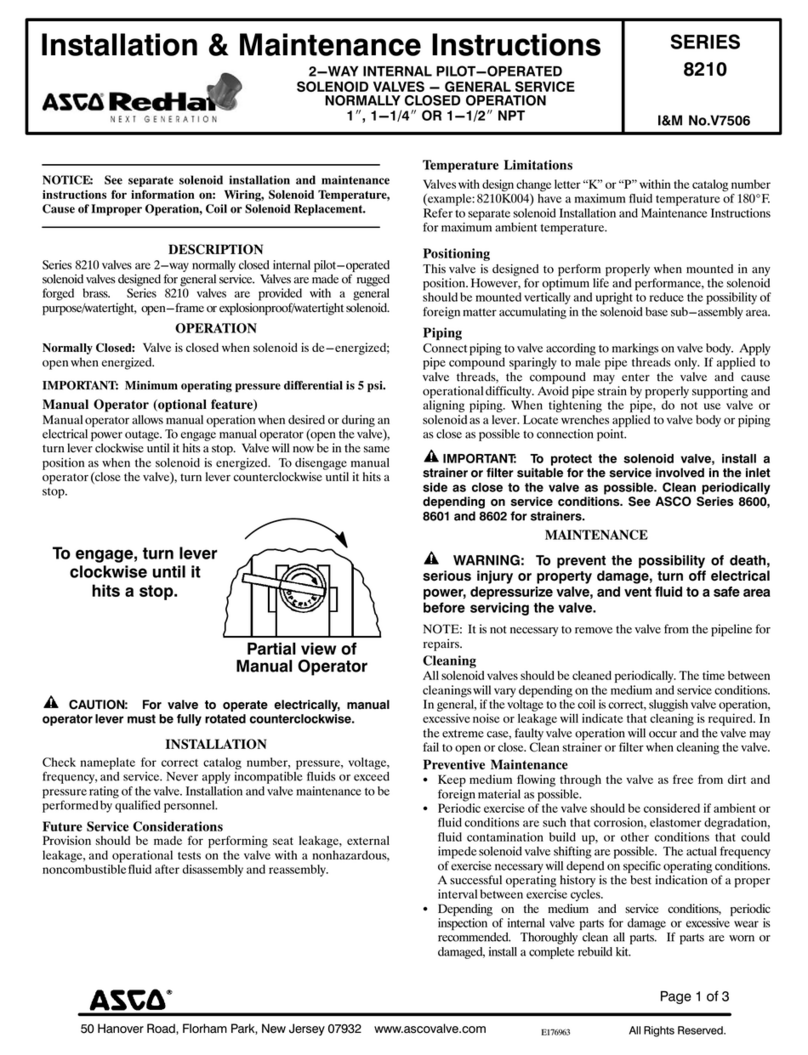

Installation & Maintenance Instructions

GENERAL PURPOSE / RAINTIGHT / WATERTIGHT AND

RAINTIGHT / WATERTIGHT / EXPLOSIONPROOF SOLENOIDS

SERIES

8004

ASCO ValvesASCO Valves®®E310657 -E310657 - 01/202101/2021 All Rights Reserved.All Rights Reserved. I&M V_6796_HBI&M V_6796_HB

©©ASCO, L.P. 160 ParkASCO, L.P. 160 Park Avenue, Florham Park,Avenue, Florham Park, New Jersey 07932New Jersey 07932 www.emerson.comwww.emerson.com Page 1 of 2Page 1 of 2

I&M V_6796_HB

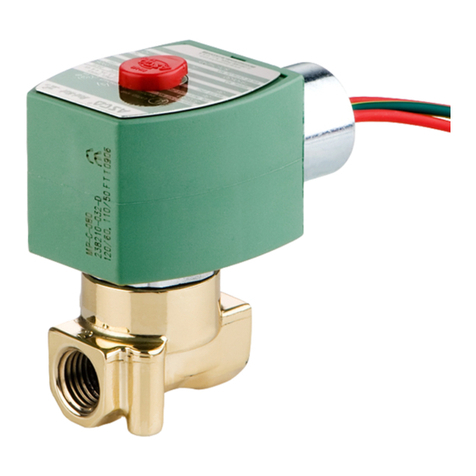

DESCRIPTION

Catalog Numbers WT8004A1 and EF8004A1 are thermoplastic

encapsulated pull-type solenoids for use with ASCO valves. These

solenoids have three lead wires with one wire for grounding and a

½” male conduit connection. Catalog No. WT8004A1 is designed

to meet Enclosure Type 1 - General Purpose, Types 3 and 3S -

Raintight, Types 4 and 4X - Watertight. Catalog No. EF8004A1

meets Enclosure Types 3 and 3S - Raintight, Types 4 and 4X -

Watertight, Types 6 and 6P - Submersible, Type 7 (A, B, C & D)

Explosionproof Class I, Division 1, Groups A, B, C, & D and Type

9 (E, F, & G) - Dust - Ignitionproof Class II, Division 1, Groups E,

F, & G. (See asterisks [*] below)

AC (6.3 W) voltages *

• 24, 100, 110, 120, 110-120, 220, 220-240 @ 50Hz

• 12, 24, 100, 110, 120, 240 @ 60Hz

DC (6.9 W) voltages *

• 6, 12, 24, 28, 48, 100, 120, 240

= Specific voltage is marked on coil

*= Div 1 voltages (UL/CSA, if marked) for EF prefix version. See

accompanying regional requirement cert (example, CCC/NEPSI)

for voltage, Ex protection and temperature limitations (if marked).

OPERATION

When the solenoid is energized, the core assembly is drawn into the

plugnut/core tube sub-assembly. When the solenoid is de-energized,

spring force returns the core assembly to the original position.

Enclosure Types 7 and 9 Only (EF8004A1)*

To prevent re or explosion, do not

install solenoid and/or valve where ignition temperature of

hazardous atmosphere is less than 160 °C. Open circuit before

disassembling. Do not exceed temperature limitations in chart

below. (See asterisk [*] in DESCRIPTION section).

Afin d’éviter le risque de feu

ou d’explosion, ne pas installer la bobine ou l’électrovanne ou

la température d’inflammation en atmosphère explosible est

inferieure à 160 °C. Ouvrez le circuit avant le désassemblage. Ne

pas dépasser les limites de température mentionnées dans le

tableau ci-dessous. (Voir l’astérisque [*] dans la section descriptive).

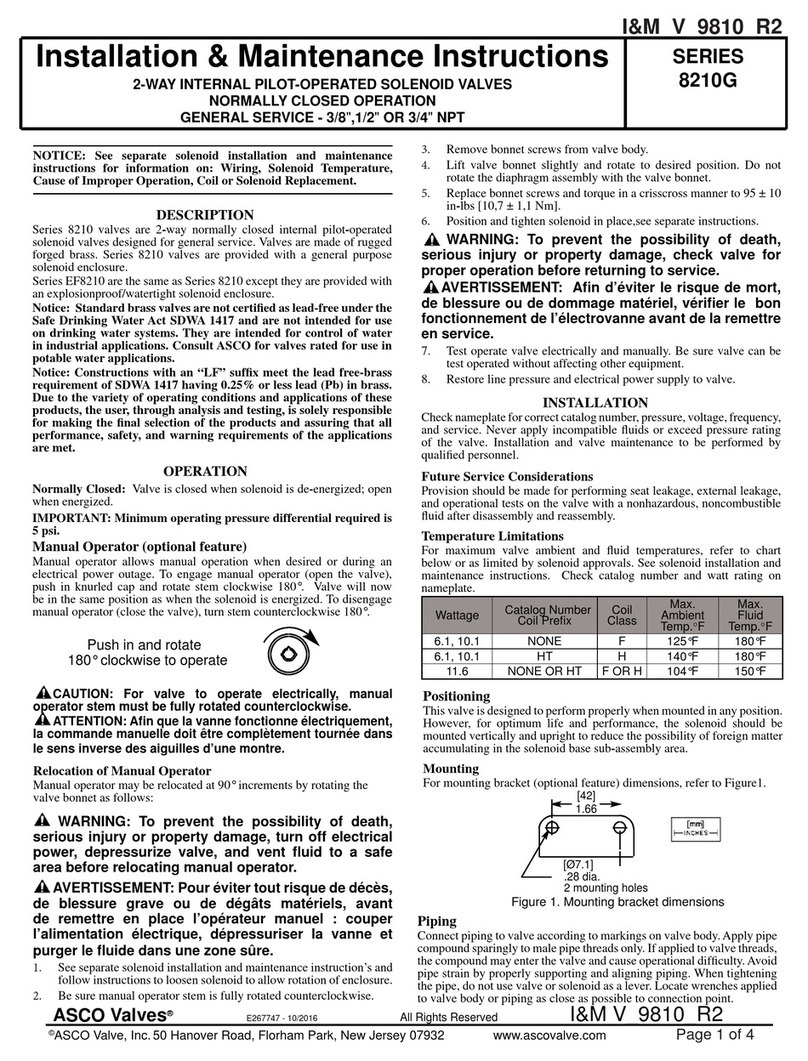

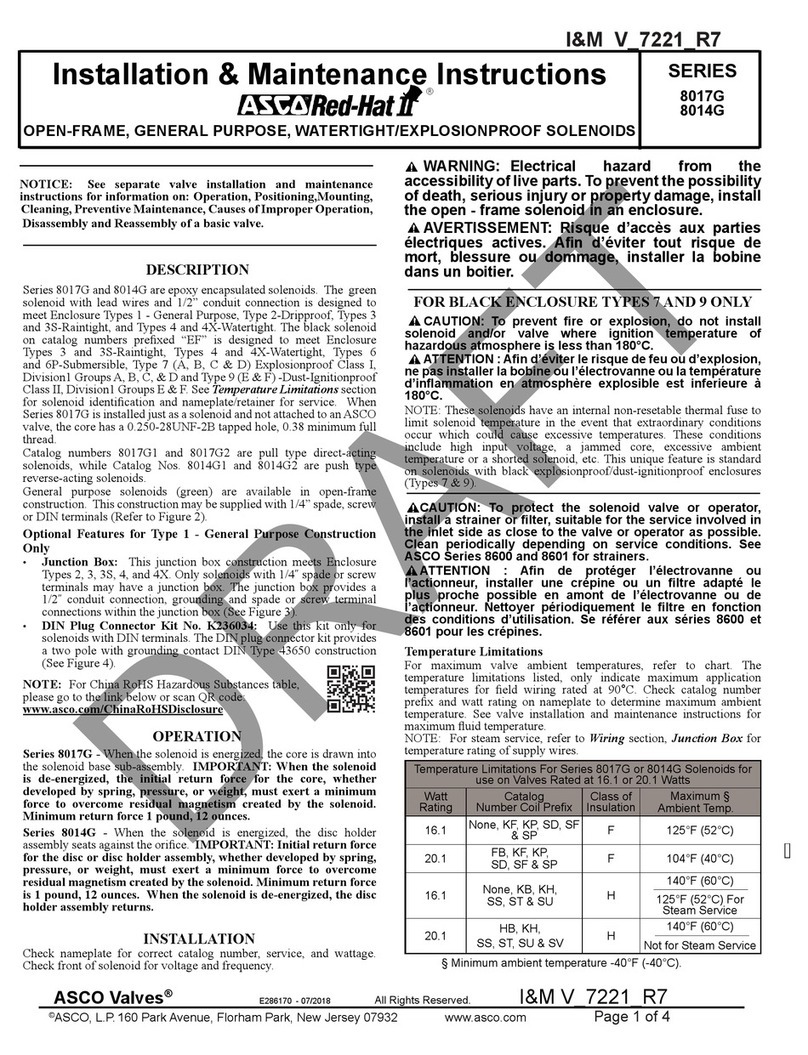

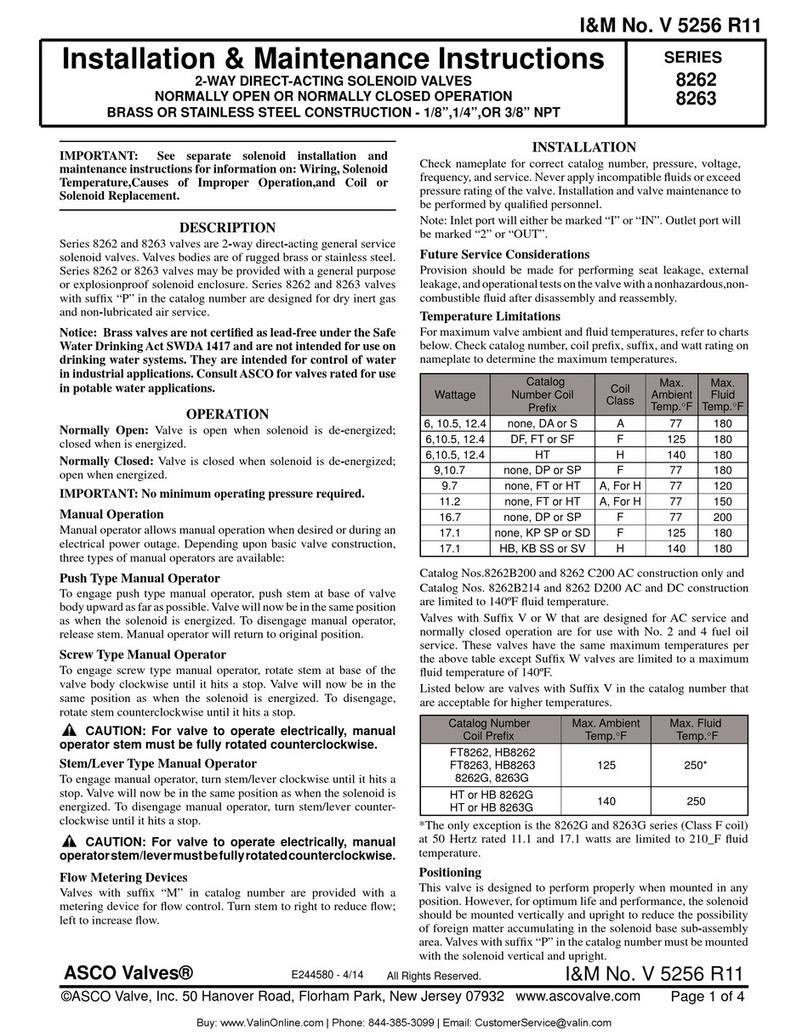

Temperature Limitations

For maximum ambient/fluid temperatures, refer to chart.

See valve installation and maintenance instructions for valve

temperature limitations.

Catalog Numbers Construction Ambient/Fluid Temperature

WT8004A1

AC Construction (6.3W)

-40 °F(-40 °C) to 140 °F (60 °C)

DC Construction (6.9W)

-40°F(-40 °C) to 125 °F (52°C)

EF8004A1*

AC Construction (6.3W)

-40 °F(-40 °C) to 104 °F (40 °C)

DC Construction (6.9W)

-40 °F(-40 °C) to 125 °F (52 °C)

(See asterisk [*] in DESCRIPTION section)

Positioning

Solenoid may be mounted in any position

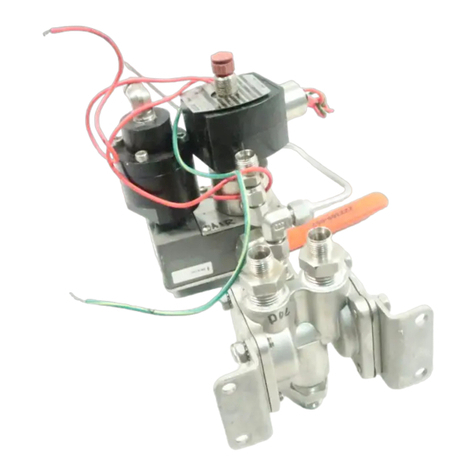

Valve Mounting

This solenoid is assembled to a valve that must be rigidly supported

using the valve body mounting provisions.

WARNING

ADVERTISSEMENT

NOTICE: See separate valve installation and maintenance

instructions for information on: Operation, Positioning, Mounting,

Cleaning, Preventive Maintenance, Cause of Improper Operation,

Disassembly and Reassembly of basic valve.

Wiring

To reduce the risk of electrocution, re, or

property damage, wiring must comply with local codes and

the National Electrical Code (NEC).

Pour réduire les risques

d’électrocution, d’incendie ou de dommages matériels, le

câblage doit être conforme aux codes locaux et au NEC.

To facilitate wiring, the solenoid may be rotated 360° in 90°

increments. To rotate solenoid, remove retaining cap (if present)

and four mounting screws, reposition solenoid and replace screws

and retaining cap (if present). Torque screws evenly in a crisscross

manner to 12 in -lbs [1,3 Nm]. Torque retaining cap to 10-12 in - lbs

[1,1-1,3 Nm] using a 21/32” socket.

The solenoid must be grounded with

included grounding wire - do not rely on process pipes for

grounding.

La bobine doit être mise

à la terre avec le l de terre inclus - ne vous ez pas aux

canalisations pour la mise à la terre.

Solenoids have a ½ - 14 NPT male thread. For connection to rigid

metal conduit, metal type NPT electrical fittings should be used or

use ASCO Part Number 264568-001, supplied.

For the explosionproof solenoid (EF8004A1), the female ½ - 14

NPT conduit connector comes preassembled and makes up the full

hazardous location solenoid assembly. Any additional required

electrical fittings must be approved for use in hazardous locations.

Solenoid Temperature

Standard solenoids are designed for continuous duty service. When

the solenoid is energized for a long period, the solenoid becomes

hot and can be touched by hand only for an instant. This is a safe

operating temperature.

MAINTENANCE

To prevent the possibility of death,

serious injury or property damage, turn o electrical power,

depressurize solenoid valve and vent uid to a safe area

before servicing,

Afin d’éviter tout risque de mort,

blessure ou dommage, couper l’alimentation électrique,

dépressuriser la vanne ou l’électrovanne et vidanger le fluide en

zone non dangereuse avant toute maintenance.

Potential Electrostatic Charging Hazard.

Use wet or damp cloth when cleaning coil, non-metallic pilot

or valve body (if applicable).

Risque de charges électrostatiques

en atmosphères explosibles. Utiliser un chion humide

ou mouillé lors du nettoyage de la bobine, Corps de pilote

ou de vanne non métallique (si applicable).

Cleaning (also, see above)

All solenoid operators and valves should be cleaned periodically.

Time between cleaning will vary depending on medium and service

conditions. In general, if the voltage to the solenoid is correct,

sluggish valve operation, excessive noise or leakage will indicate

that cleaning is required. In the extreme case faulty valve or

solenoid operation will occur and the valve or solenoid may fail to

shift. Clean strainer or filter when cleaning the valve.

WARNING

ADVERTISSEMENT

WARNING

ADVERTISSEMENT

WARNING

ADVERTISSEMENT

WARNING

ADVERTISSEMENT