4

Table of Contents

1 Product description ......................................................................................................6

1.1 Mode of operation ........................................................................................................7

1.2 Purpose ........................................................................................................................7

1.3 CE conformity ...............................................................................................................7

1.4 Technical data, general ................................................................................................8

1.4.1 Tank size RM 112 .........................................................................................................9

1.4.2 Tank size RM 182 .......................................................................................................10

1.4.3 Tank size RM 212 .......................................................................................................11

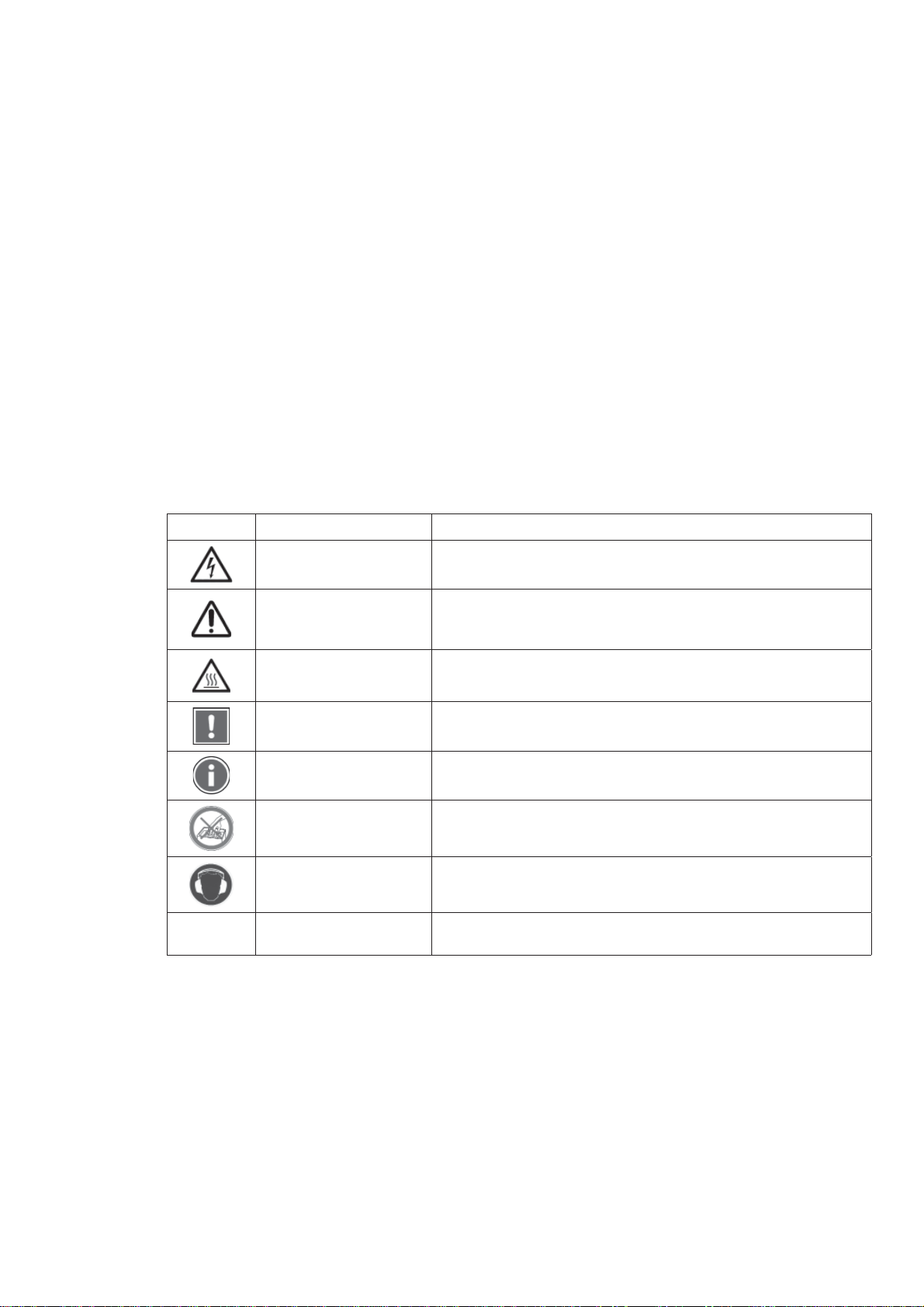

1.5 Warnings and safety precautions ...............................................................................12

2 Preparation .................................................................................................................13

2.1 Scope of delivery ........................................................................................................13

2.2 Set-up / assembly ......................................................................................................13

2.3 Start-up ......................................................................................................................14

3 Operation ...................................................................................................................15

3.1 Operating elements ....................................................................................................15

3.1.1 Ultrasound ..................................................................................................................15

3.1.2 Heating .......................................................................................................................16

3.2 Miscellaneous functions - not applicable - ...................................................................16

3.3 Device signals - not applicable - ..................................................................................16

4 Use .............................................................................................................................17

4.1 Instructions for use .....................................................................................................17

4.2 General use ................................................................................................................18

4.3 Further information .....................................................................................................21

4.3.1 Degassing ..................................................................................................................21

4.3.2 Disposal of sonication fluids .......................................................................................21