Contents

1 About This Document ......................................................................................................................................................4

1.1 Important . . . Read This Before Proceeding! ......................................................................................................................................... 4

1.1.1 Use of Warnings and Cauons .................................................................................................................................................. 4

1.2 EU Declaraon of Conformity (DoC) ..................................................................................................................................................... 4

1.3 Banner Engineering Corp Limited Warranty ......................................................................................................................................... 4

1.4 Contact Us ............................................................................................................................................................................................. 5

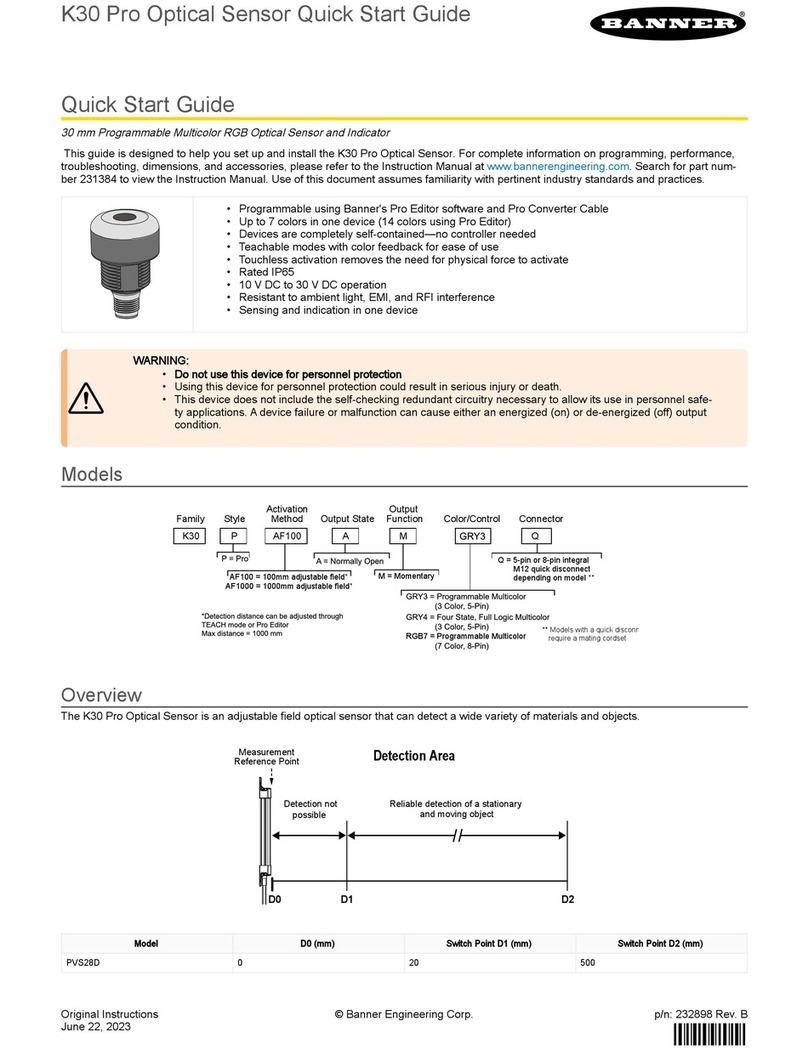

2 Introducon .................................................................................................................................................................... 6

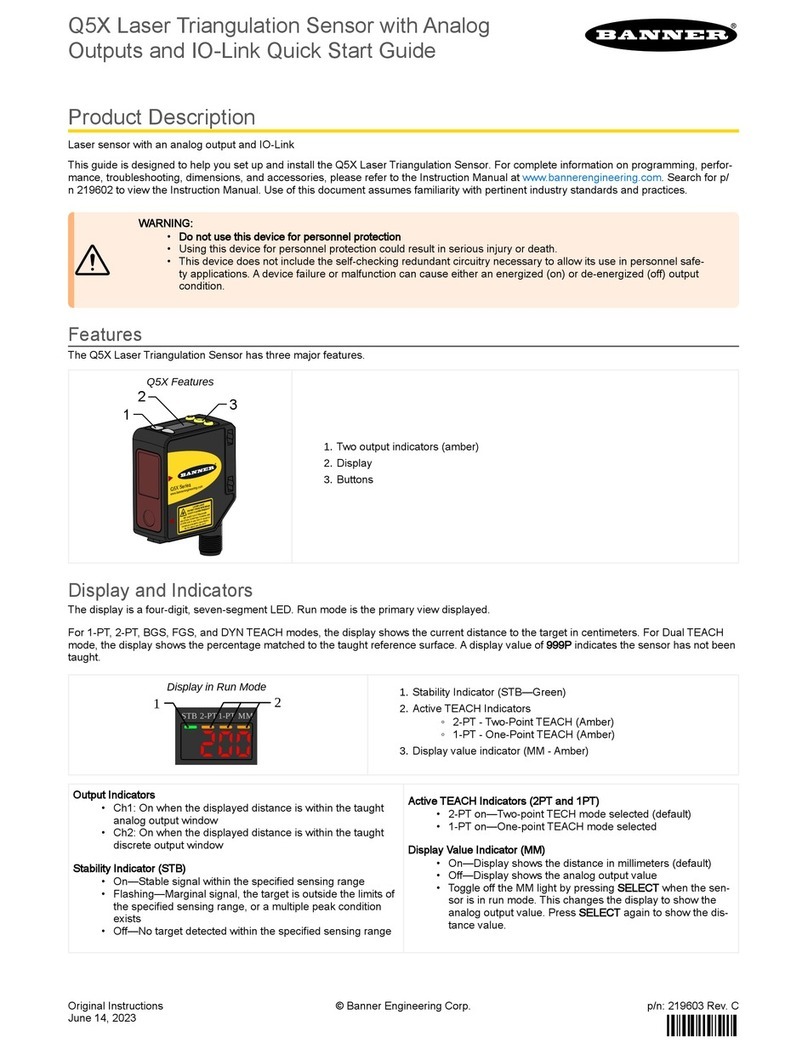

2.1 Features .................................................................................................................................................................................................6

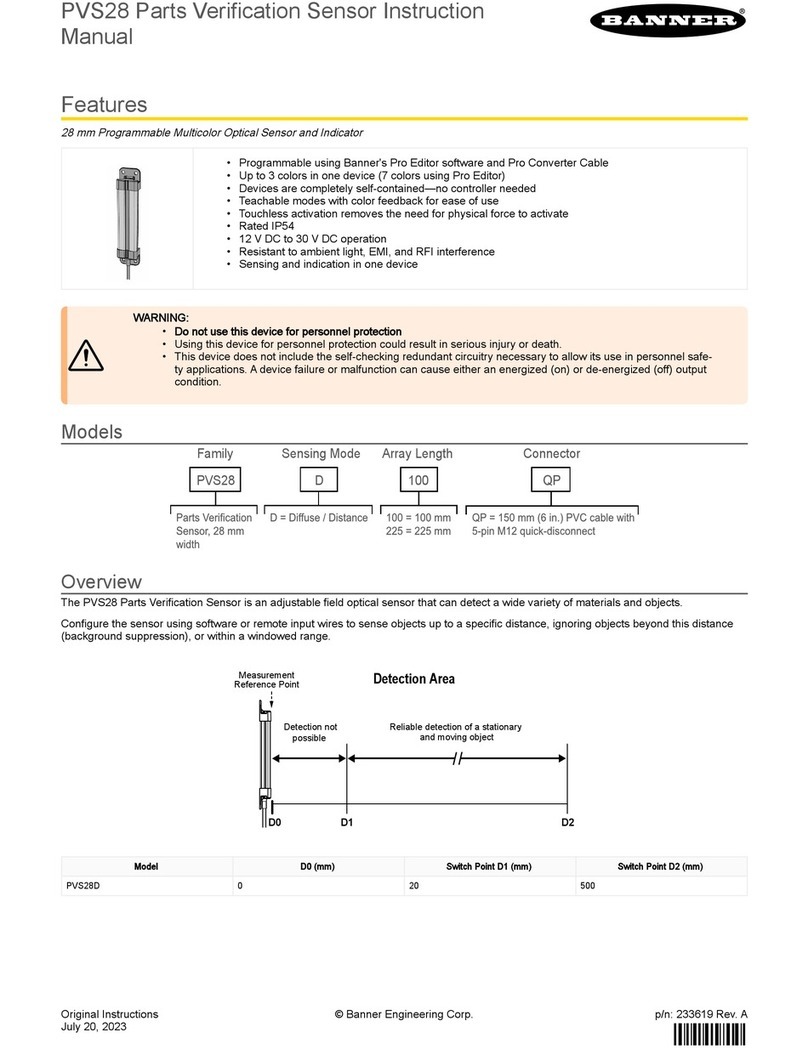

2.2 System Descripon ................................................................................................................................................................................6

2.3 Appropriate Applicaons and Limitaons .............................................................................................................................................7

2.3.1 Examples: Appropriate Applicaons ........................................................................................................................................ 8

2.3.2 Examples: Inappropriate Applicaons ......................................................................................................................................8

2.4 Control Reliability and Safety Categories ...............................................................................................................................................8

2.5 Operang Features ................................................................................................................................................................................ 9

2.5.1 Trip/Latch Output .....................................................................................................................................................................9

2.5.2 Wiring Opons for Emier/Receiver Swapability .................................................................................................................... 9

2.5.3 Manual Reset/Remote Test Input and EDM ...........................................................................................................................10

2.5.4 Status Indicators .....................................................................................................................................................................10

3 Mechanical Installaon .................................................................................................................................................. 11

3.1 Mechanical Installaon Consideraons .............................................................................................................................................. 11

3.1.1 Calculang the Safety Distance (Minimum Distance) ............................................................................................................. 11

3.1.2 Reducing or Eliminang Pass-Through Hazards ..................................................................................................................... 14

3.1.3 Supplemental Safeguarding ................................................................................................................................................... 15

3.1.4 Other Consideraons .............................................................................................................................................................. 15

3.2 Mounng System Components ............................................................................................................................................................19

3.2.1 Overview of Emier/Receiver Mounng Hardware ............................................................................................................... 19

3.2.2 Mounng and Inial Alignment of Emier/Receiver Pairs ..................................................................................................... 20

4 Electrical Installaon and Tesng ................................................................................................................................... 23

4.1 Roung Cordsets .................................................................................................................................................................................. 23

4.2 Inial Electrical Connecons ............................................................................................................................................................... 23

4.2.1 Sensor Interchangeability .......................................................................................................................................................24

4.3 Inial Checkout Procedure ...................................................................................................................................................................25

4.3.1 Conguring the System for Inial Checkout ...........................................................................................................................25

4.3.2 Inial Power-Up ......................................................................................................................................................................25

4.3.3 Opcal Alignment ...................................................................................................................................................................26

4.3.4 Opcal Alignment Procedure with Mirrors ............................................................................................................................ 28

4.3.5 Trip Test ..................................................................................................................................................................................28

4.4 Electrical Connecons to the Guarded Machine .................................................................................................................................29

4.4.1 OSSD Output Connecons ......................................................................................................................................................29

4.4.2 FSD Interfacing Connecons .................................................................................................................................................. 30

4.4.3 Machine Primary Control Elements and EDM Input ............................................................................................................... 31

4.4.4 Manual Reset/Remote Test Input and EDM ...........................................................................................................................31

4.4.5 Preparing for System Operaon .............................................................................................................................................32

4.5 Reference Wiring Diagrams ..................................................................................................................................................................32

4.5.1 Generic Emier Wiring Diagram ............................................................................................................................................ 32

4.5.2 Generic Wiring to FSDs (manual reset) .................................................................................................................................. 33

4.5.3 Generic Wiring — Interface Module (2-Channel EDM, Manual Reset) ..................................................................................34

5 System Operaon ..........................................................................................................................................................35

5.1 Security Protocol ................................................................................................................................................................................. 35

5.2 Reset Procedures ................................................................................................................................................................................ 35

5.2.1 Receiver Resets ...................................................................................................................................................................... 35

5.2.2 Emier Resets ........................................................................................................................................................................ 35

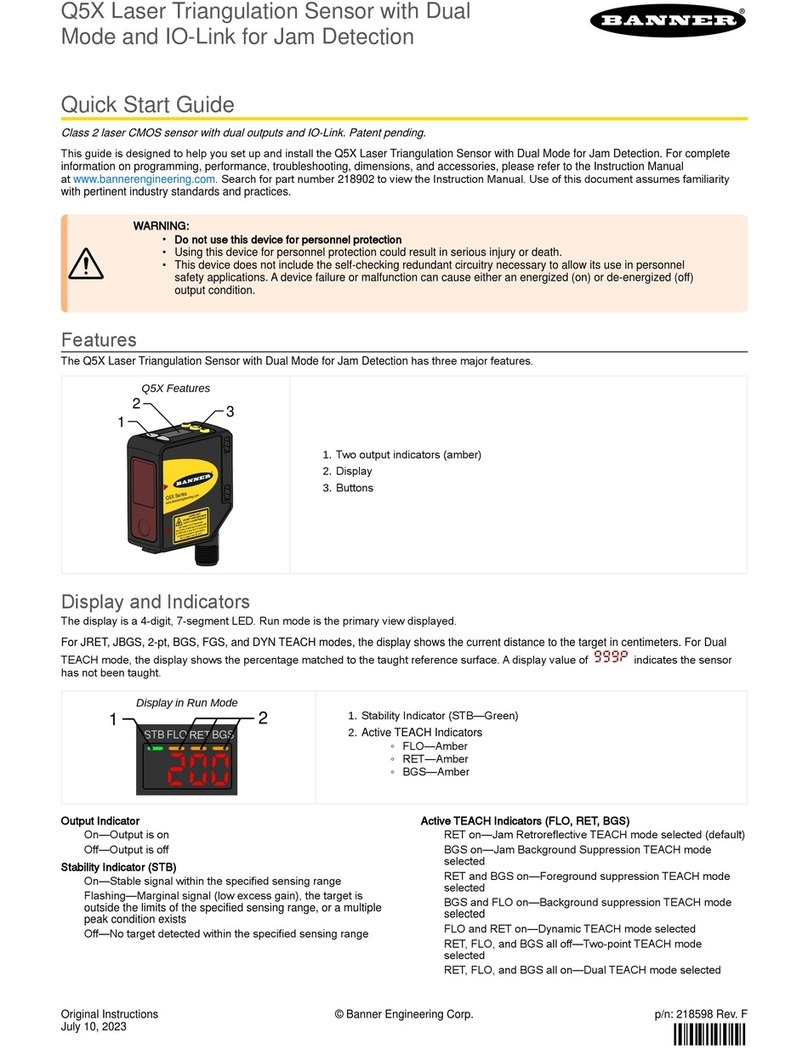

5.3 Status Indicators ..................................................................................................................................................................................35

5.3.1 Receiver ..................................................................................................................................................................................36

5.3.2 Emier ....................................................................................................................................................................................36

5.4 Normal Operaon ............................................................................................................................................................................... 37

5.4.1 System Power-Up ...................................................................................................................................................................37

5.4.2 Run Mode ...............................................................................................................................................................................37

5.4.3 Manual Reset Procedure ........................................................................................................................................................37

6 Troubleshoong and Maintenance ................................................................................................................................38

6.1 Troubleshoong and Lockout Condions ........................................................................................................................................... 38

6.2 Recovery Procedures ...........................................................................................................................................................................38

6.2.1 Receiver (System Reset) .........................................................................................................................................................38

EZ-SCREEN®Type 2 Light Screen