Instruction Manual

IMPORTANT

This automatic spray gun should be operated only by an adequately trained operator for safe use and maintenance of the equip-

ment. Any misuse or handling other than those indicated in this Instruction Manual is not covered by guarantee.

ANEST IWATA disclaims all responsibility for any accident or damage caused by failure observing the operational and safety

procedures as from this manual. In the interest of user friendliness, this manual contains information in a brief and concise form.

For any additional information you may require regarding the automatic spray gun operations, or if any missing parts or any dam-

age during transportation is found, or details of training courses, please contact your nearest ANEST IWATA Company (see last

cover page).

WA 200 AUTOMATIC SPRAY GUN

Before use, adjustment or maintenance, it is important to read this instruction manual very carefully.

This manual must be stored in a safe place for any future reference that may be necessary.

GB

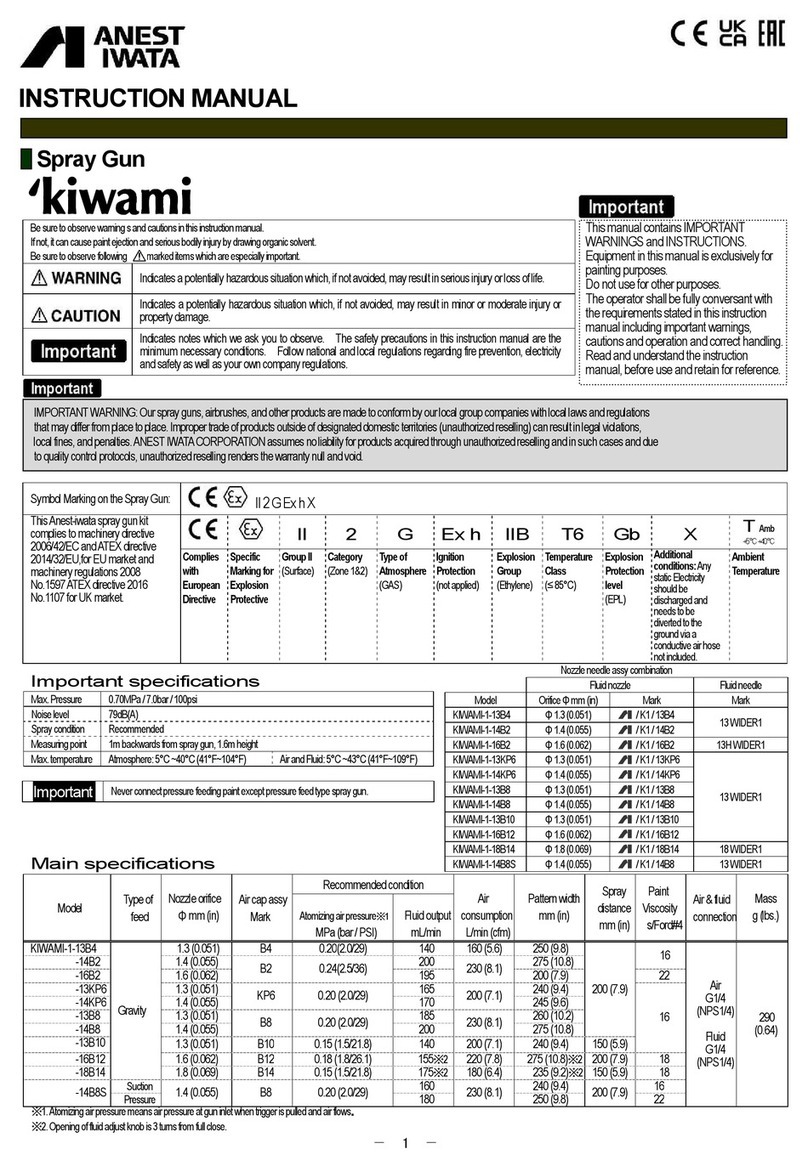

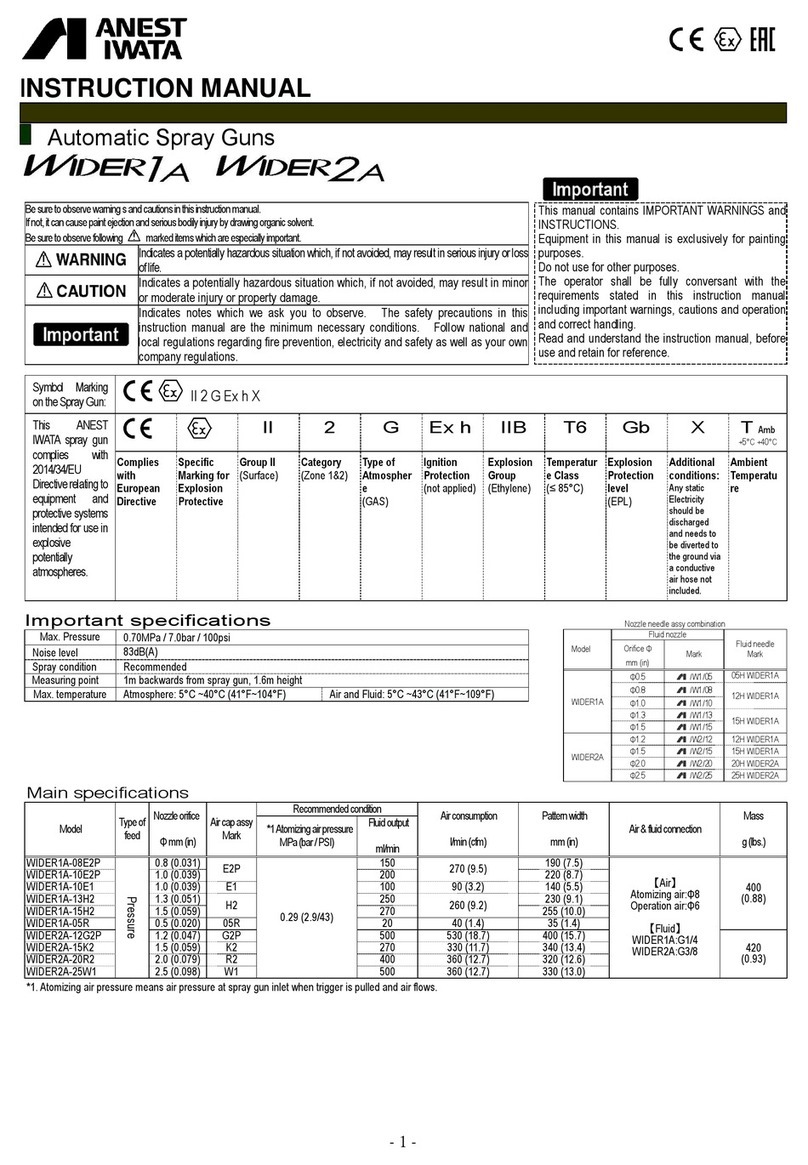

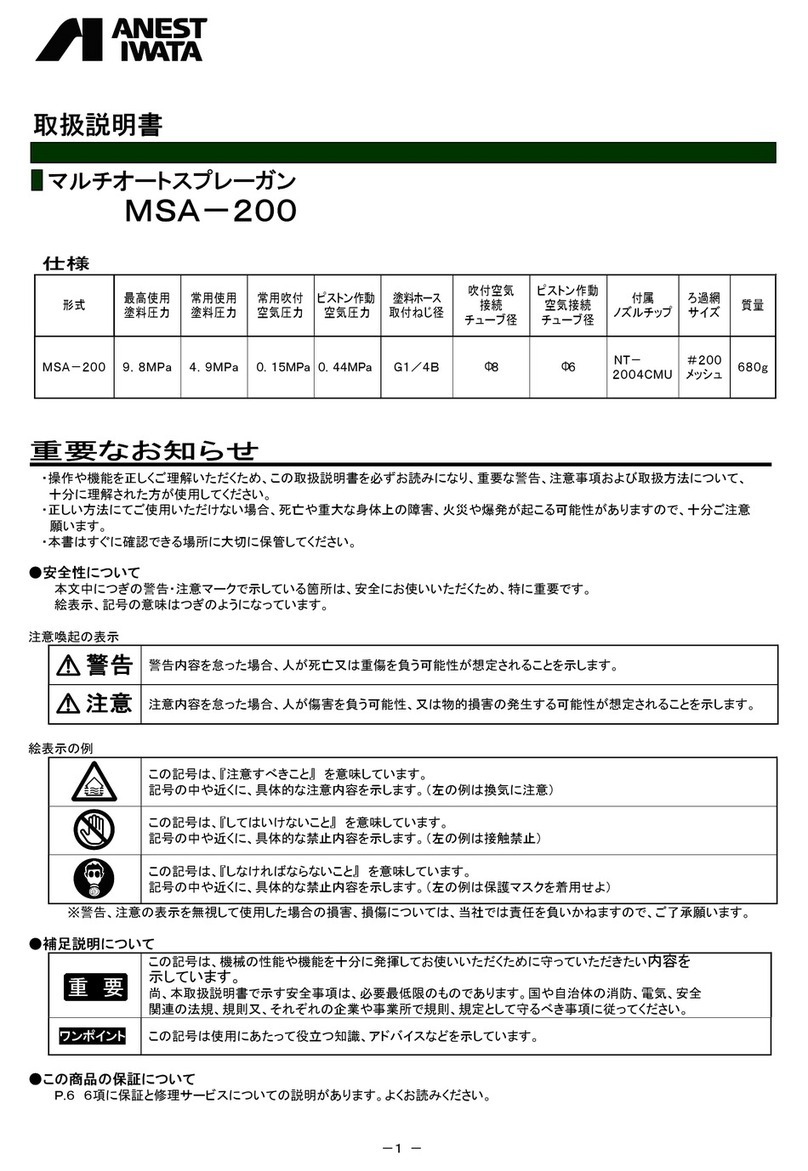

MAIN SPECIFICATIONS

PROBLEMS AND REMEDIES

Problem Where it Parts to be Cause Remedy

occurred checked Retighten Adjust Clean Replace

Air leaks Piston Piston *Dirt or damage on seat x x

(from tip

of air cap) Air valve seat set *Dirt or damage on seat x x

*Wear on air valve spring x

O ring *Damaged or deteriorated x

Paint Fluid nozzle Fluid nozzle - *Dirt, damage, wear

leaks fluid needle set on seat x x

*Loose fluid needle

adj. knob x

*Wear on needle spring x

Fluid nozzle - *Insufficient tightening x

gun body *Dirt or damage on seat x x

Fluid needle - *Needle does not return due

packing set to packing set too tight x x

*Needle does not return due

to paint buildup

on fluid needle x x

Fluid needle Needle packing *Wear x x

packing set - needle set

Packing seat *Insufficient tightening x

Paint does not Tip of gun Fluid adj. knob *Insufficient opening x

flow Tip hole of nozzle *Clogged x

Paint filter *Clogged x x

TROUBLESHOOTING

Spray Pattern Problems Remedies

1. Air is mixed into fluid passage from fluid 1. Thigten fluid needle packing (15).

Fluttering needle packing (15). or replace packing if damaged.

2. Air is mixed from between fluid nozzle (2) 2. Thigten fluid nozzle (2).Or remove

and tapered seat body. fluid nozzle (2) and clean its seat.

1. Paint buildup on air cap (1), partially 1. Remove obstructions from horn holes.

Crescent clogs horn holes. Air pressure from But do not use metal objects to clean

both horns differs. horn holes.

1. Paint buildup on air cap, partially clogs horn 1. Remove obstructions.

Inclined holes or air cap center hole causes damage. Replace if damaged.

2. Loose fluid nozzle. 2. Remove fluid nozzle, clean seated section

1. Fluid output too high. 1. Adjust fluid adj. knob or

Split 2. Paint viscosity too low. pattern adj. knob.

2. Adjus paint to increase viscosity.

Heavy 1. Fluid output too high. 1. Increase fluid output.

Center 2. Paint viscosity too low. 2. Reduce viscosity.

1. Fluid nozzle and fluid needle set are 1. Clean or replace fluid nozzle and fluid

Spit not seated properly. needle set.

2. The first-stage travel of trigger decreases. 2. Replace fluid nozzle and fluid needle set.

3. Paint buildup inside air cap set. 3. Clean air cap set.

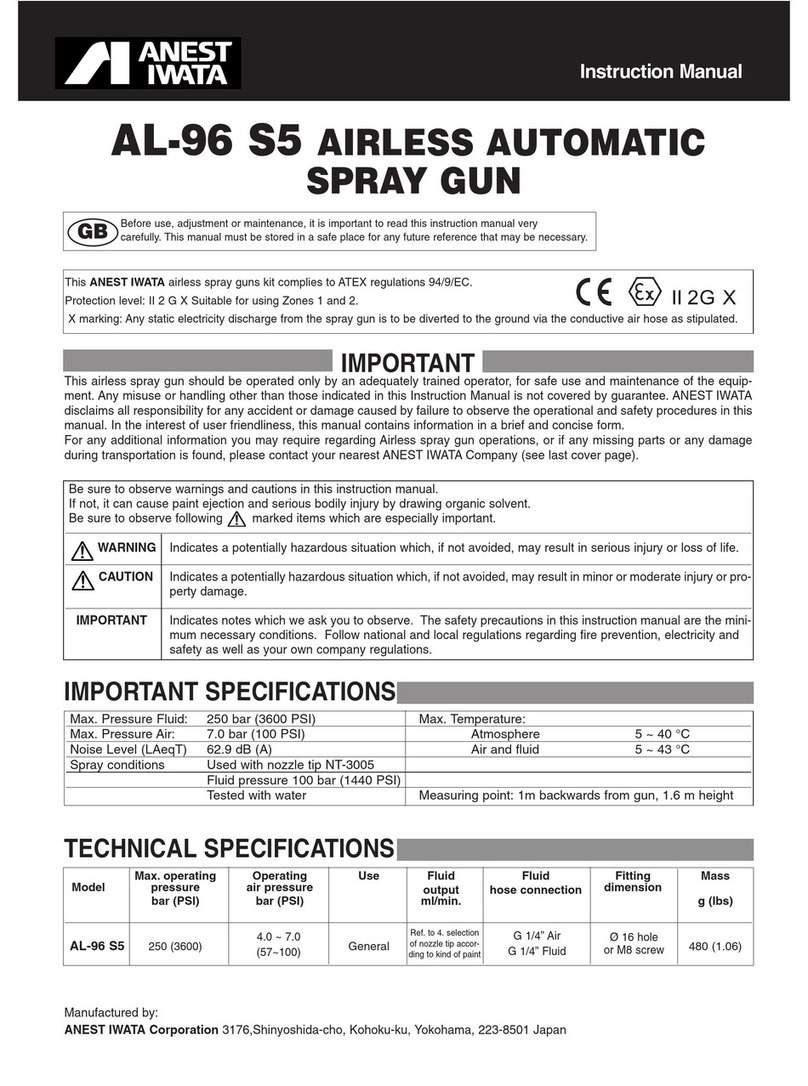

Max. Working Pressure: 6.8 bar Noise Level (LAeqT) 81.2 dB (A)

Temperature range: 5~40°C

Fluid nozzle Fluid needle set

Orifice Mark Mark

mm

1.2 W200/12 WA12

1.5 W200/15 WA15

2.0 W200/20 WA20

2.5 W400/25 WA25

MJ1207EREV.3

NOTE: for SPARE PARTS list see on page 3.

Manufactured by:

ANEST IWATA Corporation 1-9-14, Ebisuminami, Shibuya-ku, Tokyo, Japan

DIMENSIONS

G

A

BCE

F

J

H

A B C D E F G H J

30.5 47.5 89.5 - 149.5 23.5 35.5 40.5 85.5

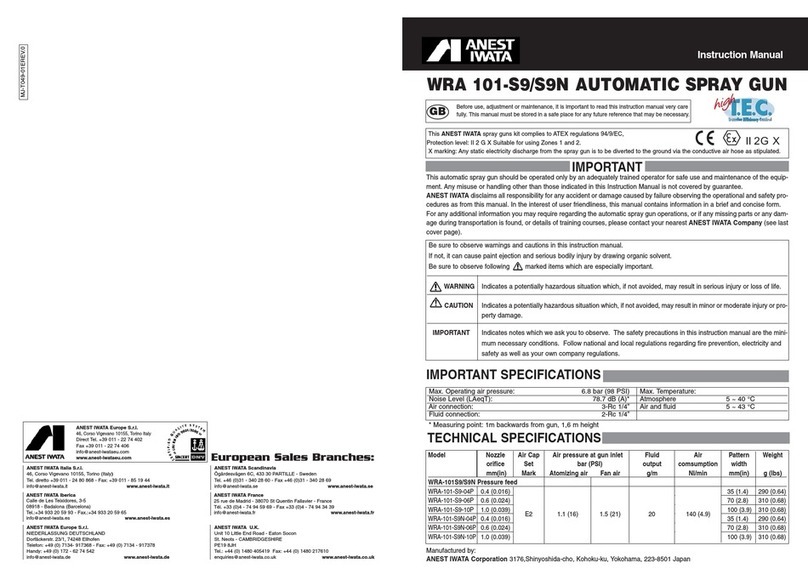

Model Nozzle Air Fluid Pattern Air Cap Weight Atomizing

Orifice Consumption Output Widht Set air pressure

mm l/min ml/min mm g bar

WA- 200-08 0.8 270 255 280 LV2

WA- 200-102 1.0 270 255 280 LV2

WA- 200-122 1.2 270 255 280 LV2

WA- 200-08P 0.8 530 500 400 G2P

WA- 200-102P 1.0 530 500 400 G2P

WA- 200-122P 1.2 530 500 400 G2P

WA- 200-152P 1.5 330 270 340 K2

WA- 200-202P 2.0 360 400 320 R2

WA- 200-251P 2.5 360 500 330 WI

WA- 200-066P FT 0.6 170 80 140 0,14

WA- 200-086P FT 0.8 185 100 150 0,16

WA- 200-106P FT 1.0 200 120 160 0,18

WA- 200-126P FT 1.2 220 140 180 0,20

500

550

FT6

3.0

2.0

S

EDI

E

UROPEE

:

ANEST IWATA Deutschland

Trollingerweg 14

D-74360 Ilsfeld-Auenstein

Telefon-Fax:+49 (0)7062-62 290

Handy: +49 (0)172-62 74 542

ANEST IWATA Europe s.r.l.

46, Corso Vigevano

10155 Torino - Italy

Tel. +39 011-24 80 868

Fax +39 011-85 19 44

www.anest-iwataeu.com

ANEST IWATA Scandinavia A.B.

Ögärdesvägen 6C

433 30 Partille

Tel. +46 (0)31-340 28 60

Fax +46 (0)31-340 28 69

ANEST IWATA France S.A.

25 Rue de Madrid - BP 7405

38074 Saint Quentin Fallavier

Cedex Centre Evolic 7405

Tél. +33 (0)4-74 94 59 69

Fax +33 (0)4-74 94 34 39

ANEST IWATA (U.K.) LTD

Unit 2, Cedar Trade Park,

Ferndown Industrial Estate,

Wimborne, Dorset - BH21 7SB U.K.

Tel. +44 (0)1202 - 895999

Fax: +44 (0)1202 - 895666