7

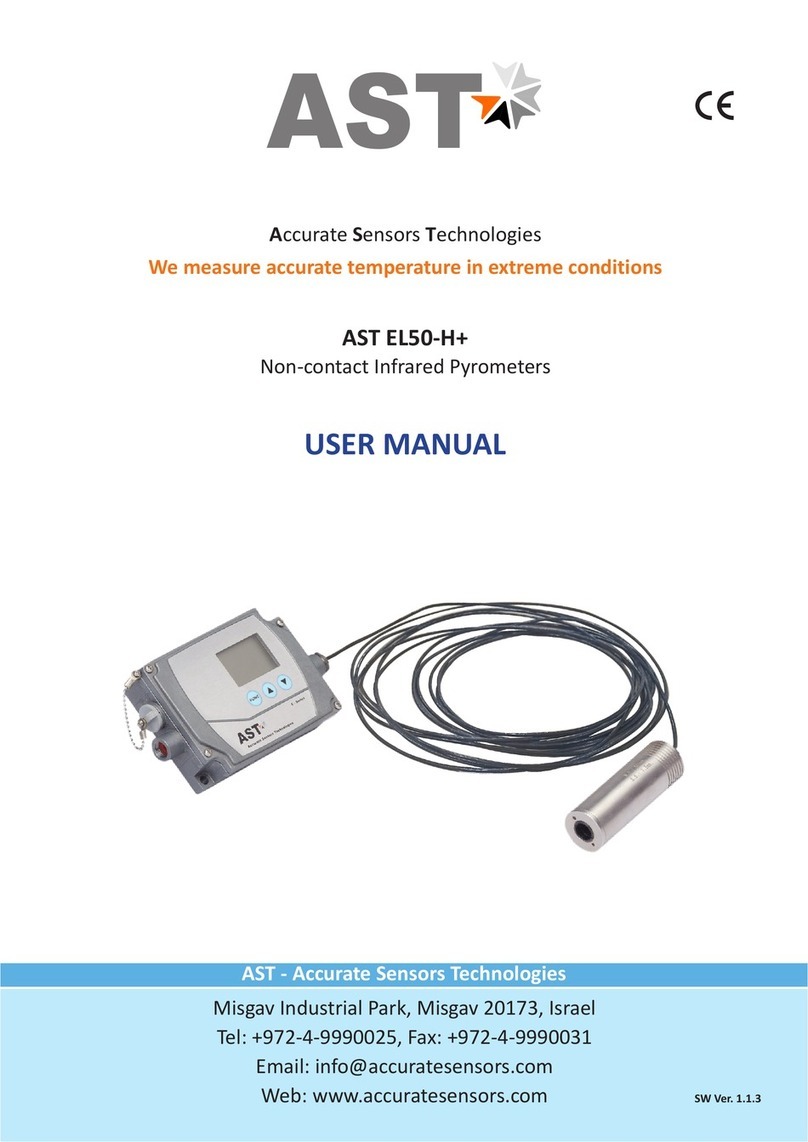

3.2.3 Display Functions

FUNC

A) Emissivity :- It is the E) Temperature Unit :- User can

relationship between the select °C or °F unit.

emissions of a real object and

the emission of a black Body

radiation source at the same temperature. For a

F) Memory clear :- To clear the

correct measurement it is necessary to adjust

save data from memory,

E m i s s i v i t y. E m i s s i v i t y d e p e n d s o n t h e

memory clear function is used.

surfacecondition of the material, the spectral range

By making memory clear

of the pyrometer and the measuring temperature.

function ON, Memory can be cleared.

Different material has different Emissivity ranging

from 0 to 1.0 User can change Emissivity by given

keypad on the instrument from 0.1 to 1.0. G) Set Date & time :- User can

B) Picker :- User can calculate a set correct date and time using

maximum “peak” temperature this parameter. To get Access

value from specified number to the menu for date & time

store real temperature in the keep pressing the FUNC button repeatedly.

sensor memory. User can either ON or OFF the picker.

(for more details Refer 4.2.2( C)) H) Auto Off :- User can set

auto off time of pyrometer

from 5mins. to 30mins. In this

C) Storage Interval :- Interval

mode the pyrometer will

determines whether only one

automatically off when no key is press in the time of

value will be stored when push

Auto Powered OFF. Example if user set 5 minutes in

button is pressed up-to the

Auto Off then the pyrometer will automatically

single triggering point. User can set storage interval

Powered OFF if no key is press for 5 minutes.

from 10ms to 500 Sec.

D) Average :- This parameter

help to switch ON & OFF

average measuring mode. In

addition to measured value,

show the average value of

the current measurement

process & save it, If it is in the range.

1

FUNC

The pyrometer is controlled by adjustment button on left side of instruments.

A

C

D

E

Function key :- There are different uses of function key first one, this key is use to see different

parameters in device and other one is set the value of parameter which is adjusted by UP &

DOWN key. By pressing of Func Push button brings up the following functions one after other.

They are appears in the bottom left of the LCD display in short form.

Function key adjustable parameters are below.

F

H

G