2.2 Performance Index

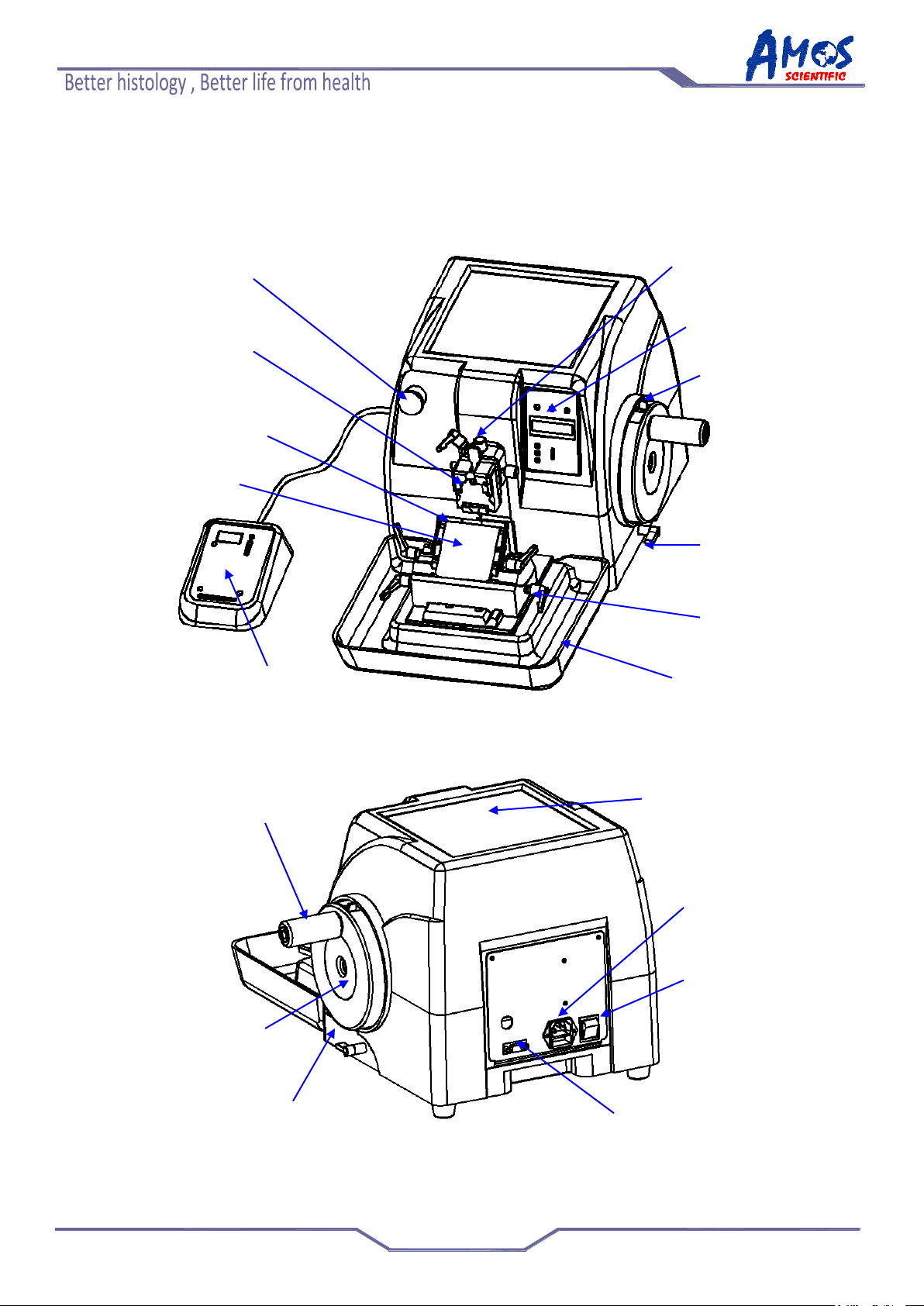

AEM480 is a motorized rotary microtome. The stepper motor operated the specimen

movement forward and back, coarse feed and sectioning in manual operation. It is better in

precision sectioning, easy operation.

⊙The crust is made in ABS plastic with fire prevention function, and streamlined

designed in artistic appearance.

⊙Spacious ingenious assembly section waste tray.

⊙Retraction function make it is better to sectioning. The retraction value can be set.

⊙Quick release cassette clamp and specimen clamp fit to internal Embedding

cassette.

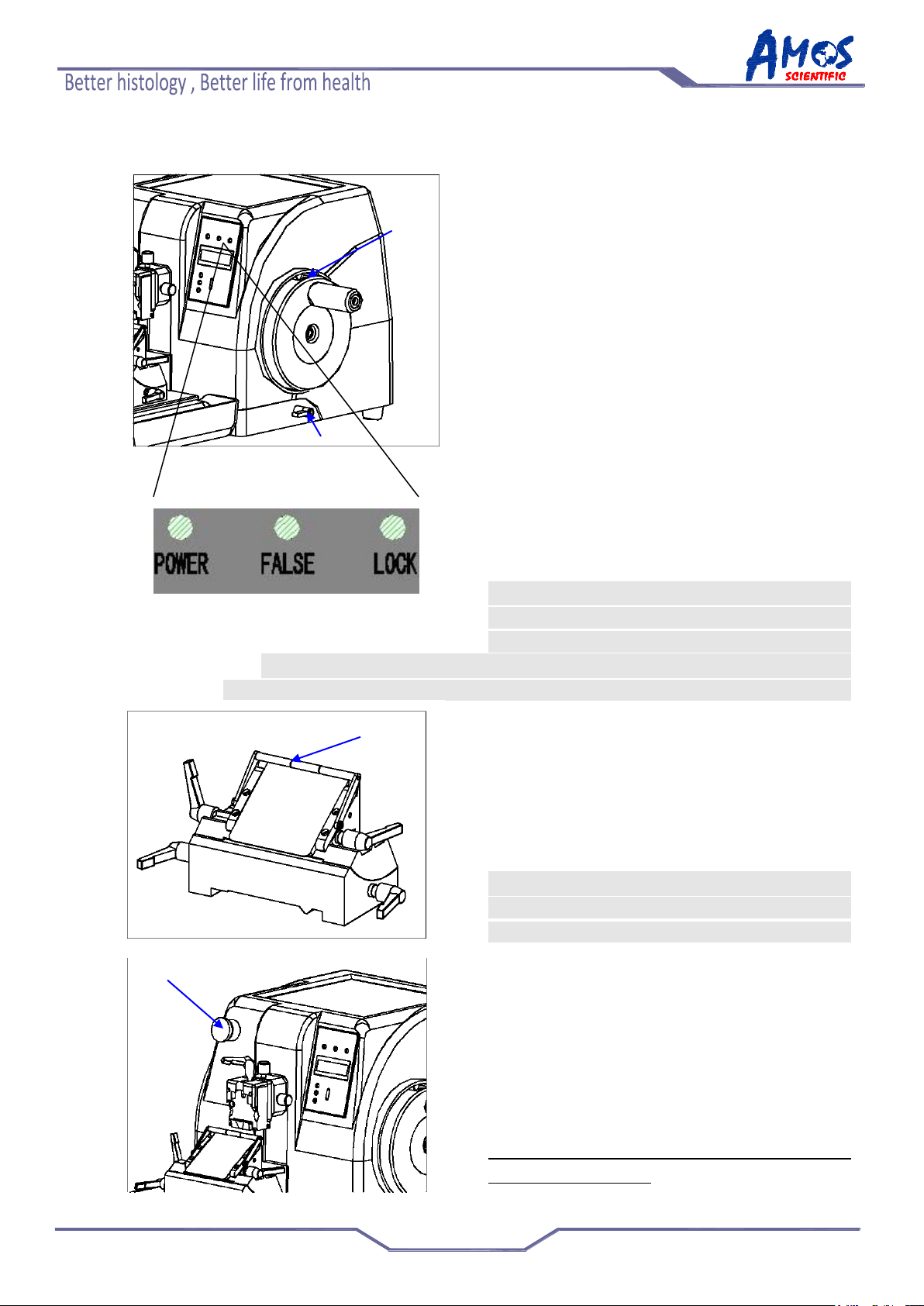

⊙Locking may be activated at any position by handwheel. It ensure cassette

changing safety when the cassette located in the toppest locked.

⊙The electric coarse feed operates two speeds which is easy to record the feed.

⊙Separate control panel is more easy to operate.

⊙Three motorized sectioning modes (Cont, Single and Step) are available, user can

choose at will.

⊙Automatic memorized coarse feed and reload fast can improve efficiency during

sectioning.

2.3 Technical Data

⊙Surroundings requirements:

Working temperature:+10℃—40℃

Working humidity: <80%,defrosting

Working pressure:(86~106)kPa;

⊙Power supply:100-240 VAC±10 %

⊙Frequency:50/60 Hz

⊙Power:<60 VA

⊙Fuse:3 A

⊙Safe classify:ClassifyⅠ- type B

⊙Section thickness:0 to 600µm

0 to 2µm,0.5µm increments

2 to 10µm,1µm increment

10 to 20µm,2µm increments

20 to 100µm,5µm increments

100 to 600µm,50µm increments

⊙Trimming thickness: 0 to 600µm

0 to 2µm,0.5µm increments

2 to 10µm,1µm increment

10 to 20µm,2µm increments

20 to 100µm,5µm increments

100 to 600µm,50µm increments