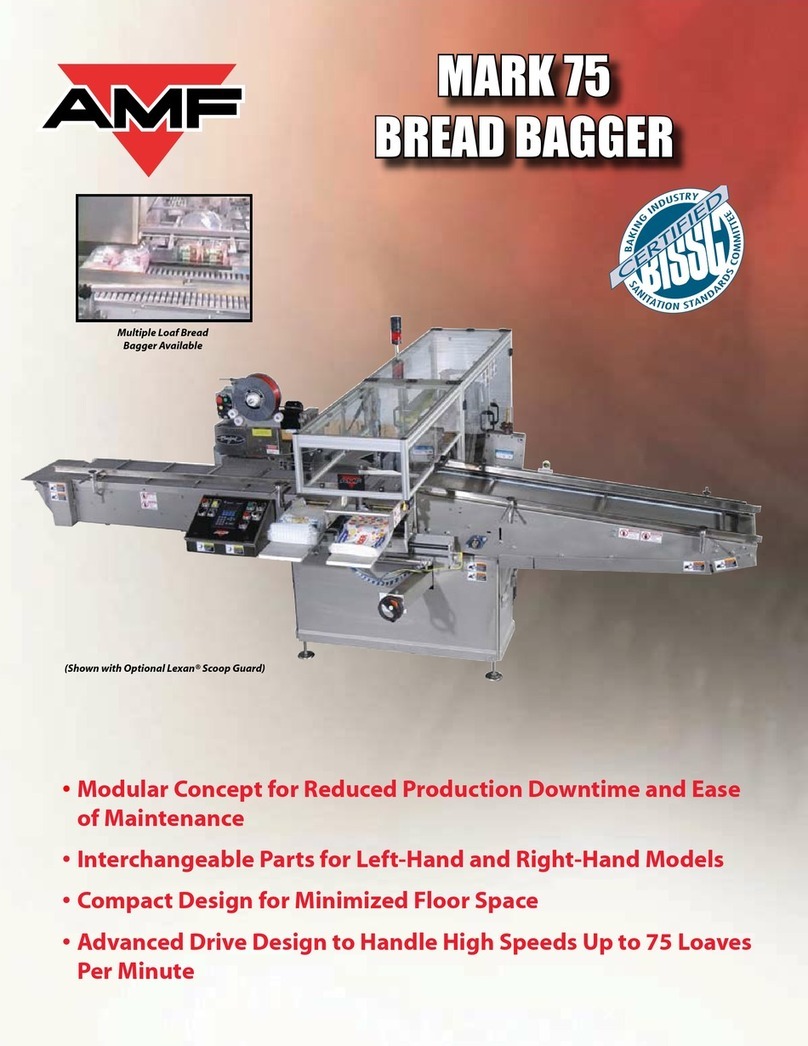

•Slicers and Baggers

•Trash Dumps

•Basket Washers

Basket/min

with/Pre-Stacker

N/A

N/A

34

Dolly Loader