CONTENTS

1、SAFETY NOTES......................................................................................................................................1

1.1OVERVIEW .............................................................................................................................................................1

1.2 SAFETY WARNING ................................................................................................................................................1

1.3 SAFETY DEVICE ....................................................................................................................................................2

2、PERFORMANCE & PARAMETERS....................................................................................................3

2.1 PRODUCT DESCRIPTION &INTENDED USE.........................................................................................................3

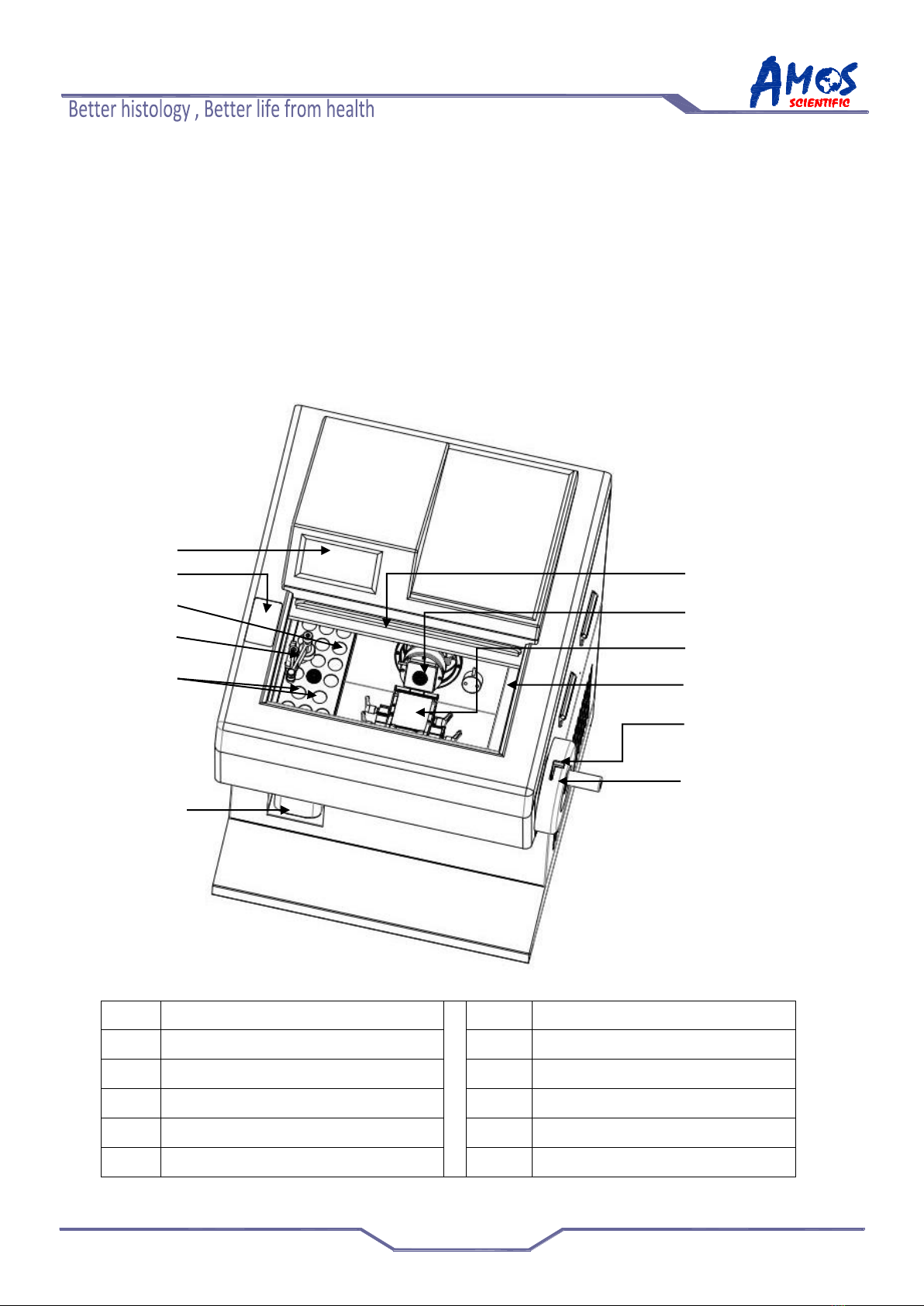

2.2 OVERVIEW-INSTRUMENT COMPONENTS ...........................................................................................................3

2.3 PERFORMANCE INDEX .........................................................................................................................................4

2.4 TECHNICAL PARAMETER .....................................................................................................................................4

3、PREPARATION BEFORE OPERATING.............................................................................................5

3.1 INSTALLATION SITE REQUIREMENT ....................................................................................................................5

3.2 STANDARD DELIVERY...........................................................................................................................................5

3.3 INSTALLATION.......................................................................................................................................................6

3.4 ELECTRICAL CONNECTION ..................................................................................................................................7

4、OPERATION ...........................................................................................................................................8

4.1 OPERATION PANEL FUNCTION &CONTROL ......................................................................................................8

4.3 AUXILIARY FUNCTION....................................................................................................................................... 10

4.4 CRYO CHAMBER TEMPERATURE SETTING........................................................................................................ 11

4.5 SPECIMEN CLAMP TEMPERATURE SETTING .................................................................................................... 12

4.6 SECTION,TRIMMING AND RETRACTION SETTING.......................................................................................... 13

4.7 LOCK SCREEN KEY &AUXILIARY FUNCTION DISPLAY .................................................................................. 14

4.8 BLADE HOLDER INSTALLATION ....................................................................................................................... 14

4.9 CLAMPING THE SPECIMEN AND INSERTING THE BLADE................................................................................. 17

4.10 SECTION REFERENCE ..................................................................................................................................... 18

5、CLEANING & MAINTENANCE......................................................................................................... 18

5.1 CLEANING........................................................................................................................................................... 18

5.2 CLEANING THE WASTE TISSUE.......................................................................................................................... 19

5.3 MAINTENANCE .................................................................................................................................................. 21

6、TROUBLE SHOOTING....................................................................................................................... 21