Page 2 of 8 (Section 1 of 2)

ASCO Valve, Inc.50 Hanover Road, lorham Park, New Jersey 07932 www.ascovalve.com

I&M No.V9564R4

WARNING: To prevent the possibility of death,

serious injury or property damage, only use the

optional ASCO connecting hardware kit for the direct

connection of these valves to one another. Complete

instructions and guidelines for piping the valves

together are included with the kit.

CAUTION: To avoid damage to the valve body, DO

NOT OVERTIGHTEN PIPE CONNECTIONS. If PTFE

tape, paste, spray, or similar lubricant is used, use extra

care when tightening due to reduced friction.

CAUTION: To protect the solenoid valve, install a

strainer or filter, suitable for the service involved, in the

inlet side as close to the valve as possible. Clean

periodically depending on service conditions. See

ASCO Series 8600 and 8601 for strainers.

Testing for External Leakage

WARNING: To prevent the possibility of death,

serious injury or property damage, turn off

electrical power, depressurize valve, extinguish

all open flames and avoid any type of sparking or

ignition. Vent hazardous or combustible fluid to

a safe area before servicing the valve.

1. Block gas flow on downstream side of valve.

2. Apply pressure to valve within nameplate rating and

energize solenoid.

3. Apply a soapy solution or a commercially availa le leak

detecting solution to the pipe connections and check for

u les. If the valve has een tested for seat leakage or

disassem led and reassem led for inspecting, cleaning,

or re uilding apply the solution around solenoid ase

su ---assem ly, onnet/ ody joint and pipe plugs.

4. If leakage exists, depressurize valve and turn off

electrical power supply. Tighten connections as required

and retest following the a ove steps.

Wiring (Electrical Position Indicator)

Wiring must comply with local codes and the National

Electrical Code. Switch housing has a 1/2conduit

connection. The position indicator switch has een preset at

the factory. This switch is not to e field adjusted. Position

indicator housing assem ly can e rotated 360for

desira le visual position. Position indicator is furnished

standard with one reed switch having a single contact to

open when the valve is in the open position. The switch

rating is 1 amp maximum, 120/60 AC maximum and 15

volts---amps maximum (Resistive Load) or 1 amp

maximum, 120 volts DC maximum and 15 watts maximum

(Resistive Load). For lamp and inductive loads, contact

protection is required.

MAINTENANCE

WARNING: To prevent the possibility of

death, severe injury or property damage, turn off

electrical power, depressurize valve, extinguish

all open flames and avoid any type of sparking or

ignition. Vent hazardous or combustible fluid to

a safe area before servicing the valve.

Cleaning

All solenoid valves should e cleaned periodically. Thetime

etween cleanings will vary depending on the medium and

service conditions. In general, if the voltage to the coil is

correct, sluggish valve operation, excessive noise or leakage

will indicate that cleaning is required. In the extreme case,

faulty valve operation will occur and the valve may fail to

open or close. Clean strainer or filter when cleaning the

valve.

Preventive Maintenance

Keep the medium flowing through the valve as free from

dirt and foreign material as possi le.

Periodic exercise of the valve should e considered if

am ient or fluid conditions are such that corrosion,

elastomer degradation, fluid contamination uild up, or

other conditions that could impede solenoid valve

shifting are possi le. The actual frequency of exercise

necessary will depend on specific operating conditions. A

successful operating history is the est indication of a

proper interval etween exercise cycles.

Depending on the medium and service conditions,

periodic inspection of internal valve parts for damage or

excessive wear is recommended. Thoroughly clean all

parts. If parts are worn or damaged, install a complete

re uild kit. Re uild kits are not availa le for valves with

Electrical Position Indicator Switch (Suffix ’C’). If parts

are worn or damaged on (Suffix ’C’) valves, replace valve.

Causes of Improper Operation

Incorrect Pressure: Check valve pressure. Pressure to

valve must e within range specified on nameplate.

Excessive Leakage: Disassem le valve and clean all parts.

If parts are worn or damaged,install a complete re uild kit.

Re uild Kits are not availa le for valves with Electrical

Position Indicator Switch (Suffix ’C’). If parts are worn or

damaged on (Suffix ’C’) valves, replace valve.

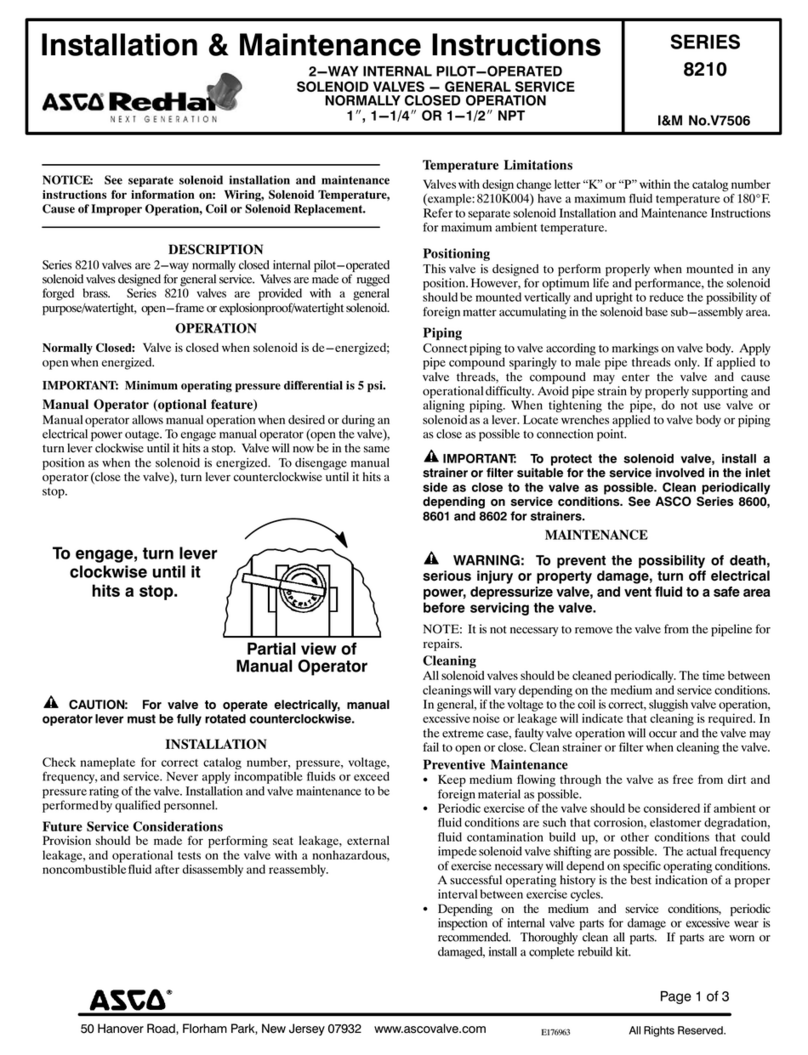

Valve Disassembly

NOTE: Determine valve construction AC (Figure 2 on page

4) or DC (Figure 5 on page 7) then proceed as follows:

1. Remove solenoid enclosure, see separate instructions. If

position indicator construction is present, refer to

appropriate instructions regarding disassem ly,

reassem ly or adjustment.

2. For AC Construction, unscrew solenoid ase

su ---assem ly. For DC Construction, unscrew solenoid

ase su ---assem ly with special wrench adapter

provided in ASCO Re uild Kit. For wrench adapter only,

order kit No. 218949. NOTE: For alternate type open

end wrench, order kit No. 168146---001 which is availa le

for solenoid ase su ---assem ly removal or

replacement.

3. Remove onnet screws, valve onnet, onnet gasket,

core/diaphragm su ---assem ly, and ody gasket.

4. All parts are now accessi le to clean or replace. If parts

are worn or damaged, install a complete re uild kit.

Re uild Kits are not availa le for valves with Electrical

Position Indicator Switch (Suffix ’C’). If parts are worn

or damaged on (Suffix ’C’) valves, replace valve.