2

GILMORE-Item code:BH62. INSTRUCTION MANUAL

This instruction manual is designed to help you build a great flying aeroplane. Please read this

manualthoroughlybeforestartingassemblyofyour GILMORE.Usethepartslistingbelowtoidentify

all parts.

WARNING

Please be aware that this aeroplane is not a toy and if assembled or used incorrectly it is

capable of causing injury to people or property. WHEN YOU FLY THIS AEROPLANE YOU

ASSUME ALL RISK & RESPONSIBILITY.

IfyouareinexperiencedwithbasicR/CflightwestronglyrecommendyoucontactyourR/Csupplier

and join your local R/C Model Flying Club. R/C Model Flying Clubs offer a variety of training

proceduresdesignedtohelpthenew pilotonhiswaytosuccessfulR/C flight.Theywillalso beable

to advise on any insurance and safety regulations that may apply.

TOOLS & SUPPLIES NEEDED

1Thick cyanoacrylate glue.

130 minute epoxy.

15 minute epoxy.

1Hand or electric drill.

1Assorted drill bits.

1Modellingknife.

1Straight edge ruler.

12mm ball driver.

1Phillips head screwdriver.

1220 grit sandpaper.

190° square or builder’s triangle.

1Wire cutters.

1Masking tape & T-pins.

1Thread-lock.

1Paper towels.

Some more parts.

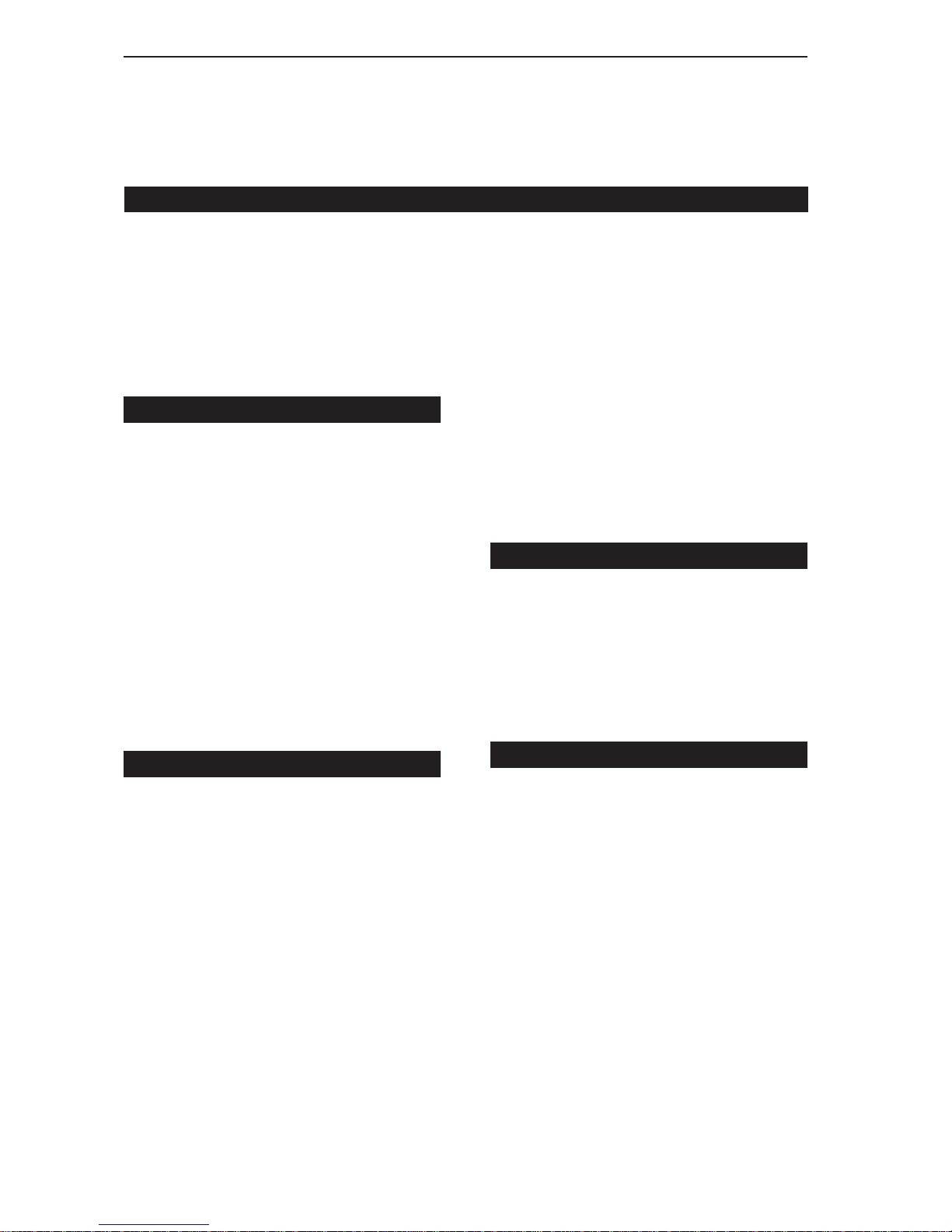

HARDWAREPACK

COWLING.

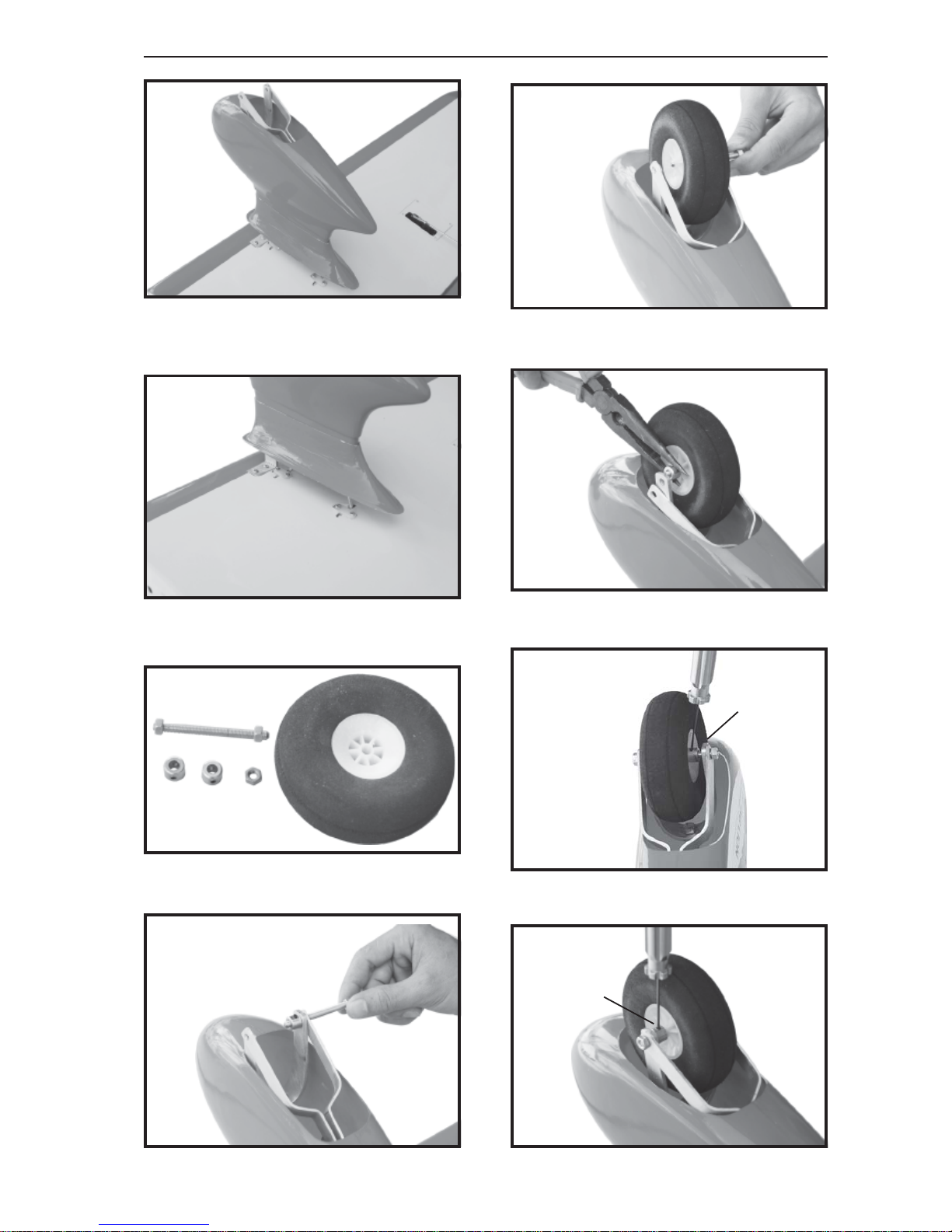

Landinggear.....

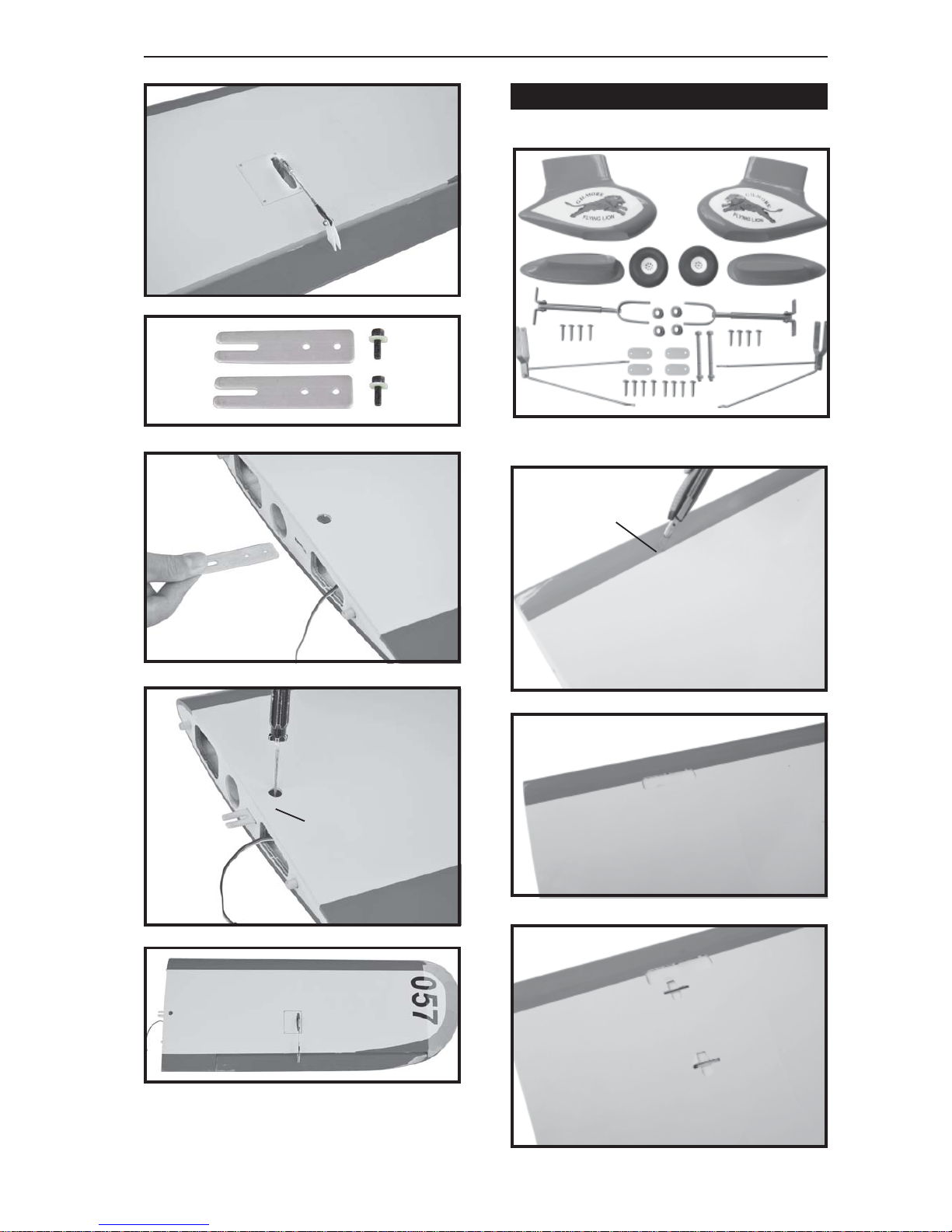

Toavoid scratching yournew airplane,do not

unwrap the pieces until they are needed for

assembly. Cover your workbench with an old

towel or brown paper, both to protect the air-

craftand toprotect thetable.Keepacoupleof

jars or bowls handy to hold the small parts af-

ter you open the bag.

Pleasetrialfitalltheparts. Makesureyouhave

the correct parts and that they fit and are

alignedproperly beforegluing!Thiswillassure

properassembly.GILMORE ARFishandmade

from natural materials, every plane is unique

andminor adjustmentsmayhave tobe made.

However, you should find the fit superior and

assembly simple.

The painted and plastic parts used in this kit

are fuel proof. However, they are not tolerant

of many harsh chemicals including the follow-

ing:paintthinner,C/Aglueaccelerator,C/Aglue

debonderandacetone. Donotletthesechemi-

cals come in contact with the colors on the

covering and the plastic parts.

PARTS LISTING

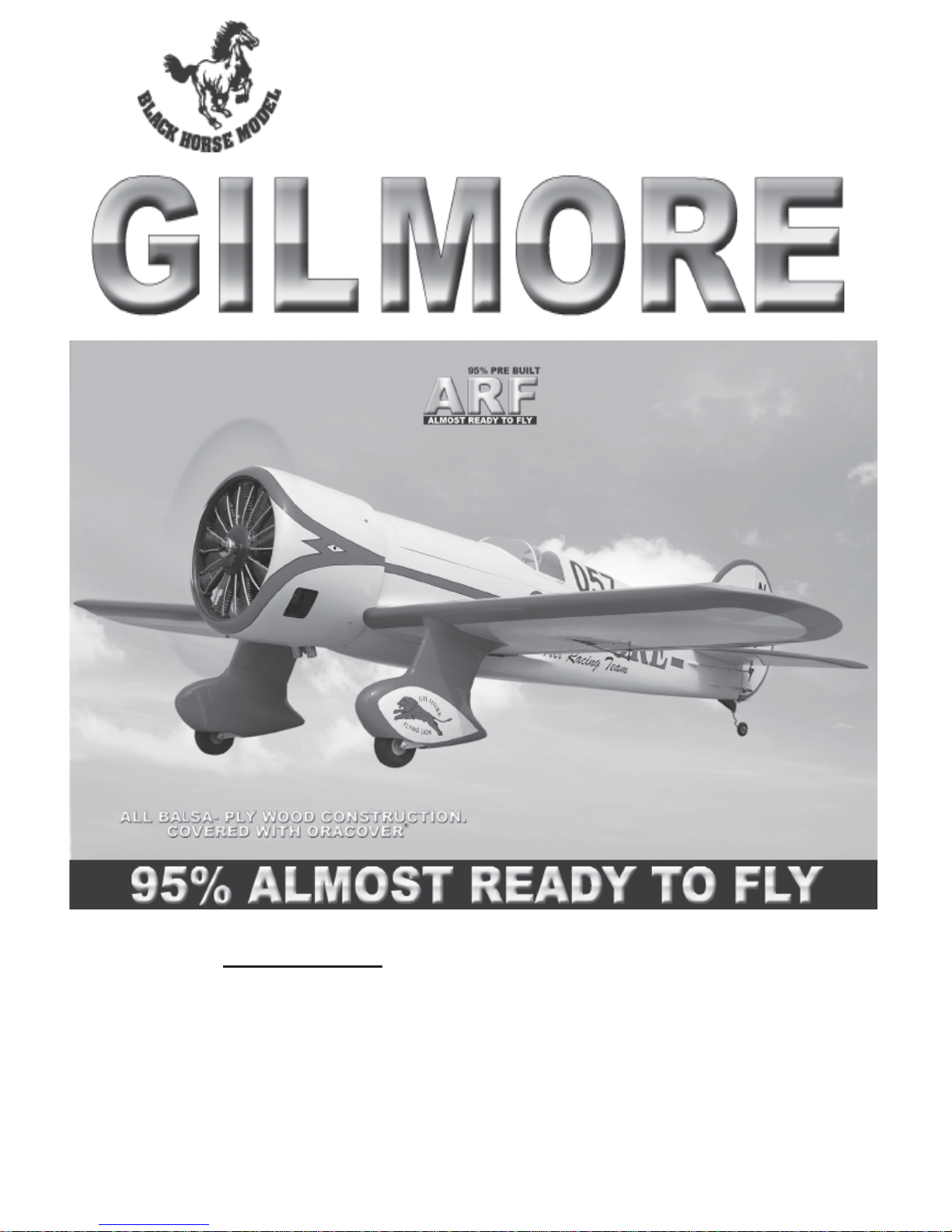

FUSELAGE ASSEMBLY

1(1) Fuselage.

WING ASSEMBLY

1(1) Right wing half with pre-installed

aileron.

1(1) Left wing half with pre-installed

aileron.

Tail section assembly

1(1) Vertical stabilizer with pre-

installedrudder.

1(1) Horizontal stabilizer with pre-

installedelevator halves.

SUGGESTION

NOTE.