ATEX Retractor System TANKO-RT/-RTS

Contents Translation - Operating/installation instructions 2020/01 I

Contents

List of Figures ..................................................................................................................................III

List of Tables....................................................................................................................................IV

Abbreviations and Units....................................................................................................................V

1 Introduction .................................................................................................................................. 1

1.1 Means of Representation .......................................................................................................... 1

1.1.1 Explanation of Signal Words............................................................................................ 1

1.1.2 Explanation of the Warnings ........................................................................................... 2

1.1.3 Pictograms and Symbols ................................................................................................. 4

1.2 Warranty and Liability................................................................................................................. 5

1.3 Product Names and Trademarks............................................................................................... 5

1.4 Related Documents.................................................................................................................... 5

2 Safety............................................................................................................................................ 6

2.1 Intended Use............................................................................................................................... 7

2.2 Spare parts, replacement parts and accessories ..................................................................12

2.3 Duties of the Owner..................................................................................................................12

2.4 Personnel Requirements .........................................................................................................15

2.4.1 Personal Protective Equipment.....................................................................................16

2.5 Identification.............................................................................................................................17

2.5.1 Type Designation............................................................................................................17

2.5.2 Type Plate.......................................................................................................................17

2.5.3 Identification for Explosion Protection..........................................................................18

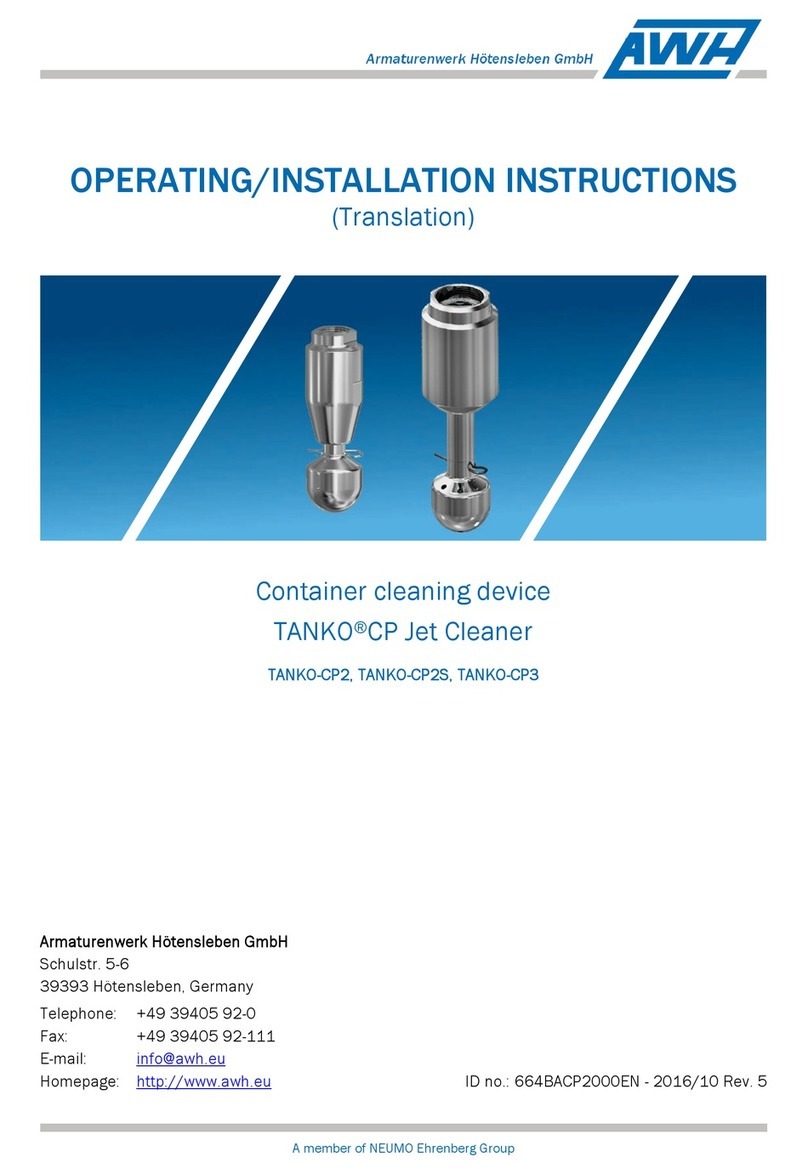

3 Design and Function................................................................................................................... 28

3.1 Design .......................................................................................................................................28

3.2 General Function Description ..................................................................................................30

3.2.1 Emergency Stop .............................................................................................................33

3.2.2 Functional Flow Chart ....................................................................................................34

3.3 Technical Data..........................................................................................................................36

3.4 Cleaning Media.........................................................................................................................44

4 Transport and Storage................................................................................................................ 49

4.1 Packaging..................................................................................................................................50

4.2 Transport...................................................................................................................................50

4.3 Storage......................................................................................................................................51

5 Installation.................................................................................................................................. 52

5.1 Safety instructions for installation...........................................................................................52

5.2 Installation ................................................................................................................................55

5.2.1 Interfaces........................................................................................................................57

5.2.2 Installation Position .......................................................................................................58

5.2.3 Installing the Device ......................................................................................................59

5.2.4 Connection of Pneumatic Actuator ...............................................................................66

6 Start-up....................................................................................................................................... 69

6.1 Safety Instructions for Start-Up ...............................................................................................69

6.2 Function Check/Trial Run ........................................................................................................74