Page 2 of 3 I&M No. V_5590_R5

©ASCO Valve, Inc.50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Solenoid Temperature

Standard catalog valves are supplied with coils designed for continuous

duty service. When the solenoid is energized for a long period, the

solenoid enclosure becomes hot and can be touched with the hand only

for an instant. This is a safe operating temperature. Any excessive

heating will be indicated by the smoke and odor of burning coil

insulation.

MAINTENANCE

WARNING: Turn off electrical power supply

and depressurize valve before making repairs. It

is not necessary to remove valve from pipe line

for repairs.

AVERTISSEMENT: Couper l’alimentation

électrique et dépressuriser la vanne avant

d’effectuer des réparations. Il n’est pas

nécessaire de retirer la vanne de la canalisation

pour effectuer des réparations.

Cleaning

Aperiodiccleaningofallsolenoidvalvesisdesirable.Thetimebetween

cleanings will vary, depending on media and service conditions. In

general, if the voltage to the coils is correct, sluggish valve operation,

excessive leakage or noise will indicate that cleaning is required. Be

sure to clean valve strainer or filter when cleaning solenoid valve.

Preventive Maintenance

• Keep the medium flowing through the valve as free from dirt and

foreign material as possible

• While in service, operate valve at least once a month to insure

proper opening and closing.

• Periodic inspection (depending on media and service conditions) of

internal valve parts for damage or excessive wear is recommended.

Thoroughly clean all parts. Replace any parts that are worn or

damaged.

Causes of Improper Operation

• Faulty Control Circuit: Check electrical system by energized

solenoid. A metallic click signifies the solenoid is operating.

Absence of the click indicates loss of power supply. Check for

loose or blown-out fuses, open circuited or grounded coil, broken

lead wires or splice connection.

• Burned-Out Coil: Check for open circuited coil. Replace coil if

necessary.

• Low Voltage: Check voltage across coil leads. Voltage must be at

least 85% of nameplate rating.

• Incorrect Pressure: Check valve pressure. Pressure to valve must be

within range specified on nameplate

• Excessive Leakage: Disassemble valve and clean all parts. Replace

worn or damaged parts with a complete Spare Parts Kit for best

results.

Coil Replacement

Turn off electrical power supply and disconnect coil lead wires.

Proceed in the following manner:

1. Remove retaining cap or clip, nameplate and cover.

CAUTION: When metal retaining clip disengages, it will

spring upward.

ATTENTION: Lorsque le clip de maintien métallique est

dégagé de sa position, il va s’éjecter vers l’extérieur.

2. Slip yoke containing coil, sleeves and insulating washers off the

solenoid base sub-assembly. For D-C Construction, slip spring

washer, coil and insulating washers off solenoid base sub-assembly.

Insulating washers are omitted when a molded coils is used.

3. Reassemble in reverse order of disassembly paying careful attention

to exploded views provided for identification and placement of parts

CAUTION: Solenoid must be fully reassembled as the

housing and internal parts are part of and complete the

magnetic circuit. Place insulating washers at each end of

coil if required.

ATTENTION: La tête magnétique doit être entièrement

remontée car le boîtier et les pièces internes complètent

le circuit magnétique. Si nécessaire placer des rondelles

isolantes à chaque extrémité de la bobine.

Valve Disassembly

1. Depressurize valve and turn off electrical power supply. Proceed in

the following manner:

2. Remove retaining cap or clip and slip entire solenoid enclosure off

the solenoid base sub-assembly.

CAUTION: When metal retaining clip disengages, it will

spring upward.

ATTENTION: Lorsque le clip de maintien métallique est

dégagé de sa position, il va s’éjecter vers l’extérieur.

3. Unscrew solenoid base sub-assembly and remove bonnet gasket,

core assembly and core spring.

4. For A-C Construction without manual operator, remove valve

bonnet screws (4) and remove solenoid base sub-assembly, core

assembly and core spring.

5. Remove diaphragm spring (A-C Construction only), diaphragm

assembly and body gasket.

6. For normal maintenance, it is not necessary to disassemble the

manual operator unless external leakage is evident.To disassemble,

remove stem pin, manual operator stem, stem spring and stem

gasket.

7. All parts are now accessible for cleaning or replacement. Replace

worn or damaged parts with a complete Spare Parts Kit for best

results.

Valve Reassembly

1. Reassemble in reverse order of disassembly paying careful attention

to exploded views provided for identification and placement of

parts.

2. Replace body gasket and diaphragm assembly. Locate bleed hole in

diaphragm assembly approximately 45° from valve outlet.

3. Replace valve bonnet and bonnet screws. Torque bonnet screws (4)

in a crisscross manner to 95 ± 10 inch pounds.

4. For A-C Construction without a manual operator, the diaphragm

spring, core assembly and core spring must be installed prior to

assembly of bonnet as the bonnet is the solenoid base sub-assembly.

Be sure diaphragm spring is installed properly. Large end of spring

to seat on diaphragm assembly. For valve with a manual operator,

the small end of spring seats on diaphragm assembly.

5. Insert core spring into core assembly, core spring and solenoid base

sub-assembly. Torque solenoid base sub-assembly to 175 ± 25 inch

pounds.

6. If removed, replace manual operator stem gasket, stem spring, stem

and stem pin.

7. Replace solenoid enclosure and retaining cap or clip.

8. After maintenance, operate the valve a few times to be sure of

proper opening and closing.

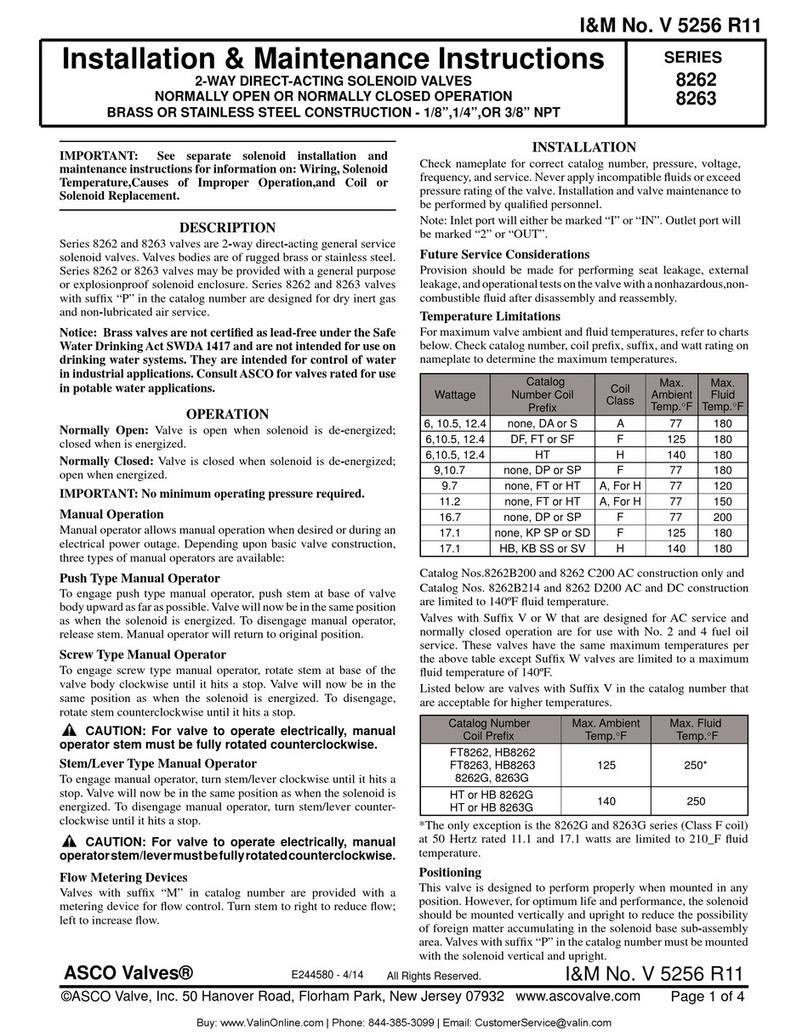

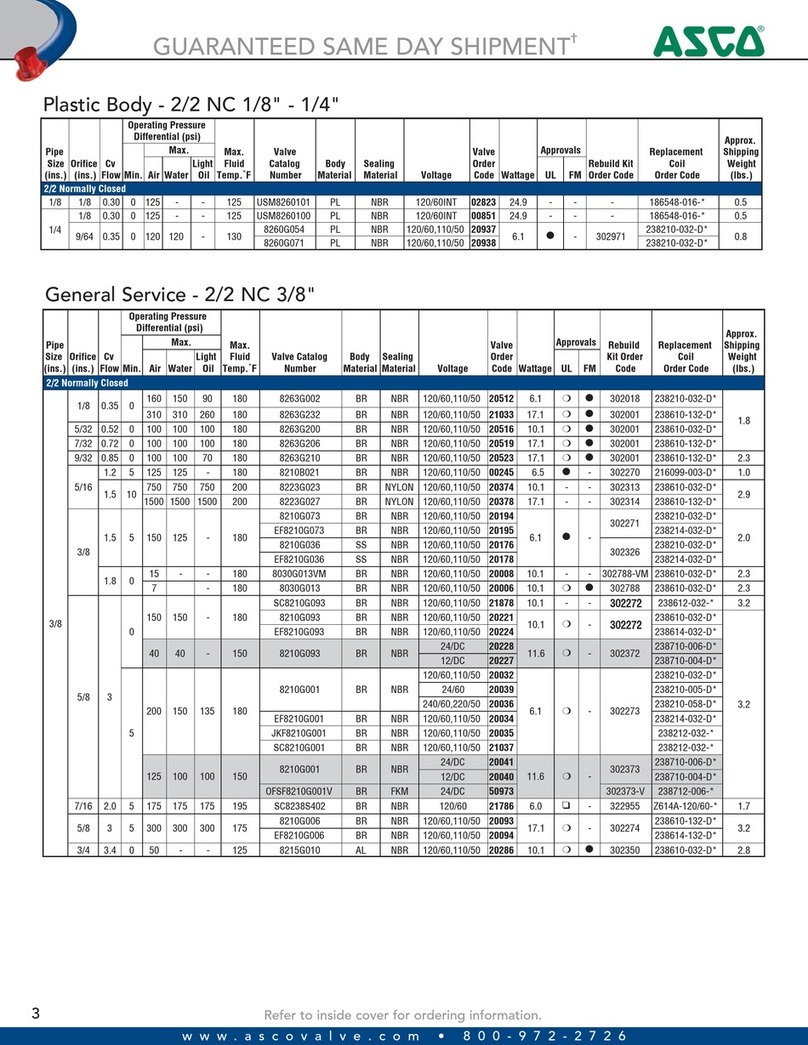

ORDERING INFORMATION FOR

ASCO REBUILD KITS

Spare Parts Kits and Coils are available for ASCO valves. Parts

marked with an asterisk (*) are supplied in Spare Parts Kits. When

Ordering Rebuild Kits forASCO valves, order the Rebuild Kit number

stamped on the valve nameplate. If the number of the kit or the coil

is not visible, order by indicating the number of kits required, and the

Catalog Number and Serial Number of the valve(s) for which they are

intended.