MARK 75 BREAD BAGGER

FEATURES &BENEFITS

MECHANICAL FEATURES

MECHANICAL OPTIONS

• Hook-up kit to Micro 75 Slicer

• Infeed conveyor phaser

• Extended 36” (91 cm) discharge conveyor

• Lexan® scoop guard in lieu of slotted stainless

• Speed range from 35 to 75 LPM

• 95% of symmetrical parts (right-hand or left-hand)

for reduced spare parts inventory

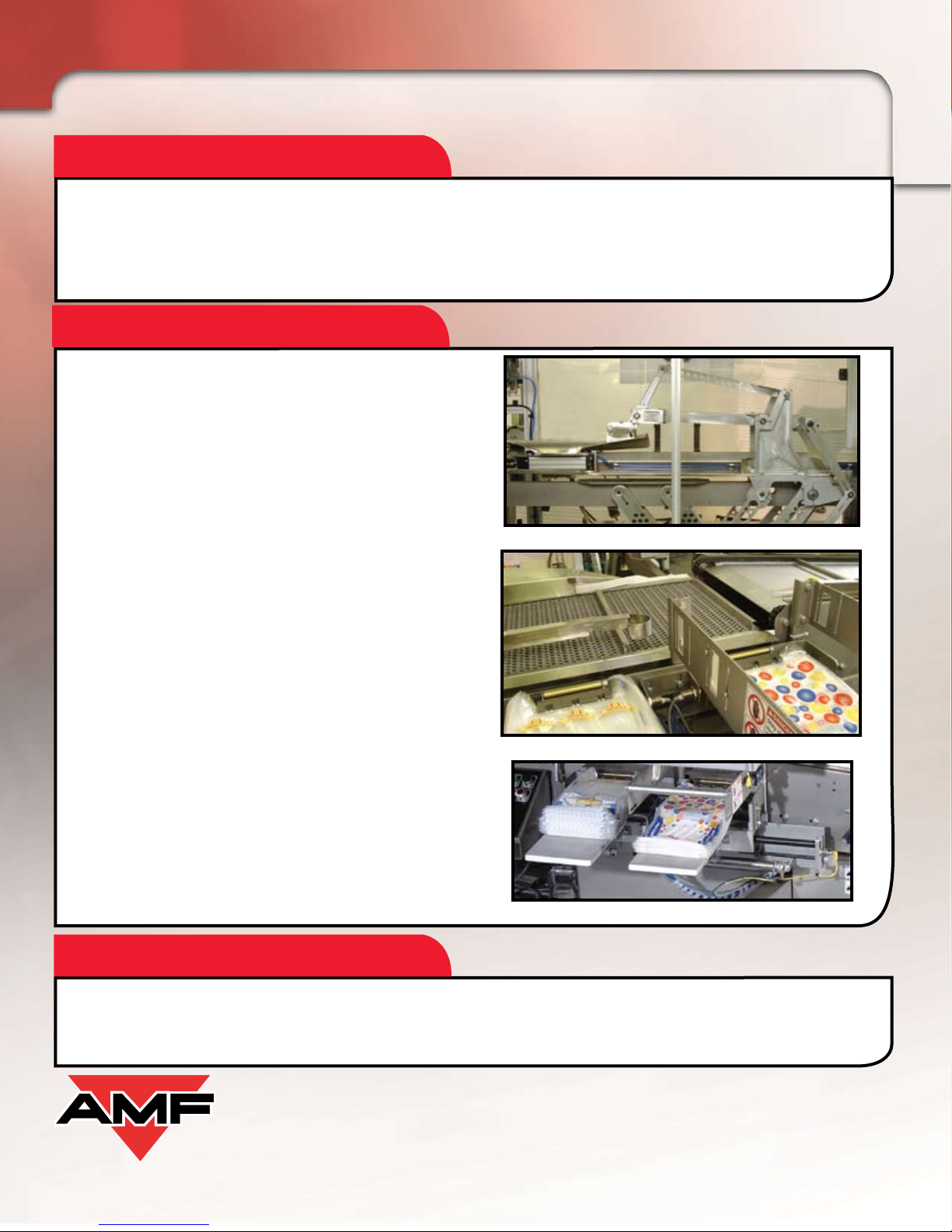

• Scoop levers configuration allows top scoop to stay

straight for more consistent bag friction and more

consistent bag release

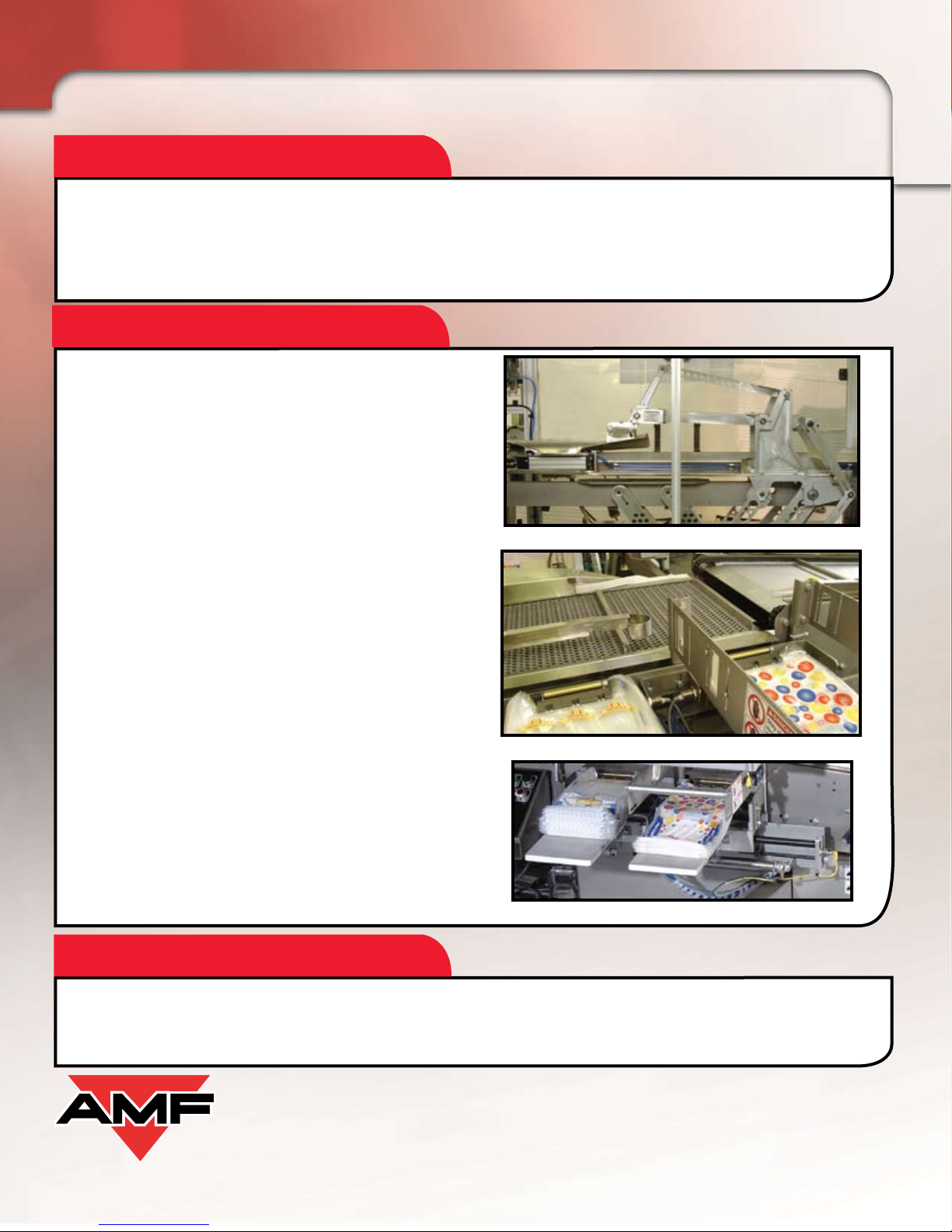

• Patented flusher-discharge conveyor eliminates

the need of a flusher bar and provides a smoother

transfer (U.S. Patent 6,766,898)

• Air operated oversized magnetic cylinder allows

automatic wicket change without stopping the

bagger

• Tilting wicket tables for easy insertion of wickets

and elimination of operator action when switching

• Shaft-driven conveyors

• In-motion scoop adjustment

• Adjustable Neoprene feet for easy installation

• Corrosion resistant stainless steel frame and

guards

• Slotted stainless steel scoop guard with safety

switches

• Computer assisted, pendulum style scoop drive for

low vibration and optimal operations

• Air operated wicket automatic changer with oversized magnetic cylinder allows wicket change without

stopping the bagger

• Flusher-discharge conveyor eliminates the need of a flusher bar and provides a smoother transfer

• Smooth, quiet and efficient operation is achieved by a belt drive system (no gearbox and clutch)

• High quality components to provide PLC with accurate information (position, speed, current bag

detection) for control and monitoring

• Skip loaf device

• Additional stainless steel scoop assemblies

• Bag tyer and printer

• Free roller pick off conveyor and tray support

Pendulum Scoop Drive

Flusher-Discharge Conveyor

Automatic Dual Wicket Changer