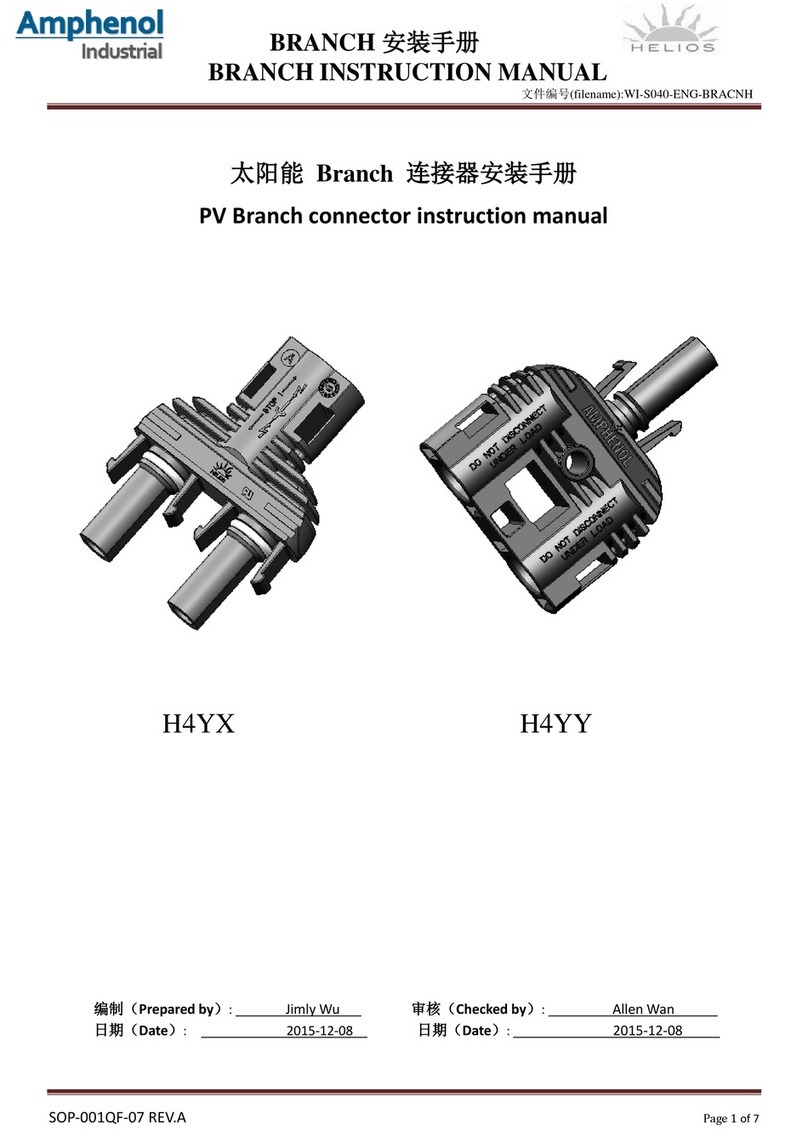

步骤6:调试好免换模压接机BZW-6C,将端子压接在线材上(详细规格参照手册最后的附录)

Step6:Set up the hexagon shape crimping machine BZW-6C, Then crimp the terminal on the wire.

(please refer to the appendix at the end of this manual for more crimping information)

⑴建议使用附录中的线材,如果要使用其它的线材,请联系当地销售,让他们提供延伸的产品

Cables written in the appendix are highly recommended for crimping, please contact our local sales for help if you want to use other cables out

of this table

⑵客户需要重新确认压接区域横截面和拉力测试,这两项达到压接的质量标准,端子压接需要满足压缩比要求:80-90%

A good crimping process is determined by 3 factors: W、H and tensile test result, please confirm these 3 targets specified are met after

crimping, Terminal crimping needs to meet the compression ratio requirements: 80-90%.

⑶横截面仅供参考(其他举例:六变带点的横截面形状),客户负责采购压接工具或刀模。

Cross section shape is only for reference(Other examples: hexagon shapes with dot), all crimping tools needed are supposed to be

prepared by customers.

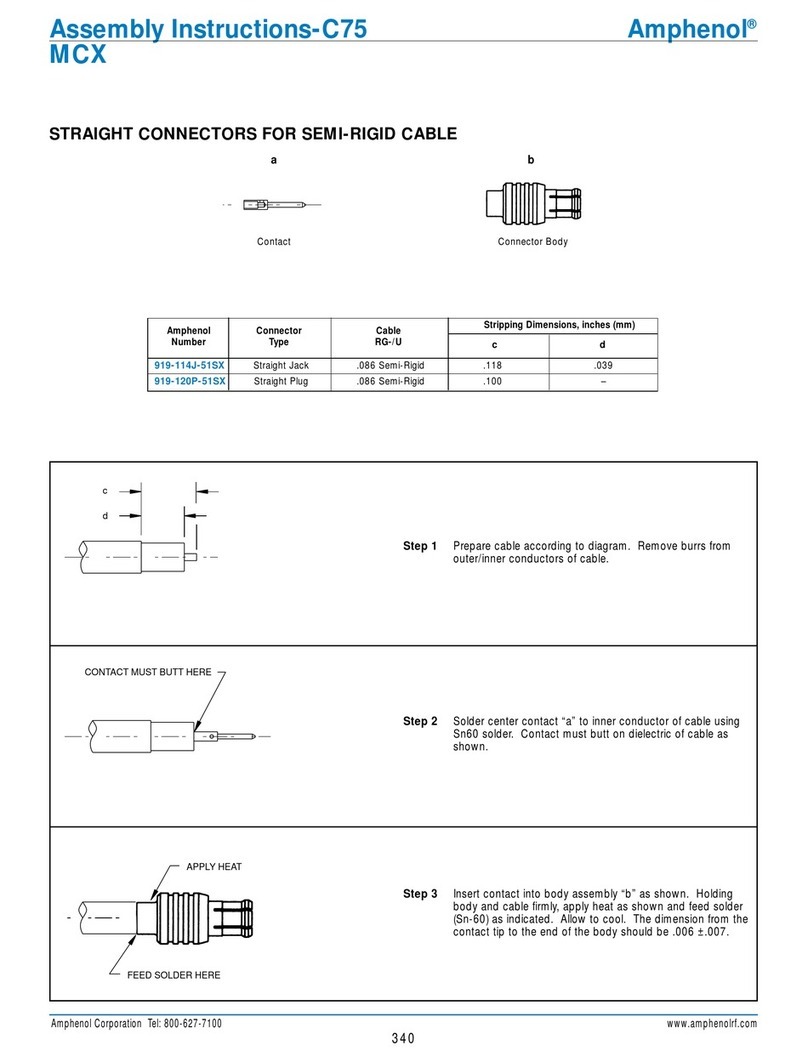

端子压接高宽度尺寸,“W”:为压接宽度,“H”为压接高度(压接高宽度尺寸及拉力标准参考手册后的附录)

Crimp height and width of the terminal. W: indicates the crimp width, and H indicates the crimp height.( Please refer

to the appendix at the end of this manual for crimp height and width and retention force details)

03/05

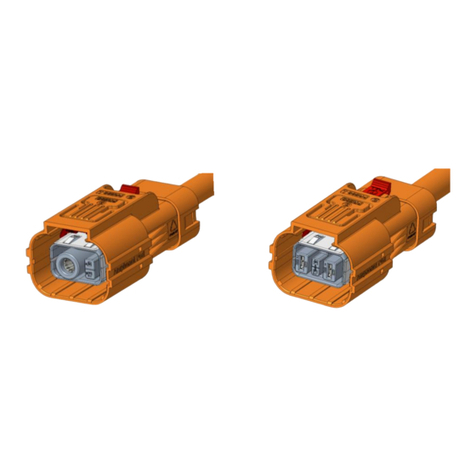

步骤7:组装④定位套到R4 端子脖颈处的沟槽 ,

Step7:Assemble ④position sleeve to the groove at the neck of the R4 terminal.

横截面

Cross section

H

W

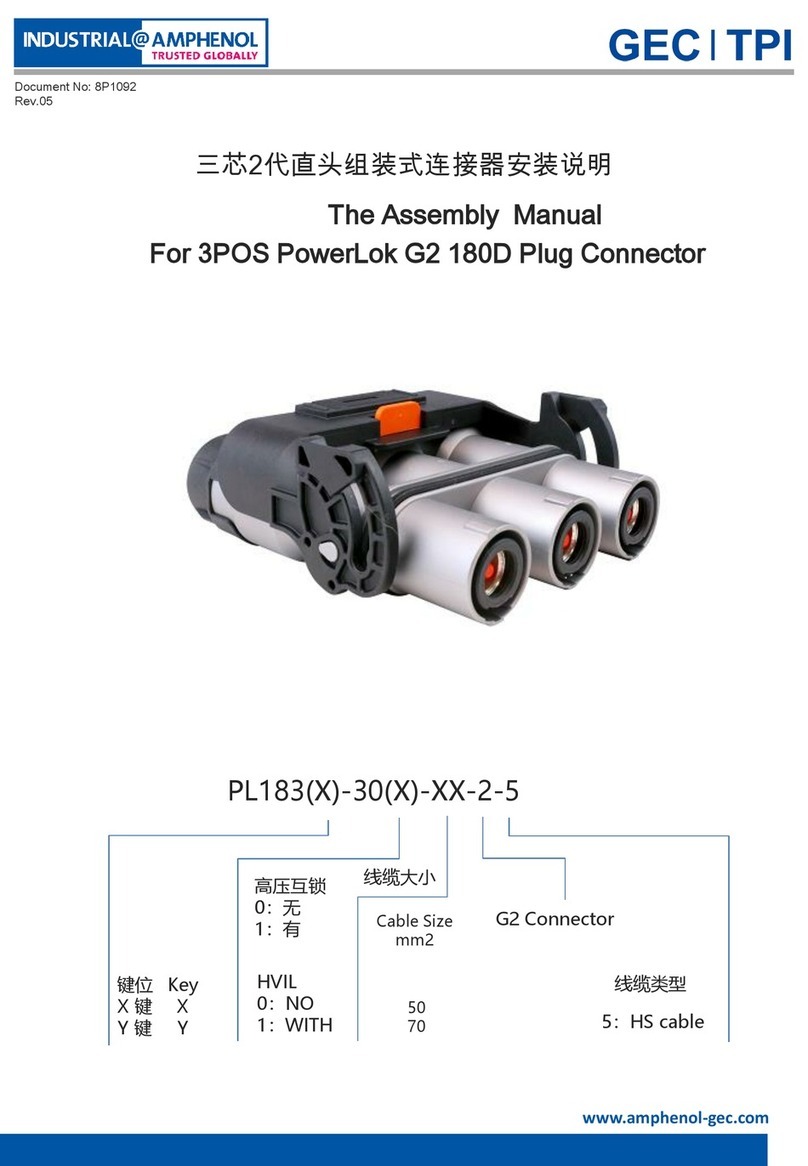

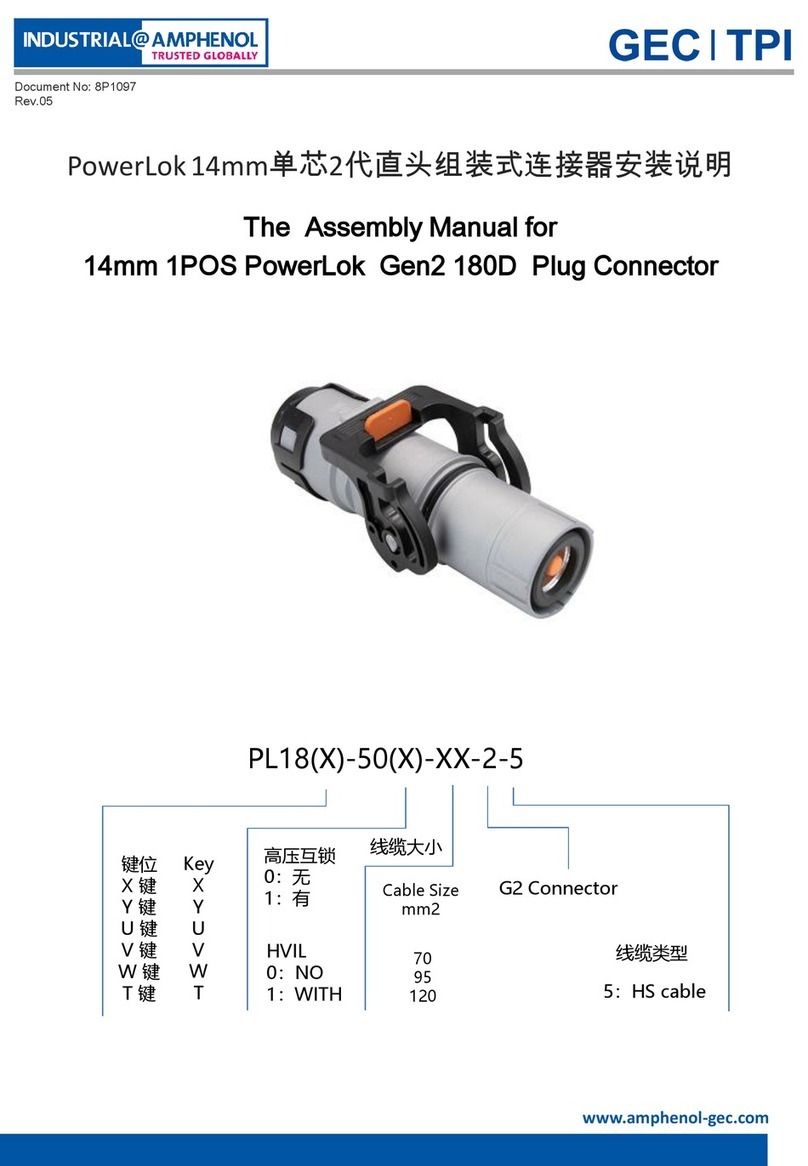

PL18X-201-50-G46 单芯50mm2直头插头组装规范 PL18X-201-50-G46 1 POS 50mm2 180D Plug Assembly Manual

Manual P/N:8P1232 _ Rev.01 2023/10/24

④

步骤8:插入R4 holder到②绝缘筒上, 转动使其触底 。

Step8:Insert the R4 holder into ②the insulation sleeve and turn it to touch the bottom.

②

步骤9:将半成品如下图示插入①屏蔽壳组件, 注意方向正确,防止损伤HVIL弹片,插到底后将密封圈推到位,

固定外壳与电缆,以10~12N∙m拧紧尾盖,完成此端线束组装。

Step9:Insert the semi-finished product into ①Shield shell assembly as shown below, pay attention to the

correct direction to prevent damage to the HVIL contact spring, then insert it into the end, push sealing into its

place, fix the housing and cable, tighten the end cap with 10~12N∙m, and complete assembly of the wire harness

at this end .

①