AnyCubic Kobra Go User manual

Other AnyCubic 3D Printer manuals

AnyCubic

AnyCubic Kossel Plus User manual

AnyCubic

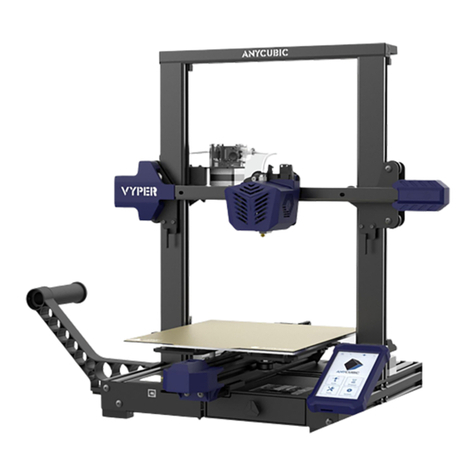

AnyCubic VYPER User manual

AnyCubic

AnyCubic Wash and Cure User manual

AnyCubic

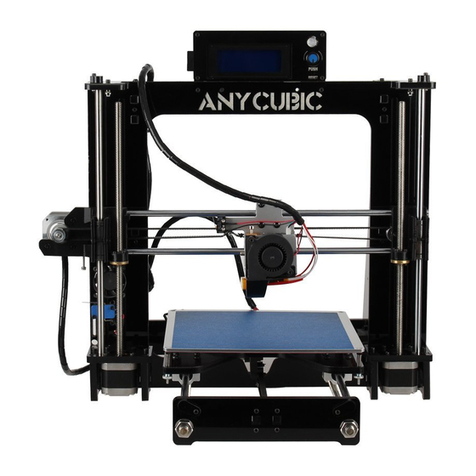

AnyCubic Prusa i3 User manual

AnyCubic

AnyCubic Kobra User manual

AnyCubic

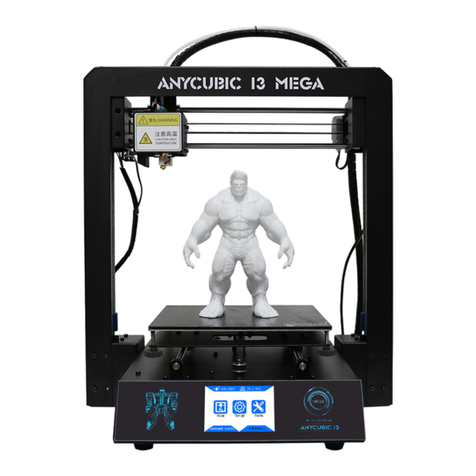

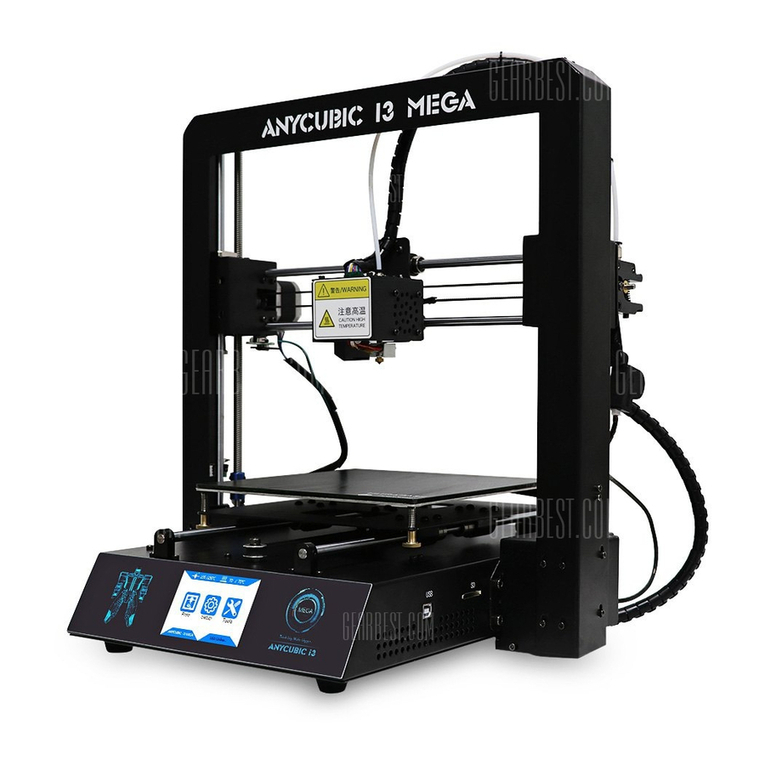

AnyCubic i3 MEGA User manual

AnyCubic

AnyCubic i3 MEGA User manual

AnyCubic

AnyCubic Photon Mono User manual

AnyCubic

AnyCubic Kobra User manual

Popular 3D Printer manuals by other brands

HP

HP Jet Fusion 4200 Product Documentation Site Preparation Guide

Rokit

Rokit AEP Series user manual

Ackuretta

Ackuretta FreeShape 120 user manual

DIYElectronics

DIYElectronics PRUSA I3 ELECTRONICS AND SOFTWARE GUIDE

Ultimaker

Ultimaker S5 Material Station installation guide

Stratasys

Stratasys FDM Vantage Series user guide