Manual No. 660885 Art’s-Way Manufacturing Co., Inc.

6 LIMITED WARRANTY

LIMITED WARRANTY FOR NEW ART’S WAY MANUFACTURING CO. FARM MACHINERY

(U.S. ONLY)

A. GENERAL PROVISIONS: Art’s Way Manufacturing Co., Inc. (Art’s Way Mfg.) warrants the products it sells to be free from defects in material and

workmanship for the periods of time set forth in the Warranty Table below. Art’s Way Mfg. obligation and liability under this limited warranty, is to repair or

replace (at Art’s Way Mfg. option) any part(s) that upon manufacture were defective in material or workmanship. Warranty service shall be performed by an

authorized Art’s Way Mfg. dealer or authorized service center and will be completed using Art’s Way Mfg. supplied parts. Parts supplied by Art’s Way Mfg. are

shipped F.O.B. Art’s Way. The original purchaser shall be responsible for service calls and transportation of the farm machinery to and from their dealer or

service center. The original purchaser is also responsible for any expedited repair charges (i.e., overtime and “next day air” deliveries) requested by the original

purchaser. The original purchaser is also responsible for any repair service, parts, and labor on repairs made to the farm machinery at the time the warranty

service was being performed.

B. SECURING WARRANTY SERVICE: The original purchaser must (1) contact their authorized dealer and report the break-down. (2) The authorized dealer

shall provide objective evidence of the farm machinery’s warranty status to Art’s Way Mfg. (3) The authorized dealer shall provide all documentation to Art’s

Way Mfg. which supports that the farm machinery was thoroughly inspected prior to set-up and delivery to the original purchaser. (4) The original purchaser

shall make the farm machinery available to their Art’s Way Mfg. authorized dealer and/or Art’s Way Mfg. authorized service center within 30 days of the

reported break-down. All parts or assemblies replaced under the limited warranty must be held for inspection for ninety (90) days, or until credit has been issued,

or a claim has been returned to a dealer. When a claim is returned to a dealer with instructions to return and/or hold the part(s) for inspection, parts must be

handled as instructed or the claim may be denied.

C. SPARE PARTS WARRANTY: Art’s Way Mfg. warrants that it will replace or repair (excluding labor) as Art’s Way Mfg. elects, without charge, any genuine

spare part purchased from Art’s Way Mfg. which is defective in material or workmanship within ninety (90) days of the date of installation. This warranty

applies to parts that, in Art’s Way Mfg. judgement, prove to be defective in either material or workmanship. All parts to be shipped F.O.B. Art’s Way Mfg. All

spare parts replaced under the spare parts warranty must be held for inspection for ninety (90) days or until credit has been issued, or a claim has been returned to

a dealer. When a claim is returned to a dealer with instructions to return and/or hold the part(s) for inspection, parts must be handled as instructed or the claim

may be denied.

D. LIMITATIONS: Art’s Way Mfg. Limited Warranty does not extend coverage to product being used in a commercial application (i.e. rented equipment). Art’s

Way Mfg. Limited Warranty does not extend to parts and elements not manufactured by Art’s Way Mfg., and which carry the warranty of another manufacturer.

Art’s Way Mfg. makes no other warranty expressed or implied and makes no warranty of merchantability or fitness for any particular purpose beyond that

expressly stated in this warranty. Art’s Way Mfg. liability is limited to the terms set forth in this warranty and does not include any liability for direct, indirect,

incidental or consequential damages or expenses of delay and Art’s Way Mfg. liability is limited to the repair and replacement of defective parts as set forth

herein. Any improper use and/or maintenance, including operation after the discovery of defective or worn parts, operation beyond the rated capacity,

substitution of parts not approved by Art’s Way Mfg. or any alteration or repair by others than the authorized Art’s Way Mfg. dealer or authorized service center

which affect the product materially and adversely, shall void the warranty. No dealer, employee or representative is authorized to change this warranty in any

way or grant any other warranty unless such change is made in writing and signed by an officer of Art’s Way Mfg. Some states do not allow limitations on how

long an implied warranty lasts or exclusions or limitations of incidental or consequential damages, so the above limitations or exclusions may not apply to you.

This warranty gives you the specific legal rights, and you may have other rights that vary from state to state.

NOTE: As of April 1, 2015, all previously distributed information concerning the limited warranty coverage of any Art’s Way Manufacturing Company,

Inc. manufactured product is to be considered null and void and replaced by this document.

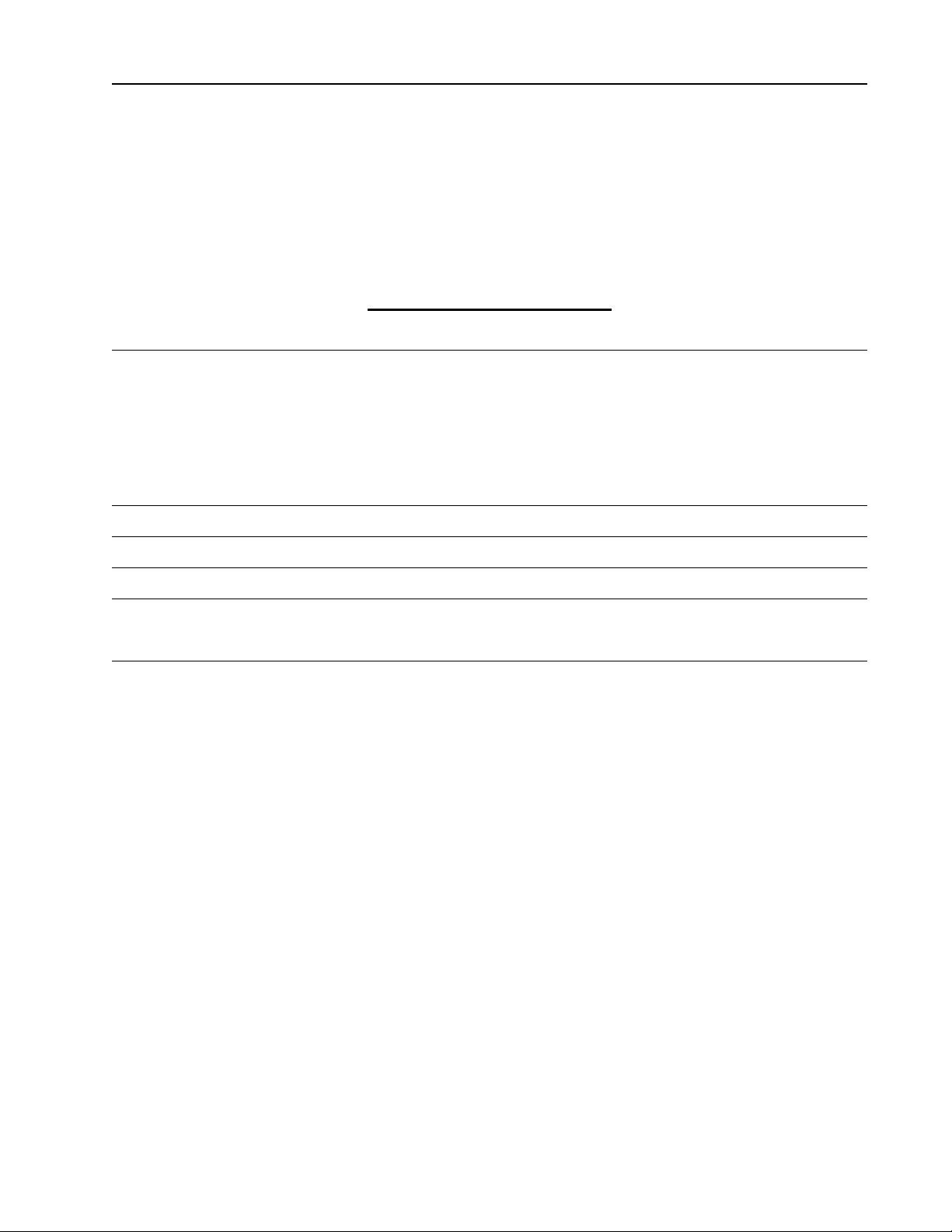

Art’s Way Mfg. Farm Machinery Warranty Coverage

Grinder / Mixer – Model 6520, 6530, 6140, 6105, and Portable and Stationary

equipment

1 (one) Year from Date of Delivery to Original Purchaser

Manure Spreader 1 (one) Year from Date of Delivery to Original Purchaser

Graders and Land Planes 1 (one) Year from Date of Delivery to Original Purchaser

Beet Harvesting Machinery 1 (one) Harvest Season from Date of Delivery to Original

Purchaser

Shredders – Model 180C and 240C 1 (one) Year from Date of Delivery to Original Purchaser

Plows 1 (one) Year from Date of Delivery to Original Purchaser

Forage Blowers – Model 1060 and 2060 1 (one) Year from Date of Delivery to Original Purchaser

Forage Boxes/Receivers – Model 5300 and 1250 1 (one) Year from Date of Delivery to Original Purchaser

Rakes 1 (one) Year from Date of Delivery to Original Purchaser

Dump Boxes 1 (one) Year from Date of Delivery to Original Purchaser

Augers 1 (one) Year from Date of Delivery to Original Purchaser

Running Gear 1 (one) Year from Date of Delivery to Original Purchaser

Snow Blowers 1 (one) Year from Date of Delivery to Original Purchaser

Harvester Reel 1 (one) Year from Date of Delivery to Original Purchaser

Effective 1 April 2015

LIMITED WARRANTY FOR NEW ART’S WAY MANUFACTURING CO. FARM MACHINERY

(U.S. ONLY)

A. GENERAL PROVISIONS: Art’s Way Manufacturing Co., Inc. (Art’s Way Mfg.) warrants the products it sells to be free from defects in material and

workmanship for the periods of time set forth in the Warranty Table below. Art’s Way Mfg. obligation and liability under this limited warranty, is to repair or

replace (at Art’s Way Mfg. option) any part(s) that upon manufacture were defective in material or workmanship. Warranty service shall be performed by an

authorized Art’s Way Mfg. dealer or authorized service center and will be completed using Art’s Way Mfg. supplied parts. Parts supplied by Art’s Way Mfg. are

shipped F.O.B. Art’s Way. The original purchaser shall be responsible for service calls and transportation of the farm machinery to and from their dealer or

service center. The original purchaser is also responsible for any expedited repair charges (i.e., overtime and “next day air” deliveries) requested by the original

purchaser. The original purchaser is also responsible for any repair service, parts, and labor on repairs made to the farm machinery at the time the warranty

service was being performed.

B. SECURING WARRANTY SERVICE: The original purchaser must (1) contact their authorized dealer and report the break-down. (2) The authorized dealer

shall provide objective evidence of the farm machinery’s warranty status to Art’s Way Mfg. (3) The authorized dealer shall provide all documentation to Art’s

Way Mfg. which supports that the farm machinery was thoroughly inspected prior to set-up and delivery to the original purchaser. (4) The original purchaser

shall make the farm machinery available to their Art’s Way Mfg. authorized dealer and/or Art’s Way Mfg. authorized service center within 30 days of the

reported break-down. All parts or assemblies replaced under the limited warranty must be held for inspection for ninety (90) days, or until credit has been issued,

or a claim has been returned to a dealer. When a claim is returned to a dealer with instructions to return and/or hold the part(s) for inspection, parts must be

handled as instructed or the claim may be denied.

C. SPARE PARTS WARRANTY: Art’s Way Mfg. warrants that it will replace or repair (excluding labor) as Art’s Way Mfg. elects, without charge, any genuine

spare part purchased from Art’s Way Mfg. which is defective in material or workmanship within ninety (90) days of the date of installation. This warranty

applies to parts that, in Art’s Way Mfg. judgement, prove to be defective in either material or workmanship. All parts to be shipped F.O.B. Art’s Way Mfg. All

spare parts replaced under the spare parts warranty must be held for inspection for ninety (90) days or until credit has been issued, or a claim has been returned to

a dealer. When a claim is returned to a dealer with instructions to return and/or hold the part(s) for inspection, parts must be handled as instructed or the claim

may be denied.

D. LIMITATIONS: Art’s Way Mfg. Limited Warranty does not extend coverage to product being used in a commercial application (i.e. rented equipment). Art’s

Way Mfg. Limited Warranty does not extend to parts and elements not manufactured by Art’s Way Mfg., and which carry the warranty of another manufacturer.

Art’s Way Mfg. makes no other warranty expressed or implied and makes no warranty of merchantability or fitness for any particular purpose beyond that

expressly stated in this warranty. Art’s Way Mfg. liability is limited to the terms set forth in this warranty and does not include any liability for direct, indirect,

incidental or consequential damages or expenses of delay and Art’s Way Mfg. liability is limited to the repair and replacement of defective parts as set forth

herein. Any improper use and/or maintenance, including operation after the discovery of defective or worn parts, operation beyond the rated capacity,

substitution of parts not approved by Art’s Way Mfg. or any alteration or repair by others than the authorized Art’s Way Mfg. dealer or authorized service center

which affect the product materially and adversely, shall void the warranty. No dealer, employee or representative is authorized to change this warranty in any

way or grant any other warranty unless such change is made in writing and signed by an officer of Art’s Way Mfg. Some states do not allow limitations on how

long an implied warranty lasts or exclusions or limitations of incidental or consequential damages, so the above limitations or exclusions may not apply to you.

This warranty gives you the specific legal rights, and you may have other rights that vary from state to state.

NOTE: As of April 1, 2015, all previously distributed information concerning the limited warranty coverage of any Art’s Way Manufacturing Company,

Inc. manufactured product is to be considered null and void and replaced by this document.

Art’s Way Mfg. Farm Machinery Warranty Coverage

Grinder / Mixer – Model 6520, 6530, 6140, 6105, and Portable and Stationary

equipment

1 (one) Year from Date of Delivery to Original Purchaser

Manure Spreader 1 (one) Year from Date of Delivery to Original Purchaser

Graders and Land Planes 1 (one) Year from Date of Delivery to Original Purchaser

Beet Harvesting Machinery 1 (one) Harvest Season from Date of Delivery to Original

Purchaser

Shredders – Model 180C and 240C 1 (one) Year from Date of Delivery to Original Purchaser

Plows 1 (one) Year from Date of Delivery to Original Purchaser

Forage Blowers – Model 1060 and 2060 1 (one) Year from Date of Delivery to Original Purchaser

Forage Boxes/Receivers – Model 5300 and 1250 1 (one) Year from Date of Delivery to Original Purchaser

Rakes 1 (one) Year from Date of Delivery to Original Purchaser

Dump Boxes 1 (one) Year from Date of Delivery to Original Purchaser

Augers 1 (one) Year from Date of Delivery to Original Purchaser

Running Gear 1 (one) Year from Date of Delivery to Original Purchaser

Snow Blowers 1 (one) Year from Date of Delivery to Original Purchaser

Harvester Reel 1 (one) Year from Date of Delivery to Original Purchaser

Effective 1 April 2015