Q5X Laser Triangulation Sensor with Dual Mode and IO-Link for Jam Detection

July 10, 2023 page9

•

•

•

•

•

•

•

BasicTEACHInstructions

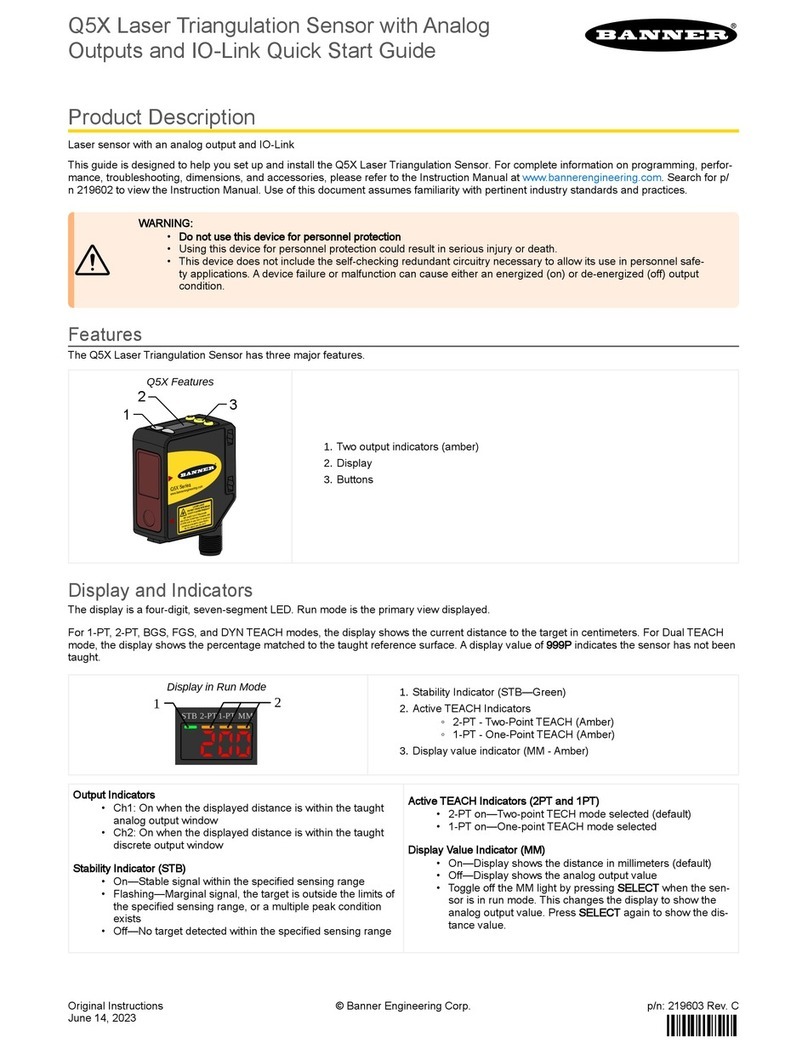

UsethefollowinginstructionstoteachtheQ5Xsensor.Theinstructionsprovidedonthesensordisplayvarydependingonthetypeof

TEACHmodeselected.Jam Retroreflective TEACH is the default TEACH mode on CH1, and Jam Background Suppression TEACH is the

default TEACH mode on CH2.

See the Instruction Manual for detailed instructions and other available TEACH modes. The TEACH modes include:

Two-pointstaticbackgroundsuppression —Two-pointTEACHsetsasingleswitchpoint.The sensor sets the switch point

between two taught target distances, relative to the shifted origin location.

Dynamicbackgroundsuppression —Dynamic TEACH sets a single switch point during machine run conditions.The sensor

takes multiple samples and the switch point is set between the minimum and the maximum sampled distances.

One-pointwindow(foregroundsuppression) —One-point window sets a window (two switch points) centered around the

taught target distance.

One-pointbackgroundsuppression —One-point background suppression sets a single switch point in front of the taught

target distance. Objects beyond the taught switch point are ignored.

Dualintensity+distance —Dualmoderecordsthedistanceandamountoflightreceivedfromthereferencesurface.

See"Dual Mode Reference Surface Considerations" on page 12formoreinformationaboutselectingareferencesurface.The

output switches when an object passing between the sensor and the reference surface changes the perceived distance or amount of

returnedlight.

Jamretroreflective —JamretroreflectiveTEACHmodeisanextensionofDualModeoptimizedforjamdetectionwhena

background is present. This mode sets a window with two switch points centered around the taught target distance. Measurements

with valid intensity inside this window are qualified as not jammed. An independent jam range (RNG) value is set which defines the

minimum movement required, which in combination with an automatically determined intensity threshold, determines that an object

ismoving(notjammed).ALossofSignalfortheuser-definedtimeistreatedasajam.

Jambackgroundsuppression —JambackgroundsuppressionTEACHmodeisanextensionofDualModeoptimizedforjam

detection when no background is present. This mode sets a background suppression point in front of the taught target distance.

Measurements with a valid intensity inside this window are qualified as not jammed. An independent jam range (RNG) value is set

by the user which defines the minimum movement required, which in combination with an automatically determined intensity

threshold,determinesthatanobjectismoving(notjammed).ALossofSignalconditionisnottreatedasajam.

Manual Adjustments

Manuallyadjustthesensorswitchpointusingthe and buttons.

NOTE: When FGS TEACH mode is selected, manual adjustment moves both sides of the symmetrical threshold

window simultaneously, expanding and collapsing the window size. Manual adjustment does not move the center point

ofthewindow.

NOTE: When Dual TEACH mode is selected, after the TEACH process is completed, use the manual adjustment to

adjust the sensitivity of the thresholds around the taught reference point. The taught reference point is a combination of

the measured distance and returned signal intensity from the reference target. Manual adjustment does not move the

taughtreferencepoint,butpressing increasesthesensitivity,andpressing decreasesthesensitivity.Whenre-

positioningthesensororchangingthereferencetarget,re-teachthesensor.

RNG

WhenthesensorisinJRETorJBGSTEACHmode,usethe or buttonstoadjusttheRNGvalue.TheRNGvaluedefinesthe

minimum movement the sensor must see to determine that an object is moving (not jammed). For most applications, the default setting

isacceptable.

PressandholdTEACHforlongerthan2secondstostarttheselectedTEACHmode.

Presentthetarget.

PressTEACHtoteachthetarget.Thetargetistaughtandthesensorwaitsforthesecondtarget,ifrequiredbytheselectedTEACH

mode,orreturnstoRunmode.

CompletethesestepsonlyifitisrequiredfortheselectedTEACHmode.

Presentthesecondtarget.

PressTEACHtoteachthetarget.ThetargetistaughtandthesensorreturnstoRunmode.

FromRunmode,presseither or onetime.Theselectedchanneldisplaysbriefly,thenthecurrentsettingvalueflashes

slowly.

Press toincreasethesettingor todecreasethesetting.After1secondofinactivity,thenewsettingvalueflashesrapidly,

thenewsettingisaccepted,andthesensorreturnstoRunmode.

© Banner Engineering Corp.