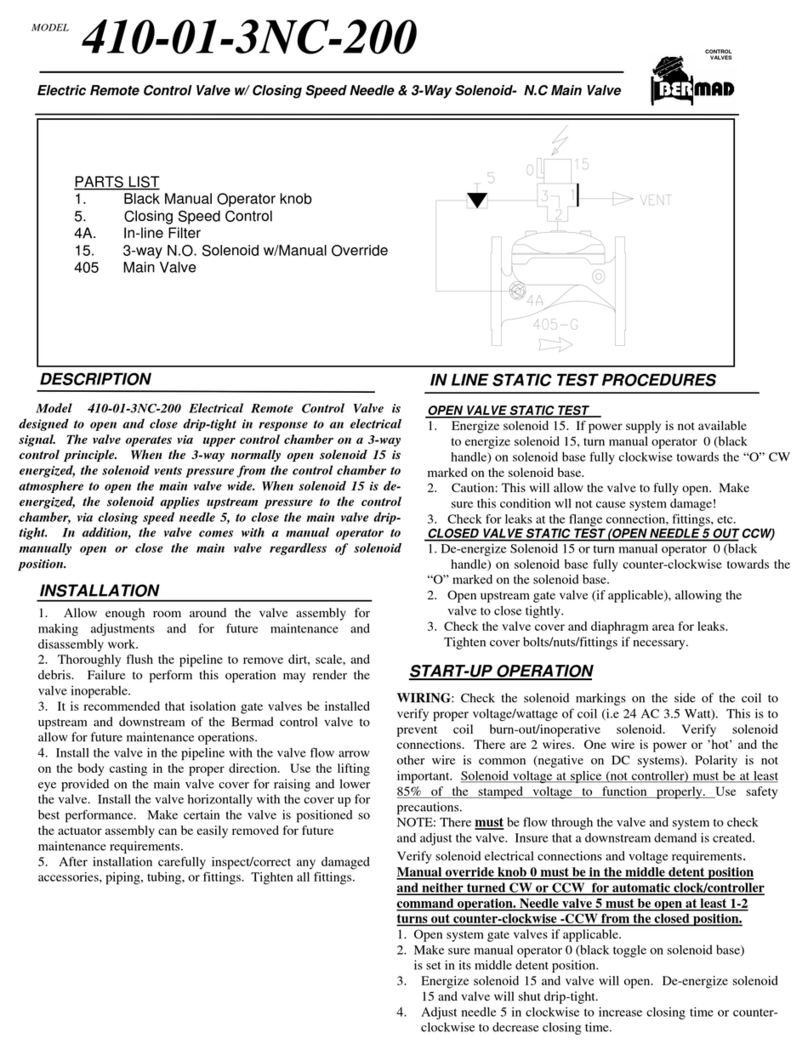

MODEL 450-66-Z

BI LEVEL RESERVOIR FLOAT VALVE (with manual selector)

INSTALLATIONOPERATIONMAINTENANCE

The information contained in this document is subject to change without notice.

BERMAD shall not be liable for any errors contained herein. All Rights Reserved. © opyright by BERMAD ontrol Valves. Page 1

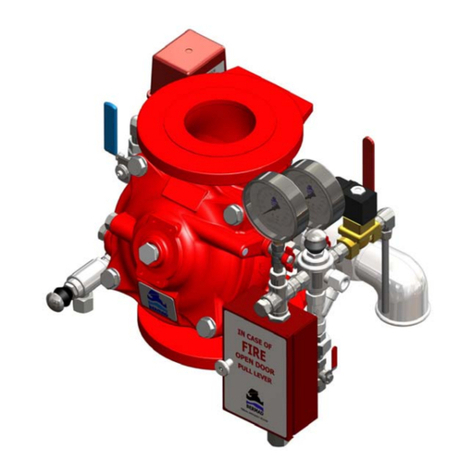

DESCRIPTION

Model 750-66 Bi-level Reservoir Control Valve is an

automatic control valve designed for two-level

control of the water level in reservoirs and tanks.

Four-way operation enables full opening even at very

low pressure. Full valve opening reduces head loss

to a minimum, prevents abrasion and reduces

cavitation damage. The valve can be operated via an

independent external pressure source when line

pressure is very low, or when the water/liquid is very

dirty or highly corrosive.

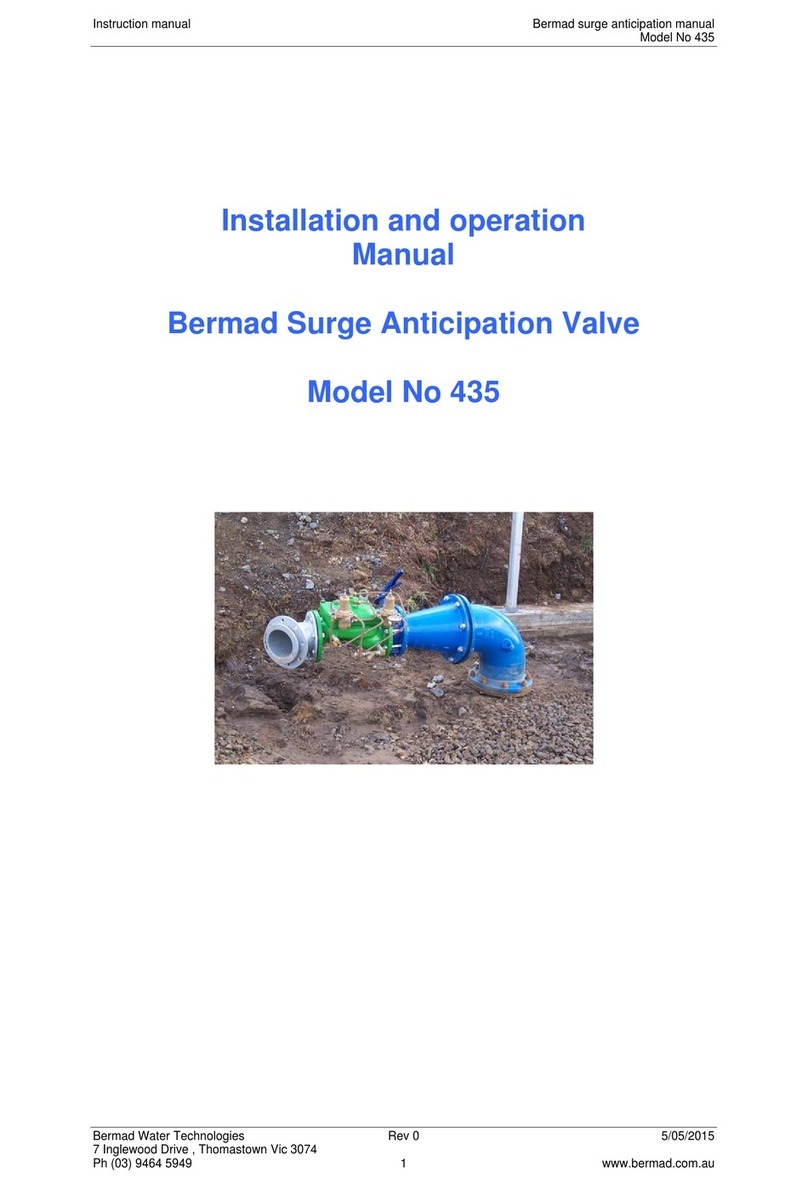

INSTALLATION

1. Allow enough room around the valve assembly for

making adjustments and for future maintenance /

disassembly work.

2. Thoroughly flush the pipeline to remove dirt, scale,

and debris. Failure to perform this operation may render

the valve inoperable.

3. Isolation valves A and B should be installed upstream

and downstream of the Bermad control valve to allow

future maintenance operations.

4. Install the valve in the pipeline with the valve flow

arrow on the body casting in the proper direction. Use

the lifting eye provided on the main valve cover for

raising and lowering the valve. For best performance,

install the valve horizontally with the cover up. Ensure

that the valve is positioned so that the actuator assembly

can be easily removed for future maintenance.

5. After installation carefully inspect /correct any

damaged accessories, piping, tubing, or fittings.

ON LINE STATIC TEST PROCEDURES

OPEN VALVE: STATIC TEST

1. Turn cock valve #26 to open position.

Caution: This will allow the valve to open fully. Make sure that

this condition does not cause system damage.

2. Check for leaks at the flange connection fittings etc.

CLOSED VALVE: STATIC TEST

1. Turn cock valve #26 to close position, vent any trapped air in

the main valve cover by loosening the tube fitting at the highest

point on the cover. This will trap the main valve in a closed

position while the pipeline is pressurized.

2. Check the valve cover and diaphragm area for leaks, tighten

the actuator bolts where necessary.

START-UP OPERATION

1. Close the main valve by closing cock valve #26 and lifting the

float to the upper level.

NOTE: Isolating valves A and B should be open.

2. Check valve operation by lifting and dropping the float; the

main valve should open and close.

3. If the main valve operating speed increases, fit a needle

valve on either port V on the four-way float pilot or on the

pressure hydraulic tube supply above filter 4. Adjust the needle

valve until the desired flow speed is obtained.

4. Pilot adjustment: Install the pilot valve 66 to the reservoir

wall, higher than the upper level (refer to the drawing). Remove

the plastic float, loosen the counterweight locking screw (9) and

balance the lever system horizontally by moving the

counterweight to find the equilibrium. After balancing, replace

the float and tighten the counterweight locking screw.

5. Adjust the upper/lower water level by moving the float stops

up/down (float while the float is held between the float stops).

6. The float control should be placed where the liquid surface is

free from turbulence; where this is not possible, a stilling tank

must be placed around the float to prevent it from swinging.

7. There should be adequate space between the reservoir wall

and the float.