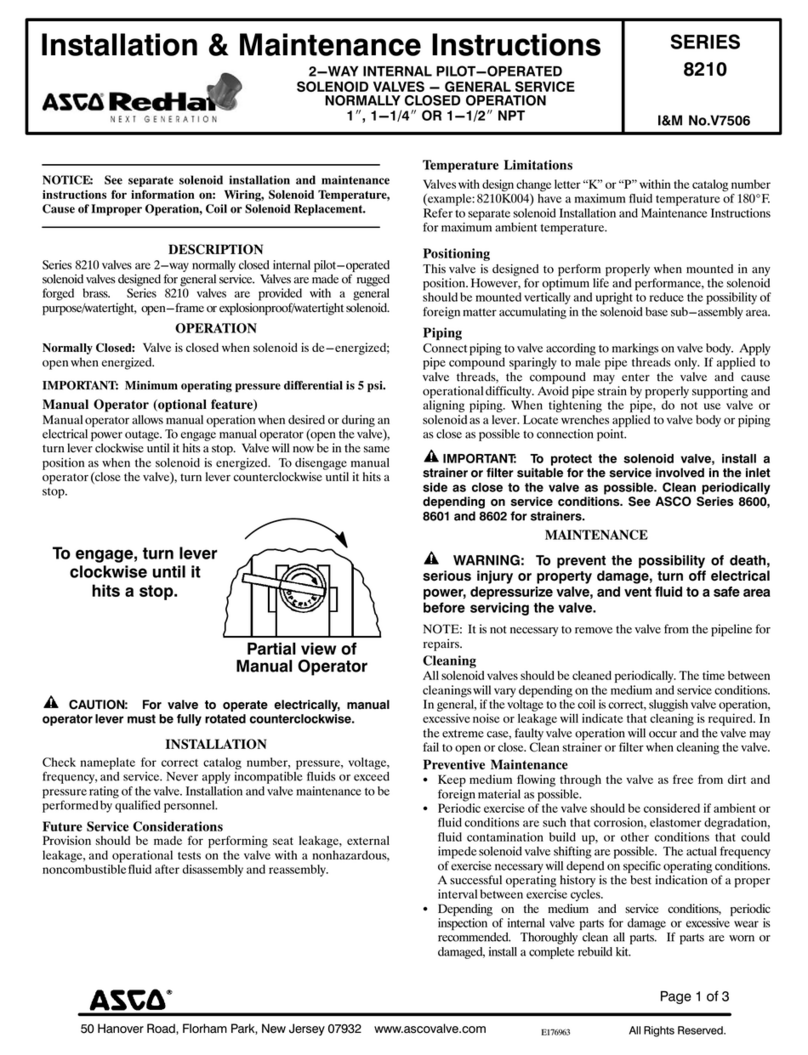

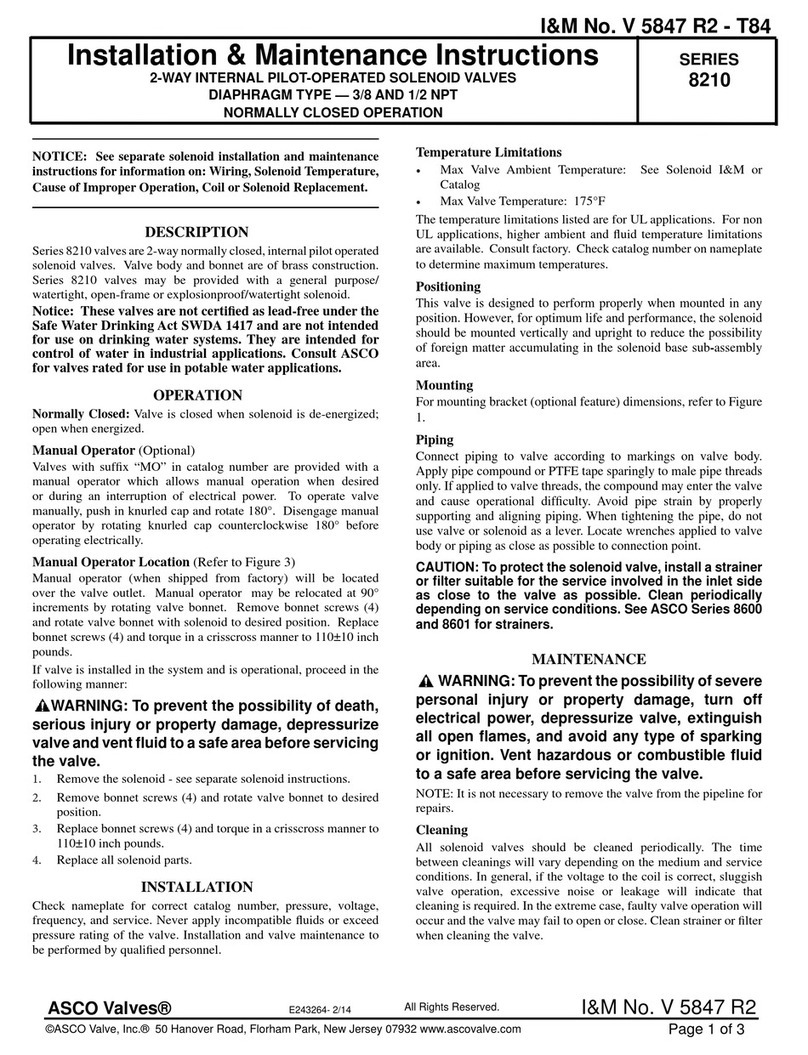

Installation & Maintenance Instructions

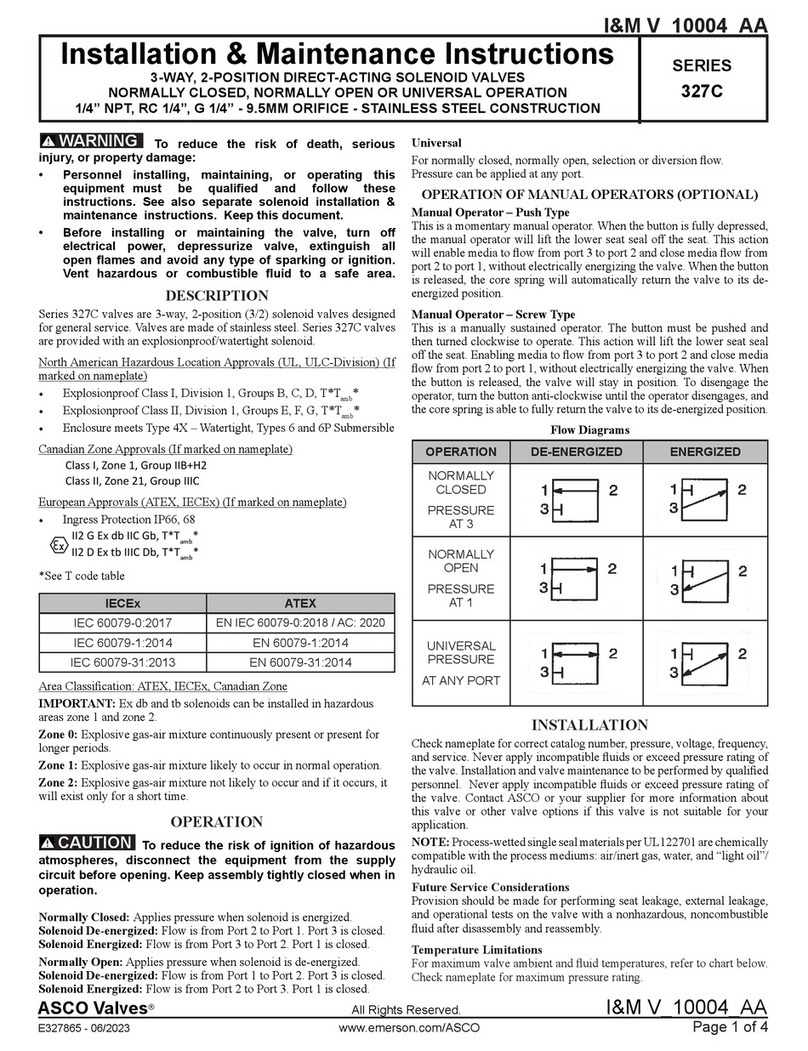

2-WAY INTERNAL PILOTED-OPERATED SOLENOID VALVES

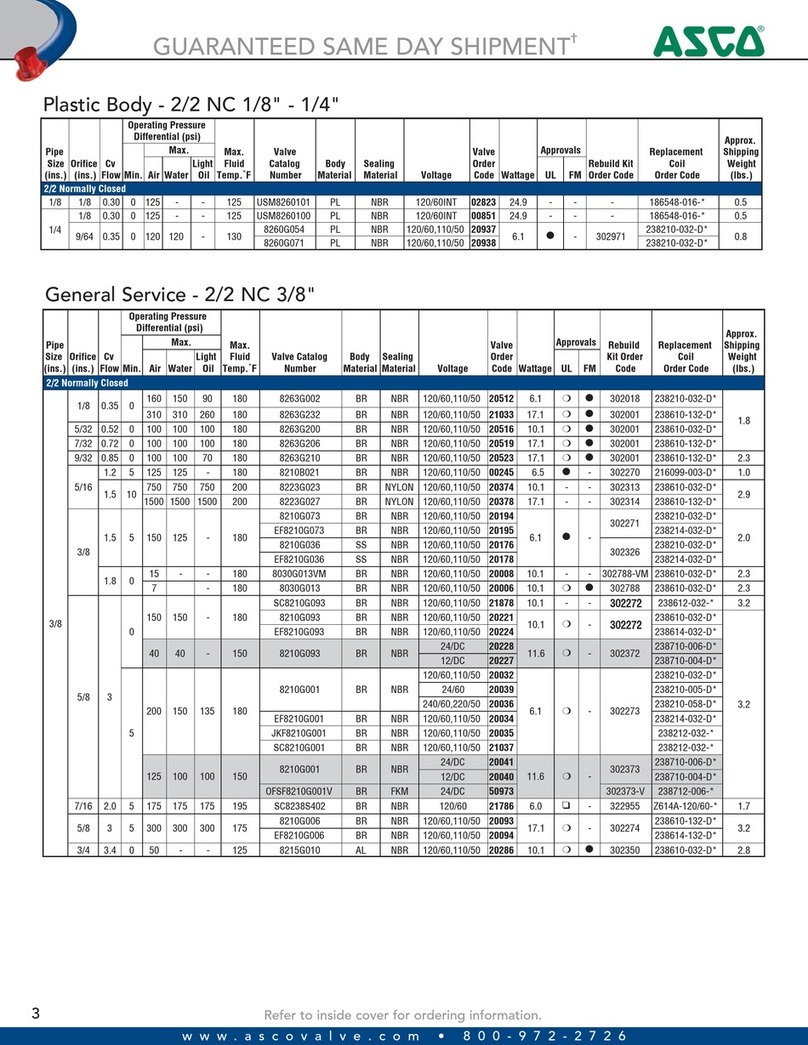

NORMALLY OPEN OPERATION — GENERAL SERVICE

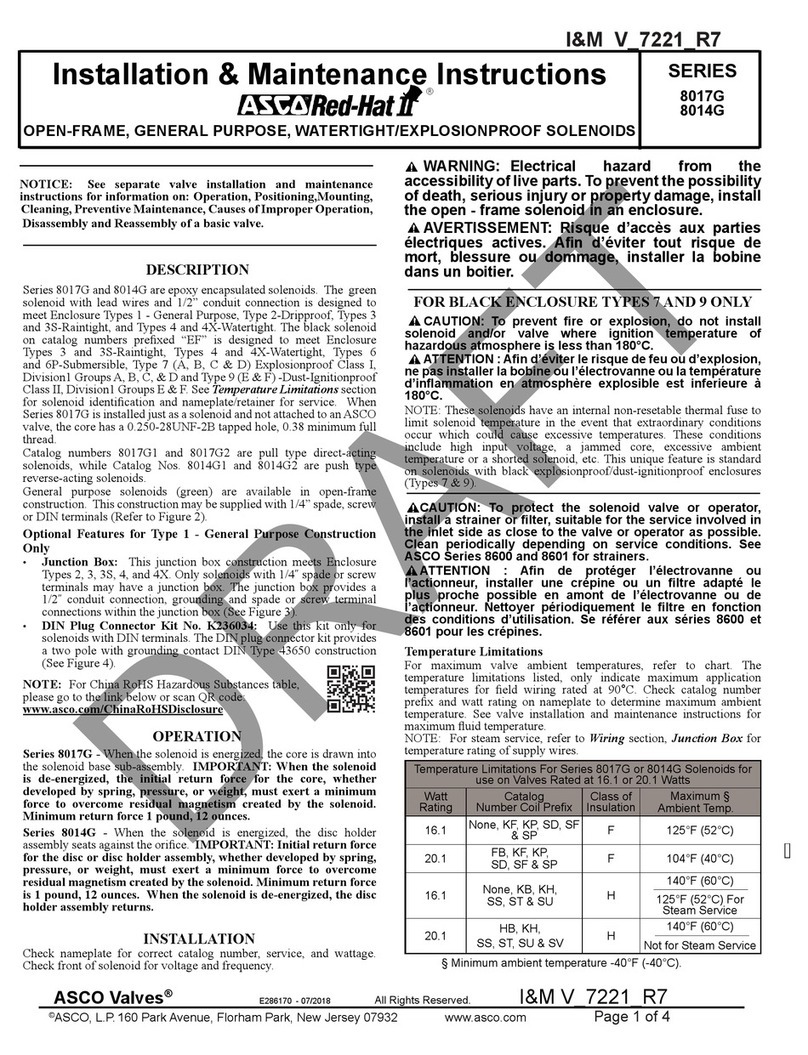

3/4"NPT

SERIES

8210

8211

[52,4]

2.062

.343 dia. (2 holes)

[Ø8,7]

NOTICE: See separate solenoid installation and maintenance

instructions for information on: Wiring, Solenoid Temperature,

Cause of Improper Operation, Coil or Solenoid Replacement.

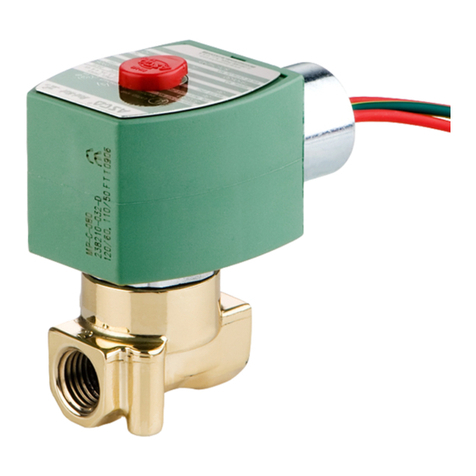

DESCRIPTION

Series 8210 valves are 2-way normally open internal pilot-operated

solenoid valves designed for general service. Valves are made of rugged

forged brass. Series 8210 valves are provided with a general purpose

solenoid enclosure.

Series EF8210 and 8211 are the same as Series 8210 except they are

provided with an explosionproof or explosionproof/watertight solenoid

enclosure.

Notice: These valves are not certified as lead-free under the Safe

Water Drinking Act SWDA 1417 and are not intended for use on

drinking water systems. They are intended for control of water in

industrial applications. Consult ASCO for valves rated for use in

potable water applications.

OPERATION

Normally Open: Valve is open when solenoid is de-energized; closed

when energized.

IMPORTANT: Minimum operating pressure differential required

is 5 psi.

Manual Operator (optional feature)

Manual operator allows manual operation when desired

or during an electrical power outage. To engage manual

operator (close the valve), insert screwdriver and turn

stem clockwise until it stops. Valve will now be in the

same position as when the solenoid is energized. To disengage manual

operator (open the valve), turn stem counterclockwise until it stops.

CAUTION: For valve to operate electrically, manual

operator stem must be fully rotated counterclockwise.

INSTALLATION

Check nameplate for correct catalog number, pressure, voltage,

frequency, and service. Never apply incompatible fluids or exceed

pressure rating of the valve. Installation and valve maintenance to be

performed by qualified personnel.

Future Service Considerations

Provision should be made for performing seat leakage, external leakage,

and operational tests on the valve with a nonhazardous, noncombustible

fluid after disassembly and reassembly.

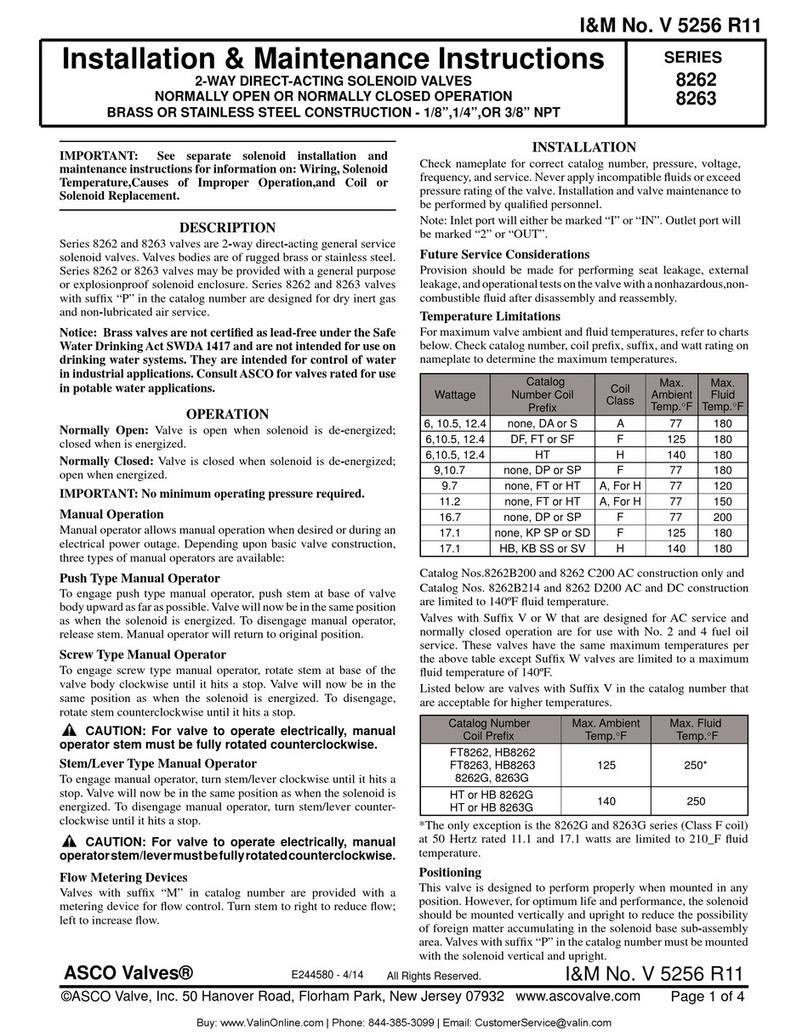

Temperature Limitations

For maximum valve ambient and fluid temperatures, refer to chart

below. Check catalog number and watt rating on nameplate.

Positioning

This valve is designed to perform properly when mounted in any

position. However, for optimum life and performance, the solenoid

should be mounted vertically and upright to reduce the possibility of

foreign matter accumulating in the solenoid base sub-assembly area.

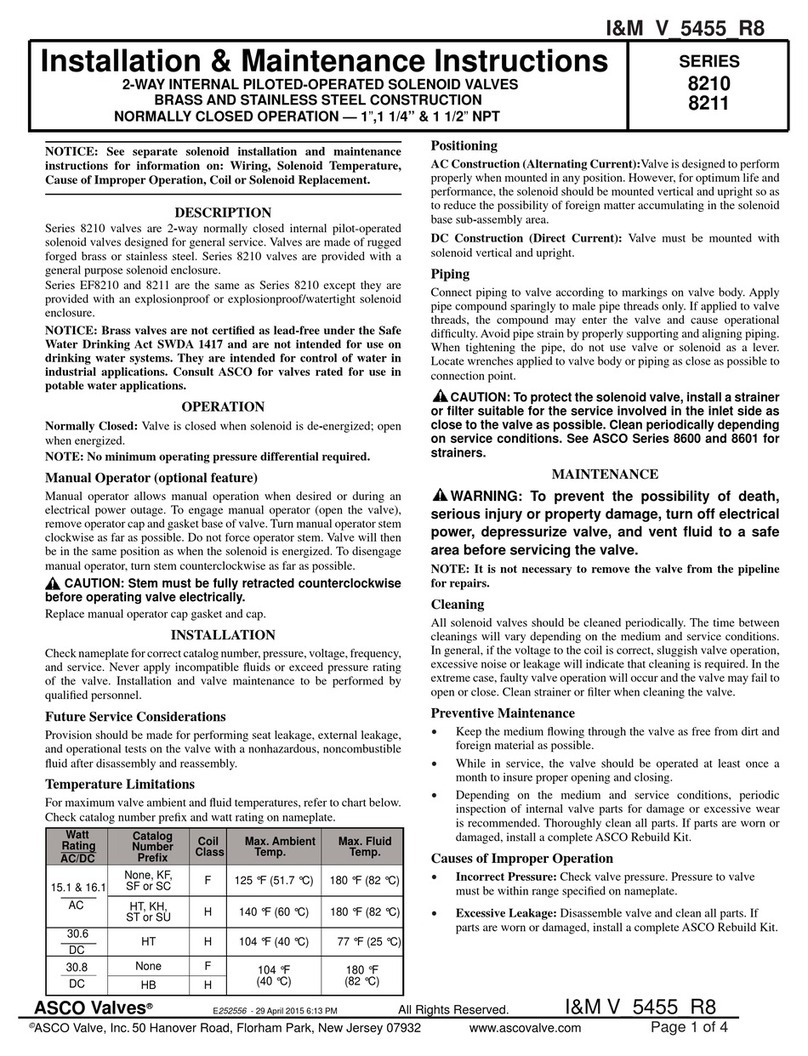

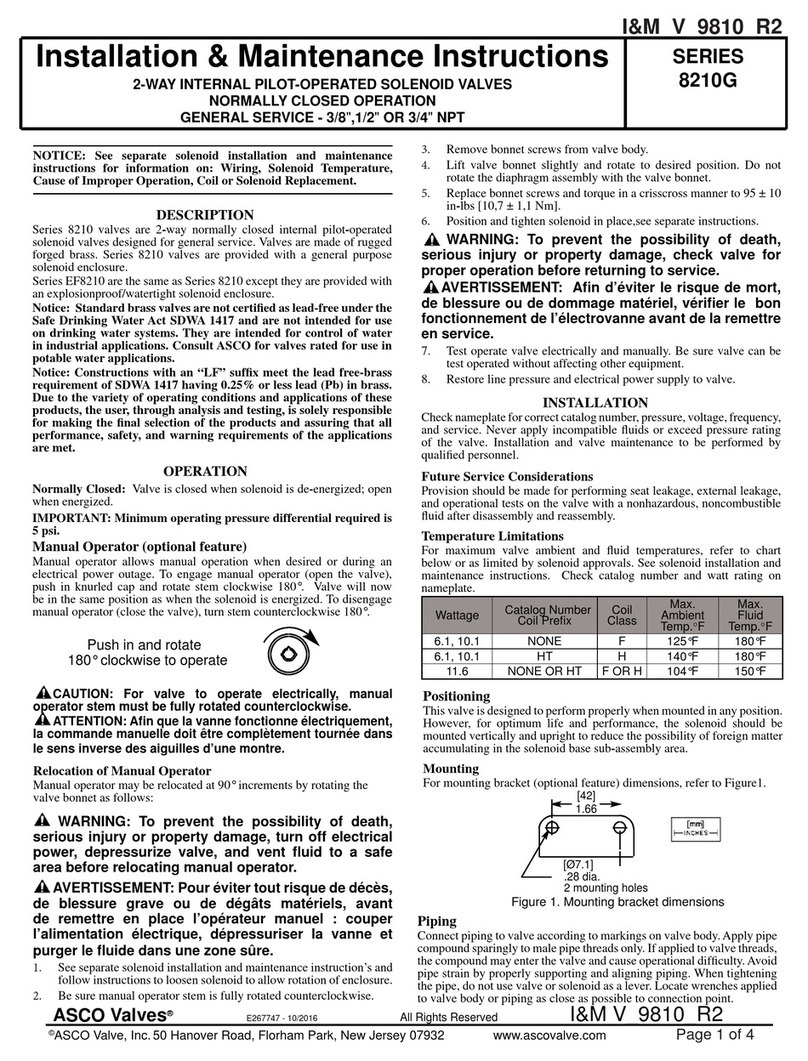

Mounting

For mounting bracket (optional feature) dimensions, refer to Figure1.

Piping

Connect piping to valve according to markings on valve body. Apply

pipe compound sparingly to male pipe threads only. If applied to valve

threads, the compound may enter the valve and cause operational

difficulty. Avoid pipe strain by properly supporting and aligning piping.

When tightening the pipe, do not use valve or solenoid as a lever.

Locate wrenches applied to valve body or piping as close as possible to

connection point.

CAUTION: To protect the solenoid valve, install a strainer

or filter suitable for the service involved in the inlet side as

close to the valve as possible. Clean periodically depending

on service conditions. See ASCO Series 8600 and 8601 for

strainers.

MAINTENANCE

WARNING: To prevent the possibility of death,

serious injury or property damage, turn off electrical

power, depressurize valve, and vent fluid to a safe

area before servicing the valve.

NOTE: It is not necessary to remove the valve from the pipeline for

repairs.

Cleaning

All solenoid valves should be cleaned periodically. The time between

cleanings will vary depending on the medium and service conditions.

In general, if the voltage to the coil is correct, sluggish valve operation,

excessive noise or leakage will indicate that cleaning is required. In the

extreme case, faulty valve operation will occur and the valve may fail to

open or close. Clean strainer or filter when cleaning the valve.

Preventive Maintenance

• Keep the medium flowing through the valve as free from dirt and

foreign material as possible.

• While in service, the valve should be operated at least once a month

to insure proper opening and closing.

• Depending on the medium and service conditions, periodic

inspection of internal valve parts for damage or excessive wear

is recommended. Thoroughly clean all parts. If parts are worn or

damaged, install a complete ASCO Rebuild Kit.

I&M No. V 5826 R4

Figure 1. Mounting bracket dimensions

ASCO Valves® All Rights Reserved. I&M No. V 5826 R4

©ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

E243876- 3/14 Page 1 of 3

Watt

Rating

AC or DC

Catalog

Number

Prefix

Solenoid

Class

Max.

Amb.

Temp.

Max.

Fluid

Temp.

15.4 OR 16.1

AC

None, KF, SF

or SC F125 °F

(51.7 °C) 180 °F

(82°C)

HT, KH, ST or

SU H140 °F

(60 °C) 180 °F

(82°C)

16.8

DC None or HT F or H 77 °F

(25°C) 180 °F

(82°C)