001.10610.EN rev. 13

Foreword 1

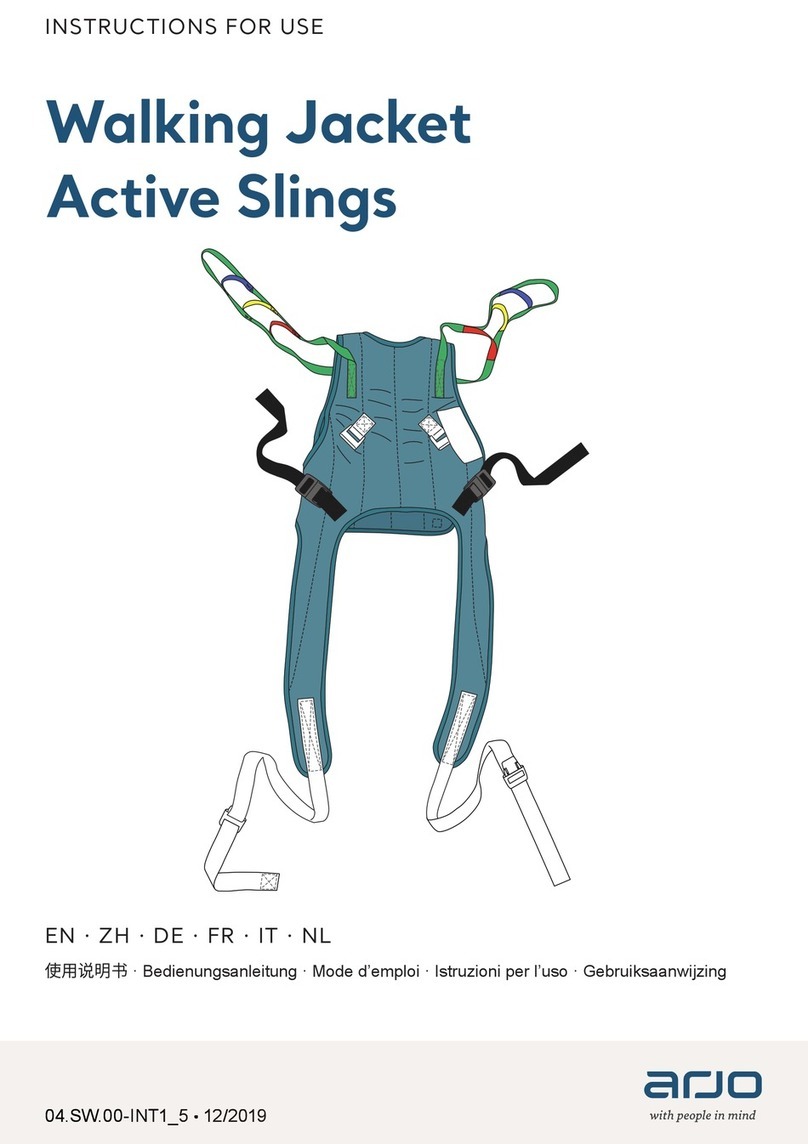

Thank you for choosing Arjo

products.

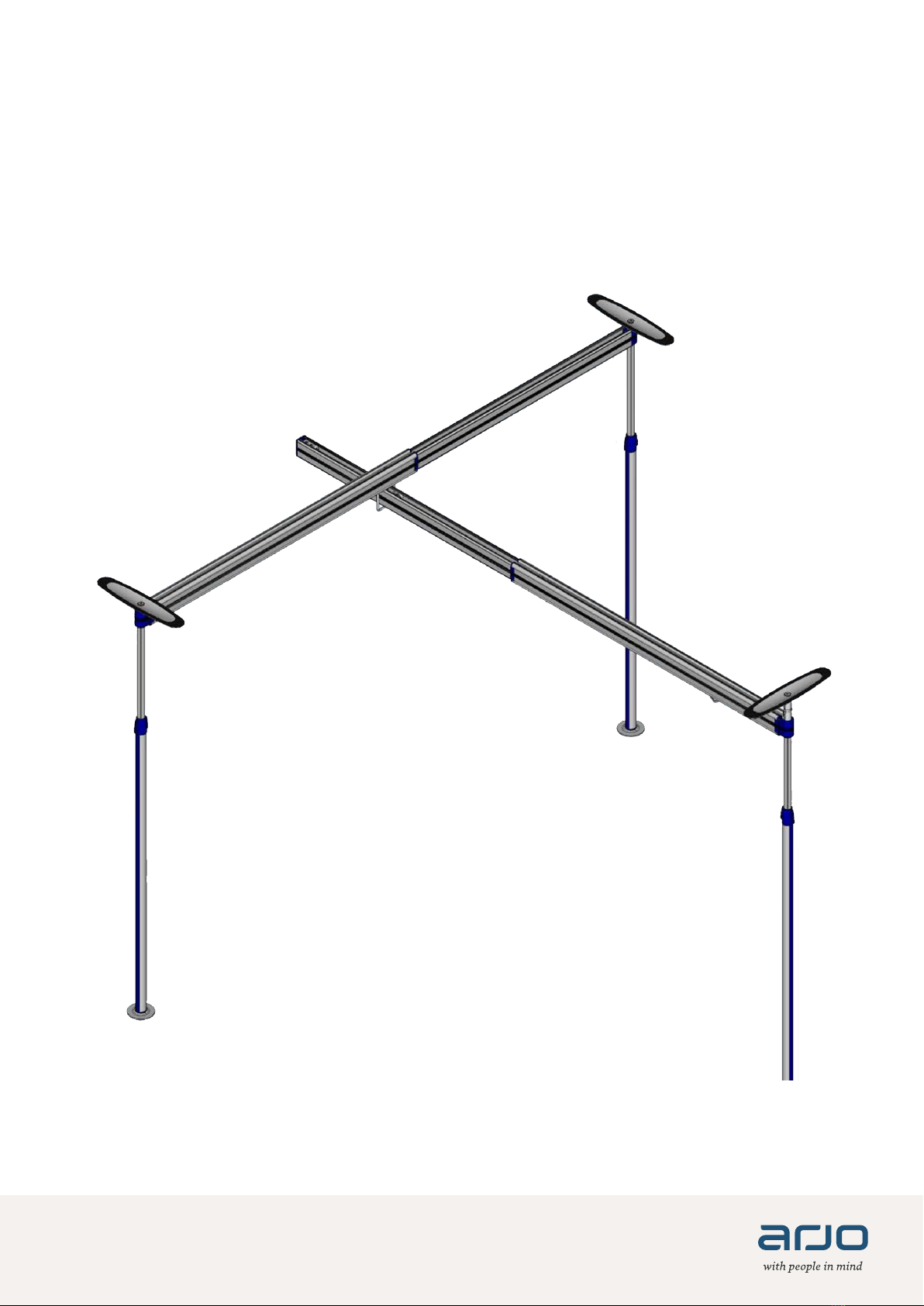

Your EASYTRACK®is part of a series of quality

products designed specially for home care,

nursing homes and other health care uses.

We are dedicated to serving your needs and

providing the best products available along with

training that will bring your staff maximum

benet from every Arjo product.

Please Read this Manual Thoroughly!

The information in this manual is crucial to the

proper use and maintenance of the

EASYTRACK. It will help protect your product

as well as ensure that it performs to your

satisfaction.

Lifting and transferring a person always

presents a potential risk. This manual contains

safety related information that must be read

and understood to help prevent injuries.

WARNING: Arjo strongly advises and warns

that to avoid injuries that can be attributed to

the use of inadequate parts, only parts

designated by Arjo should be used on

product and other appliances supplied by

Arjo.

WARNING: Unauthorized modications on

any Arjo product may affect its safety. Arjo

will not be held responsible for any accidents,

incidents or lack of performance that occur

as a result of any unauthorized modication

to its products.

Do not attempt to service or repair the

EASYTRACK. If any item is defective, contact

your local Arjo vendor.

If a serious incident occurs in relation to this

medical device, affecting the user, or the patient

then the user or patient should report the

serious incident to the incident to the medical

device manufacturer or the distributor. In the

European Union, the user should also report

the serious incident to the Competent Authority

in the member state where they are located.

Service and Support

A service routine has to be done on your

EASYTRACK by Arjo trained service personnel.

This will ensure it remains safe and functional.

Please contact your local Arjo vendor for any of

the following:

• If you require further information.

• Want to report an unexpected event,

change in the performance or a

malfunction.

• Need any help in setting up, using or

maintaining your EASYTRACK.

• Need replacement parts.

Your Arjo vendor can offer support and service

programs to maximize the long-term safety,

reliability and value of the product.

Additional copies of this manual can be

purchased from your local Arjo agent. When

ordering, include the Instructions for Use part

number (see front page).

Manufacturer Information

This product was manufactured by:

ArjoHuntleigh AB

Hans Michelsensgatan 10

211 20 Malmö

SWEDEN

Denitions Used in this Manual

WARNING:

Means: Failure to understand and follow this

instruction may result in injury to yourself and

others.

CAUTION:

Means: Failure to follow this instruction may

cause damage to the product(s).

NOTE:

Means: Important information regarding correct

use of the product.

Foreword