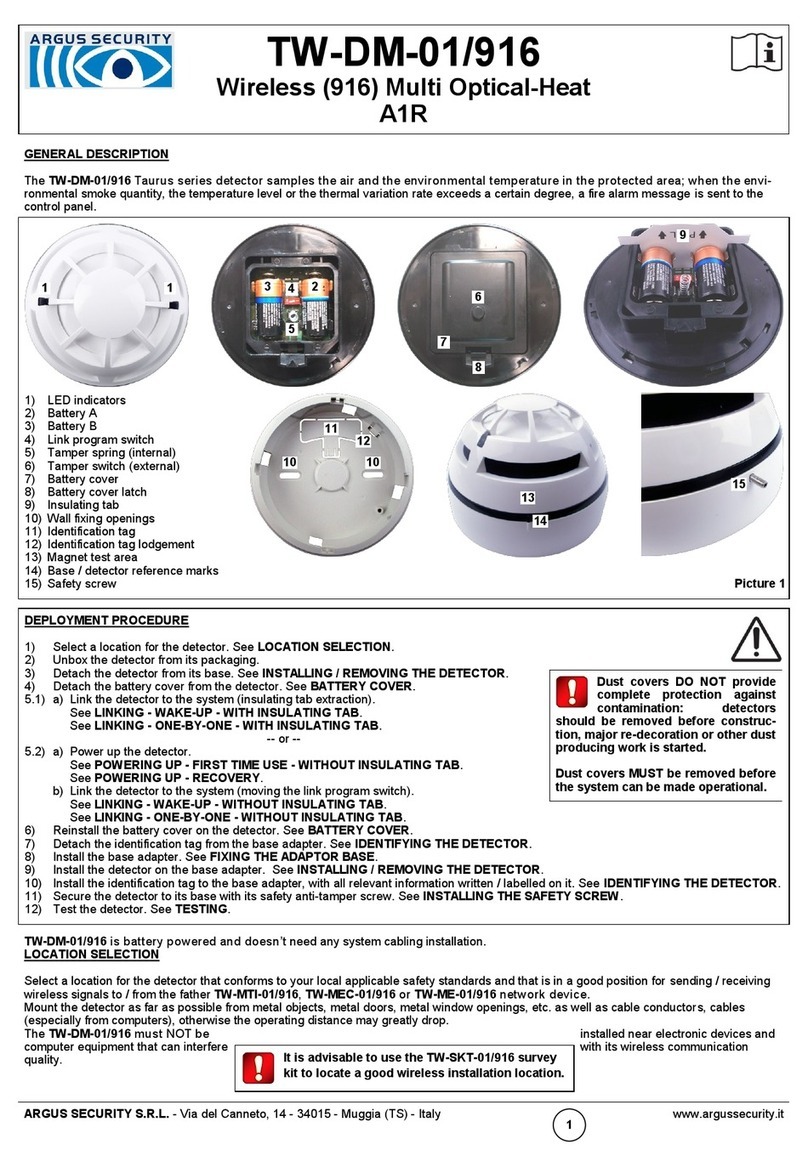

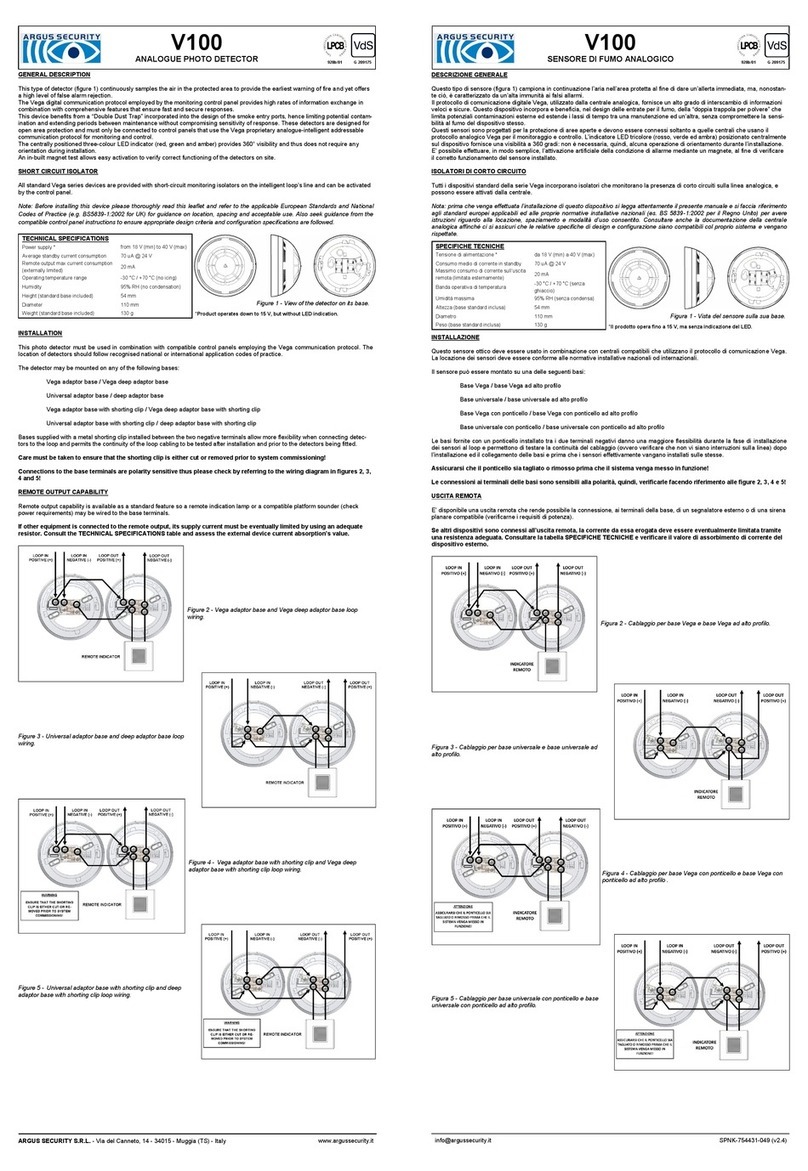

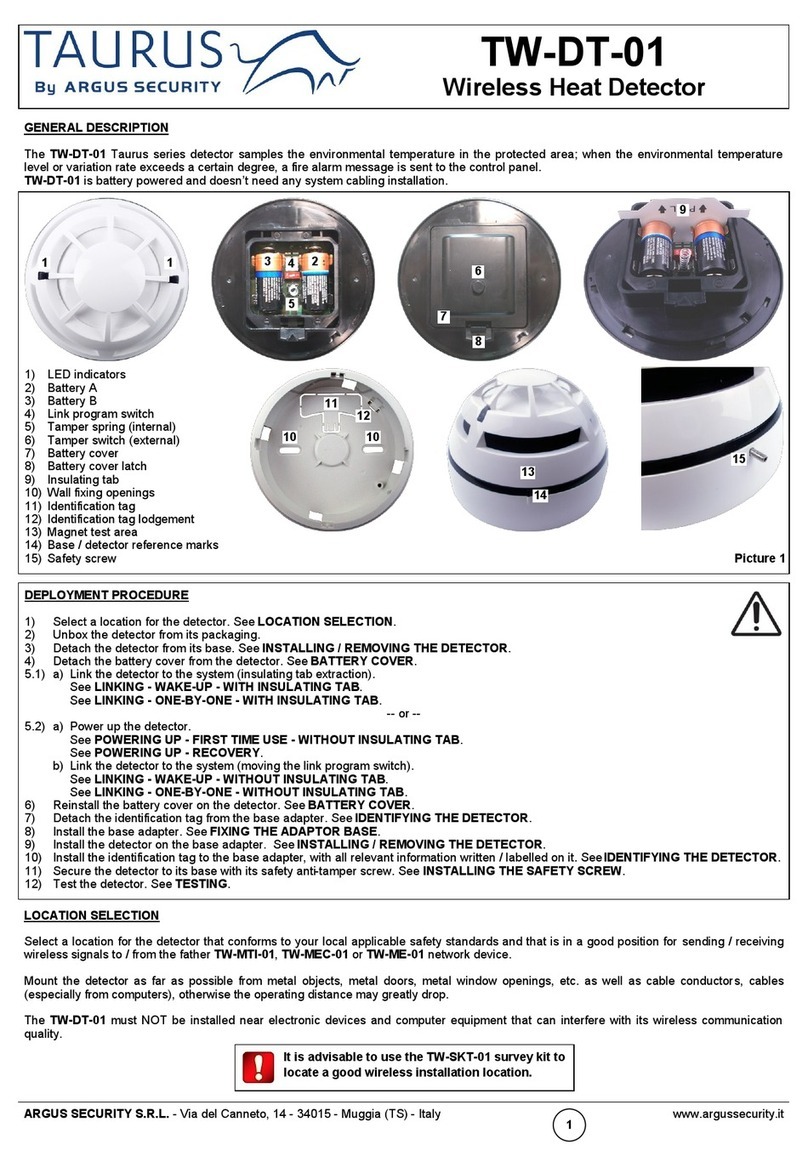

INSTALLATION

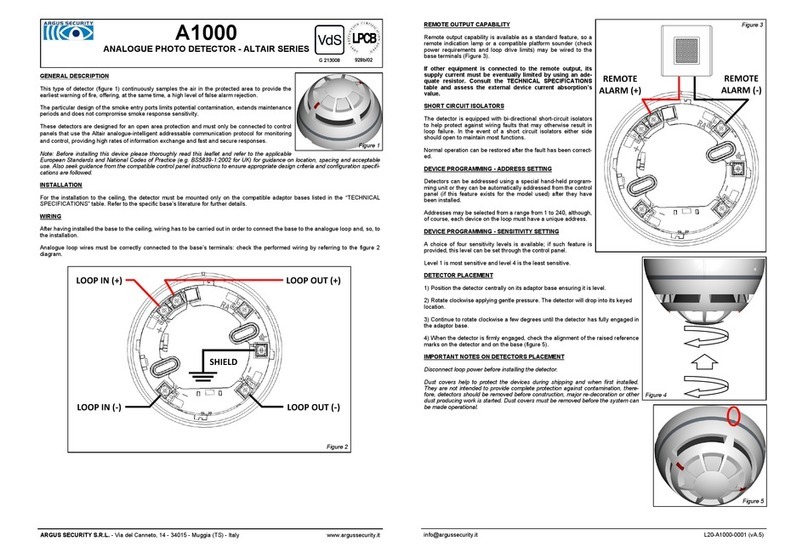

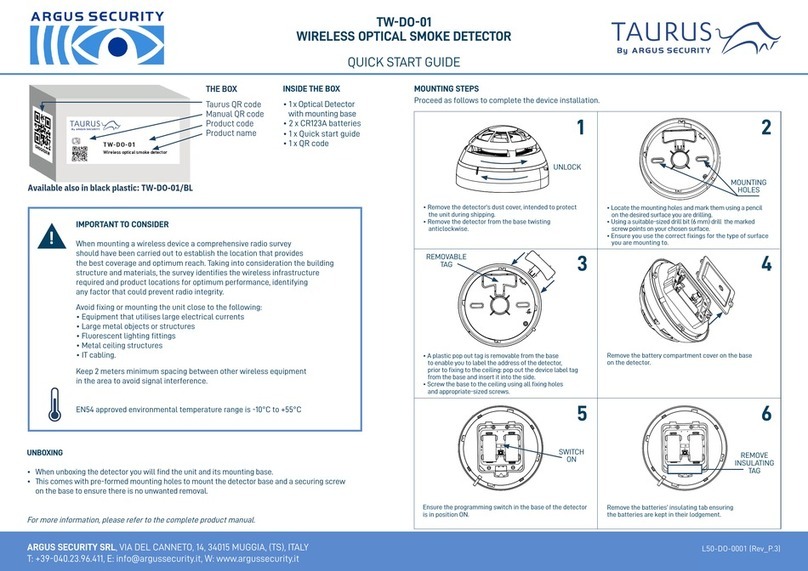

1.Position the detector centrally on its mounting base.

2.Rotate clockwise applying gentle pressure. The detector will

drop into its mechanical holding location.

3.Push the detector to win the force of the contacts.

4.Continue to rotate clockwise a few degrees until the detector is

firmly held on the detector base.

5.When the detector is firmly held verify the alignment between

the detector and the raised marks on the base (picture 5).

6.After installing all detectors, apply power to the fire security

system.

7.Test the detectors as described in the paragraph headed

“TESTING”.

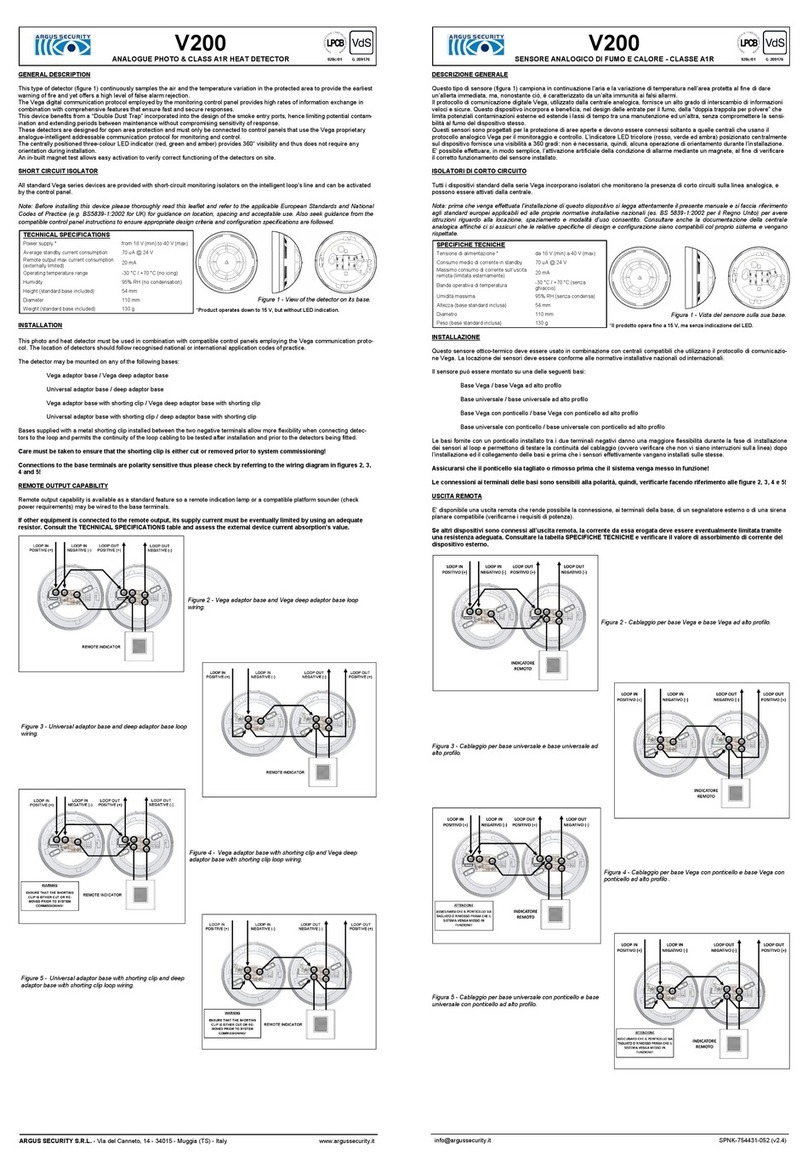

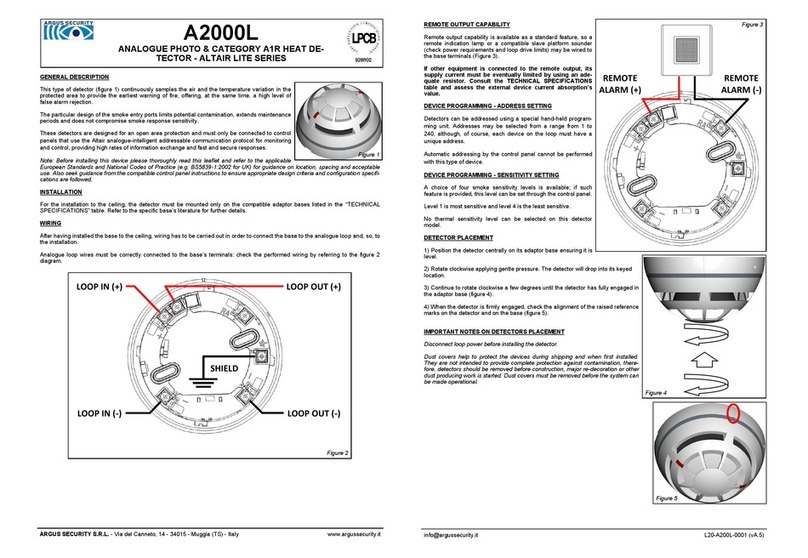

Picture 3 - Wiring used

when the alarm current

is limited by the resistor

on the mounting base.

1. Position the detector.

2. Rotate.

3. Push.

4. Rotate.

CAUTION

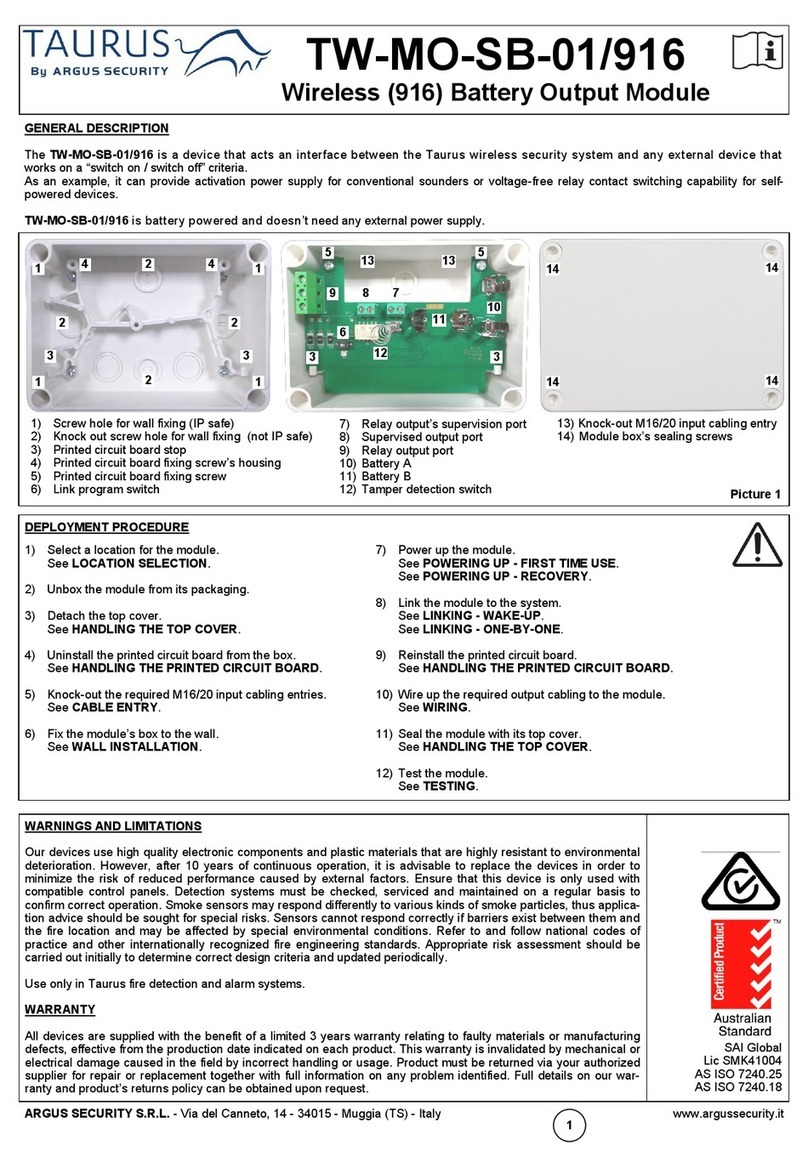

Dust covers help to protect the devices during

shipping and when first installed. They are not

intended to provide complete protection against

contamination, therefore, sensors should be

removed before construction, major re-decoration

or other dust producing work is started. DUST

COVERS MUST BE REMOVED BEFORE THE

SYSTEM CAN BE MADE OPERATIONAL.

TESTING

Sensors should be tested after installation and during periodic maintenance visits (it is recommended each device should be tested at

least once per year). When the system has been reset, allow, after each test, at least one minute for power stabilisation before the

next test. Detectors can be tested as follows:

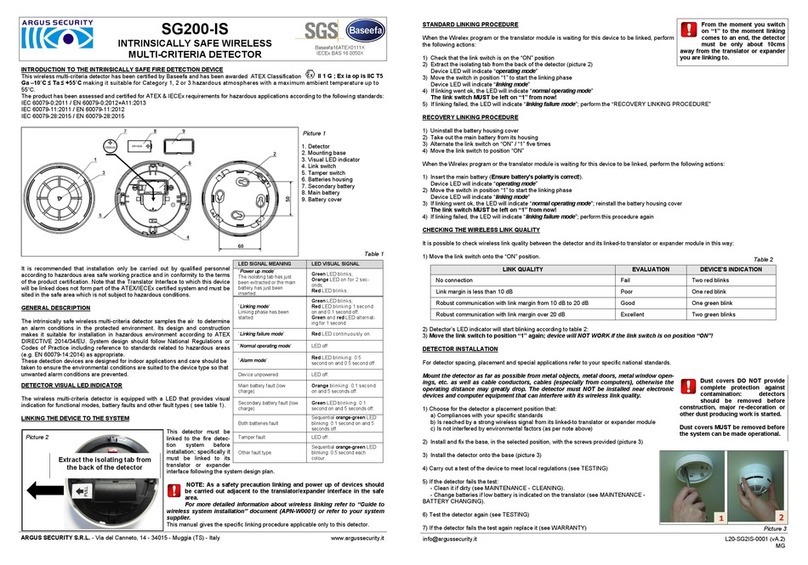

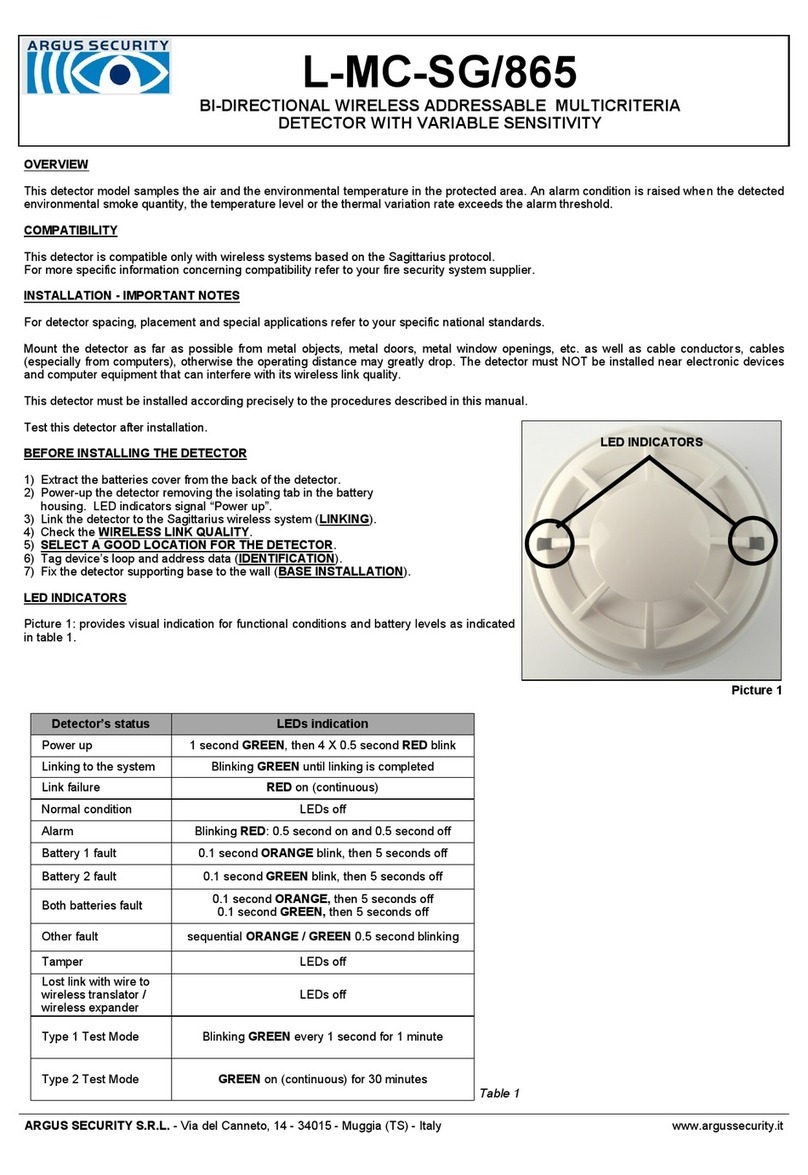

ANTI-TAMPER MECHANICAL BLOCK FEATURE

The sensor may be blocked onto its base by remov-

ing the small plastic element on the base’s detector

blocking tongue by using a suitable tool (e.g. a

small screwdriver) inserted through the access hole

on the side of the mounting base (picture 4).

To remove the sensor from the base, if mechani-

cally blocked, insert a suitable tool through the

access hole on the side of the mounting base

(picture 4).

TAMPER DETECTION

Each detector’s mounting base has two “–” marked terminals. These are electrically identical, but they are connected to each other

only when a detector is correctly fitted onto the base; this feature is used in combination with an appropriate “end of line” (EOL)

component, designated by the control panel manufacturer, in order to indicate a fault condition if a detector is removed from its

base. To enable the function to operate correctly it is important that incoming and outgoing negative wires are separated in the

above said way

Picture 4 - The anti-tamper block and its handling.

Picture 5 - The correctly installed detector.

Magnet

test position

(model TMD-01).

Alignment between base and detector.

ARGUS

SECURITY

S.R.L.

- Via Archimede 42, 20041, Agrate Brianza, Milano, Italy www.argussecurity.it [email protected] L20-S2000-0001 (v1.0) LINE IN

POSITIVE (+)

LINE IN

NEGATIVE (-) LINE OUT

POSITIVE (+)

LINE OUT

NEGATIVE (-)

REMOTE INDICATOR

END OF LINE RESISTOR

WIRING - BASE WITH RESISTOR AND BASE WITH RESITOR AND SCHOTTKY DIODE

This configuration is to be used when the alarm current depends only on the value of the resistor fitted on the base (picture 3).

Magnet test

Position the magnet (model TMD-01, optional) next to the sensor between the two raised

marks on the base (picture 5).

The magnet test verifies the function of all electronic circuits of the sensor and its com-

munication with the control panel.

The sensor should trigger an alarm condition on the control panel and turn the red LED

on.

Aerosol (simulated smoke) test

Use a test aerosol from an approved manufacturer in accordance with their application

instructions. This is important to prevent contamination or possible damage.

The red LED alarm indicator on the detector should illuminate (normally within 60 sec-

onds, but may vary) and trigger an alarm condition on the control panel.

Heat test

Use a hair dryer of 1000-1500 W or an heat tool from an approved manufacturer.

Direct the heat towards the sensor from its side. Hold the heat source at about 15 cm

away from the sensor in order to prevent damage to its cover during testing.

The red LED on the detector should latch into alarm and the control panel should

activate into alarm condition.

If testing fails after installation or maintenance then replace the sensor and return

it for servicing.

MAINTENANCE

Before starting any maintenance work, isolate and disable the system in order to avoid accidental and unwanted fault conditions.

Remove the sensor from its mounting base to allow inspection in good light at ground level. Inspect the smoke entry ports around the

sensor and the thermistor area; use a small, soft bristle brush to dislodge any evident contaminants such as insects, spider webs,

hairs, etc. Use a small vacuum tube or clean, dry and compressed air to suck up or blow away any remaining small particles from the

smoke entry screen area and the thermistor area. Wipe the exterior housing of the sensor with a clean, damp, lint free cloth to re-

move any surface film that can later attract airborne contaminants. After all sensors have been inspected, repositioned on their

mounting bases and power has been re-applied, check correct operation as described under the “TESTING” paragraph.