General Instructions for 230V Machines

07

UNDER NO CIRCUMSTANCES SHOULD CHILDREN

BE ALLOWED IN WORK AREAS

t is good practice to leave the machine unplugged

until work is about to commence, also make sure

to unplug the machine when it is not in use, or

unattended. Always disconnect by pulling on the

plug body and not the cable. Once you are ready to

commence work, remove any tools used in the setting

operations and place safely out of the way. Re-connect

the machine. It is also recommended that you use

switched supply outlets.

Carry out a final check e.g. check the cutting tool,

drill bit, saw blade etc., is securely tightened in the

machine, check you have the correct speed and

function set, check that the cutting path of the timber

is unobstructed, etc.

Most machines these days are fitted with NVR contact

switches so that machines cannot remain inadvertently

switched ‘ON’. However, it is a good habit to train

yourself to check that the machine is not ‘switched

on’ prior to connecting the mains supply, in case you

happen to be using one of the older machines.

Make sure you are comfortable before you start work,

balanced, not reaching etc.,

If the work you are carrying out is liable to generate

flying grit, dust or chips, wear the appropriate safety

clothing, goggles, gloves, masks etc., If the work

operation appears to be excessively noisy, wear

ear-defenders. If you wear your hair in a long

style, wearing a cap, safety helmet, hairnet, even a

sweatband, will minimise the possibility of your hair

being caught up in the rotating parts of the machine,

likewise, consideration should be given to the removal

of rings and wristwatches, if these are liable to be a

‘snag’ hazard. Consideration should also be given to

non-slip footwear, etc.

DO NOT work with cutting or boring machines of any

description if you are tired, your attention is wandering

or you are being subjected to distraction. A deep cut, a

lost fingertip or worse; is not worth it!

DO NOT use this machine within the designated safety

areas of flammable liquid stores or in areas where there

may be volatile gases. There are very expensive, very

specialised machines for working in these areas,

THIS IS NOT ONE OF THEM.

CHECK that cutters, drills, blades etc., are the correct

type and size, are undamaged and are kept clean and

sharp, this will maintain their operating performance

and lessen the loading on the machine.

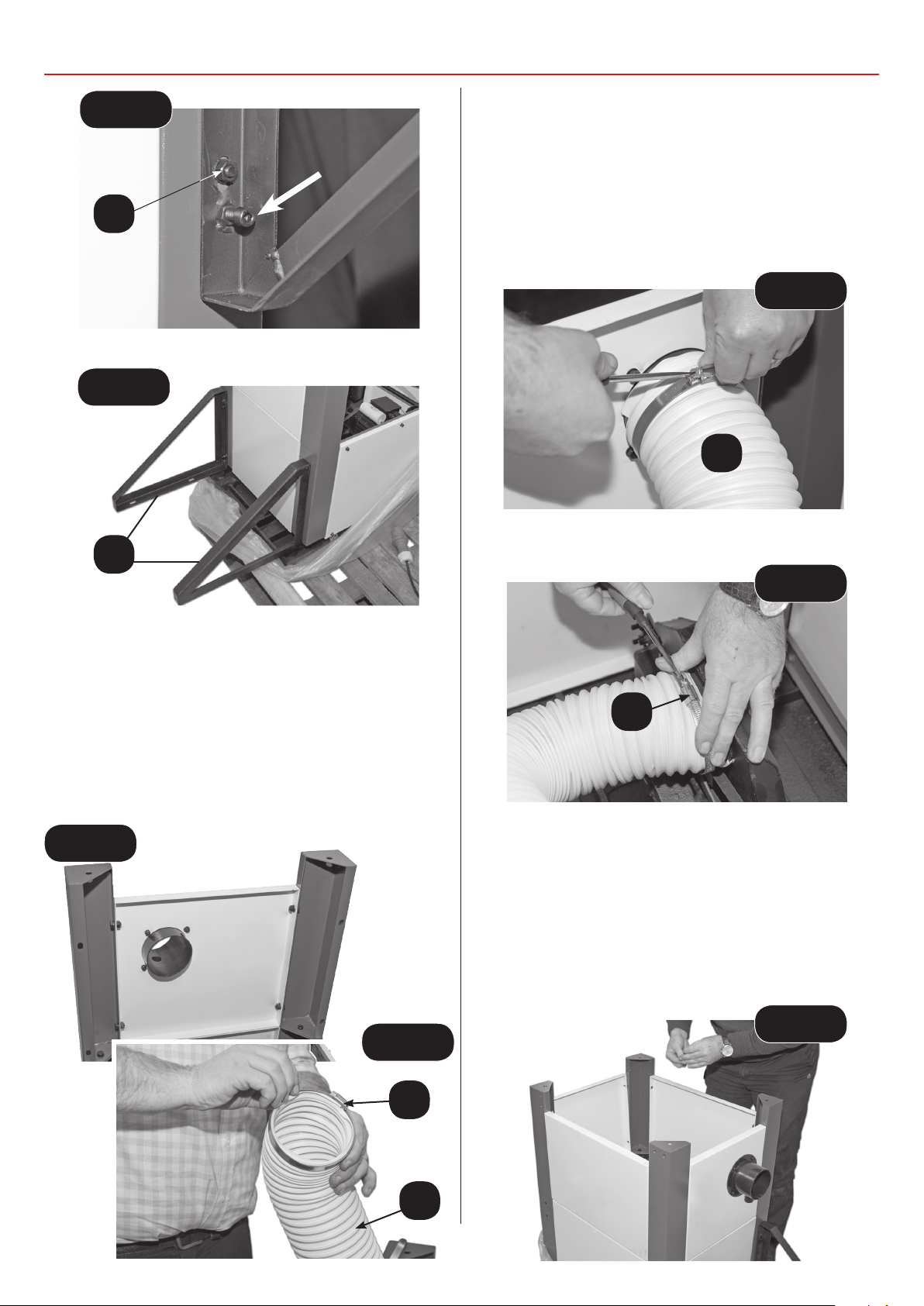

If possible always fit dust extraction to machines that

are producing high rates of sawdust, shavings, chips

etc. Above all, OBSERVE.... make sure you know what

is happening around you, and USE YOUR COMMON

SENSE.

REMEMBER, YOU ARE ULTIMATELY RESPONSIBLE

FOR YOUR OWN SAFETY THIS MACHINE IS

DESIGNED TO CUT TIMBER AND TIMBER

DERIVATIVE PRODUCTS. DO NOT USE FOR ANY

OTHER MATERIALS.