HEADQUARTERS

AMFBakery Systems

2115WestLaburnum Avenue

Richmond,Virginia23227

1-800-225-3771

or804-355-7961

FAX : 1-804-342-9724

EUROPEAN OPERATION

WestPark Ring Road

LeedsLS166QQEngland

Tel. : 1132-787110

Fax : 1132-741415

www.amfbakery.com

FORMORE INFORMATIONPLEASECALLYOUR ACCOUNT MANAGEROR

AMF’s continuing engineering is constantly improving product performance. Consequently machinery specifications are subject to change without notice.

Printed in Canada

07/2003

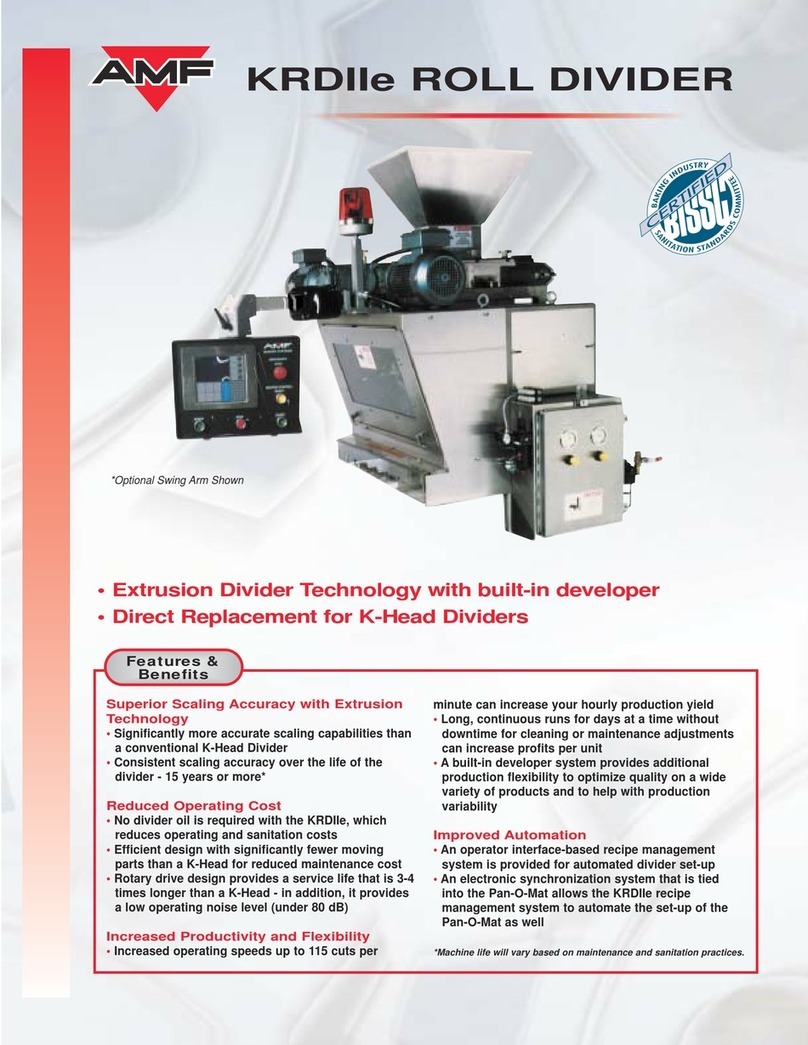

MILLENNIUM

DOLLY LOADER

MILLENNIUM

DOLLY LOADER

FEATURES & BENEFITS

•Smooth basket lift and dolly lift through servo drives, air over oil has been eliminated

•Vertical loading dolly magazine significantly reduces floor space

•Smooth stack transfer from stacker or conveyor to dolly loading zone through a t-plate

transfer system with a smooth belt drive and Nyoil roller transfer

•Can be integrated with a basket stacker or stand alone with conveyor

•Available in single and double stack configurations

• The Millennium Dolly Loader is designed to receive a stack of filled

bread/bun baskets from an AMF Automatic

Bottom-up Basket Stacker or conveyor, gently transfer

and place the stack of baskets on the dolly, and eject

the loaded dolly for distribution.

Vertical Dolly Storage with Servo Lift

and Smooth Pneumatic Transfer

NEW

MILLENNIUM

DOLLY LOADER

MILLENNIUM

DOLLY LOADER

FEATURES & BENEFITS

•Smooth basket lift and dolly lift through servo drives, air over oil has been eliminated

•Vertical loading dolly magazine significantly reduces floor space

•Smooth stack transfer from stacker or conveyor to dolly loading zone through a t-plate

transfer system with a smooth belt drive and Nyoil roller transfer

•Can be integrated with a basket stacker or stand alone with conveyor

•Available in single and double stack configurations

• The Millennium Dolly Loader is designed to receive a stack of filled

bread/bun baskets from an AMF Automatic

Bottom-up Basket Stacker or conveyor, gently transfer

and place the stack of baskets on the dolly, and eject

the loaded dolly for distribution.

Vertical Dolly Storage with Servo Lift

and Smooth Pneumatic Transfer

NEW

HEADQUARTERS

AMFBakery Systems

2115WestLaburnum Avenue

Richmond,Virginia23227

1-800-225-3771

or804-355-7961

FAX : 1-804-342-9724

EUROPEAN OPERATION

WestPark Ring Road

LeedsLS166QQEngland

Tel. : 1132-787110

Fax : 1132-741415

sales@amfbakery.com

www.amfbakery.com

FORMORE INFORMATIONPLEASECALLYOUR ACCOUNT MANAGEROR

AMF’s continuing engineering is constantly improving product performance. Consequently machinery specifications are subject to change without notice.

Printed in Canada

07/2003

• Oil impregnated nylon basket stack transfer

roller system for durable and smooth stack transfer

• Compact Design with significantly smaller footprint

than old air over oil systems

• Significantly reduced parts count resulting in lower

maintenance

• Left or right hand configurations

• Heavy duty framing and stainless steel guarding

• Servo driven basket lift with ability to pick up

multiple basket handle positions

• “No Drop” stack transfer system provides smooth

transfer of basket stack to the dolly

• Vertical dolly magazine for reduced floor space

requirement

• Servo driven dolly lift to allow indexing of dollies

one at a time

MECHANICAL FEATURES

MILLENNIUM DOLLY LOADER

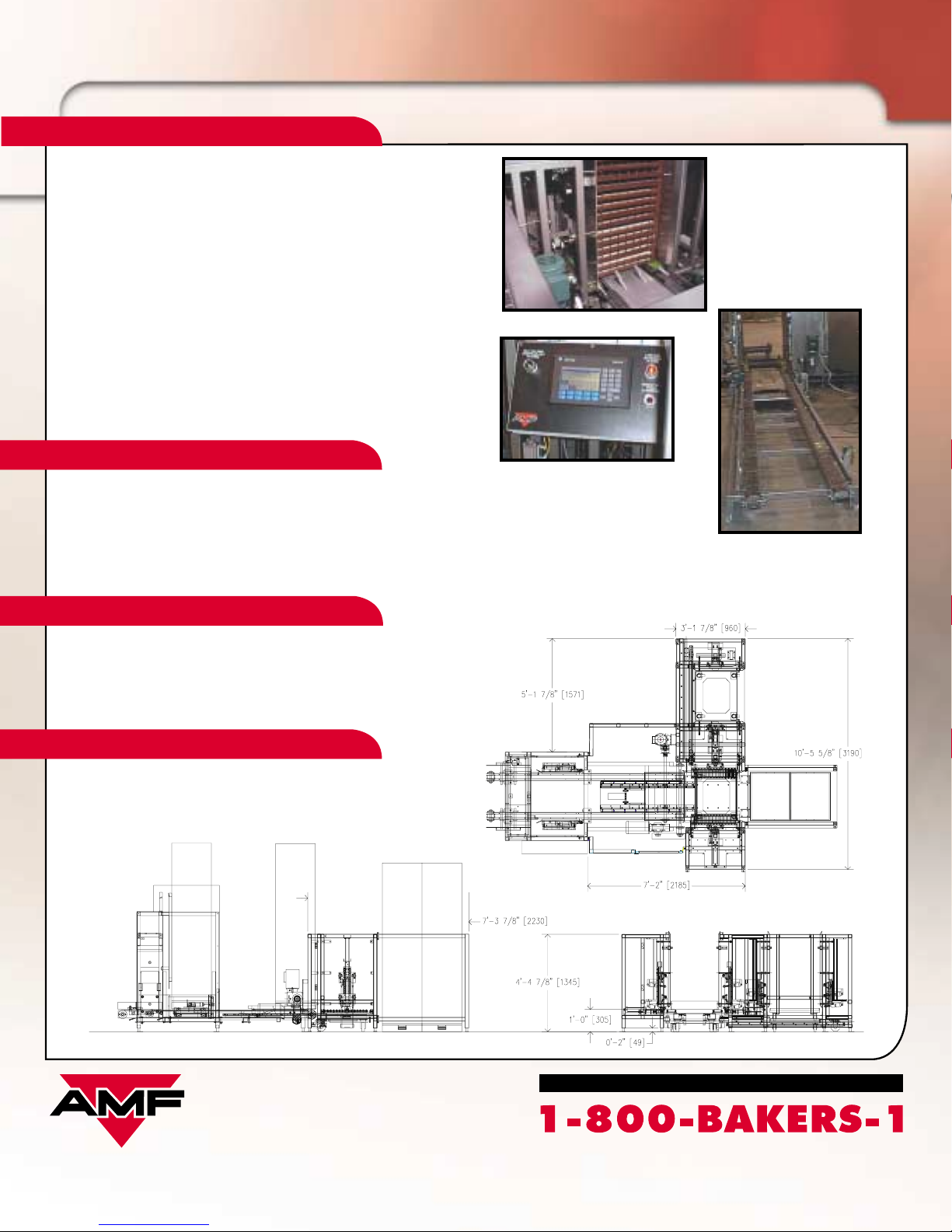

• Allen Bradley 550 operator interface control

with product set-up and diagnostics

• Allen Bradley SLC 5/03 processor

• Allen Bradley 160 inverter drive for pusher

• 42” X 36” X 12” grey powder coated, machine

mounted electrical panel

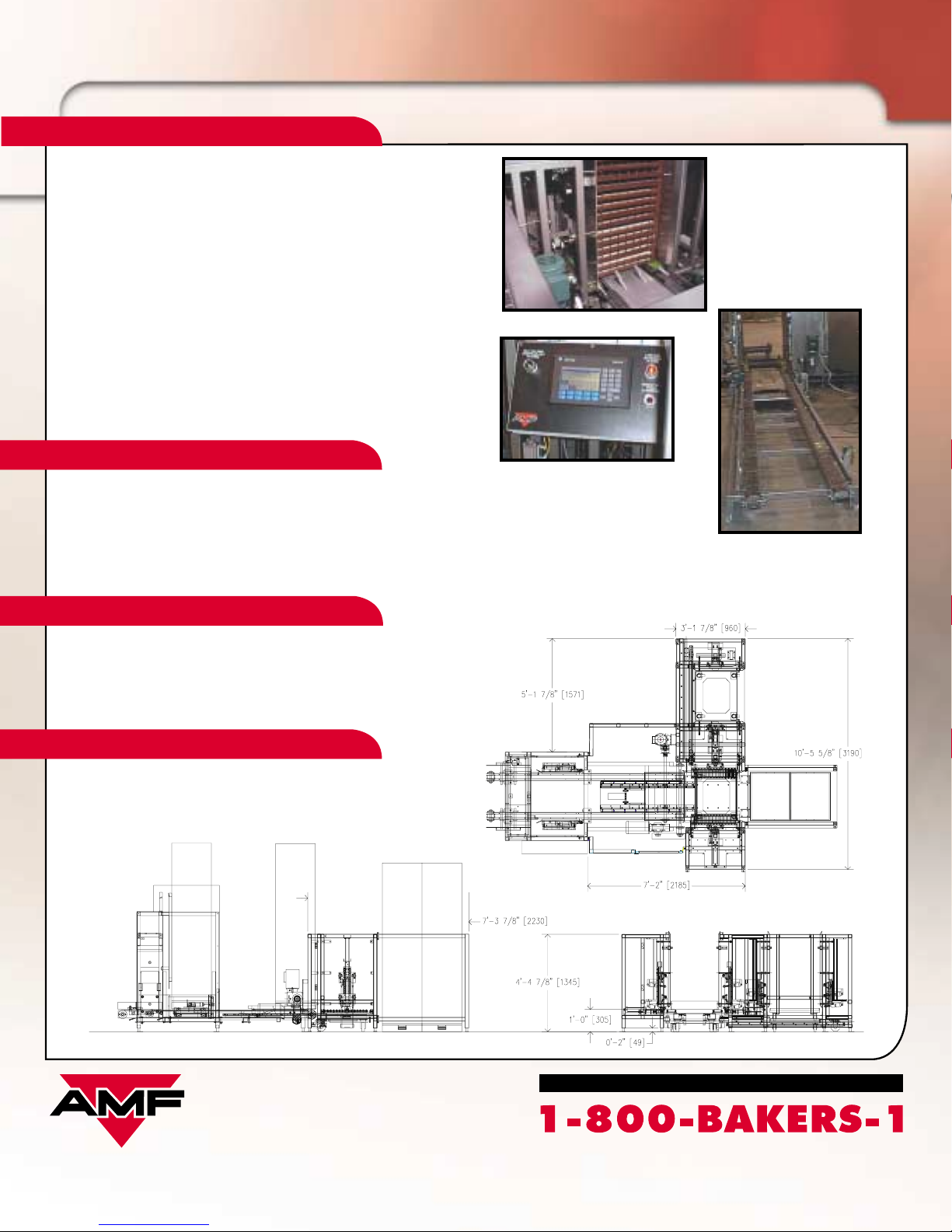

• Stack feed conveyor

• PLC other than standard

• Operator interface other than standard

• Basket stacker integration

• Stainless steel electrical panel

OPTIONS

• Electrical requirements: 208/230/460 volts,

3 phases, 60 Hz

• Approximate shipping weight: 2500 lb.

• Approximate dimensions: 96” X 84” X 84”

SPECIFICATIONS

Oil Impregnated Nylon

Basket Stack Transfer Roller

System and Transfer Pusher

for Durable and Smooth

Stack Transfer

Optional Stack

Feed Conveyor

Operator Interface

ELECTRICAL FEATURES

• Oil impregnated nylon basket stack transfer

roller system for durable and smooth stack transfer

• Compact Design with significantly smaller footprint

than old air over oil systems

• Significantly reduced parts count resulting in lower

maintenance

• Left or right hand configurations

• Heavy duty framing and stainless steel guarding

• Servo driven basket lift with ability to pick up

multiple basket handle positions

• “No Drop” stack transfer system provides smooth

transfer of basket stack to the dolly

• Vertical dolly magazine for reduced floor space

requirement

• Servo driven dolly lift to allow indexing of dollies

one at a time

MECHANICAL FEATURES

MILLENNIUM DOLLY LOADER

• Allen Bradley 550 operator interface control

with product set-up and diagnostics

• Allen Bradley SLC 5/03 processor

• Allen Bradley 160 inverter drive for pusher

• 42” X 36” X 12” grey powder coated, machine

mounted electrical panel

• Stack feed conveyor

• PLC other than standard

• Operator interface other than standard

• Basket stacker integration

• Stainless steel electrical panel

OPTIONS

• Electrical requirements: 208/230/460 volts,

3 phases, 60 Hz

• Approximate shipping weight: 2500 lb.

• Approximate dimensions: 96” X 84” X 84”

SPECIFICATIONS

Oil Impregnated Nylon

Basket Stack Transfer Roller

System and Transfer Pusher

for Durable and Smooth

Stack Transfer

Optional Stack

Feed Conveyor

Operator Interface

ELECTRICAL FEATURES