4

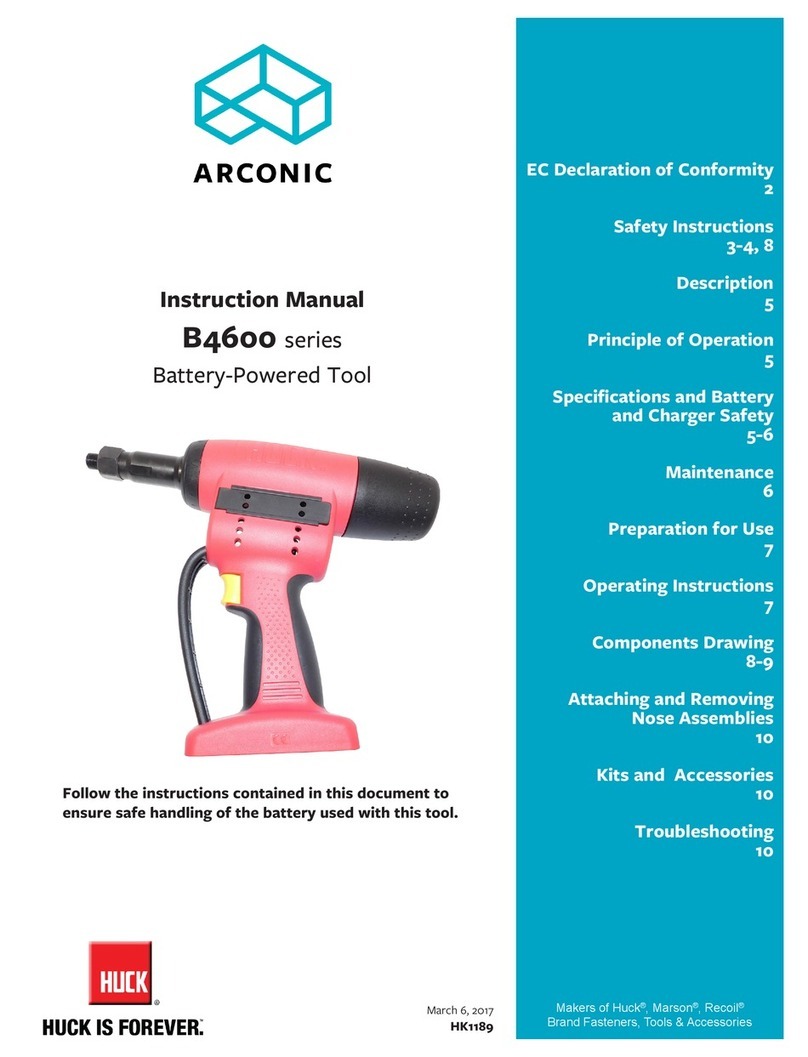

B1100 Battery-Powered Tools (HK1211)

IV. REPETITIVE MOTION HAZARDS:

1. When using the assembly power tool, the operator

can experience discomfort in the hands, arms,

shoulders, neck or other parts of the body.

2. When using tool, the operator should adopt a

comfortable posture while maintaining a secure

footing and avoid awkward or off balanced postures.

3. The operator should change posture during

extended tasks to help avoid discomfort and fatigue.

4. If the operator experiences symptoms such as

persistent or recurring discomfort, pain, throbbing,

aching, tingling, numbness, burning sensations or

stiffness, these warnings should not be ignored. The

operator should tell the employer and consult a

qualied health professional.

V. ACCESSORIES HAZARDS:

1. Disconnect tool from energy supply before changing

inserted tool or accessory.

2. Use only sizes and types of accessories and

consumables that are recommended. Do not use

other types or sizes of accessories or consumables.

VI. WORKPLACE HAZARDS:

1. Be aware of slippery surfaces caused by use of the

tool and of trip hazards caused by the air line or

hydraulic hose.

2. Proceed with caution while in unfamiliar

surroundings; there could be hidden hazards such as

electricity or other utility lines.

3. The assembly power tool is not intended for use in

potentially explosive environments.

4. Tool is not insulated against contact with electrical

power.

5. Ensure there are no electrical cables, gas pipes, etc.,

which can cause a hazard if damaged by use of the

tool.

VII. DUST AND FUME HAZARDS:

1. Dust and fumes generated when using cutting-off

and crimping power tools can cause ill health; risk

assessment and implementation of appropriate

controls for these hazards are essential.

2. Risk assessment should include dust created by

the use of the tool and the potential for disturbing

existing dust.

3. Operate and maintain the cutting-off or crimping

power tool as recommended in the instruction

handbook, in order to minimize dust or fume

emissions.

4. Direct the exhaust so as to minimize disturbance of

dust in a dust-lled environment.

5. Where dust or fumes are created, the priority shall be

to control them at the point of emission.

6. All integral features or accessories for the collection,

extraction or suppression of airborne dust or fumes

should be correctly used and maintained.

7. Use respiratory protection in accordance with

employer’s instructions and as required by

occupational health and safety regulations.

VIII. NOISE HAZARDS:

1. Exposure to high noise levels can cause permanent,

disabling hearing loss and other problems such

as tinnitus, therefore risk assessment and the

implementation of proper controls is essential.

2. Appropriate controls to reduce the risk may include

actions such as damping materials to prevent

workpiece from ‘ringing’.

3. Use hearing protection in accordance with

employer’s instructions and as required by

occupational health and safety regulations.

4. Operate and maintain tool as recommended in the

instruction handbook to prevent an unnecessary

increase in the noise level.

5. Select, maintain and replace the consumable /

inserted tool as recommended to prevent an

unnecessary increase in noise.

6. If the power tool has a silencer, always ensure that it

is in place and in good working order when the tool

is being operated.

IX. VIBRATION HAZARDS:

1. Exposure to vibration can cause disabling damage to

the nerves and blood supply to the hands and arms.

2. Wear warm clothing when working in cold conditions

and keep hands warm and dry.

3. If numbness, tingling, pain or whitening of the skin

in the ngers or hands, stop using the tool, tell your

employer and consult a physician.

X. ELECTRIC SHOCKS, INJURIES OR FIRE HAZARDS

1. Do not overload the tool; work within the prescribed

work capacity.

2. Never use the tool in humid or wet environment or

close to inammable substances or gases. Risk of

explosion!

3. Ensure that the battery is properly secured in the grip.

4. Remove the battery when the tool is not in use and

when it is undergoing repair or service.

5. Do not use the tool as a hammer.

6. When not in use, keep tool in a dry, closed room and

out of the reach of children.

7. When working with the tool, always wear protective

goggles. Personal protection like clothes, gloves,

safety helmet, non-slip shoes, ear protection and anti-

fall protection are highly recommended.

8. The air inlets for the motor should not be obstructed.

Do not place anything in them.

9. When setting tool down, make sure that it cannot fall.

10. Use only genuine spare parts for repair.

11. Repair work must be carried out by skilled workers, or

send the tool back to the manufacturer.

12. Do not use the tool outside of riveting holes! The

fastener could be ejected from the tool! Never turn

the tool towards yourself or towards another person!

13. The mandrel container must be mounted on the tool

during operation.

Safety Instructions continued