Rev 1.0

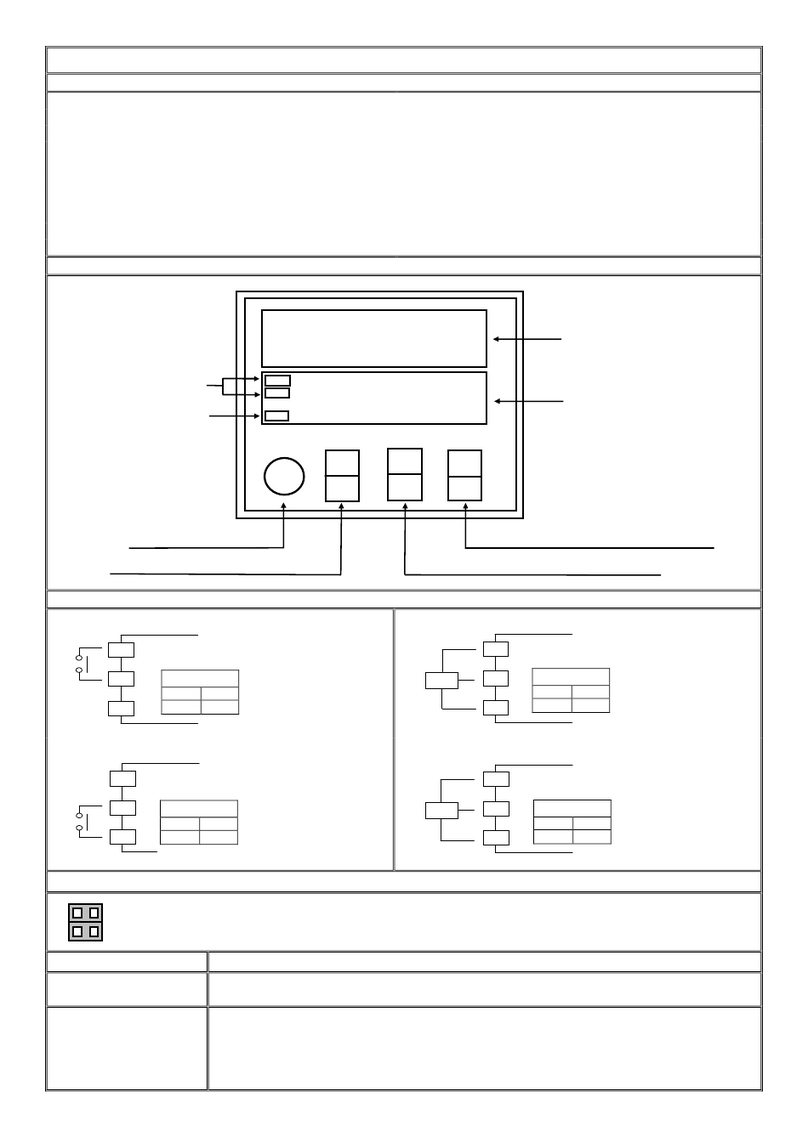

Key Introduce Operation Manual

Key Function

1.In normal display, The key function is call out setting group

2.In parameter setting page, The key function is data Enter , and goto next page

Key Function

1.In normal display, The key function is call out alarm value setting page

2.Into parameter setting page, the parameter mark & data is alternate display, If need modify data

can press shift key into setting procedure, The display is lock parameter data, this time must let off

key about 0.2 sec, press again, the cursor(twinkle express)is cycle moving left. (Key Response

about 0.2 sec)

Key Function

1.In normal display, The key function is call out adjustment display scale page

2.Into parameter setting page, the parameter mark & data is alternate display, If need modify data

can press up key into setting procedure, The display is lock parameter data, this time must let off

key about 0.2 sec, press again, the parameter data will increment. (Key Response about 0.2 sec)

Key Function

1.In normal display, The key function is call out adjustment analog output ZERO&SPAN page

2.Into parameter setting page, the parameter mark & data is alternate display, If need modify data

can press down key into setting procedure, The display is lock parameter data, this time must let

off key about 0.2 sec,

press again the parameter data will decrement. (Key Response about 0.2 sec)

& Key Function

In setting group or setting page press & key return normal display,

but if in setting page the

modify data will be lost

No Key in anything In setting group or setting page no key in anything about 2 minutes, return normal display,

Setting page the modify data will be lost

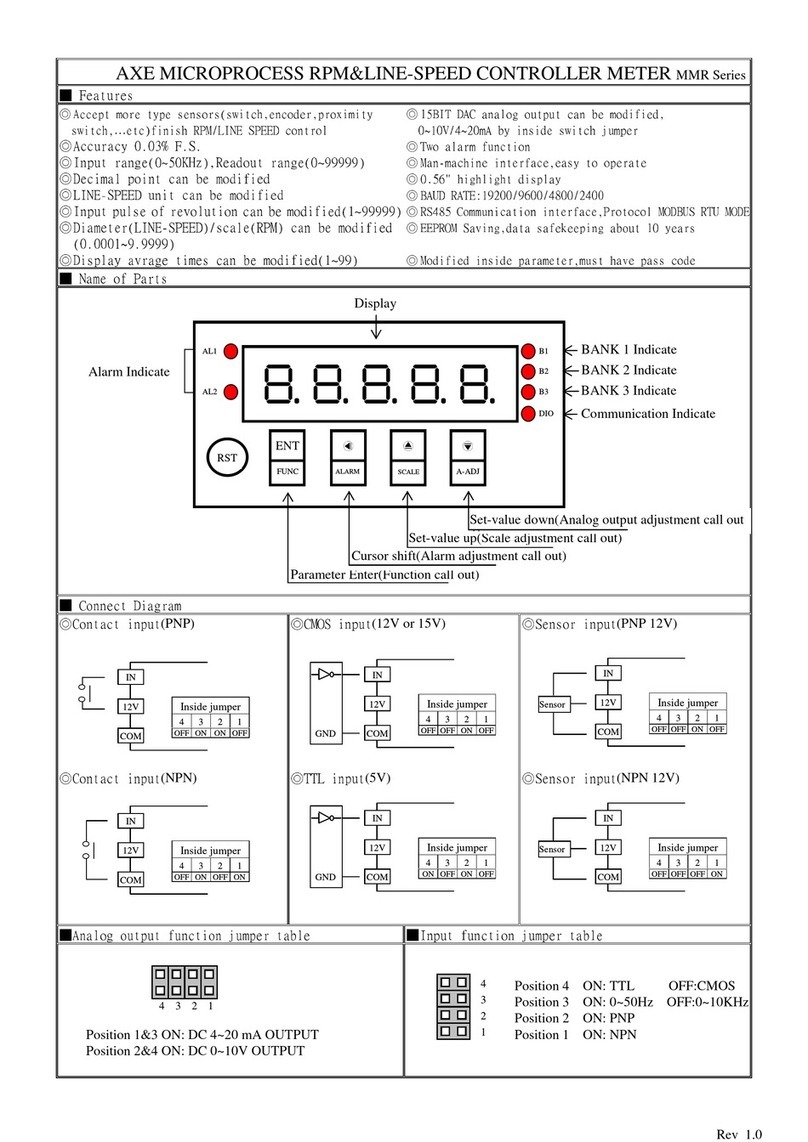

Step Parameter Mark Description

Parameter Mark

Operation Manual

1

Normal display

Press /FUNC key into P.COD setting page

2

P.COD(Pass code input page)

1.Key in 5 digit pass code with or or key

2.Press key,

the pass code is right into Display Mode setting page,

otherwise return normal display

3-1

DISPLAY MODE(Mode)

Default=A

1. Decide display mode with & key

A

B

B-A

(B/A)x100 (unit %)

(B/A-1)x100 (unit %)

(B/(A+B))x100 (unit %)

(1-B/A)x100 (unit %)

2. Press key enter data and into

DP setting page

3-2

DP(Decimal Point setting

page)Default=0

1.Decide decimal point position with or key (0 to 4)

2.Press key enter data and into TYPE setting page

3-3

TYPE(Display Type)

Default=RPM

1.Decide display type with or key(RPM/LINE)

2.Press key enter data,

If select LINE into UNIT setting page,

otherwise into PPR-1 setting page

3-4

UNIT(Line Speed Unit)

Default=METER

1.Decide line speed unit with or key(METER/FOOT/YARD)

2.Press key enter data and into PPR

-1 setting page

3-5

PPR-1(Pulse Per Revolution)

Default=1

1.Decide pulse per revolution with & & key(1~99999)

2.Press key enter data and

into PPR-2 setting page

3-6

PPR-2(Pulse Per Revolution)

Default=1

1.Decide pulse per revolution with & & key(1~99999)

2.Press key enter data and into TBASE set

ting page

3-7

TBASE (Sampling Time

Base)

Default=0.1

1.Decide sampling time base with & & key(0.1~99.9

sec)

2.Press key enter data and into AVG setting page

3-8

AVG (Display Average

times)

Default=1

1.Decide display average times with & & key(1~99)

2.Press key enter data and into

ACT setting page