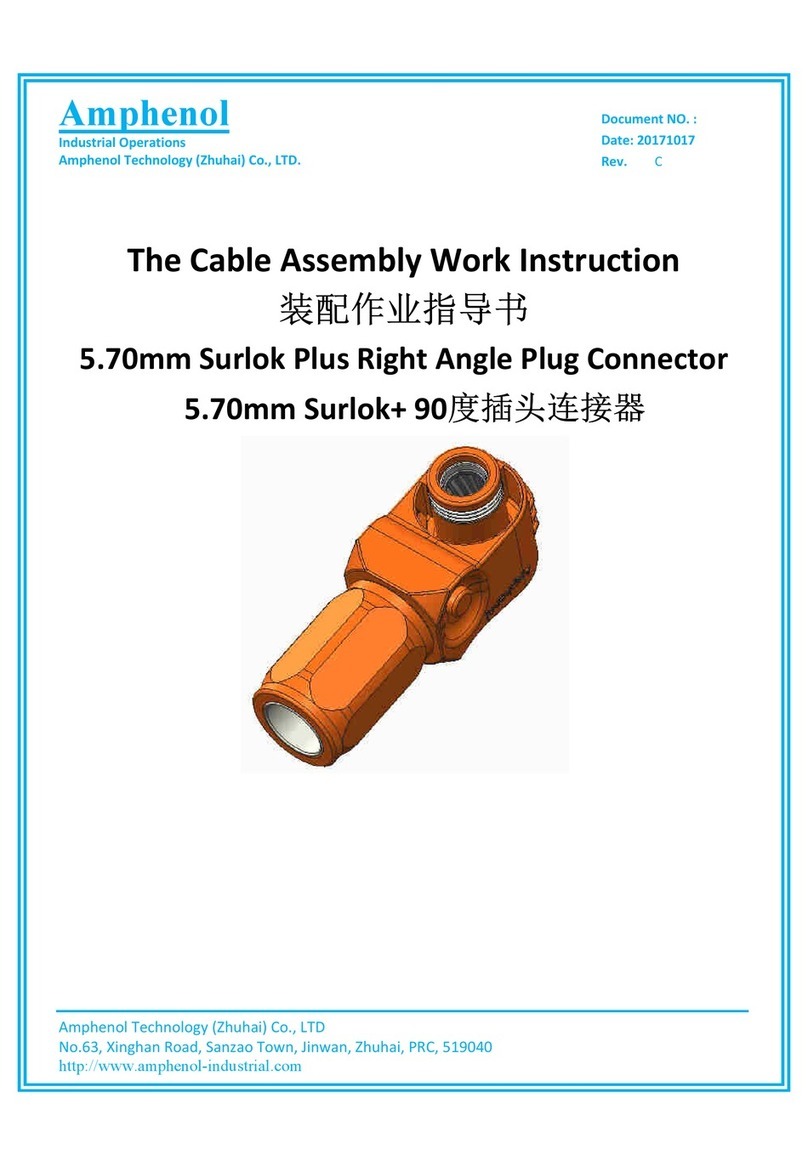

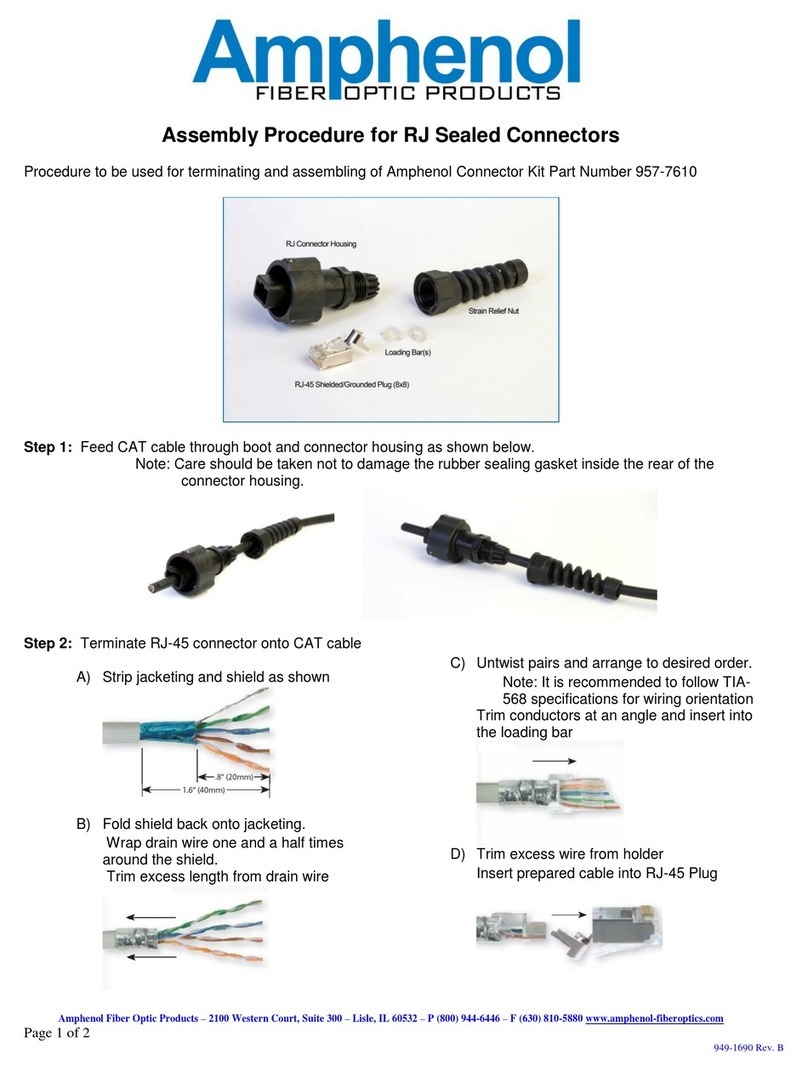

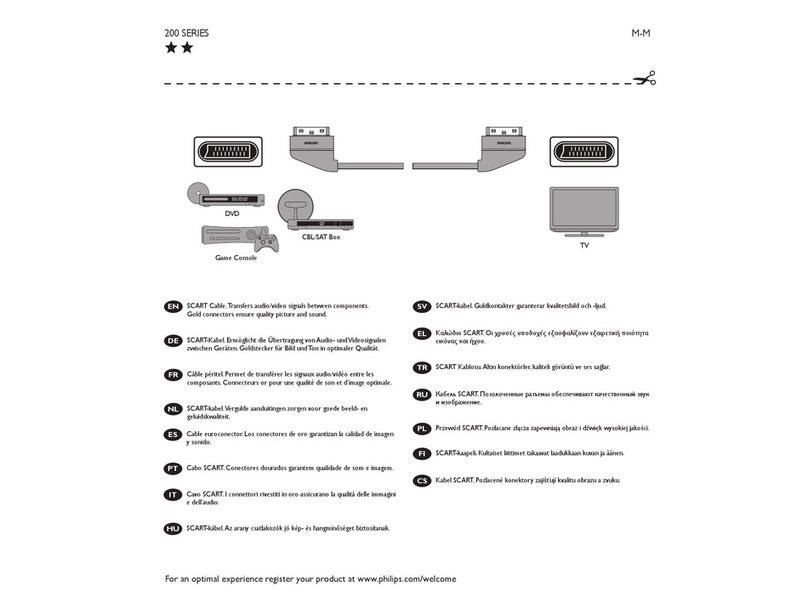

步骤4:取1pcs的③R4 holder 自左端穿上线缆,并压接在其上(规格参照表4)

Step 4: Take a ③R4 holder, load it to the cable end on the left, then crimp(refer to table 4)

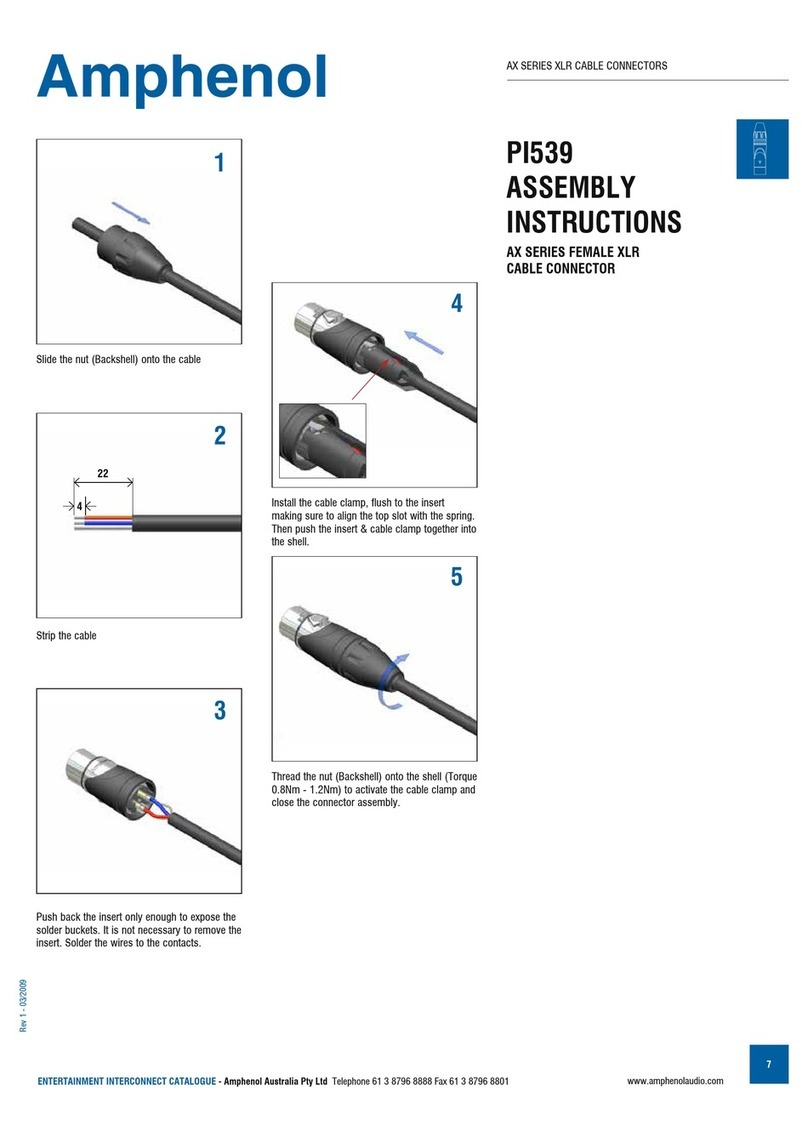

步骤5:取1pcs的⑥螺旋弹簧安装在⑦外铜环上

Step 5: Take 1pcs ⑥Coil spring is installed on ⑦Outer Copper Ring

步骤6:取2pcs的④锁块,将2pcs④锁块前端的台阶放置入端子和内皮之间的间隙

Step 6: Take 2pcs ④lock housing, Place the front step of the 2pcs ④lock housing into the space between

the terminal and the Insulation

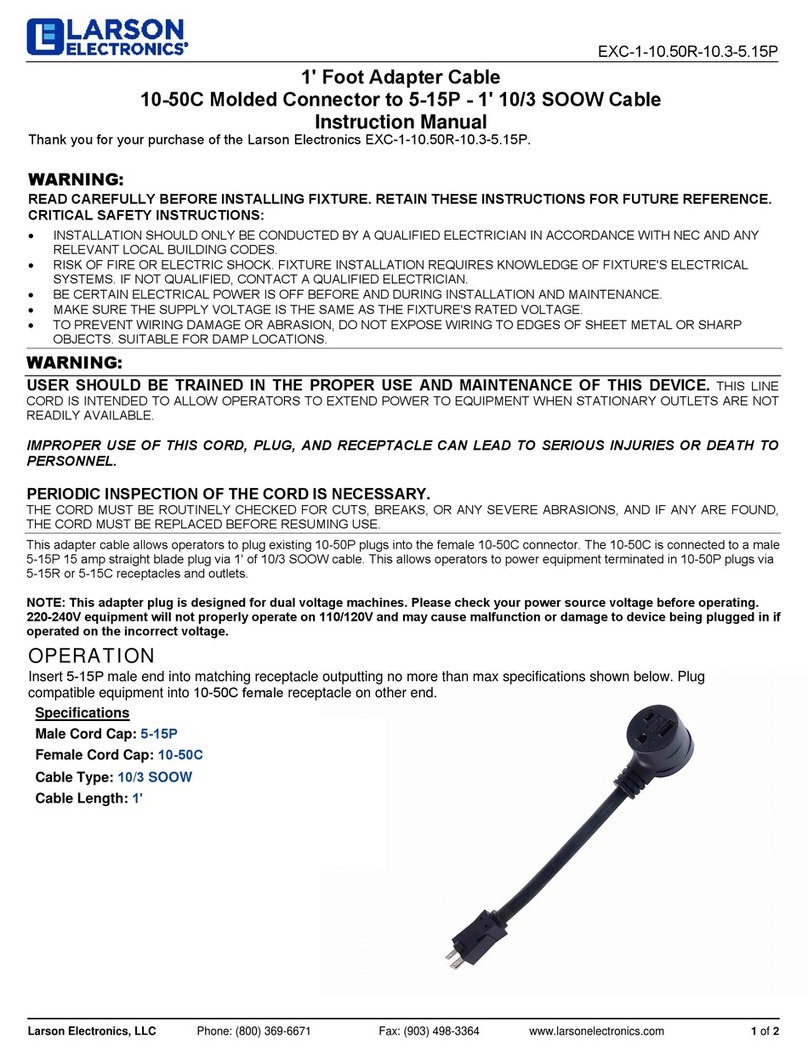

表4:端子与线缆压接压接规格&拉拔力要求

Table 4:Contact and Conductor Crimping spec & retention force requirement

120mm²横截面

120mm²Cross section

⑴建议使用H+S线材(H+S线材型号详见步骤1-1),如果客户选用其它电缆,请联系安费诺业务,协商订制零配件

Recommend to use H+S cable. (See section 1-1 for details of H+S cable part numbers.)If you need to use customized cable, Please

contact local sales for product extentions

⑵压接高度和拉拔力需要配合压接截面的金相分析,客户才能判断压接质量合格

Customers need to reconfirm cross section on crimping area and pull out force test to confirm the quality of crimp process

⑶横截面仅供参考(其他举例:等边六变形的横截形状),客户负责采购压接工具或刀模

Cross section only reference tooling geometry (ex. hex and indent dimensions ),customer will take liability for sourcing tools or dies

⑥Coil spring

螺旋弹簧

④Lock Housing

锁块

⑦Outer Copper Ring

外铜环

Crimp cable here

此处压接线束

Be sure the gap here is 2.5±1mm

确保这里的间隙是1.5mm到3.5mm之间

③R4 holder

95mm²横截面

95mm²Cross section

04-07

连接器

Connector

线缆尺寸

Cable size

线缆外径 ⑴

Accepted cable OD (mm)

压接高度⑵

Crimping height (mm)

参考抗拉拔力 ⑵

Retention Force

500/501 系列

500 /501 Series

70mm² 17.0±0.3 13.18 ±0.25 3400N

95mm² 19.9±0.4 13.29±0.25 4200N

120mm² 22.6±0.4 15.44±0.25 5000N

压接工具:油压机

Crimping tool : Hydraulic press

70mm²压模: L132153150D70

70mm²Die: L132153150D70

95mm²压模: L132173140D95

95mm²Die: L132173140D95

120mm²Die: L150195150D120

120mm²压模:L150195150D120 70mm²横截面

70mm²Cross section

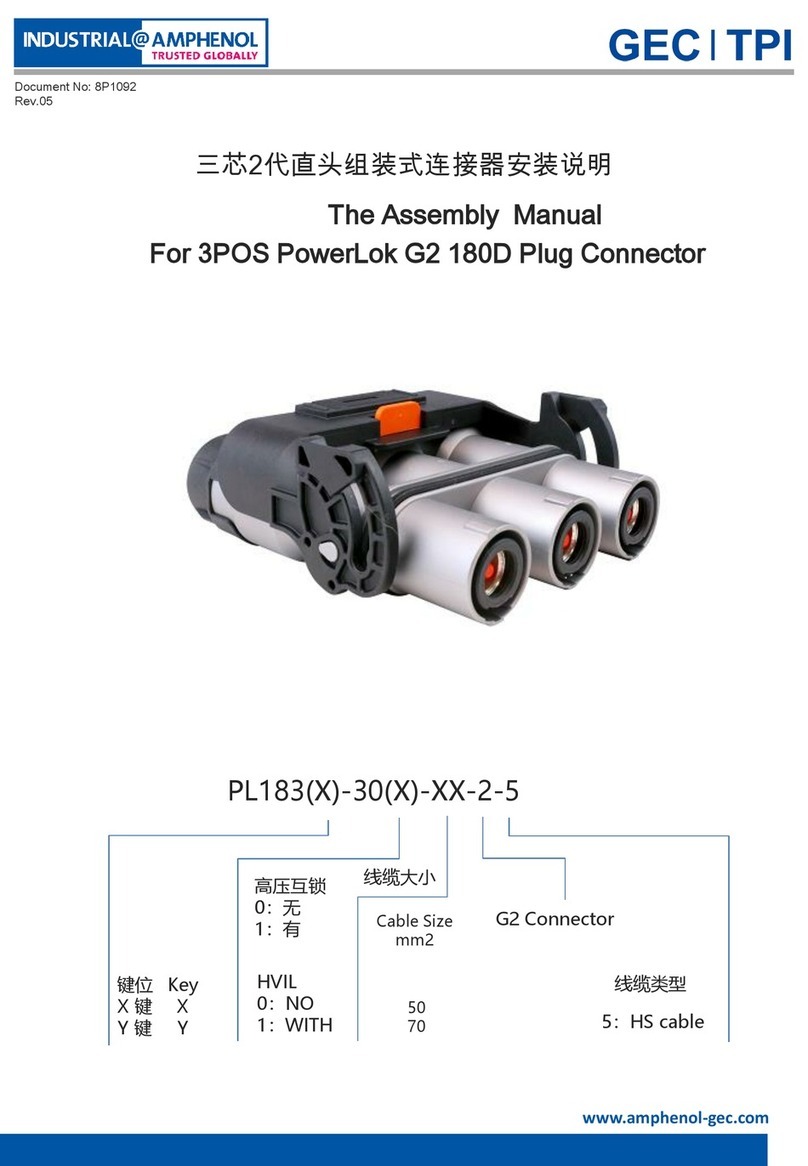

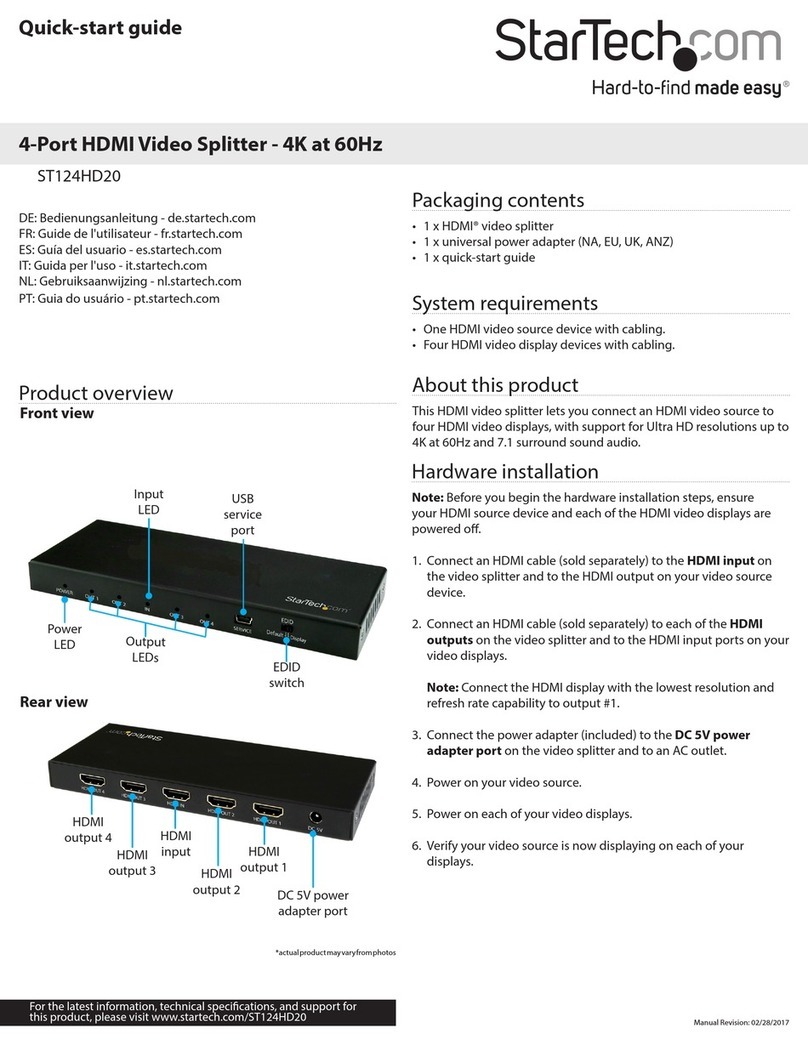

单芯2代14mm直头组装式连接器安装说明 The Assembly Manual for 1POS 14mm PowerLok G2 180D Plug Connector

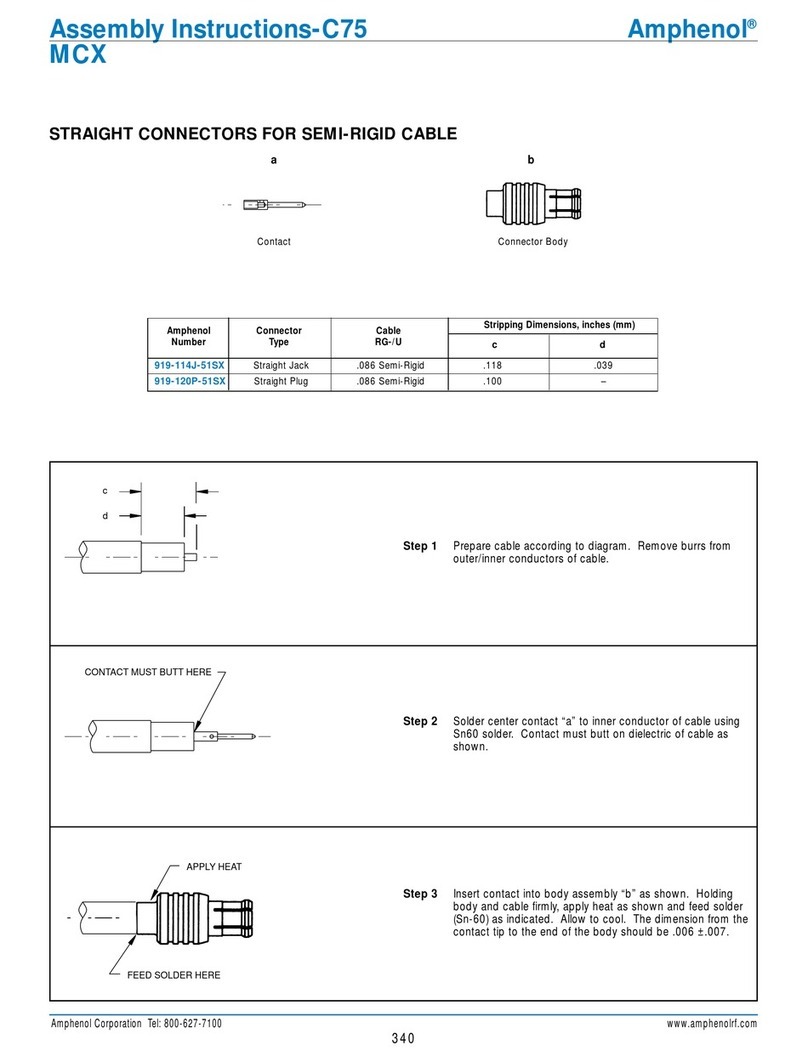

锁块缺口与端子止转面对齐

Gap of lock is in the same line with

the holder anti-rotation chamfer

Rev.05 20211124 Document No: 8P1097