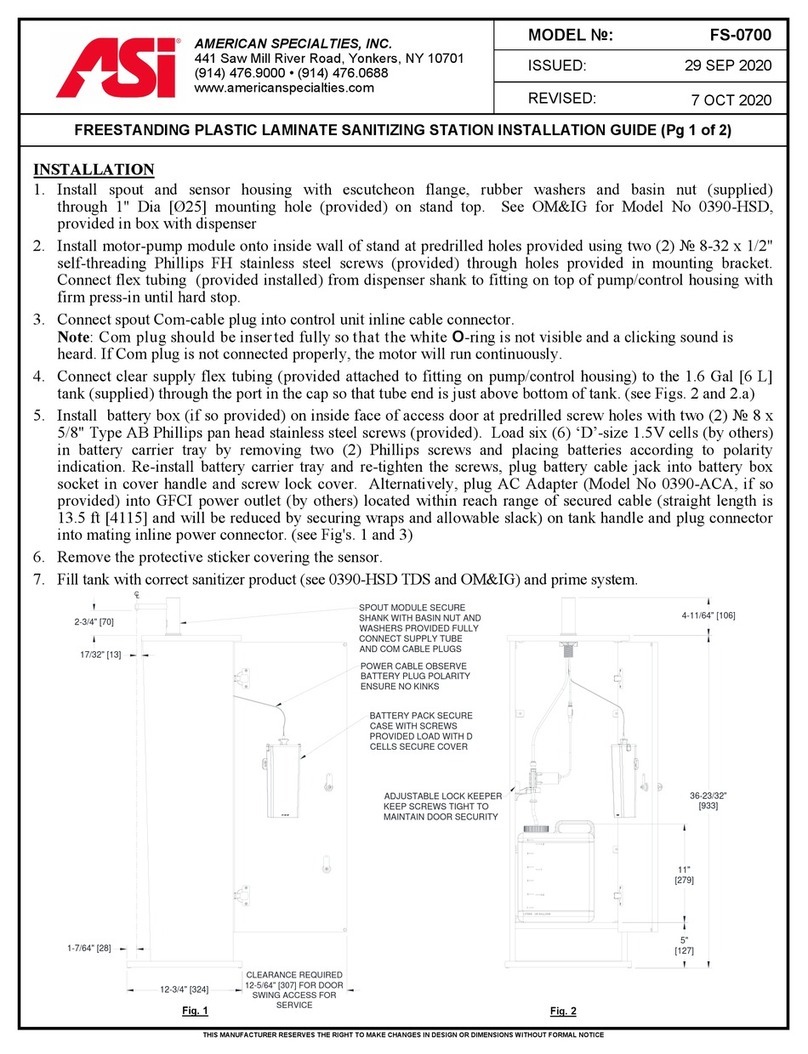

7. PERIODICALLY CLEAN THE TANK

(Every 10 soap refills or 6 months, whichever is sooner)

1. Disconnect the power supply.

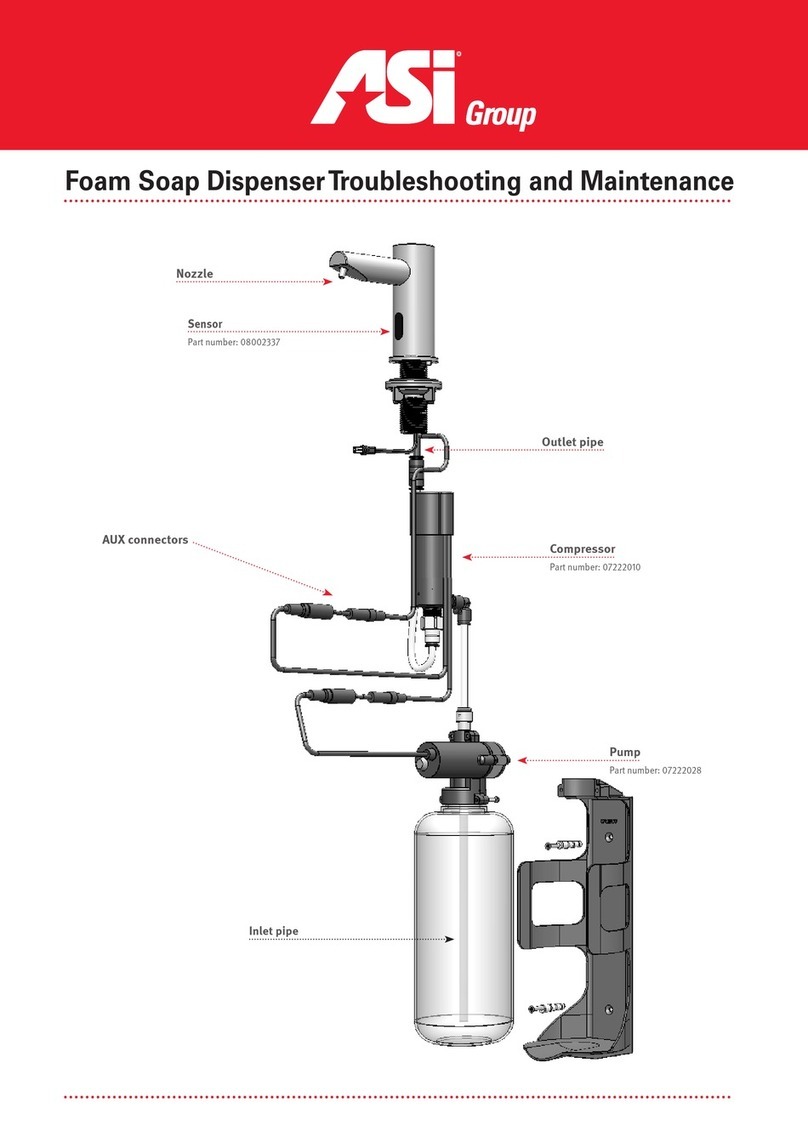

2. Disconnect the corrugated soap tube (A), the air-venting tube (B), the soap tube (C),

and the two soap level sensors (D & E). (A,B,C,D,E. Fig. 1 below, right)

Retain the rubber washer inside of the corrugated soap tube.

Remove tank from mounting bracket.

3. Fill the soap tank with water and shake it lightly.

Manually press the soap pump a few times

(full strokes, 3~8 times) to allow water to rinse

through and clean the soap pump.

4. Reinstall the corrugated soap tube

(with rubber washer {item 19} reinstalled

into coupler), the venting tube,

the soap tube, and the two soap level

sensors disconnected in step 2 above.

(A,B,C,D,E. Fig. 1 below, right).

Reinstall the soap tank into

the mounting bracket.

5. Reconnect the AC Adapter plug into the socket.

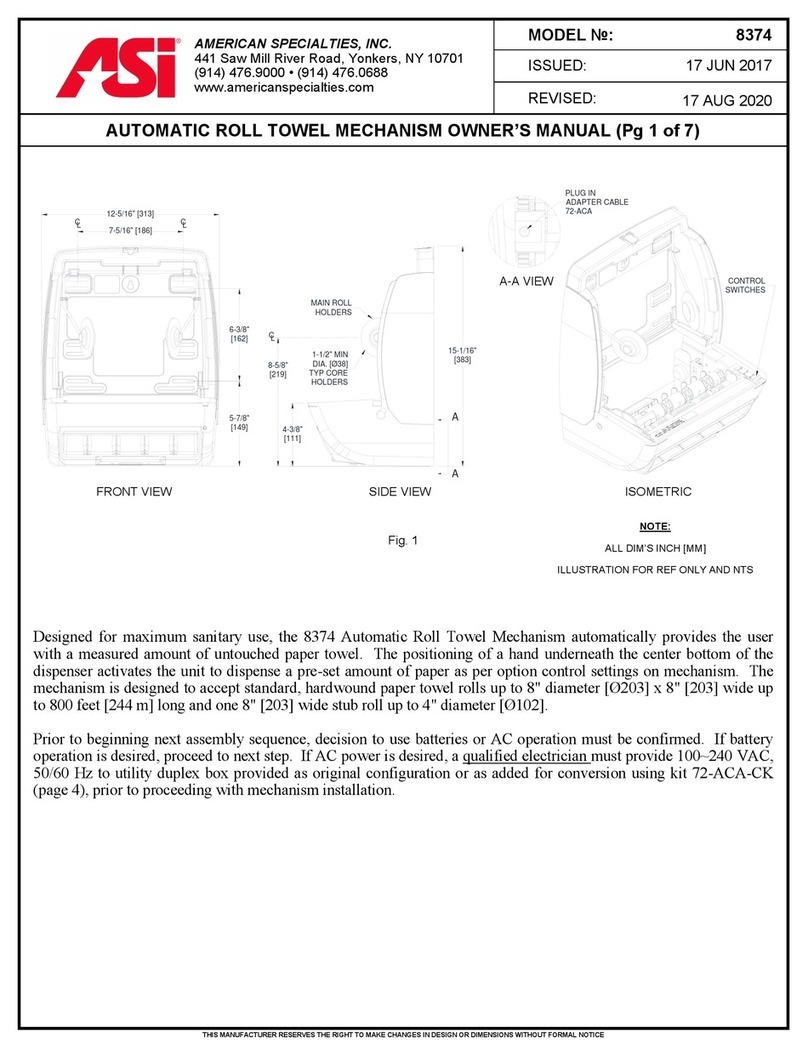

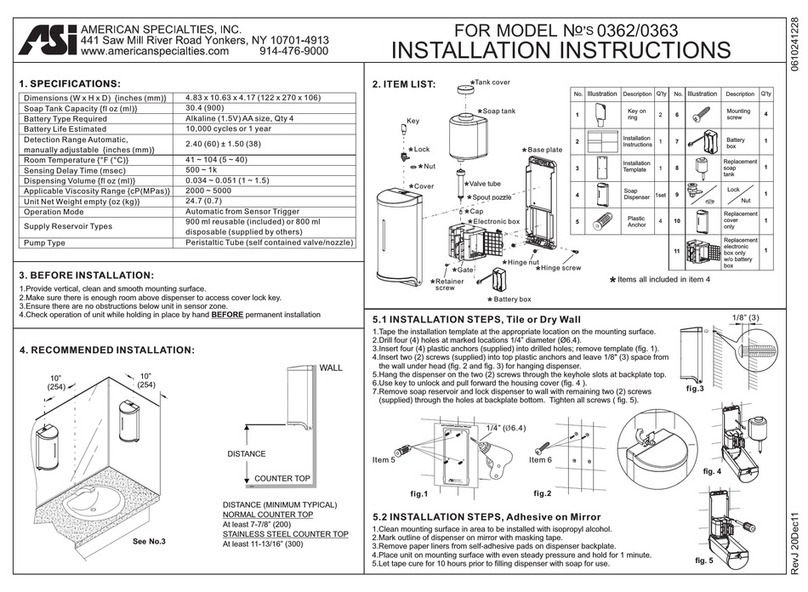

8. SENSING RANGE

Sensing is automatically controlled to set the appropriate distance for the triggering zone. This is based upon

mounting height above the counter and the ambient and reflected lighting conditions. There are no user adjustable

controls for this feature. It is important to observe the guidelines in Section 4 (on reverse side of these instructions)

and install unit to avoid false or inadvertent triggering from near-field obstructions and environmental conditions.

Orientation of spout to avoid “seeing” faucet running water and the arm or shirt cuff of a user will provide a more

satisfactory experience for the user.

10. CLEANING AND MAINTENANCE

DO NOT use steel wool or cleansing agents containing alcohol, acid, abrasives, or the like. Use of any cleaning or

maintenance products containing these substances could damage the finish of the soap dispenser. For surface

cleaning, use ONLY mild soap and water on a wet cloth, then wipe dry with a clean cloth or towel. When cleaning

bathroom tiles or counters, protect the soap dispenser from any splattering of harsh cleansers.

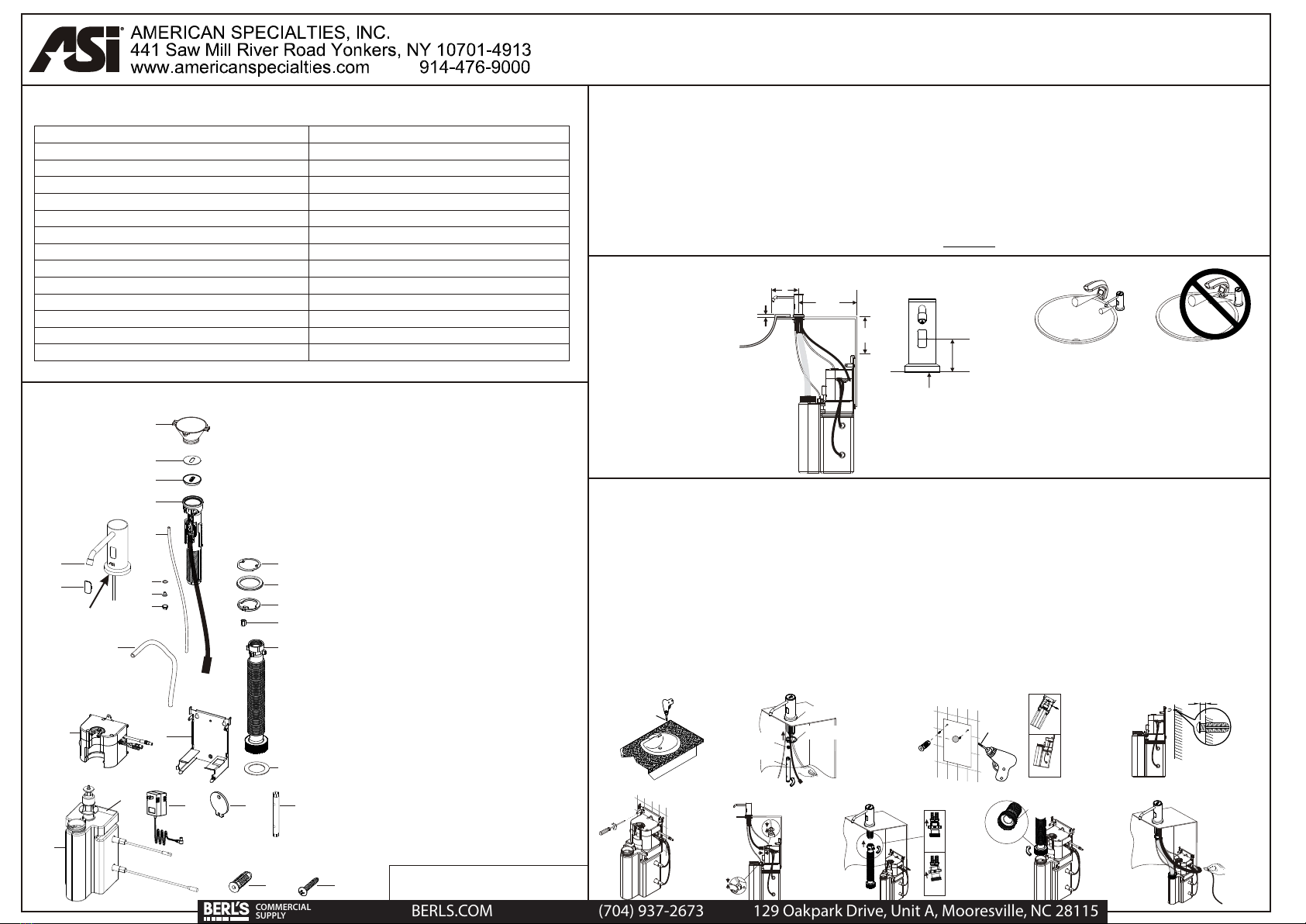

11.TROUBLESHOOTING

Problem Symptom

Unit activates, but no soap is

dispensed

Low volume soap dispensed

Solution Diagnostic

Check soap qualities, properties and level in reservoir.

Check spout nozzle, soap supply tube, and valve pump for clogs.

Soap leaks at bottom of housing Check if valve pump is not properly seated on connector neck

of reservoir or reservoir is damaged/punctured or top plate

connector or soap tube is damaged or not connected properly,

or valve pump body is damaged.

Unit does not respond at all or has

delayed response

Check all connections.

Clean any dirt/smudges from sensor.

Remove any obstructions near or in front of sensor.

If using AC adapter, make sure it is plugged into outlet completely

and that adapter is supplying correct power (see sections 1,5).

LED indicator blinking green Refill soap.

Green LED indicator stays on The wrong type of soap may have been used or the soap may

have thickened and congealed after long periods of inactivity.

Change to the right soap type or clean the soap tank and add

new soap to return to normal function.

No over-fill auditory warning

during soap refilling

Check all connections.

T

The soap level sensor may be damaged. Change the

soap tank assembly (item 20).

he control box may be damaged. Change the pump-motor-control

box (item 17).

1. Ensure no bright light source is aimed or reflected at the sensor.

2. Use fresh new liquid soap only and clean the soap container properly before each re-fill. Deposits of old

soap will lead to malfunction and jamming.

3. Do not dilute liquid soap unless concentrate. DO NOT use soap containing abrasive. Observe indicated

viscosity factor of liquid soap.

4. Do not immerse the soap dispenser in water or clean it under running water. This will lead to short circuit.

5. Should the dispenser be out of order do not attempt any repair work. Call your dealer for professional assistance.

9. IMPORTANT NOTICE

Remove soap tank and wash out spout nozzle and valve pump

and replace with fresh new soap.

6. OPERATION INSTRUCTIONS

A. Filling Soap

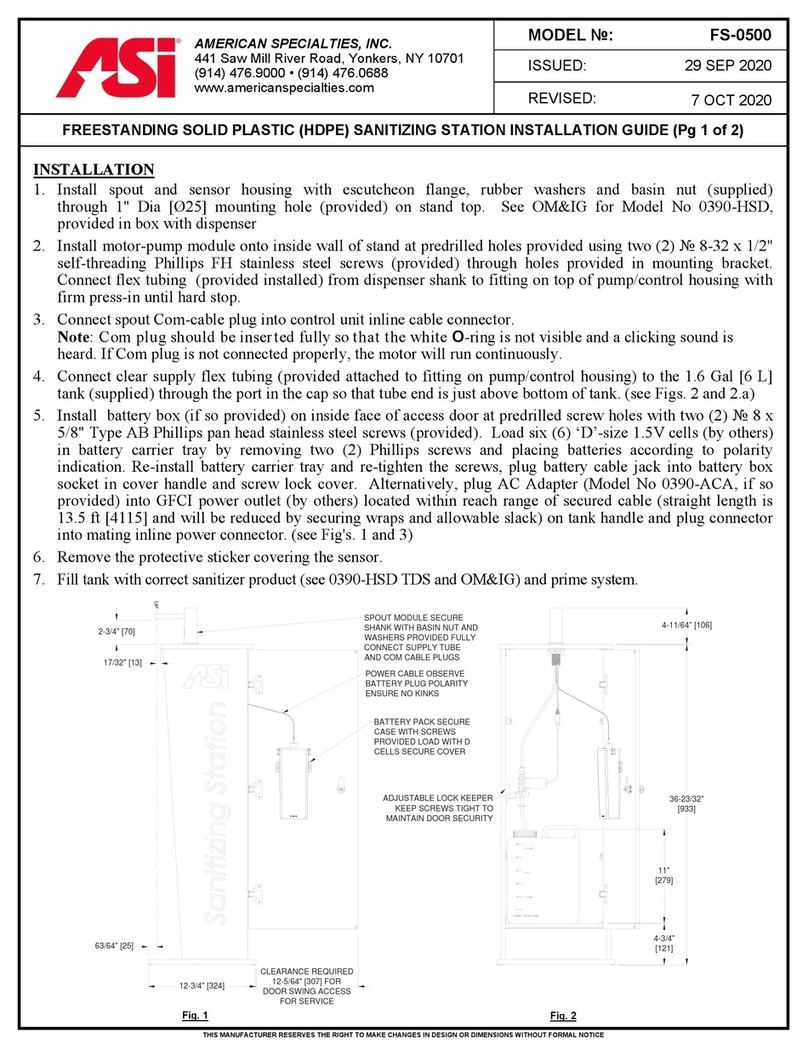

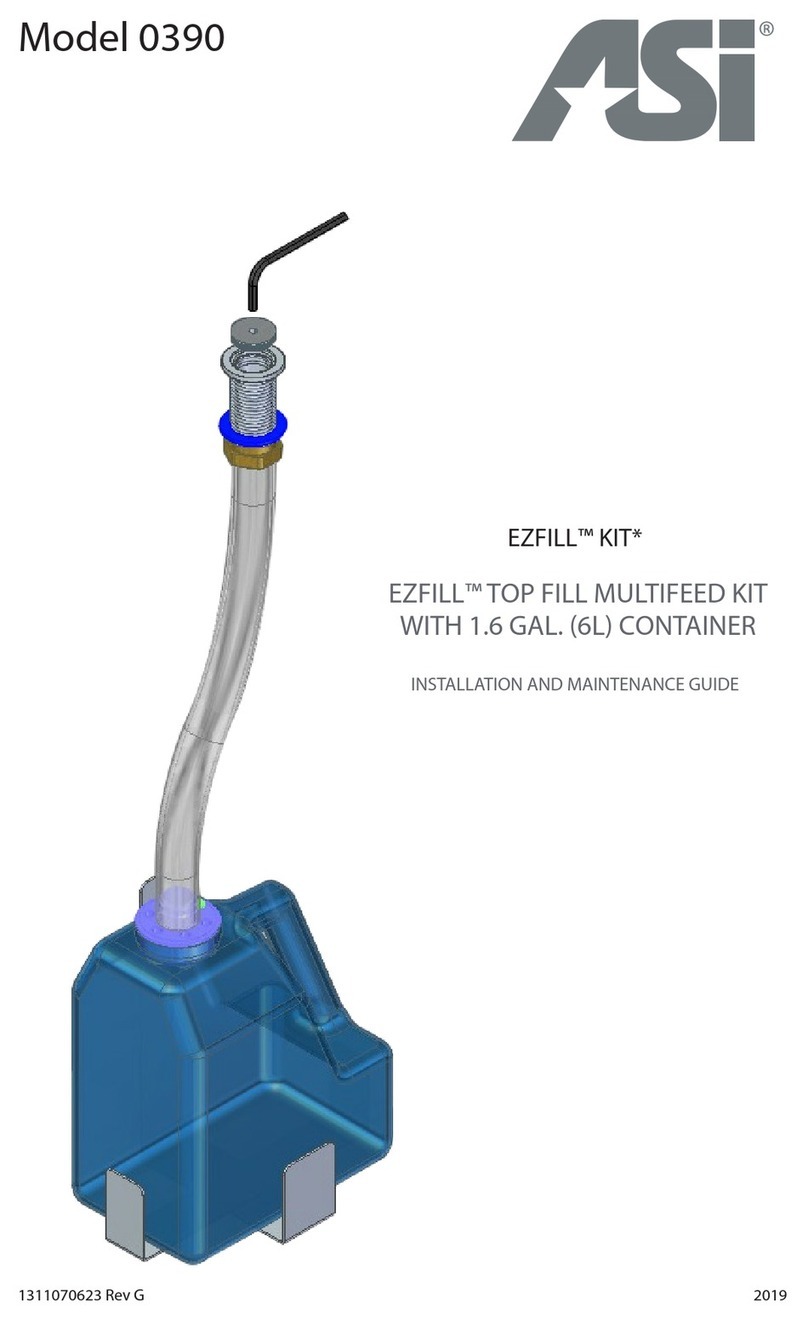

1. Open the fill port cap with the funnel-key or the provided paddle-key. (Fig. 10)

2. Thread in the funnel-key to the fill port to fill soap. (Fig. 11)

3.

4. Replace the cap after soap filling and use the funnel-key or paddle-key to tighten. (Fig. 12)

5.

When the soap level is filled a buzzer will sound. Stop refilling when the

warning is heard. Do not overfill. The auditory warning will last for 20 seconds during

which time the sensor will be turned off to prevent unwanted activation.

Place hands in front of the sensor to prime the system. The soap dispenser will activate up

to 10 times or until hands are removed to finish priming.

Note:Soap dispenser will automatically dispense once every 48 hours of inactivity to prevent

clogging in the soap tube and at the nozzle.

(Fig. 10) (Fig. 11) (Fig. 12)

(Fig. 1)

B. User's Instructions

1. Place hand below the dispenser spout within the sensing range. The dispenser will

automatically release the preset amount of liquid soap from the nozzle spout.

2. Obtain additional soap by withdrawing hand and then again placing hand below the

dispenser spout within the sensing range.

Rev A 2 August 2019

A

B

C

D

E

~

~

( )

REF

WASHBASIN

1904011610 Pg 2 of 2

BERLS.COM (704) 937-2673 129 Oakpark Drive, Unit A, Mooresville, NC 28115

COMMERCIAL

SUPPLY