Page 6

•Transport equipment - e.g. lighting, warning signs and any protective equipment, must be checked

and mounted!

•Triggers for fast couplers must be hanging loosely and must not trigger themselves when lowered.

•Never leave the driver's platform while driving!

•The driving behaviour, steering and braking capacity are also affected by mounted or towed

implements and ballast weights. For this reason, always ensure sufficient steering and braking

capacity!

•When driving in curves, take account of the wide radius and/or the centrifugal mass of the

implement!

•The implement may only be operated when all of the protective devices are installed and in safety

position!

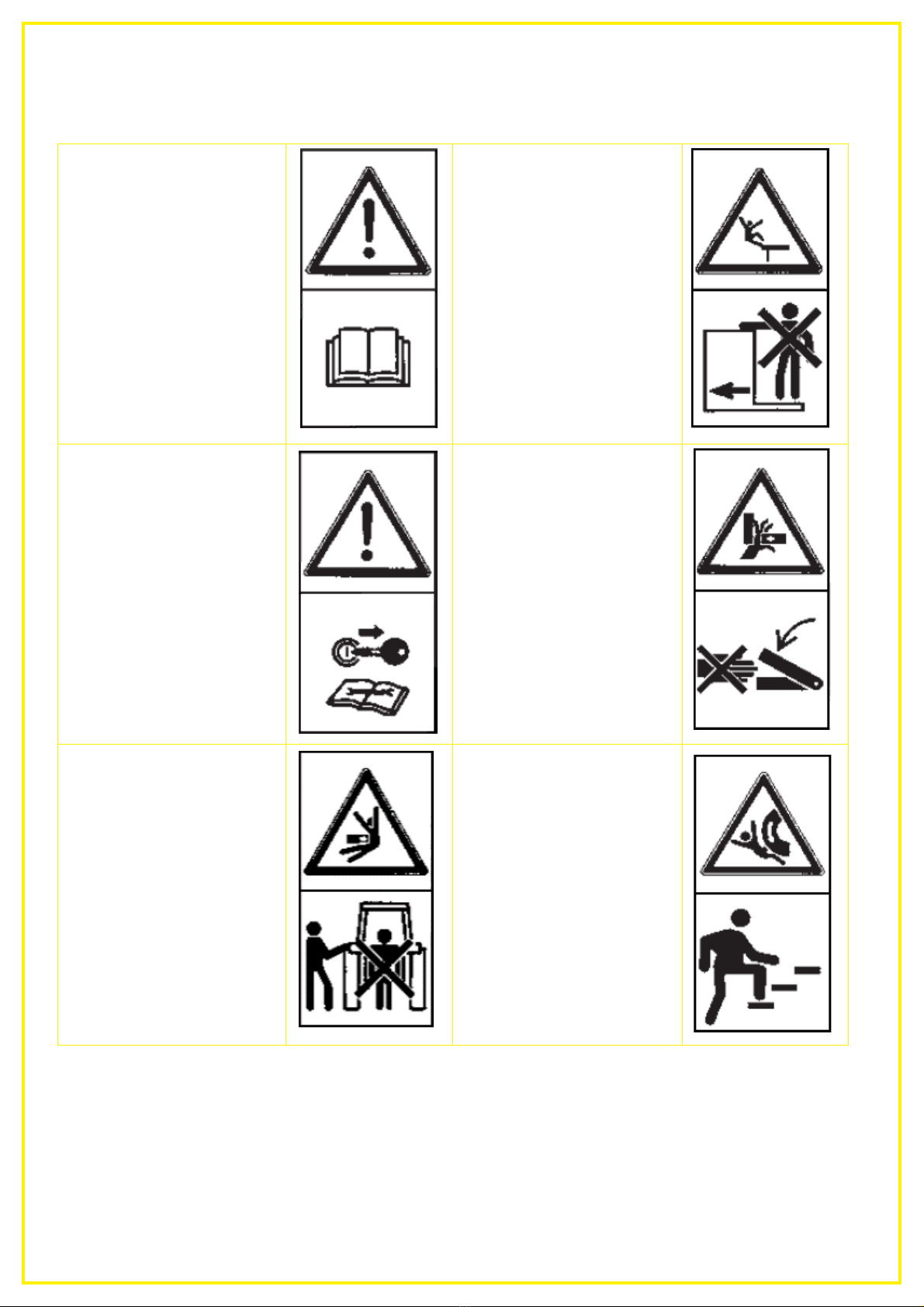

•It is forbidden to stand in the working area of the implement!

•Do not stand near rotating and swivelling parts of the implement!

•Hydraulic folding frames may only be actuated when nobody is standing in the swivelling range.

•There are pinch and shear points on externally powered (e.g. hydraulic) parts!

•On implements with manual folding, always ensure that the implement is stable!

•For implements that are driven rapidly with soil-driven tools - Danger after lifting due to the still

rotating centrifugal mass! Only approach the implement when it has come to a standstill!

•Before exiting the tractor, lower the implement onto the ground, switch off the motor and remove the

ignition key!

•Standing between the tractor and the implement is forbidden unless the vehicle is secured against

rolling away using the parking brake and/or with wheel chocks!

•Folded frames and lifting devices must be locked in transport position!

•Packer catch arms must be swivelled in and locked before road transport!

•Lock the track markers in transport position!

•The rotary hoe may only be used on agricultural land. It may not be used on normal road surfaces,

on asphalt or concrete. In particular, the rotary hoe may not be used in the building industry on

construction sites, for winter services, for road construction, or for underground mining.

•When driving on roads, which is only permitted with folded side wings and the rotary hoe raised, the

tractor hydraulic system prevents lowering of the rotary hoe as well as of the folded up components

(additionally secured with a chain), also in case of failure of the tractor hydraulic system.

•The specifications in the operating manual regarding mounting as well as the calculation of the

weight ratios and the axle loads of the tractor must be observed.

•No other persons may be in the hazard area of the rotary hoe. Visual check by the driver!

•When performing the work passes, the tractor's speed must maintained as specified in the operating

instructions. This can be between 2 and 25 km/h.

•People must not be carried on the rotary hoe during intended use on agricultural land and when

driving on roads.

•When mounting the rotary hoe, the operator must ensure that there is a metallic connection made to

the tractor.

•The view of the rotary hoe and the hazardous movement area must be clear to check the procedure.

•During assembly, the operator must ensure that the requirements for the tractor in terms of the

power, axle loads and weight distribution as specified in the operating manual are met and that the

connections specified in the operating instructions are made correctly.

•Hearing protection should be used, if necessary.

•The implements must be checked regularly by the operator (before every use) for any fractures and

cracks, chafe marks, leaks, loose bolts and connections, vibrations, unusual sounds, and to ensure

they function correctly.

•The implement may not be used during storms and rain, and it must be parked under a shelter.

•The operator must ensure that no one is in the vicinity of the rotary hoe when it or its components are

being moved by the tractor's hydraulic system. Visual check by the driver!

5.3 Mounted implements

•Before mounting and dismounting implements on the three-point linkage, move the operating devices

into the position that excludes unintentional lifting or lowering!