July 20, 2023page6

PVS28 Parts Verification Sensor Instruction Manual

•

•

•

•

•

•

Factory Default Settings via Remote Teach Mode

Default Settings

Setting FactoryDefault

Discrete Output and Remote Input Bimodal

Remote Input Wire Enabled

Teach Offset Distance 50mm(2in)

OperationMode ObjectMode

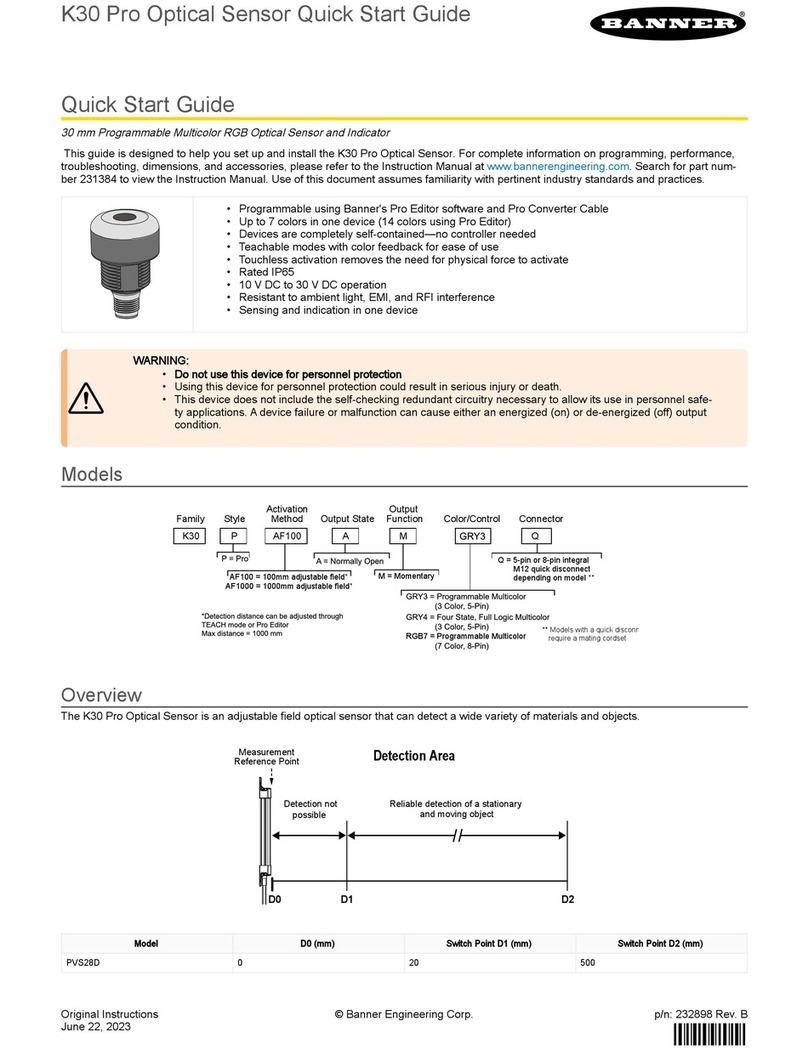

D1 20 mm (0.8 in)

D2 500 mm (19.7 in)

NO/NC Normallyopen

OnDelay 0ms

OffDelay 0ms

Specifications

SupplyVoltage(Vcc)

12VDCto30VDC

Supply Current

Maximumcurrent(exclusiveofload):

100 mm: 85 mA

225 mm: 150 mA

Typical current at 24 V DC (exclusive of load):

100 mm: 35 mA

225 mm: 55mA

SupplyProtectionCircuitry

Protected against output short-circuit

Leakage Current Immunity

400 µA

Range

Thesensorcandetectanobjectatthefollowingranges,de-

pending on the material and size of the target: 20 mm to 500

mm

Retroreflectivemodeextendsthemaximumdistanceto1000

mm

Output Ratings

MaximumLoad: 150 mA

ON-State Saturation Voltage:

<2VDCat10mA

<2.5VDCat150mA

OFF-State Leakage Current: < 10 µA at 30 V DC

Remote Input

Allowable Input Voltage Range: 0 to Vsupply

Active High (internal weak pull-down): High state > (Vsupply -

2.25 V) at 2 mA maximum

Active Low (internal weak pull-up): Low state < 2.25 V at 2 mA

maximum

DelayatPower-up

< 1 s

ResponseTime

Object Mode/Diffuse Mode:

Switching Frequency: 4 Hz

DiscreteOutputResponse:120ms

Retroreflective Mode:

Switching Frequency: 2 Hz

DiscreteOutputResponse:240ms

Sensor Array and Beam Spacing

100 mm model: 2 sensors, 50 mm

225 mm model: 4 sensors, 60 mm

Application Note

For best performance, allow 5 minutes for the sensor to warm

up

Construction

Housing: Polycarbonate

End Caps: ABS

Connections

150 mm (6 in) PVC-jacketed cable with a 5-pin M12 male

quick-disconnect connector

Models with a quick disconnect require a mating cordset

NOTE: A shielded cable is required if the

sensorismountedoutdoorsoriftheca-

bleislongerthan30m(98.4ft).

Pro Editor Configuration

Connection to Pro Editor software enables control of:

Animation:Steady,Flash,TwoColorFlash,50/50,

50/50 Rotate, Chase, Intensity Sweep, Color Sweep

Color:Green,Red,Yellow,Blue,White,Cyan,Ma-

genta

Intensity:Low,Medium,High

Speed:Slow,Standard,Fast

Output State:NormallyOpen,NormallyClosed,Mo-

mentary,Latching,OnDelay,OffDelay

Logic Type:FourStateFullLogic

ProConverterCablerequiredtointerfacebetweenPCandin-

dicator, see accessories

VibrationandMechanicalShock

Meets IEC 60068-2-6 requirements (Vibration: 10 Hz to 55

Hz, 1.0 mm amplitude, 5 minutes sweep, 30 minutes dwell)

MeetsIEC60068-2-27requirements(Shock:30G11msdura-

tion, half sine wave)

Impcat: IK06 (IEC 6006-2-27)

OperatingTemperature

–20°Cto+50°C(–4°Fto+122°F)

Storage Temperature

–40°Cto+70°C(–40°Fto+158°F)

Sensing Beam

Infrared, 940 nm

EnvironmentalRating

IP54

© Banner Engineering Corp.