Page 2 of 4 I&M No. V_9810_R2

©ASCO Valve, Inc.50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

CAUTION: To protect the solenoid valve, install a strainer

or filter suitable for the service involved in the inlet side as

close to the valve as possible. Clean periodically depending

on service conditions. See ASCO Series 8600 and 8601 for

strainers.

ATTENTION : Afin de protéger l’électrovanne ou

l’actionneur, installer une crépine ou un filtre adapté le

plus proche possible en amont de l’électrovanne ou de

l’actionneur. Nettoyer périodiquement le filtre en fonction des

conditions d’utilisation. Se référer aux séries 8600 et 8601

pour les crépines.

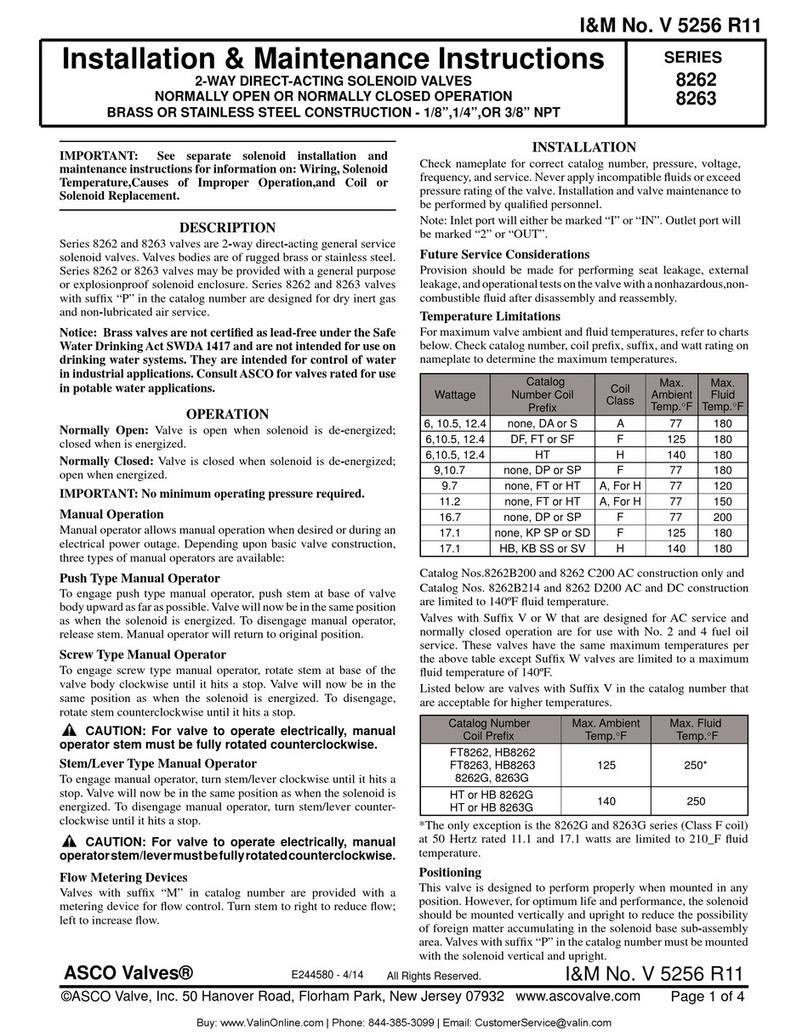

MAINTENANCE

WARNING: To prevent the possibility of death,

serious injury or property damage, turn off electrical

power, depressurize valve, and vent fluid to a safe

area before servicing the valve.

AVERTISSEMENT: Pour éviter tous danger de mort,

de blessure grave ou de dommage matériel, avant

d’intervenir sur la vanne, couper le courant, purger la

vanne dans une zone sécurisée.

NOTE: It is not necessary to remove the valve from the pipeline for

repairs.

Cleaning

All solenoid valves should be cleaned periodically. The time between

cleanings will vary depending on the medium and service conditions.

In general, if the voltage to the coil is correct, sluggish valve operation,

excessive noise or leakage will indicate that cleaning is required. In the

extreme case, faulty valve operation will occur and the valve may fail to

open or close. Clean strainer or filter when cleaning the valve.

Preventive Maintenance

• Keep the medium flowing through the valve as free from dirt and

foreign material as possible.

• While in service, the valve should be operated at least once a month

to ensure proper opening and closing.

• Depending on the medium and service conditions, periodic

inspection of internal valve parts for damage or excessive wear

is recommended. Thoroughly clean all parts. If parts are worn or

damaged, install a complete ASCO Rebuild Kit.

Causes of Improper Operation

• Incorrect Pressure: Check valve pressure. Pressure to valve must

be within range specified on nameplate.

• Excessive Leakage: Disassemble valve and clean all parts. If parts

are worn or damaged, install a complete ASCO Rebuild Kit.

Valve Disassembly

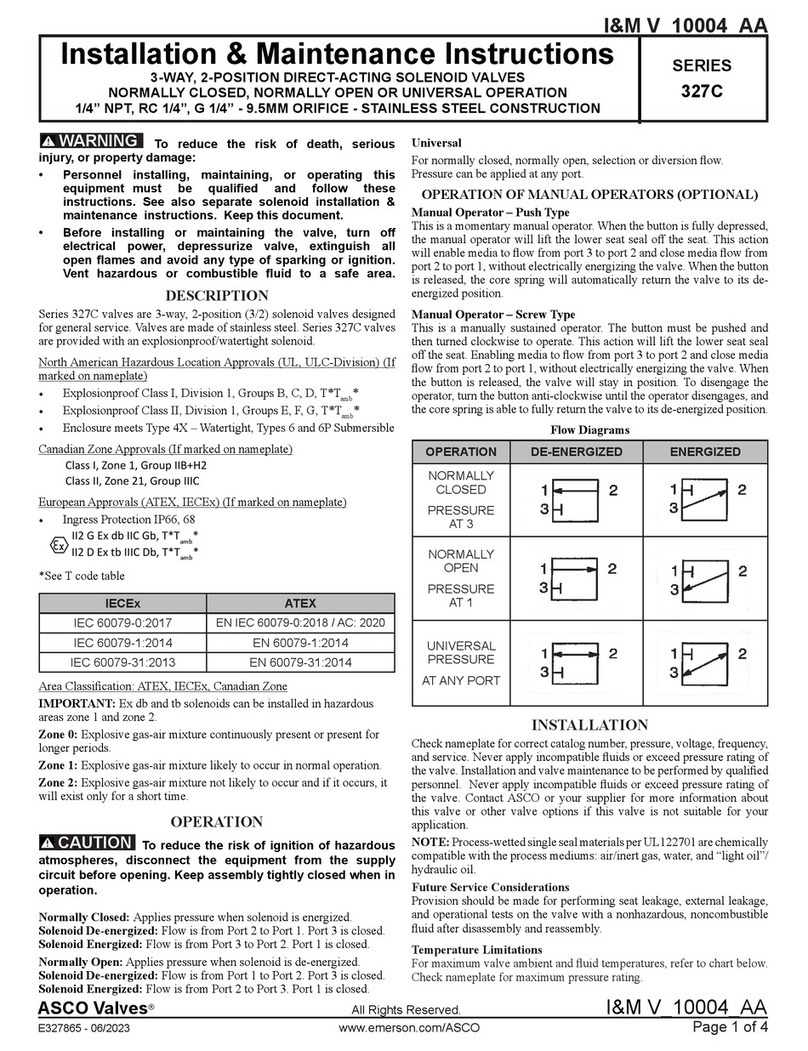

1. Disassemble valve in an orderly fashion using exploded views

for identification and placement of parts. Refer to Figure 2 for

AC construction; Figure 3 for DC construction.

2. Remove solenoid enclosure. See separate instructions.

• For AC construction (standard or with manual operator), proceed

as follows:

3. For standard construction, remove bonnet screws, solenoid base

sub-assembly, core spring, core assembly, diaphragm spring,

diaphragm assembly and body gasket from valve body.

4. For manual operator constructions, unscrew solenoid base sub-

assembly first then follow step 3 for removal of parts.

5. For normal maintenance (cleaning) it is not necessary to

disassemble the manual operator unless an ASCO Rebuild Kit

is being installed. To disassemble, remove stem pin, manual

operator stem, stem spring and stem gaskets (2).

• For DC construction (standard or with manual operator), proceed

as follows:

6.Unscrew solenoid base sub-assembly first then follow step 3

and 5 for removal of parts.

Note: Diaphragm spring is omitted for DC construction.

7. All Parts are now accessible for cleaning or replacement. If

parts are worn or damaged, install a complete ASCO Rebuild

Kit.

Valve Reassembly

1. Lubricate body gasket and solenoid base gasket with

Xiameter®PMX 200 Silicone Fluid or an equivalent high-grade

silicone fluid.

2. Lubricate manual operator stem gaskets (2) with Molykote®111

Compound or equivalent high-grade silicone grease.

3. Replace body gasket and diaphragm assembly. Locate bleed hole

in diaphragm assembly approximately 45°from valve outlet.

• For AC construction (standard or with manual operator), proceed

as follows:

4. Position diaphragm spring on diaphragm assembly. Be sure large

end of diaphragm spring seats in cup of diaphragm assembly.

For manual operator constructions,small end of diaphragm

spring seats in cup of diaphragm assembly.

5. Install wide end of core spring in core assembly first, closed end

protrudes from top of core assembly.

6. For standard construction, position core assembly with core

spring and solenoid base sub-assembly (integral with bonnet)

over diaphragm spring and diaphragm assembly.

7. Install bonnet screws and hand thread screws as far as possible,

then torque bonnet screws in a crisscross manner to 95 ± 10 in-

lbs [10,7 ± 1,1 Nm].

8. For valve constructions with a manual operator, first install

valve bonnet and bonnet screws as described in step 7.

9. Install solenoid base gasket,core assembly with core spring and

solenoid base sub-assembly.

10. Torque solenoid base sub-assembly to 175 ± 25 in-lbs [19,8 ±

2,8 Nm].

11. For valves with a manual operator proceed as follows:

A. Install two manual operator stem gaskets on stem. Refer to

Step 2 for lubrication instructions.

B. Install stem spring and stem assembly with gaskets into

valve bonnet.

C. Push stem assembly into valve bonnet; align stem pin hole

and install stem pin.

D. Operate manual operator to be sure there is no

misalignment or binding. Then rotate manual operator

stem counterclockwise as far as possible.

• For DC construction (standard or with manual operator), proceed

as follows:

12. For standard or manual operator constructions, replace valve

bonnet and follow steps 7, 9 and 10. For manual operator

constructions, install core spring in core assembly following

step 5.

13. Install solenoid. See separate instructions.

WARNING: To prevent the possibility of death,

serious injury or property damage, check valve for

proper operation before returning to service. Also

perform internal seat and external leakage tests with a

nonhazardous, noncombustible fluid.

AVERTISSEMENT: Afin d’éviter le risque de mort,

de blessure ou de dommage matériel, vérifier le bon

fonctionnement de l’électrovanne avant de la remettre

en service. Contrôler aussi les fuites externe et interne

avec un fluide non dangereux.

14. Restore line pressure and electrical power supply to valve.

15. After maintenance is completed, operate the valve a few times

to be sure of proper operation. A metallic click signifies the

solenoid is operating.

ORDERING INFORMATION

FOR ASCO REBUILD KITS

Parts marked with an asterisk (*) in the exploded view are supplied in

Rebuild Kits. When Ordering Rebuild Kits for ASCO valves, order the

Rebuild Kit number stamped on the valve nameplate. If the number of

the kit is not visible, order by indicating the number of kits required, and

the Catalog Number and Serial Number of the valve(s) for which they

are intended.