May 5, 2020

Allofourproductsaredesignedandmanufacturedtohighqualitystandards.Toensurelonglifeand

beauty,theproductshouldbecleaned,protectedandmaintained.

Cleaning‐ Usuallystainlesssteelunitsthathavejustbeeninstalledwillrequirecleaningafterthe

protectivefilmhasbeenremoved.Dependinguponhowlongtheunitshavebeeninstoragepriorto

installation,aproductsuchas3M6041maybehelpfulinremovinganystubbornvinylandadhesive

residue.Unitsthatareinservicegenerallyonlyrequireroutinecleaninginaccordancewiththestandard

wash‐rinse‐dry‐polishproceduresapplicableforanystainlesssteelcabinetasdetailedinthePCM

document.

StainlessSteelshouldbeprotectedagainstMuriaticacidandcausticorabrasivematerialsandharsh

cleaningdetergents[withapHoutsidetherangeof7±1.0].Intheeventsuchagentscausediscoloration,

polishingwithastainlesssteelcleanersuchas3MStainlessSteelCleaner&Polish®andasoftclothon

brightormirrorfinishes,orforsatinfinishsurfacestheSScleanerand3MScotchBrite®padeitherblue

(lessaggressive)orgreen(moreaggressive)padisrecommended.

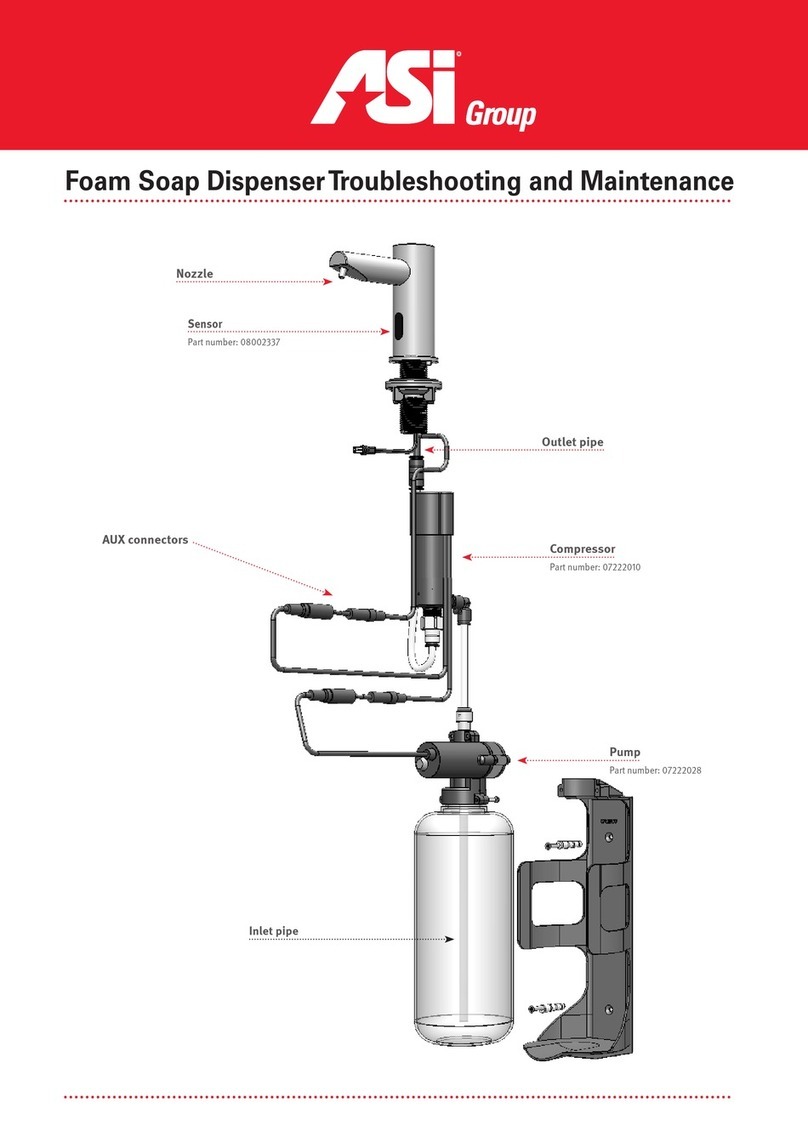

ValveMaintenance‐Soapdispenserslocatedinlowtrafficareasshouldhavethesoapdispenservalves

wipeddowntoremoveanyair‐hardenedsoapresidueleftonthenozzlespouts.Thisshouldbedoneas

partoftheday‐to‐dayjanitorialmaintenanceroutine.Generalcleaningonaregularscheduleisadequate

forsoapdispensersinhighertrafficareas,withnospecialattentionrequired.Note:youMUSTprimethe

V‐320/V‐321valveinordertostartsoapflowoninitialset‐up.Pushthevalveinandplacefingeron

dispenserspoutandletthevalvecomeout.Repeat5‐6timesuntilthevalvestartstodispenseliquidsoap

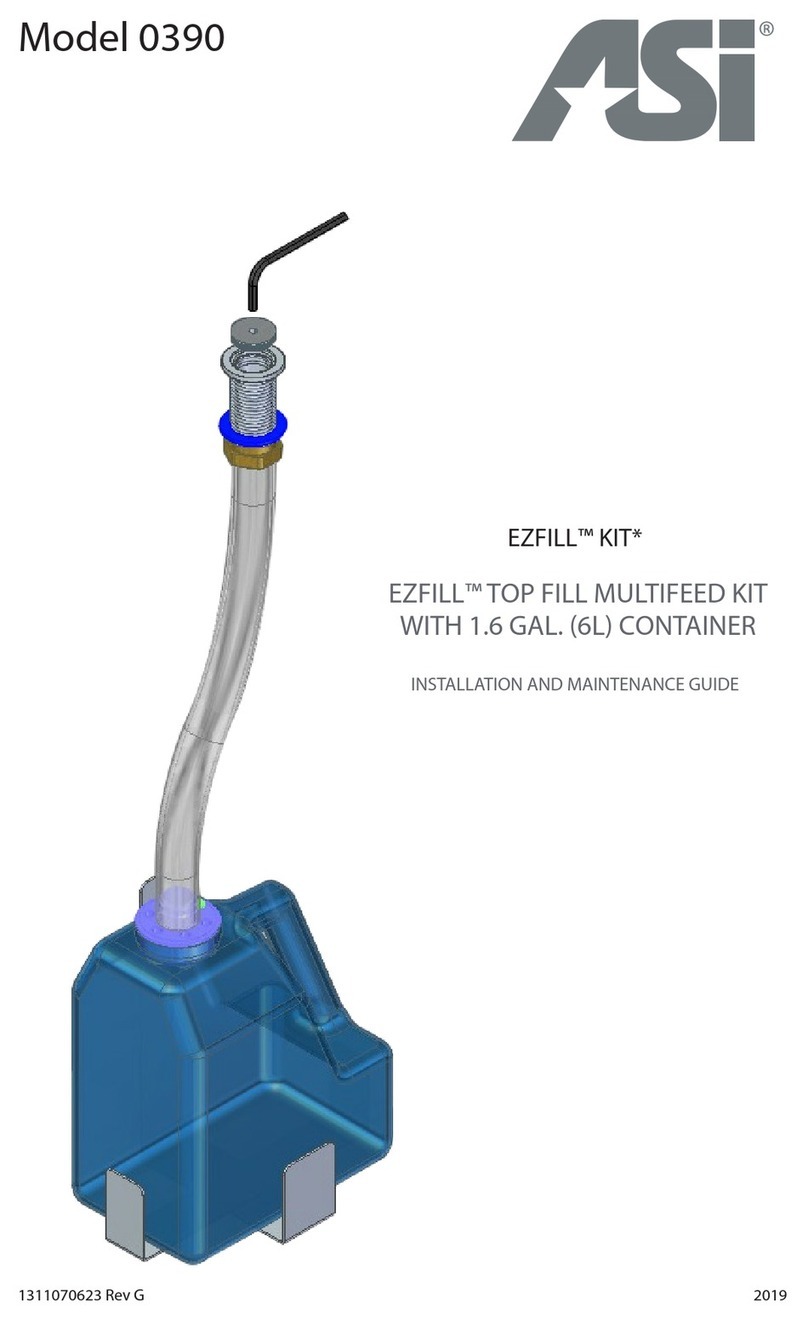

inhand.Normalrefillactivitywillnotrequirethisprocedure.See0390‐ROMforcompleteinstructionsfor

theEZFill™cleaningintervalfunction.

Advice:Wherepossible,maintenancestaffshoulduseafunneltopourliquidsoapsintosoapdispensers

toavoidspillageontounits.Wherespillageoccurs,thesoapshouldbecleanedupimmediately.Dispensers

withinternalplastictanksrequirethetanktoberemovedfromthehousingduringtherefillingoperation

toavoidspillagethatcoulddamageelectronicsandinternalcomponents.

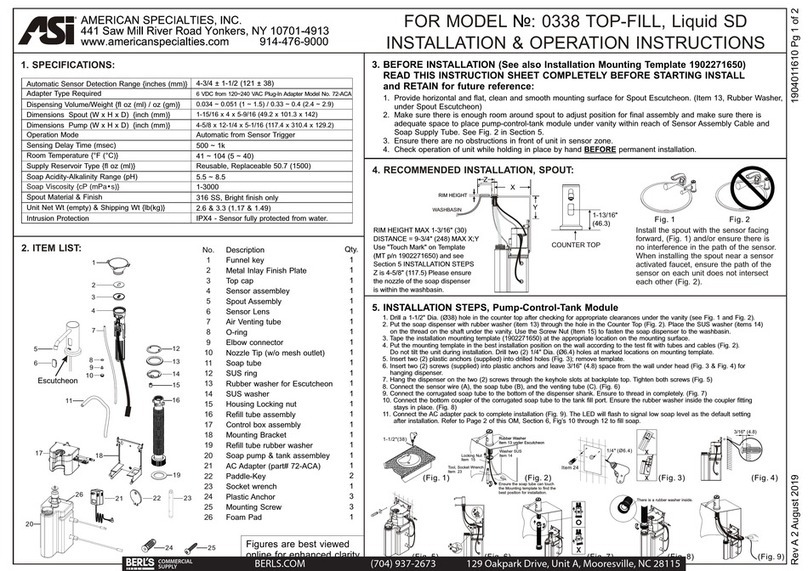

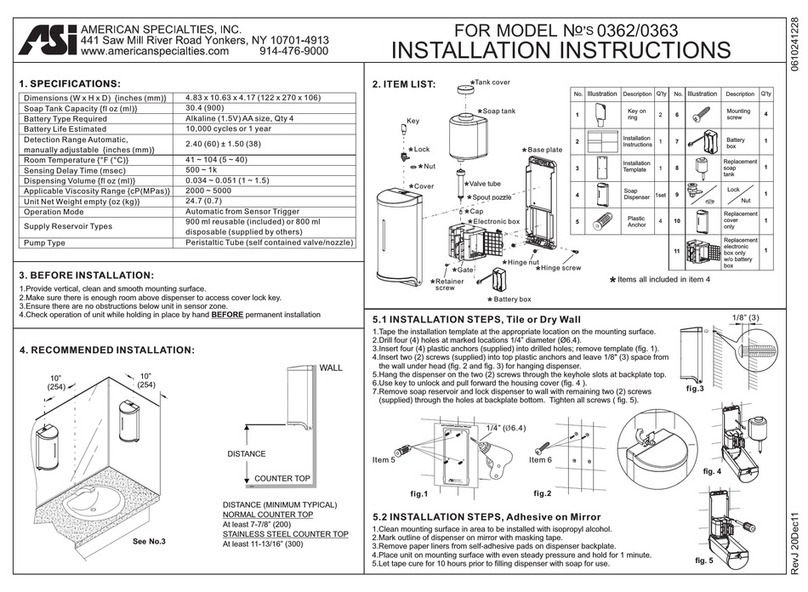

SoapforLiquidSoapDispensers‐Soapthicknessisdeterminedbyameasurementcalledviscosity.Soap

viscosityshouldbewithintherecommendedrangeforpropersoapdispenseroperation(refertothechart

inthisdocumentforalistofrecommendedviscosities).

DONOTuseanyalcoholorIodinebasedsoap.DONOTuseanypumicetypesoap,orsoapscontaining

abrasives.Exceptionforuseofliquids/foamscontainingalcohol:onlymodels0361,0362,20364,and

20365accepthandsanitizerwithintheirrespectiverequiredliquidorfoampHandviscosityrange.

Cleaning&RefillingStainlessSteelSoapTankDispensers‐Removethesoapdispenserfromthewall.

Emptyallsoapfromtankandflushtankandvalvewithwarmtohotwater.Thisshouldremoveany

particlesofdriedupsoap.Testvalveoperationwithwarmwaterpriortoreinstallationonwall.Shakeout

andwipeoffexcesswateranddrywithasoftcloth.Thetankshouldnowbereadyforplacingbackinto

positiononthewallandrefilling.

Pre‐packagedSoapforModels#5001‐SSᎊ

Procedureforloading800mlBag‐in‐a‐Boxintotypicalunit:

1. Loadboxintounitwithnozzletubefacingforward

2. Pulltube/nozzleallthewayoutoftheboxafterremovingcardboardaccessclosure

3. Orientnozzletocradleifnecessarybytwistingtubenearbagoutletunion

4. Reachthroughdooropeningandpushleverbackallthewayasfarasitgoes

5. Seatnozzleintocradle,makingsureitremainscentered

6. Whileholdingleverback,closedoorandlockwithkey

7. Checktoensurethatnozzletipremainedincradle

8. Testoperatetheunittoensureproperperformance

Allautomaticsoapdispensersarevoidofwarrantyifmodifiedinanyway.Including,butnotlimitedto;

usewithotherthantherecommendedbatteriesorACAdapterwhereprovided,useofimpropersoap

required(asnotedonthenextpage)and/orimpropermaintenanceincludingfailuretofollow

recommendedrefillingprocedures[containertobepulledawayfromtheunitandcleanedontheoutside

inthecaseofanyoverfloworspillstoavoidsoapfromleakingontothePCBorintothebatterycase].

Note:Theaboveinformationisasummary

SOAP & HAND SANITIZER DISPENSING

GENERAL INFORMATION & REQUIREMENTS CHART