ATEX Jet Cleaner TANKO-JX

Contents Translation of the original operating/installation instructions 2021/04 I

Contents

Contents ......................................................................................................................................................I

List of Figures ............................................................................................................................................III

List of Tables............................................................................................................................................. IV

Abbreviations and Units............................................................................................................................. V

1 Introduction ............................................................................................................................................ 1

1.1 Means of Presentation.......................................................................................................................... 1

1.1.1 Explanation of Signal Words....................................................................................................... 1

1.1.2 Explanation of the Warnings ...................................................................................................... 2

1.1.3 Pictograms and Symbols ............................................................................................................ 4

1.2 Warranty and Liability............................................................................................................................ 5

1.3 Product Names and Trademarks.......................................................................................................... 5

1.4 Related Documents............................................................................................................................... 5

2 Safety...................................................................................................................................................... 6

2.1 Intended Use.......................................................................................................................................... 7

2.2 Spare Parts, Replacement Parts and Accessories ............................................................................ 13

2.3 Duties of the Operating Company ...................................................................................................... 13

2.4 Requirements for Personnel............................................................................................................... 16

2.4.1 Personal Protective Equipment................................................................................................ 17

2.5 Marking ................................................................................................................................................ 18

2.5.1 Type Designation....................................................................................................................... 18

2.5.2 Type Plate .................................................................................................................................. 18

2.5.3 Marking for Explosion Protection ............................................................................................. 18

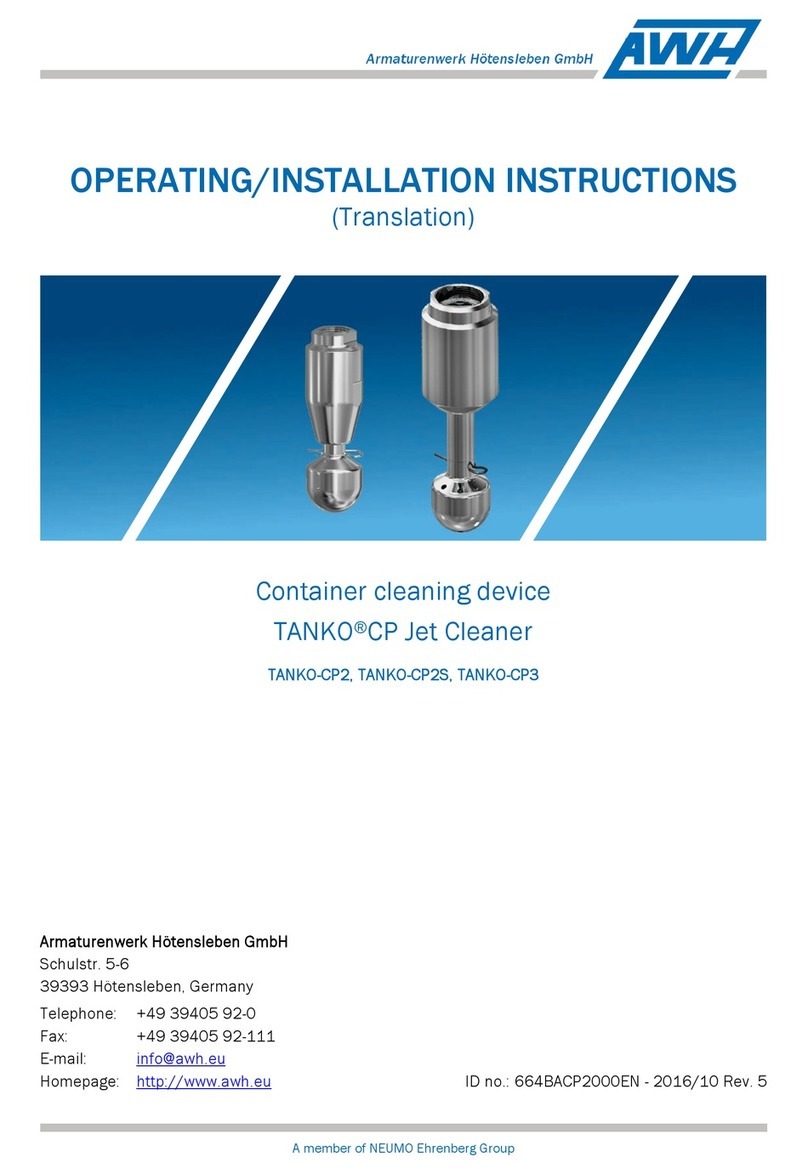

3 Construction and Function ...................................................................................................................30

3.1 Construction......................................................................................................................................... 30

3.1.1 Special Designs......................................................................................................................... 31

3.2 General Function Description ............................................................................................................. 37

3.2.1 JX Function ................................................................................................................................ 39

3.3 Technical Data..................................................................................................................................... 40

3.4 Cleaning Media.................................................................................................................................... 43

4 Transportation and Storage..................................................................................................................49

4.1 Packaging............................................................................................................................................. 50

4.2 Transportation ..................................................................................................................................... 51

4.3 Storage................................................................................................................................................. 51

5 Installation............................................................................................................................................ 53

5.1 Safety Instructions for Installation ..................................................................................................... 53

5.2 Installation ........................................................................................................................................... 59

5.2.1 Interfaces................................................................................................................................... 60