AMERICAN SPECIALTIES, INC.

441 Saw Mill River Road, Yonkers, NY 10701

(914) 476.9000 • (914) 476.0688

www.americanspecialties.com

MODEL №:

ISSUED:

REVISED:

THIS MANUFACTURER RESERVES THE RIGHT TO MAKE CHANGES IN DESIGN OR DIMENSIONS WITHOUT FORMAL NOTICE

CONVERTING FROM BATTERY OPERATION TO AC

OPERATION INSTRUCTIONS

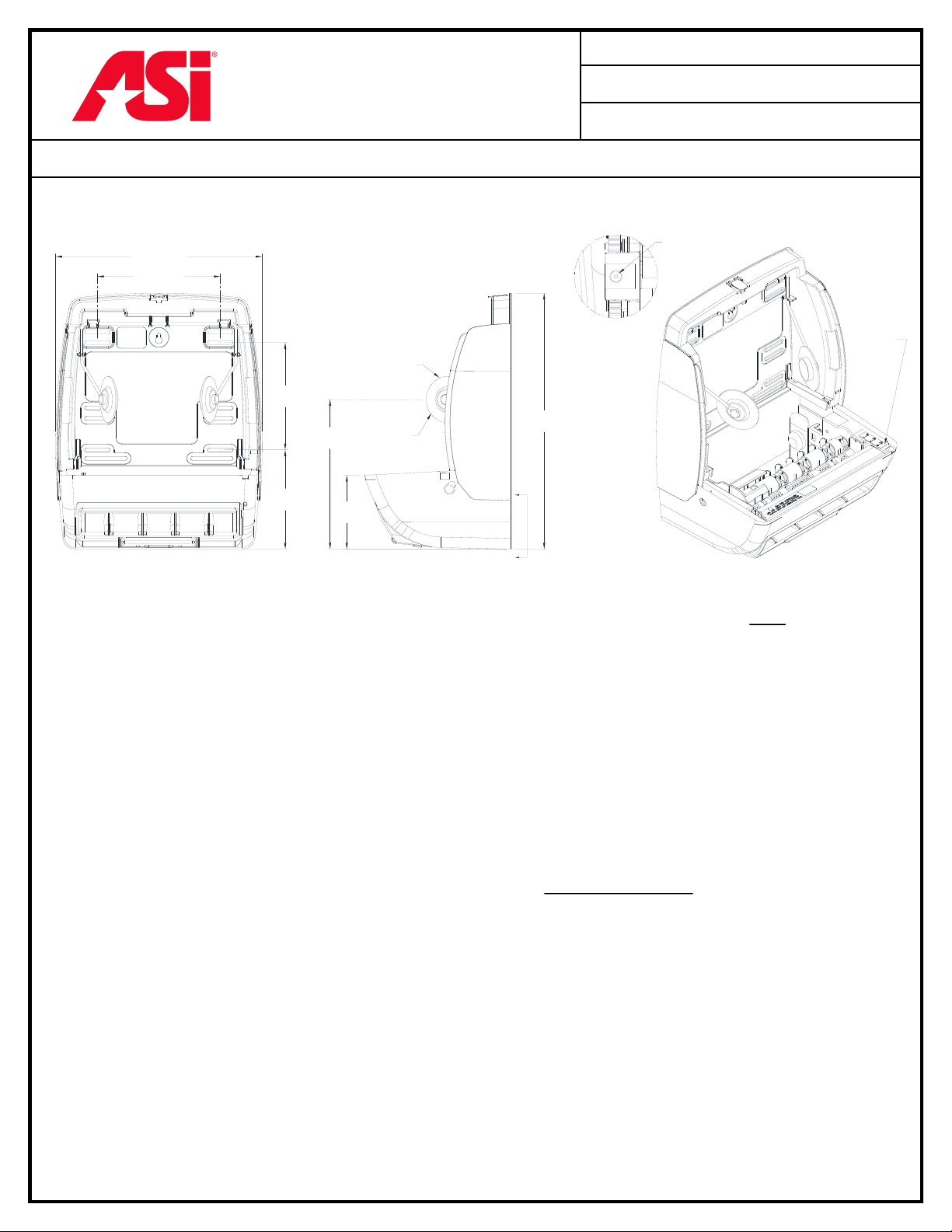

All ASI units with Automatic Dispensing Mechanisms come furnished with the electrical utility box mounting

holes and knockout holes. Whether originally equipped for battery usage or outfitted with the AC conversion

from the factory, the cabinet enclosure is the same. Therefore, no alterations are required in the field if converting

at a later date. The location of the electrical outlet is shown on the Technical Data Sheet of the corresponding

(-AC) version, i.e. #8523A (battery) converts to #8523AC (100-240V electrical). The TDS sheets will also

include the proper electrical supply requirements to be installed to the utility box by a licensed electrician. These

TDS sheets can be found and printed off the ASI website (http://www.americanspecialties.com).

The ASI Conversion Kit (Part# 10-72-ACA-CK) includes:

10-72-ACA AC/DC TRANSFORMER 100-240V AC

10-0780000660 UTILITY BOX – SEAMLESS STEEL, DUPLEX

10-0780000864 COVER, FORMED STEEL, DUPLEX

10-0780002711 CONNECTOR ELECTRIC

10-07800CR15W RECEPTACLE, DUPLEX, 15A

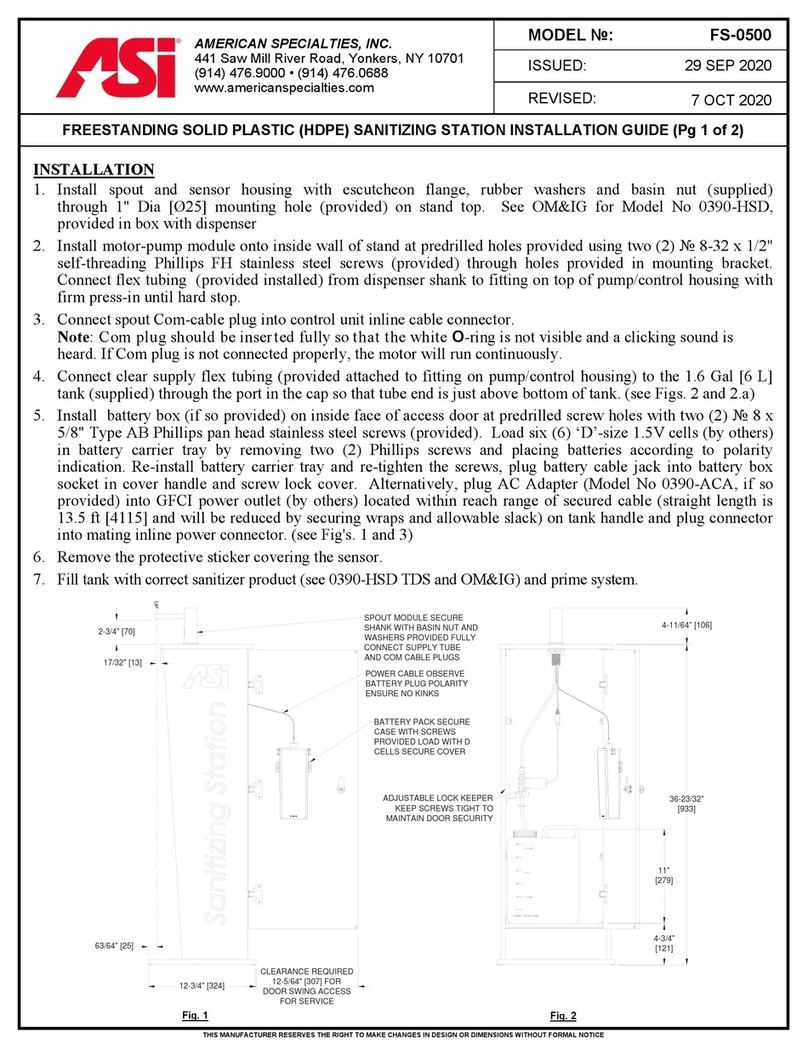

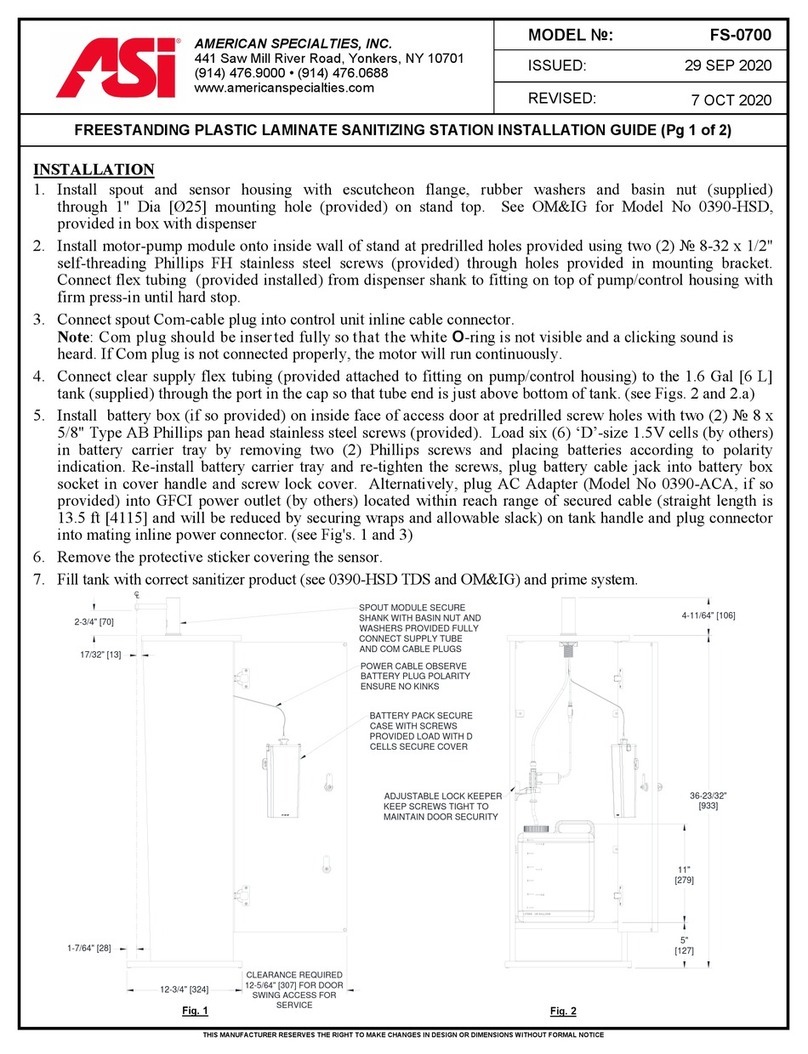

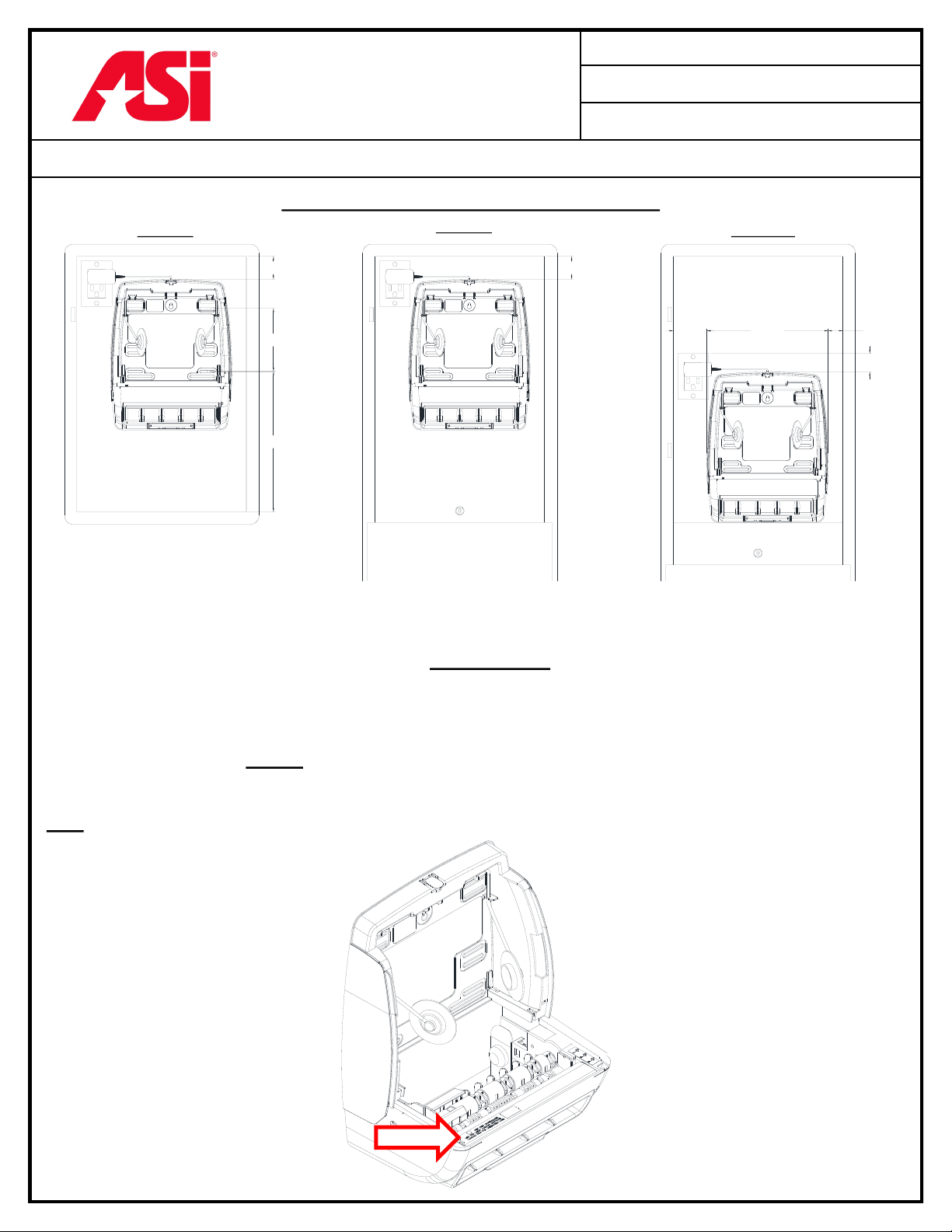

1. The supplied electrical utility box is fastened with two (2) #8 - 32 x 3/8" pan-head screws (supplied) into the

threaded weld nuts provided in the cabinet enclosure (see Fig. 4).

2. A licensed electrician can install the remaining industry standard components to the electrical supply per local

codes.

3. The AC/DC transformer wire jack end is plugged into a socket located in the lower right corner of the towel

mechanism unit (when viewed from front). The socket is hidden facing to the back (Fig. 5). Loosen the towel

mechanism mounting bolts slightly and tuck the loose wire inside the hollow plastic frame of the mechanism, up

the right side, across the top to where the transformer is plugged into the electrical outlet. This will keep it from

getting tangled in the towel rolls during operation. Retighten mounting screws and remove all installed batteries

before electric power is supplied .

8374

17 JUN 2017

17 AUG 2020

AUTOMATIC ROLL TOWEL MECHANISM OWNER’S MANUAL (Pg 4 of 7)