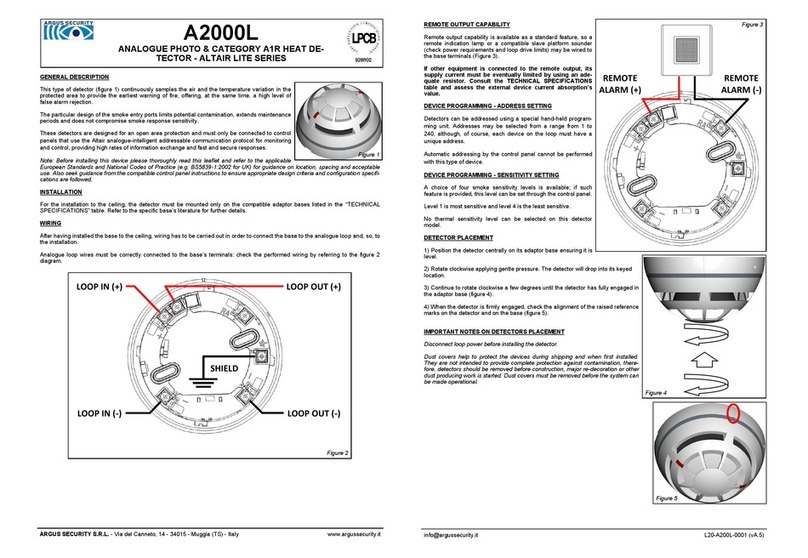

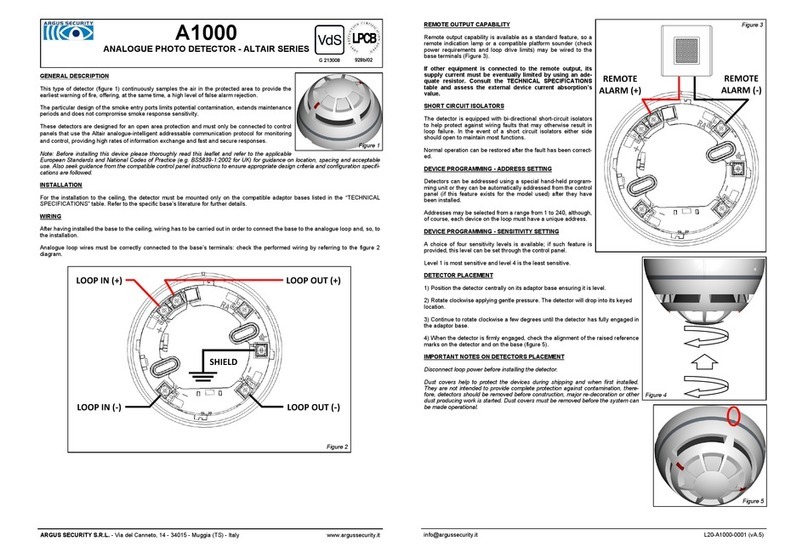

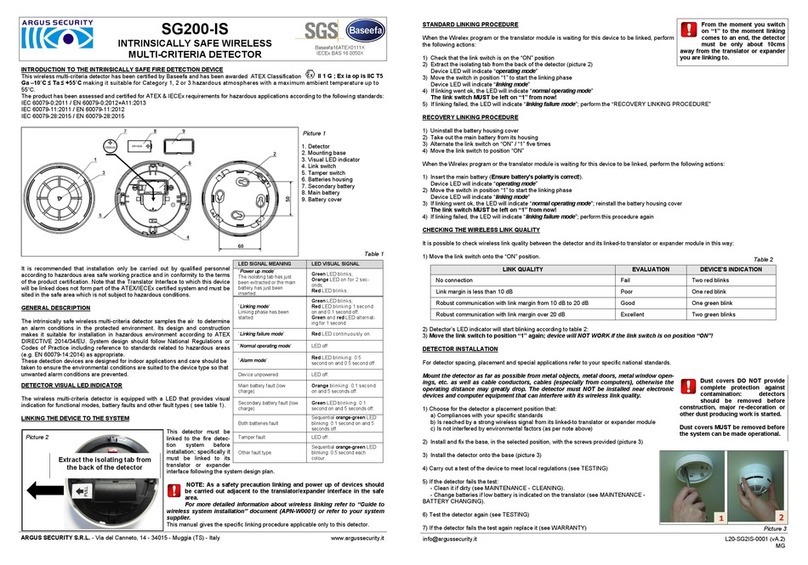

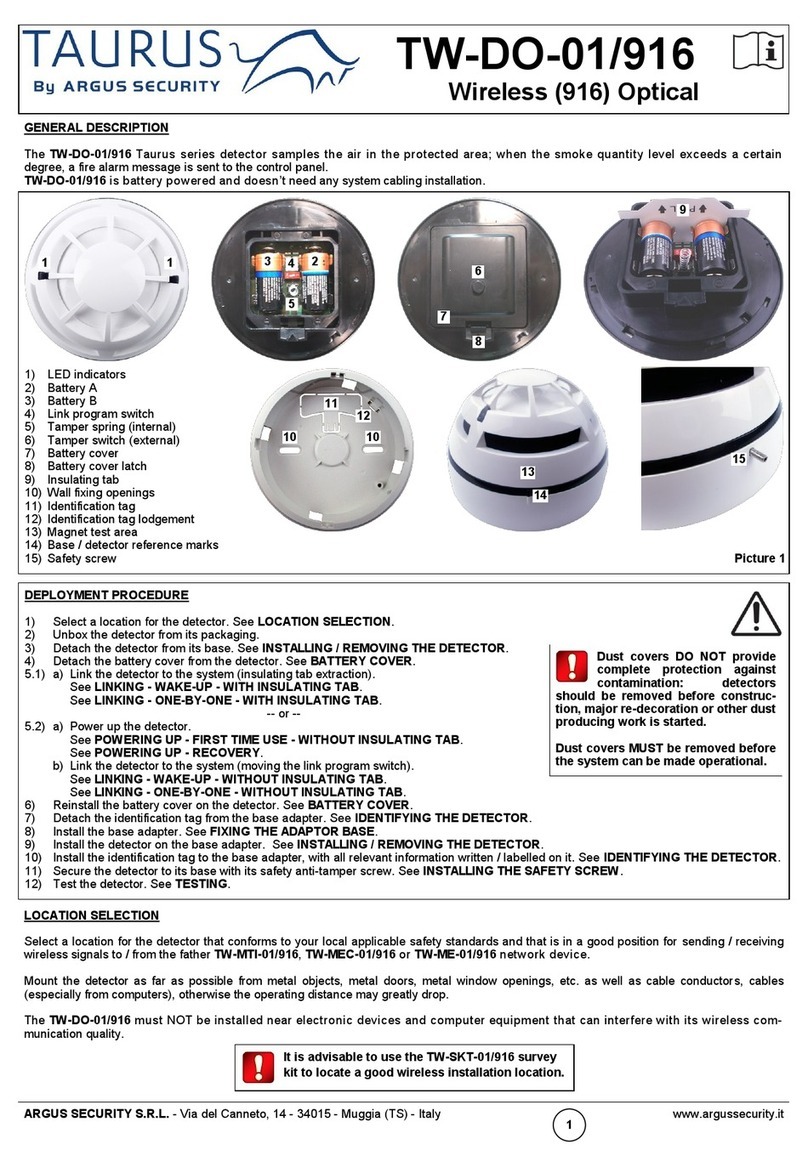

ANTI -TAMPER DETECTOR LOCK

The detector can be locked to its base as a deterrent to intentional removal performed by non authorized personnel.

Using a cutter, remove the anti-tamper plastic detail, as illustrated in figure 6.

To unlock the detector, insert the tip of a screwdriver into the side slot of the base by exerting only a light pressure (figure 7), and

release the detector by turning it anticlockwise.

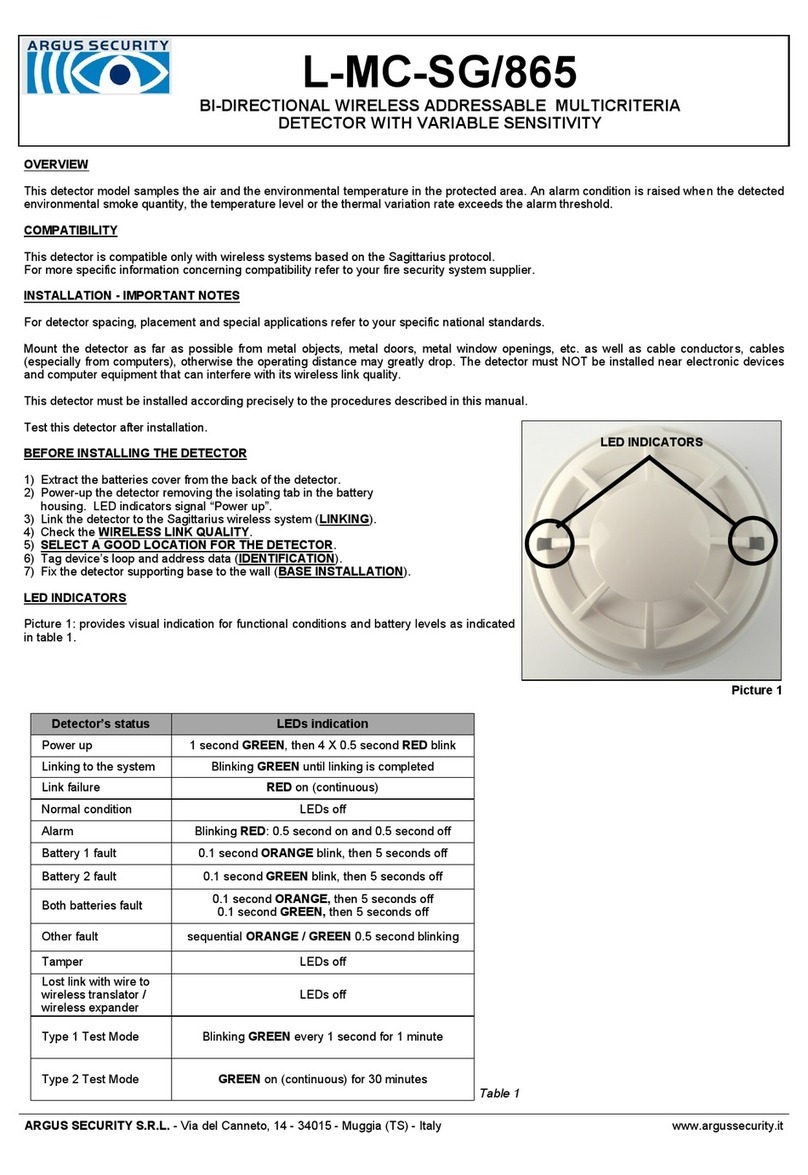

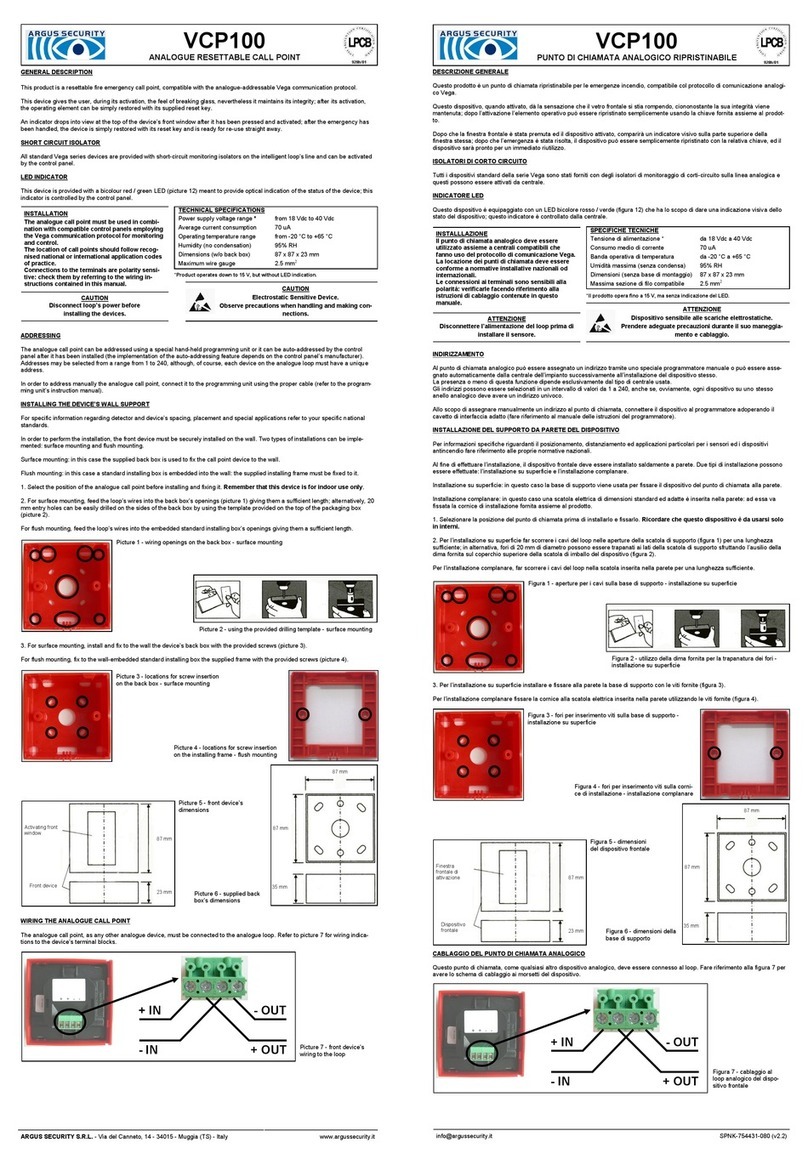

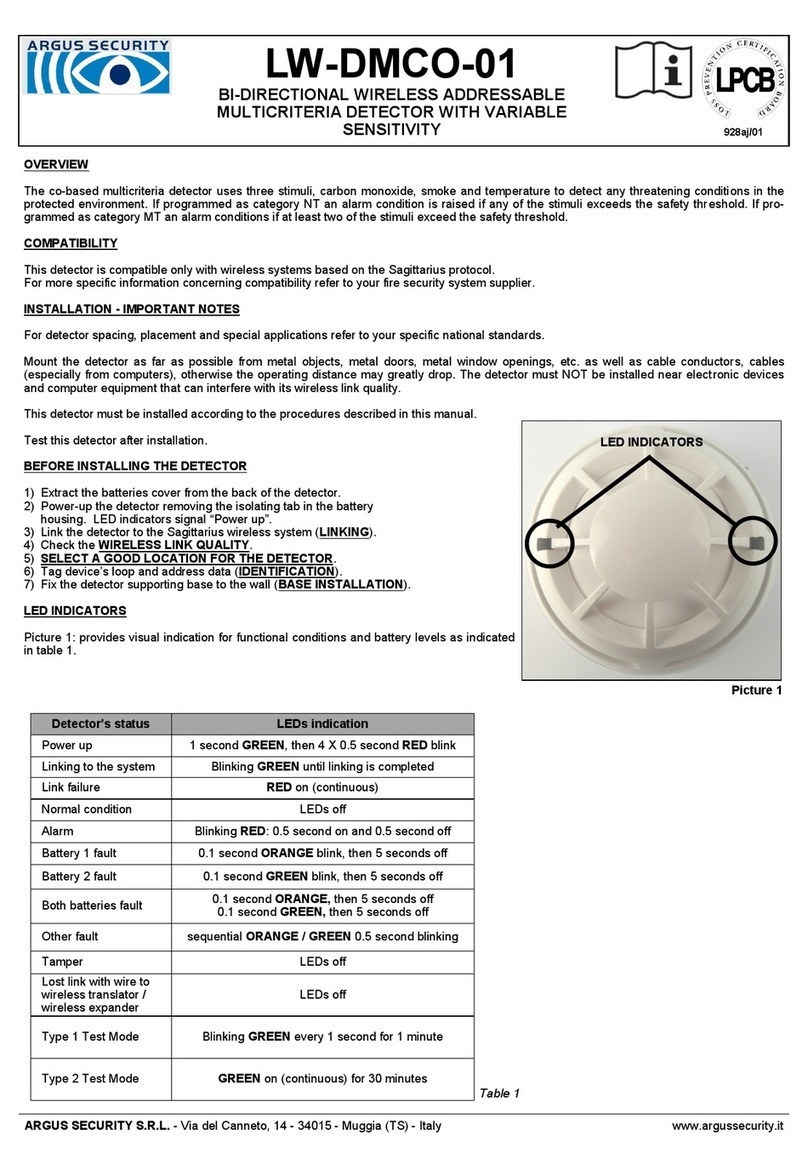

LED INDICATORS

This detector is equipped with dual LEDs that can illuminate Green, Red or Amber to indicate

status condition:

Green: blinking, indicates the normal operative status of the detector.

Red: indicates an alarmed condition of the detector.

Amber: if implemented in panel software, indicates a fault condition of the detector.

LED indicators are managed directly by the control panel and the green blinking can be disabled

by the installer either from the control panel itself or through the programming unit.

Positioning of these LEDs is illustrated in figure 8.

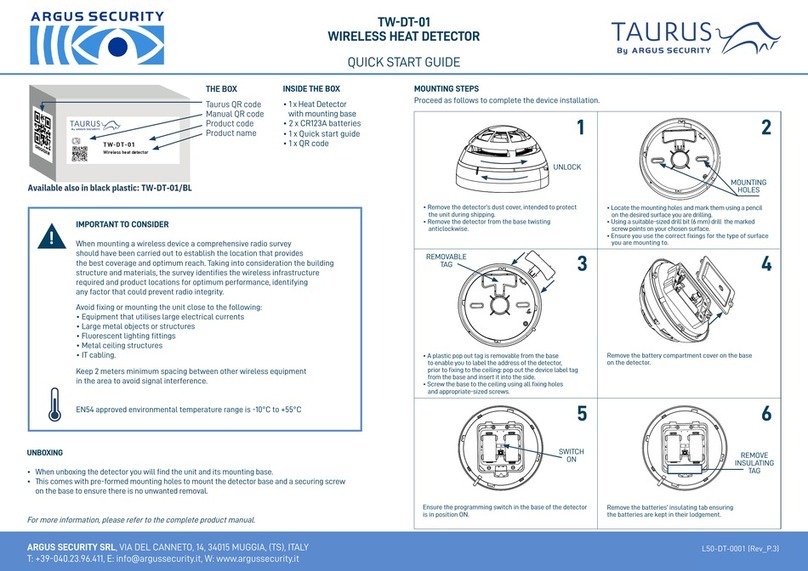

IDENTIFICATION TAB

The adaptor base is equipped with a plastic tab where identification data can be visibly displayed.

Detach the tab from the base; write or label it with the required information, then insert it into its adaptor base’s slot.

TESTING THE DETECTORS - PRELIMINARY NOTE

Detectors should be tested after installation and during periodic maintenance

visits; it is recommended each device should be tested at least once per year.

After each test reset the system and allow at least one minute for power stabilisa-

tion.

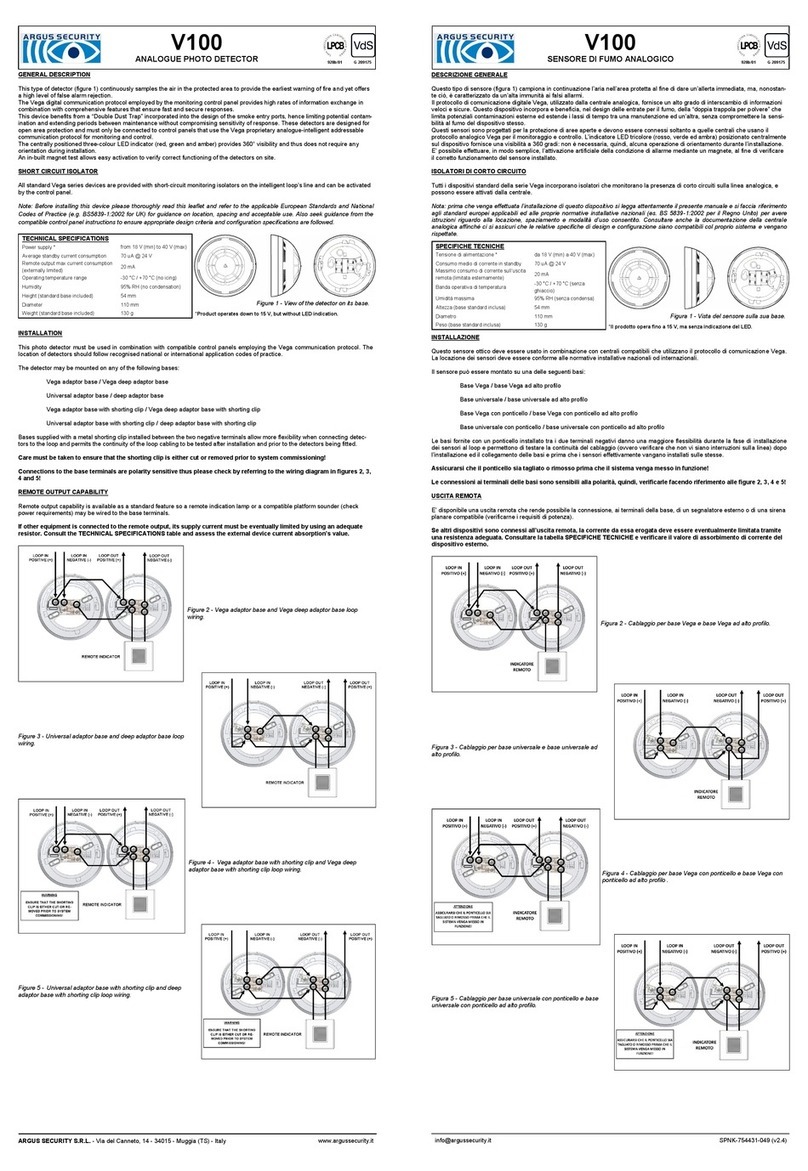

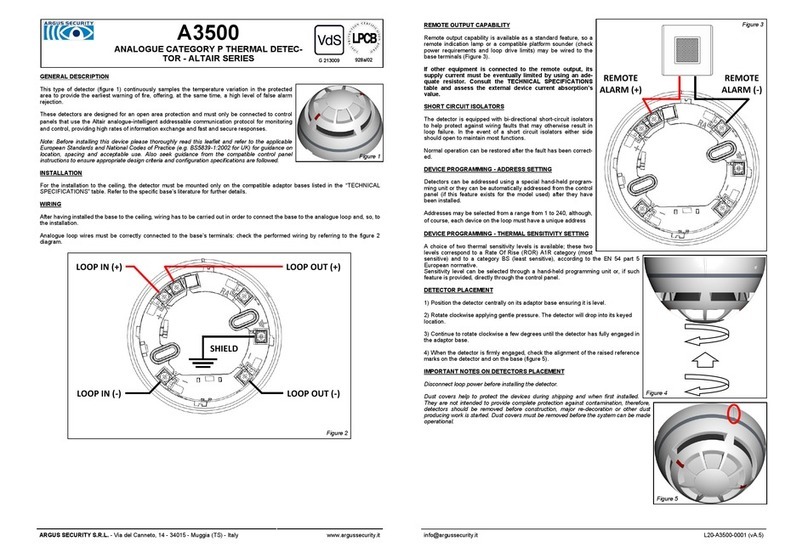

MAGNET TEST

Position the test magnet next to the detector, in correspondence of the raised

mark, then move it 45 degrees anticlockwise (figure 10).

The magnet test simulates smoke in the optical chamber or heat on the thermistor

and verifies the function of all electronic circuits of the detector and its communi-

cation with the control panel. The detector should trigger an alarm message to the

control panel, and, successively, the detector’s red LED should be activated by

the control panel itself.

AEROSOL TEST (SIMULATED SMOKE TEST)

For this test only use test aerosols from an approved manufacturer, in accordance with their application instructions, in order to

prevent contamination or possible damage to the detector. We suggest to spray the aerosol into the detector by using a recommend-

ed applicator. The detector should trigger an alarm message to the control panel, and, successively, the detector’s red LED should

be activated by the control panel itself.

If the detector does not respond to the tests correctly it may be necessary to clean it: in this case follow the instructions indicated in

the “MAINTENANCE” paragraph.

If testing fails again after maintenance then replace the detector with a new one and return the faulty one for servicing.

HEAT TEST

Use a hair dryer of 1000-1500 W or an heat tool from an approved manufacturer. Direct the heat towards the detector from its side.

Hold the heat source at about 15 cm away from the detector in order to prevent damage to its cover during testing.

The detector should trigger an alarm message to the control panel, and, successively, the detector’s red LED should be activated by

the control panel itself.

MAINTENANCE

Before starting any maintenance work, isolate and disable the system in order to avoid accidental and unwanted alarm or fault condi-

tions. Remove the detector from its mounting base to allow inspection in good light at ground level. Inspect the smoke entry ports

around the detector and the thermistor area and use a small, soft bristle brush to dislodge any evident contaminants such as insects,

spider webs, hairs, etc. Use a small vacuum tube or clean, dry and compressed air to suck up or blow away any remaining small

particles from the smoke entry screen area and the thermistor area. Wipe the exterior housing of the detector with a clean, damp, lint

free cloth to remove any surface film that can later attract airborne contaminants. Use the hand-held programming unit to read the

pollution percentage of the chamber; please, refer to the programming unit instruction manual. After all detectors have been inspect-

ed, repositioned on their mounting bases and power has been re-applied, check correct operation by testing the device.

TECHNICAL SPECIFICATIONS **

*Product operates down to 15 V, but without LED indication.

**Check latest version of document TDS-A2000 for further data, obtainable from your

supplier.

WARNINGS AND LIMITATIONS

Our devices use high quality electronic components and plastic materials that are highly

resistant to environmental deterioration. However, after 10 years of continuous operation, it

is advisable to replace the devices in order to minimize the risk of reduced performance

caused by external factors. Ensure that this device is only used with compatible control

panels. Detection systems must be checked, serviced and maintained on a regular basis to

confirm correct operation.

Smoke detectors may respond differently to various kinds of smoke particles, thus applica-

tion advice should be sought for special risks. Detectors cannot respond correctly if barriers

exist between them and the fire location and may be affected by special environmental

conditions. Refer to and follow national codes of practice and other internationally recog-

nized fire engineering standards. Appropriate risk assessment should be carried out initially

to determine correct design criteria and updated periodically.

WARRANTY

All devices are supplied with the benefit of a limited 5 years warranty relating to faulty

materials or manufacturing defects, effective from the production date indicated on each

product.

This warranty is invalidated by mechanical or electrical damage caused in the field by

incorrect handling or usage. Product must be returned via your authorized supplier for

repair or replacement together with full information on any problem identified.

Full details on our warranty and product’s returns policy can be obtained upon request.

Figure 6

Figure 7

Figure 8

Power supply *from 18 V (min) to 40 V (max)

Average standby current consumption 55 uA @ 24 V

Remote output max current consumption (externally limited) 20 mA

Compatible adaptor bases LAB1000 - “Low Profile Adaptor Base”

Thermal alarm threshold (ROR A1R category) 58 °C

Operating temperature range -30 °C / +70 °C (no icing)

Humidity 95% RH (no condensation)

IP rating 40 (42 with base’s waterproof protection)

ARGUS SECURITY S.R.L.

Via del Canneto, 14

34015 Muggia (TS)

Italy

.

EN 54-5:2017+A1:2018

EN 54-7:2018

EN 54-17:2005

CEA 4021:2003

A2000

For use in compatible fire detection and alarm

system

Category A1R

Figure 10

ARGUS SECURITY S.R.L.

- Via del Canneto, 14 - 34015 - Muggia (TS) - Italy www.argussecurity.it [email protected] L20-A2000-0001 (vA.5)

Figure 6

Figure 9

2831 0832

12 21

AT5910CPR AT5910UK