5

USING YOUR ARKSEN WATER/ALCOHOL DISTILLER

Before making your rst fermented and distilled beverages, or distilling water, perform the following:

• Wash all parts of your distiller with hot water and dish soap and dry completely.

• Perform a “Vinegar Run” described in the Distilling section (page 12).

• If distilling water only, perform a “Water Run” by distilling 1 gallon or more of clean water,

which will be discarded.

• Your Arksen Distiller can be used for the fermentation process, and then used for the distillation process.

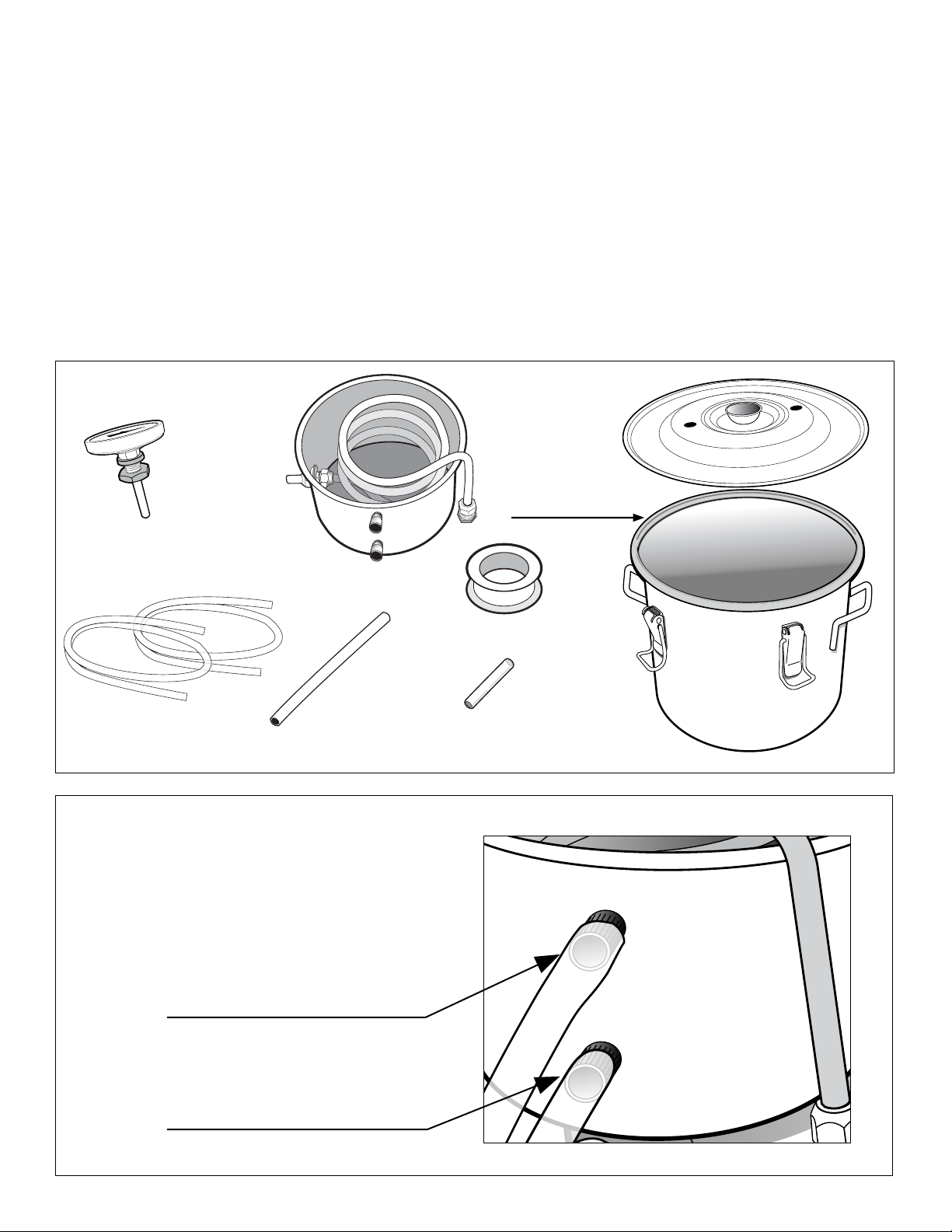

• For fermenting, use the Fermenting Conguration, for Distilling use the Distilling Conguration.

• This product manual is not a complete guide to fermenting and distilling. In order to produce a satisfying

and safe product suitable for adult consumption, please consult books, recipes, and how-to resources and

videos on-line, in book stores and libraries.

• Caution: RISK OF METHANOL POISONING

Avoid consumption of Methanol (Methyl Alcohol)! Methanol can cause blindness and be fatal.

Carefully follow precautions in recipes for distilled beverages. Discard the rst 4-7 oz (100-200ml) of

liquid as it comes out of the Condenser Distillate Outlet, for of each 5 gallons (20L) of fermented

“mash”. These rst ounces are often referred to as “heads”or “foreshots”. DO NOT CONSUME THEM.

MAKING DISTILLED SPIRITS:

A 2 Stage Process: Fermenting & Distilling

STAGE 1: FERMENTATION

• Fermenting beverages into wine or beer is the rst step to then producing brandy, whiskey or gin.

The next step is distilling the results of fermentation, resulting in greater concentrations of alcohol, and

renement of color and avors. Distilling the result a second time further concentrates alcohol and clarity.

• Fermentation is the process of microorganisms, usually yeast, converting (metabolizing) sugars into

carbon dioxide and alcohol. The carbon dioxide bubbles out of the beverage, leaving behind alcohol. Beer,

Ale and Wine are fermented beverages which are complete at this stage. They do not need to go through

the second stage: distillation.

• A wide variety of foods can be fermented. Grains such as corn, wheat, barley, or rye, are used for many

beverages, such as beer and whiskey. Fruits, sugars, rice, and molasses are most often used to make wine,

brandy, rum, and other spirits. Potatoes are used to create vodka.

• Specic steps for fermenting can be found in the recipes on pages 14 -17.

• Use the Fermenting Conguration on pages 6 and 7.

OR

• You can use a separate large container for fermenting. The fermentation process happens over several

days or weeks. You may wish to keep your Arksen Distiller available for distilling only. Use clean glass,

stainless steel or food-safe ceramic or plastic containers. It’s helpful to have 2 or more containers available.