ARB 3940420 User manual

Last Rev Date 17/05/2019

Page 1 of 36

Fitting instructions# 3789528

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Part Number:

3940420

Product Description:

SUMMIT SAHARA BULL BAR

Suited to vehicle/s:

FORD RANGER PX MK2 & EVEREST (NOT TITANIUM)

Optional Kits:

5100310 SAHARA TUBE KIT PXII RANGER

5100230 BUFF KIT 2 PCE REAR SAHARA BUMPER

3500720 WINCH INSTALL KIT

3500640 ARB AUX FOG LIGHT ADAPTOR

3500530 ARB AUX FOG LIGHT LOOM (2015 ON WILDTRAK,

EVEREST & ON-FACTORY FOG LAMP VEHICLES)

3500680 FOG LAMP HOUSING CLEAR LENS KIT

3500590 FOG LIGHT KIT (LH&RH LIGHTS)

3540200 ADAPTIVE CRUISE CONTROL KIT

3540190 ADAPTIVE CRUISE CONTROL COVER

NOTE: ARB recommends purchase of correctly colour coded sensors from a Ford dealer.

Painting over sensors is not recommended as sensor operational faults can result.

WARNING

REGARDING VEHICLES EQUIPPED WITH SRS AIRBAG;

When installed in accordance with these instructions, the front protection bar does not affect operation of

the SRS airbag.

ALSO, NOTE THE FOLLOWING:

This product must be installed exactly as per these instructions using only the hardware supplied.

In the event of damage to any bull bar component, contact your nearest authorised ARB stockist. Repairs or

modifications to the impact absorption system must not be attempted.

Do not use this product for any vehicle make or model, other than those specified by ARB.

Do not remove labels from this bull bar.

This product or its fixing must not be modified in any way.

The installation of this product may require the use of specialized tools and/or techniques

It is recommended that this product is only installed by trained personnel

These instructions are correct as at the publication date. ARB Corporation Ltd. cannot be held responsible

for the impact of any changes subsequently made by the vehicle manufacturer

During installation, it is the duty of the installer to check correct operation/clearances of all components

Work safely at all times

Unless otherwise instructed, tighten fasteners to specified torque

ARB 4x4 ACCESSORIES

Corporate Head Office

42-44 Garden St Tel: +61 (3) 9761 6622

Kilsyth, Victoria Fax: +61 (3) 9761 6807

AUSTRALIA 3137

www.arb.com.au

Last Rev Date 17/05/2019

Page 2 of 36

Fitting instructions# 3789528

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

GENERAL CARE AND MAINTENANCE

By choosing an ARB Bar, you have bought a product that is one of the most sought after 4WD products in the

world. Your bar is a properly engineered, reliable, quality accessory that represents excellent value. To keep your

bar in original condition it is important to care and maintain it following these recommendations:

Prior to exposure to the weather your bar should be treated to a Carnauba based polish on all exposed

surfaces. It is recommended that this is performed on a six monthly basis or following exposure to salt, mud,

sand or other contaminants.

As part of any Pre Trip Preparation, or on an annual basis, it is recommended that a thorough visual

inspection of the bar is carried out, making sure that all bolts and other components are torqued to the correct

specification. Also check that all wiring sheaths, connectors, and fittings are free of damage. Replace any

components as necessary. This service can be performed by your local authorized ARB Stockist

Important electrical system information

The 2011-On Ford Ranger uses an advanced wiring system allowing new chassis control systems to be

used. Due to this, placing large amounts of additional load to the wiring harness may trigger faults in the

ECU or cause permanent damage to the wiring harness.

To prevent overloading the turn and clearance lights must be activated through relays. Relay looms are

provided within this kit to wire these lights. For further reference please see the attached wiring diagram at

the end of these instructions.

Maintenance of adaptive cruise control components (if fitted, available on 2015 ON Ranger) must only be

performed by an authorized ARB workshop. No adjustments to the radar and/or bull bar are permissible

following original fitment unless conducted by your local authorized ARB stockist. Regular cleaning of the

radar must be carried out in order to ensure optimal operation. Ensure that no foliage, dirt or material is

obstructing the radar‟s field of vision as this may impact the performance of the radar

FITTING REQUIREMENTS

REQUIRED TOOLS FOR FITMENT OF PRODUCT:

BASIC TOOL KIT

ELECTRIC DRILL & Ø2, Ø5.5,Ø7 & Ø10MM BITS

JIG SAW OR MULTI-TOOL WITH BLADE

SUITABLE FOR PLASTIC

MATTE BLACK SPRAY PAINT

FILE OR SAND PAPER

MASKING TAPE

BASIC MEASURING TOOLS

ELECTRICAL TAPE (BLACK)

CONVOLUTED TUBE (7MM & 12MM)

HACK SAW OR EQUIV.

TORQUE WRENCH 9-100 Nm CAPACITY

LARGE G-CLAMP

HAVE AVAILABLE THESE SAFETY ITEMS WHEN FITTING PRODUCT:

Protective eyewear

Hearing protection

NOTE: „WARNING‟ notes in the fitting procedure relate to OHS situations, where to avoid a

potentially hazardous situation it is suggested that protective safety gear be worn or a safe work

procedure be employed. If these notes and warnings are not heeded, injury may result.

FASTENER TORQUE SETTINGS:

SIZE

Torque (Nm)

Torque (ftlb)

Plastics Screws

0.8

0.6

M6

9

7

M8

22

16

M10(TOP FRAME ONLY)

22

16

M10

44

32

M12

77

57

M16

90

66

Last Rev Date 17/05/2019

Page 3 of 36

Fitting instructions# 3789528

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

APPLICATION.

PART NO.

DESCRIPTION

QTY

FIT MOUNT

BRACKET TO

CHASSIS

3759563

BRACKET CHASSIS MOUNT RANGER LRG RAD

1

3759574R

BRACKET CHASSIS BRACE INNER RIGHT

1

3759574L

BRACKET CHASSIS BRACE INNER LEFT

1

3759575R

BRACKET CHASSIS BRACE OUTER RIGHT

1

3759575L

BRACKET CHASSIS BRACE OUTER LEFT

1

3759576R

BRACKET BULL BAR BRACE RIGHT

1

3759576L

BRACKET BULL BAR BRACE LEFT

1

4584375

SPACER Ø1 ¼” 15MM THICK

2

5848427

PACKER CHASSIS 5MM THICK

4

6151357

BOLT SEMS M10 X 30 ZP Gd 8.8

10

4581011

WASHER FLAT, M12 x 27 x 4

10

4581083

WASHER FLAT, M10 x 21 x 2 ZP

2

4581050

WASHER SPRING 1/2 x 3/16 x 3/16 ZP

10

4581048

WASHER SPRING M10 TZP480

2

6151360

BOLT M12 x 1.75 x 35 Gd 8.8 ZP

10

6151428

NUT FLANGE M12 X 1.75 ZP

10

6151456

BOLT M10 x 1.5 x 45 Gd 8.8 ZP

2

6151727

BOLT HXFL M16 x 2.0 x 35 FT PC8.8 TZP

2

6151728

NUT FL SM M16 x 2.0 PC8 TZP

2

FIT BAR TO

MOUNT

BRACKET

4584376

SPACER Ø1 ¼ “ 35MM THICK

2

6151357

BOLT SEMS M10 X 30 ZP Gd 8.8

4

6151306

NUT CAGED M12 1.8-3.2

6

4581050

WASHER SPRING 1/2 x 3/16 x 3/16 ZP

6

6151360

BOLT M12 x 1.75 x 35 Gd 8.8 ZP

4

6151168

BOLT M12 x 1.75 x 80 CL8.8 ZP

2

3194293

PLATE NUT MOUNT RANGER T6

2

4581007

WASHER FLAT 1/2 x 1.1/2 x 4MM SILVER

6

6151321

NUT FLANGE M10 x 1.5 ZP

12

MISC

3789424

CUTTING TEMPLATE BUMPER RANGER 15 ON

1

6151349

8 - 15 X 15mm BUTTON HEAD SELF TAPPING GP

4

180302

CABLE TIE 4.8 X 180 MM BLACK

12

6191037

PINCH WELD 1000mm

1

FIT LICENSE

PLATE

BRACKET

6151213

BOLT M6 x 1.0 x 20 Gd8.8 BZ

3

4581287

WASHER SPRING M6 x 2.5 x 1.6 BLK ZN

3

4584295

WASHER FLAT M6 X 12 X 1.3 BLK ZN

3

6151128

NUT FLANGE M6 x 1.0 ZP

3

3759488

BRACKET LIC PLATE FIXED LARGE RAD

1

6821189

GROMMET RND FC 1500 080 090

2

6151384

SCREW 10G x 5/8 SELF TAPPING

2

FIT WINCH

ACCESS PANEL

6151213

BOLT M6 x 1.0 x 20 Gd8.8 BZ

4

4581287

WASHER SPRING M6 x 2.5 x 1.6 BLK ZN

4

4584295

WASHER FLAT M6 X 12 X 1.3 BLK ZN

4

6151128

NUT FLANGE M6 x 1.0 ZP

4

6522985

PRESS FORM WINCH COVER PANEL

1

Last Rev Date 17/05/2019

Page 4 of 36

Fitting instructions# 3789528

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

PARTS LISTING

APPLICATION.

PART NO.

DESCRIPTION

QTY

FIT UNDER

PANELS

6522940R

PANEL UNDER WING RANGER 11ON

LRG RAD

1

6522940L

PANEL UNDER WING RANGER 11ON

LRG RAD

1

3758957

BRACKET WING PANEL RANGER T6

2

6151132

NUT FLANGE M8 x 1.25 ZP

7

4581082

WASHER FLAT, M6 x 19 x 1.6 BZ

10

4581047

WASHER SPRING M8 x 3/32 x 3/33 BLK

14

4581287

WASHER SPRING M6 x 2.5 x 1.6 BLK ZN

10

6151234

BOLT M8 x 1.25 x 25 Gd 8.8 BP

14

6151213

BOLT M6 x 1.0 x 20 Gd8.8 BZ

10

6151300

NUT CAGED M6 2.6-3.5

10

6151301

NUT CAGED M8 3.3-4.7

7

6522838

PANEL SPLASH RANGER T6

1

3758956

BRACKET OE STONE SHEILD RANGER T6

1

6151357

BOLT SEMS M10 X 30 ZP Gd 8.8

2

6151321

NUT FLANGE M10 x 1.5 ZP

2

4581307

WASHER FLAT, M8 x 20 x 2 BLK ZN

14

LIGHTS AND

MOULDINGS

6821287

LAMP LED INDICATOR CLEARANCE

1

3163082

KIT SURROUND ARB FOGLIGHT

1

6821116

GROMMET NYLON SNAP IN TYPE

4

3500880

GRILLE SPLIT PAN KIT

1

5100200

BUFF KIT 2PCE FRONT SECTION

1

5100210

BUFF KIT 2PCE REAR UPRIGHT BAR

1

DIGITAL RADIO

ANTENNA

RELOCATION

6151464

SCREW BUTTON HEAD M8 x 1.25 x 25 BLK ZN

2

4581047

SPRING WASHER M8 BLK ZN

2

4581307

WASHER FLAT M8 BLK ZN

2

6151548

NUT FLANGE M8 x 1.25

2

PARKING

SENSORS

3500960

SENSOR SURROUND KIT

1

3163222

BLANKING PLUGS

2

WING BRACE

4681588R

BRACE WING RH

1

4681588L

BRACE WING LH

1

6151045

BOLT M10 x 1.5 x 25

8

4581083

WASHER FLAT, M10 x 21 x 2 ZP

8

4581048

WASHER SPRING M10 TZP480

8

6151321

NUT FLANGE M10 x 1.5 ZP

8

Last Rev Date 17/05/2019

Page 5 of 36

Fitting instructions# 3789528

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE

Note: Read the instructions thoroughly before

starting.

1. Open the bonnet and remove the screws and

retaining clips used to retain the plastic cover

above the grille.

Carefully detach plastic cover.

Note: Everest requires the 2 bolt securing air

duct to be removed.

FOR RANGER:

2. Remove the screws and retaining clips used

to retain grille.

Carefully detach grille piece from vehicle.

FOR EVEREST:

3. Remove 2 screws retaining grille.

Retain screws and clips.

Note: Take note where fasteners are removed

from as some have to be replaced later in the

fitment.

4. Remove all the bumper fasteners along the

inside edge of the wheel arches.

FOR RANGER:

5. Remove all the fasteners securing the bottom

of the bumper to the vehicle.

EVEREST

Last Rev Date 17/05/2019

Page 6 of 36

Fitting instructions# 3789528

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE

FOR RANGER:

6. Undo and remove the screws and plastic clips

behind the grille near the lower inner edge of

the head lights.

FOR RANGER:

7. Remove the screws and clips holding the

inner grille air deflectors to the vehicle.

8. Retain air deflectors, screws and clips.

FOR RANGER:

9. Carefully remove all clips used to retain

bumper to crash beam.

FOR EVEREST:

10. On both sides undo and remove the screws

behind the grille near the lower inner edge of

the head lights.

FOR EVEREST:

11. Remove all the fasteners securing RH SIDE

outer trim panel to the vehicle and detach.

Discard the panel.

12. Repeat on LH Side

Last Rev Date 17/05/2019

Page 7 of 36

Fitting instructions# 3789528

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE

FOR EVEREST:

13. Remove all the fasteners securing centre trim

panel to the vehicle and detach. Discard the

panel.

14. Disconnect all sensors and fog lights attached

to the bumper and allow them to hang loose.

NOTE: Parking sensor connector is on LH

side of bumper.

15. Starting on the RH side of the vehicle,

carefully pull the rear most corner away from

the vehicle un-clipping the bumper. With the

assistance of another person remove the

bumper from the vehicle and place in a safe

place where it will not be damaged.

FOR RANGER:

16. Remove the plastic panel attached to the front

cross beam by removing the plastic clips.

Discard the panel.

FOR EVEREST:

17. Remove the foam piece attached to the front

cross beam by removing the plastic clips.

Discard the foam piece.

Last Rev Date 17/05/2019

Page 8 of 36

Fitting instructions# 3789528

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE

18. If vehicle is fitted with radar, refer to fitting

instructions supplied with adaptive cruise

control kit (Part No. 3540200 - purchased

separately) for removal and relocation.

If not, proceed to step 19.

NOTE: Radars are initialised to each vehicle

and cannot be used on other vehicles.

19. Use a screw driver to push the 2 x plastic clips

inward from the front cross beam. Do not

remove the clips as they will be used later.

20. Remove the factory under panel and place in

a safe place. Do not completely remove the

rear bolts. Leave loose.

21. Remove the front cross beam and discard.

Last Rev Date 17/05/2019

Page 9 of 36

Fitting instructions# 3789528

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE

22. Remove screws retaining RH & LH

bumper retention blocks to vehicle and

remove the retention blocks from both

sides and set aside.

23. Remove and discard the inner guard

support brackets from both sides of the

vehicle.

24. Following fitting instructions 3789197 supplied in kit 6821287; install the LED combination

lamp looms (also supplied in same kit).

Notes:

-Use a test light or multimeter to pick the appropriate wire to attach the loom to.

-Cover each joint with either insulation tape or heat shrink tube.

- Use cable ties to secure all wiring

Function

LED

Wire

Vehicle Wire

RANGER

EVEREST

Ground

Black

BLK/Purple (RHS)

BLK/Yellow (LHS)

Indicator

Green

Blue/Orange (RHS)

Green/Blue (LHS)

Clearance

Red

Brown/Yellow (RHS)

Green/Yellow (LHS)

Pink/Yellow (RHS)

Green/Orange (LHS)

NOTE: The wiring in vehicles fitted with factory 35W fog lights (2015 ON Wildtrak Model or

Everest) is not suitable for running ARB fog lamps. Proceed to step 28.

For vehicles without factory fog lamps and where optional ARB fog lamps are to be fitted:

25. Install optional ARB wiring loom 3500530 and switch into vehicle. Refer to instructions supplied

with loom. Place switch inside cabin in a suitable position.

26. Connect optional ARB fog lights (# 3500590) to wiring loom.

27. Proceed to step 34.

CAUTION: Ensure that all cables are securely fastened away from sharp, abrasive or hot

surfaces.

INDICATOR

*LHS shown

EVEREST

RANGER

CLEARANCE

Last Rev Date 17/05/2019

Page 10 of 36

Fitting instructions# 3789528

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE

For vehicles with factory fog lamps:

28. The factory fog light switch can be used in

conjunction with the ARB loom 3500530 to

power the ARB fog lights.

29. Discard loom switch and thin yellow wire from

3500530.(Harness from bullet terminals to

switch)

30. Install ARB wiring loom 3500530 to vehicle.

Do not install switch or yellow wire with

fuse.

CAUTION: Ensure that all cables are securely

fastened away from sharp, abrasive or hot

surfaces.

31. Identify the black/white trigger wire from

3500530 as shown.

32. Connect the black/white trigger wire to the

positive terminal on the factory fog light wire

using the supplied scotch lock or a female

bullet connector.

33. Tape the bullet terminal from the black wire

from 3500530 to prevent short-circuits.

Securely fasten it away from sharp, abrasive or

hot surfaces.

Notes:

-Use a test light or multimeter to pick the

appropriate wire to attach the loom to.

-Check the operation of all lights wired during

bar fitment

34. Carefully mask the area surrounding each

side of the guard as shown (RH shown).

35. Thoroughly clean the area.

36. Using Matte Black spray paint, paint the

masked area.

37. Allow to dry.

REPEAT FOR LHS

38. If parking sensors are fitted, carefully unclip

sensors and sensor loom from bumper bar and

set aside for fitment to bull bar.

Cover black wire bullet

terminal with tape

Discard these items

Keep these items

Black/white trigger wire

Last Rev Date 17/05/2019

Page 11 of 36

Fitting instructions# 3789528

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE

BUMPER CUT FOR RANGER: STEP 39-61

If fitting to Everest skip to step 62

39. Place the bumper on a stand facing upwards.

40. Using masking tape, cover front corner section

of bumper.

41. Using ridge on bumper as a guide, mark a line

following the ridge across the front section of

bumper as shown.

42. Continue the line onto the bumper as shown

using the edge of bumper as a guide.

43. Mark a line perpendicular to bumper 30mm

inwards from locating hole on top surface as

shown until it meets line on bumper edge.

44. Using scissors carefully cut out the supplied

template.

30mm

RIDGE

30mm

TOP

TOP VIEW

LOOKING DOWN

Last Rev Date 17/05/2019

Page 12 of 36

Fitting instructions# 3789528

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE

45. Position template onto bumper as shown and

using a marker pen, mark contour onto bumper

until it meets other line on bumper.

46. Carefully remove the template and repeat

steps 39-45 for LHS.

47. Using a jig saw or similar, carefully cut along

marked lines.

48. De-bur the cut edges with a file or sandpaper.

Note: It is advised that you take steps to prevent

damage to the bumper when cutting such as

placing extra masking tape on the kept portion

of the bumper.

49. Position cut bumper onto bumper retention

block set aside and mark a line onto block as

shown using a white marker pen. (RH side

shown)

50. Remove cut bumper and carefully cut along

inside edge of marked line using a multitool.

51. Repeat for LHS.

52. Use a file or sandpaper to de-bur all cut

edges.

53. Set aside for re-fitment later on.

Warning: Cutting operations

can result in flying debris,

safety glasses should be

worn.

MARK LINE HERE

Warning: Cutting operations

can result in flying debris,

safety glasses should be

worn.

Last Rev Date 17/05/2019

Page 13 of 36

Fitting instructions# 3789528

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE

54. Place masking tape across front section of

grille where ridge is as shown.

55. Mark line onto grille 40mm below ridge in grille

as shown.

56. Using a multitool, carefully cut along marked

line.

57. De-bur the cut edges with a file or sandpaper.

58. For chrome grille, position pinch weld supplied

in kit along cut edge (centre the pinch weld

across width of grille).

59. Fit the two self tapping screws into the lower

section of the grille to join the two parts

together as shown

IF FITTING WINCH:

For Warn, Magnum and Bushranger control boxes,

additional cut out for grille is required.

60. Using a multitool cut a 240 X 40 mm section

out of lower section of grille.

61. Apply Pinch weld to cut edges.

40mm

Cut out central to grille

40mm

240mm

Warning: Cutting operations can result in flying

debris, safety glasses should be worn.

Warning: Cutting operations

can result in flying debris,

safety glasses should be worn.

Last Rev Date 17/05/2019

Page 14 of 36

Fitting instructions# 3789528

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE

BUMPER CUT FOR EVEREST: STEPS 62-78

62. Place the bumper on a stand facing upwards.

63. Place 50mm masking take below the ridge of

the bumper.

64. On the masking tape, mark a line across the

bumper 5mm below the ridge line.

65. Below the grille place 50mm masking take

above the ridge of the bumper.

66. On the masking tape, mark a line 20mm

above from the ridge line.

67. On both sides of the bumper mark a vertical

line 100mm inboard of the edge of the grille.

68. Using scissors carefully cut out the supplied

template.

69. Position template onto bumper as shown and

using a marker pen, mark contour onto bumper

until it meets other line on bumper.

70. Carefully remove the template and repeat for

LHS.

RIDGE

5mm

RIDGE

20mm

100mm

Last Rev Date 17/05/2019

Page 15 of 36

Fitting instructions# 3789528

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE

71. Using a jig saw or similar, carefully cut along

marked lines.

72. De-bur the cut edges with a file or sandpaper.

Note: It is advised that you take steps to prevent

damage to the bumper when cutting such as

placing extra masking tape on the kept portion

of the bumper.

73. Position cut bumper onto bumper retention

block set aside and mark a line onto block as

shown using a white marker pen. (RH side

shown)

74. Remove cut bumper and carefully cut along

inside edge of marked line using a multitool.

75. Repeat for LHS.

76. Use a file or sandpaper to de-bur all cut

edges.

77. Set aside for re-fitment later on.

IF FITTING WINCH:

If fitting winch additional cut out for bumper is

required.

78. Using a multitool, cut a section 240mm wide

and 5mm rearward of grille out of bumper.

NOTE:

-To aid in cutting of bumper removal of grille is

recommended.

-Keep bumper as one piece.

-Cut out is central to bumper.

Warning: Cutting operations

can result in flying metal

debris, safety glasses should

be worn.

MARK LINE HERE

Warning: Cutting operations

can result in flying debris,

safety glasses should be worn.

240mm

Cut out is central to grille

GRILLE

5mm

BUMPER

Warning: Cutting operations

can result in flying debris,

safety glasses should be

worn.

Last Rev Date 17/05/2019

Page 16 of 36

Fitting instructions# 3789528

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE

79. Remove clips from digital aerial antenna and

disconnect at connector.

80. Using a multitool carefully cut around metallic

plate corresponding to digital aerial antenna.

81. Retain antenna for remittent later on.

82. Unbolt digital radio module and unclip wire

harness.

83. Reattach digital radio module to outer most

bolting position and re-attach wire harness.

FOR RANGER:

84. Mark a line onto RH air deflector removed in

step 7 as shown 30mm below mounting tab.

85. Carefully cut along marked line and dispose of

lower section of air deflector.

86. De-bur the cut edges with a file or sandpaper.

87. Repeat for LH air deflector.

Warning: Cutting operations can result in flying

debris, safety glasses should be worn.

Mark line onto air deflector

Mounting tab

Warning: Cutting operations can result in flying

debris, safety glasses should be worn.

Last Rev Date 17/05/2019

Page 17 of 36

Fitting instructions# 3789528

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE

FOR RANGER:

88. The horn & harness will require to be rotated

for clearance to brackets. Unplug the harness

and remove the horn by removing the

mounting bolt.

89. Turn the horn over and loosen the retaining

nut. Rotate the arm 180°, and tighten the

retaining nut.

90. Re fit the horn in its original position and re-

route the harness to the top. Use cable ties if

necessary to reposition the harness.

FOR EVEREST:

91. On LH side remove 2 X screws holding duct to

vehicle.

Carefully detach duct piece from vehicle.

FOR EVEREST:

92. On the LH side carefully detach sensor.

93. Mark lines on air deflectors as shown.

94. Carefully cut along marked line and dispose of

lower section of air deflector.

95. De-bur the cut edges with a file or sandpaper.

Warning: Cutting operations can result in flying

debris, safety glasses should be worn.

Mark line onto air deflector

RH SIDE

LH SIDE

SENSOR

Mark line onto air deflector

Last Rev Date 17/05/2019

Page 18 of 36

Fitting instructions# 3789528

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE

FOR EVEREST

96. On RH side of lower air deflector mark a

vertical and horizontal line 15mm from the

centre of the clipping point.

97. Using the marked lines as a guide cut out a

50mm deep section form the deflector.

98. De-bur the cut edges with a file or sandpaper.

99. Fit the inner brace with the packer to the

chassis rail end. Ensure that the front edge is

pushed forward to the chassis flange. The

brace may need to be tapped to ensure a flush

fitment to the chassis is achieved.

Note: Ensure that packer is placed

correctly, with tabs pushed against brace.

100. Fit the M16 x 35 flange bolt through the front

access cut out of the front flange of the

chassis.

Clipping

point

Warning: Cutting operations can result in flying

debris, safety glasses should be worn.

Last Rev Date 17/05/2019

Page 19 of 36

Fitting instructions# 3789528

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE

101. Loosely position the outer bracket brace with

the packer to the chassis rail. Fit the M16

flange nut to hold it in place. Ensure that the

front edge is pushed forward to the chassis

flange.

NOTE: Ensure that packer is placed and

aligned correctly.

102. Fit 4 x M12 x 35 bolts, 4 x M12 flat washers, 4

x M12 Flange nuts.

M12 - 77 Nm.

NOTE: Do not fit the M12 spring washers these

will be fitted later on.

103. Using a spanner to hold the M16 flange bolt,

torque the M16 flange nut.

M16 - 90 Nm.

NOTE: Take care to torque as per requirement.

DO NOT torque outside the specs provided.

104. Using a large G-clamp, clamp the top rear

corner of the outer and inner brace together.

This will make the alignment of the top flange

easier for fitment of the brace.

105. Fit the M10 x 1.5 x 45 bolt, M10 spring washer

and M10 flat washer.

Last Rev Date 17/05/2019

Page 20 of 36

Fitting instructions# 3789528

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE

106. Fit the 2 x M10 x 30 SEMS bolts and M10

flange nuts to the bottom of the brackets to

clamp them together.

107. Fit the M10 x 30 SEMS bolt and M10 flange

nut to the brace and outer bracket.

108. Fit the 15mm wide spacer between the brace

and the outer bracket and then fit the M10

flange nut

109. Remove the 4 x M12 x 35 bolts, 4 x M12 flat

washers and 4 x M12 flange nuts fitted in step

102 and set aside for later.

Note: Keep all M10 fasteners loose and only

finger tight at this point.

Repeat steps 96-109 for the LH side.

110. Attach the mount bracket to the chassis end

plates using 4 x M10 x 30 SEMS bolts into the

captive nuts. Leave loose at this stage.

111. Attach the mount bracket to the chassis using

3 x M12 x35 bolts, 3 x M12 spring washers, 3 x

M12 flat washers and 3 x M12 Flange nuts.

112. Repeat on the LH side.

M12 - 77 Nm.

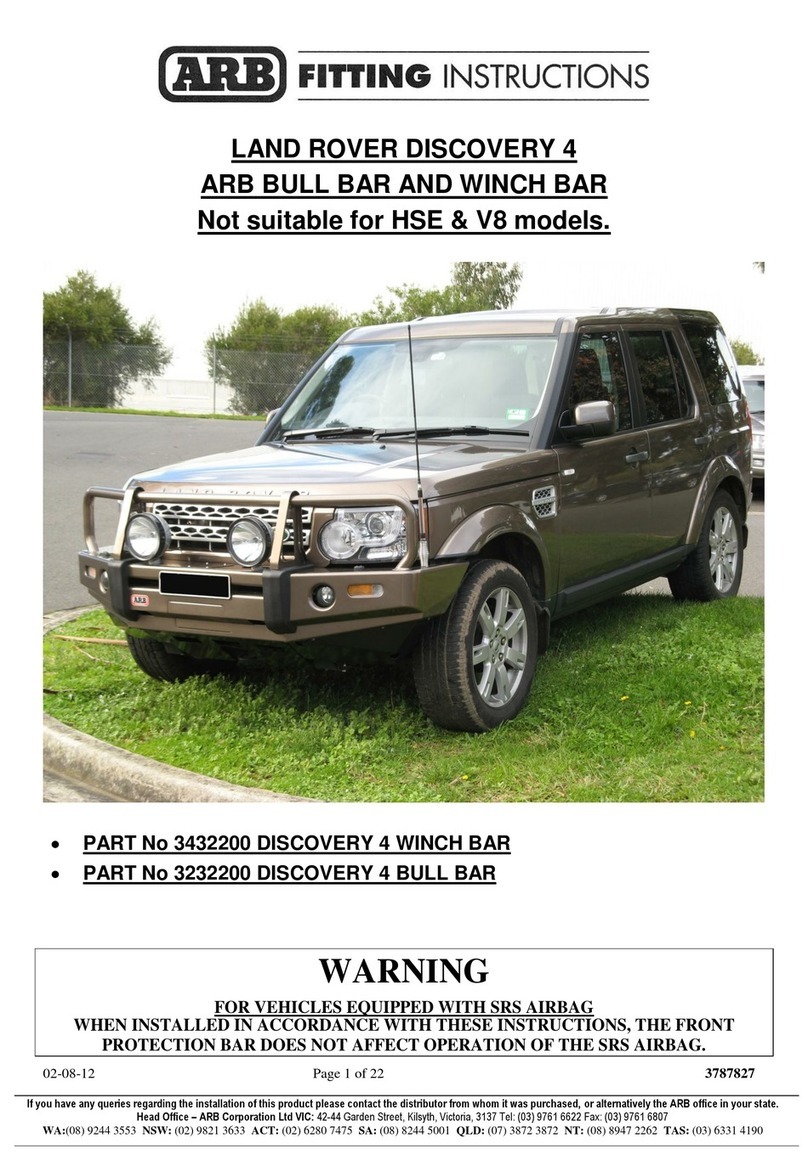

Table of contents

Other ARB Automobile Accessories manuals

ARB

ARB AIRLOCKER RD168 User manual

ARB

ARB DELUXE BULL BAR User manual

ARB

ARB 10900013 User manual

ARB

ARB Air Locker RD111 User manual

ARB

ARB ESPERANCE 802200 User manual

ARB

ARB Airlocker RD140 User manual

ARB

ARB Flinders User manual

ARB

ARB AIRLOCKER RD208 User manual

ARB

ARB 3432200 User manual

ARB

ARB AC08C User manual

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction