3/68

1. Introduction

SAFETY GUIDELINES DEFINITIONS

This manual contains information for the proper assembly, op-

eration and care of your sprayer. Carefully read and follow the

instructions contained in this manual before using your sprayer.

This equipment was designed for spraying plants protection

products approved by regulatory authorities to be used in knap-

sack sprayers.

It is important for you to read and understand this manual. The infor-

mation it contains relates to protecting YOUR SAFETY and PREVENTING

PROBLEMS. The symbols below are used to help you recognize this in-

formation.

2. Specifications

Model HD 400/ 550

Net weight 3.7 kg/ 4.2 kg

Gross weight 4.3 kg/ 4.9 kg

Spray lance length 600 mm

Hose length 1650 mm

Chemical tank

Capacity 16 L/ 20 L

Filling opening diameter 115 mm

Material Polyethylene

Pump

Type Piston

Maximum working pressure 75 psi (5.1 bar)

Nozzle installed Blue adjustable cone

Material Polypropylene

DANGER!

Indicates an imminently hazardous situation which, if not avoid-

ed, will result in death or serious injury.

WARNING!

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION!

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

Notice: Used without the safety alert symbol indicates a potentially haz-

ardous situation which, if not avoided, may result in property damage.

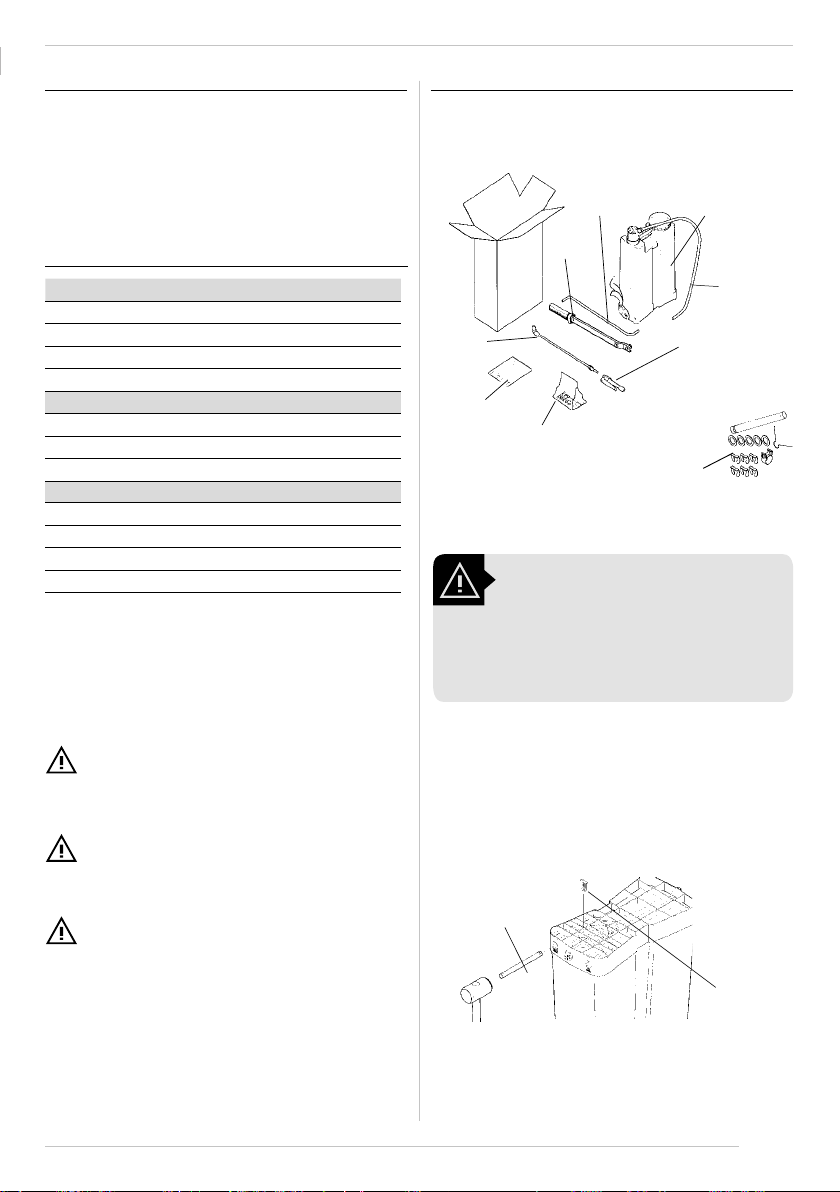

3.1. Unpacking

3. Preparing the Product For Use

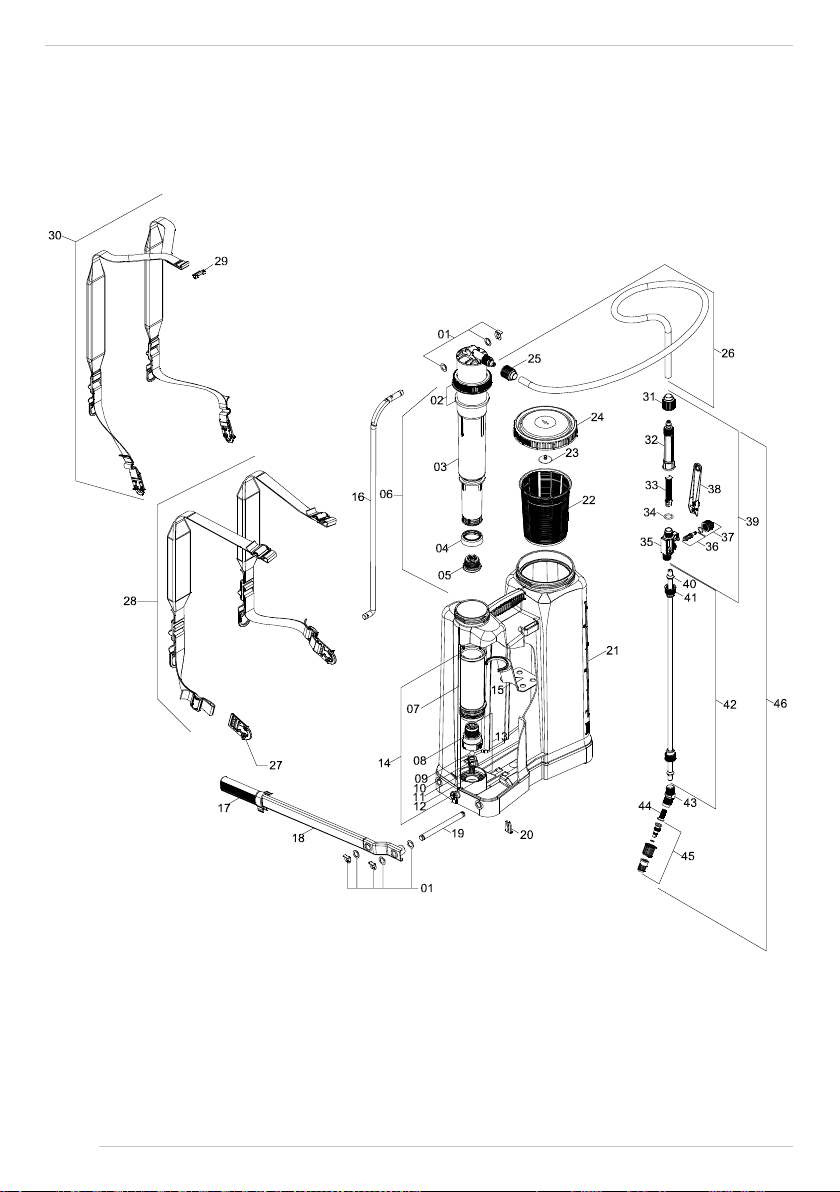

Remove from the sprayer carton the following parts:

WARNING!

Be careful when taking out the sprayer out

of the carton because the lever is loose and

can cause damage or personal injury. Note

that the agitator is loose inside the tank and

must be properly assembly.

Manual

Haste Tank

Lance

Accessories

plastic bag Contents of the

plastic bag

Lever

Trigger

valve

Hose

3.2. Installing the shaft

• Insert the shaft (1) in the free opening on the tank base (on

the same side of the chamber).Fit the shaft lock (2).

Shaft

(1)

Shaft

lock(2)

NOTE: Carton can be discarded in recyclable waste.

NOTE: Minimum space needed for use, maintenance and repair

is 1,5 m².

SAVE THESE INSTRUCTIONS: This manual contains important

safety instructions for the proper use and maintenance of this

product.