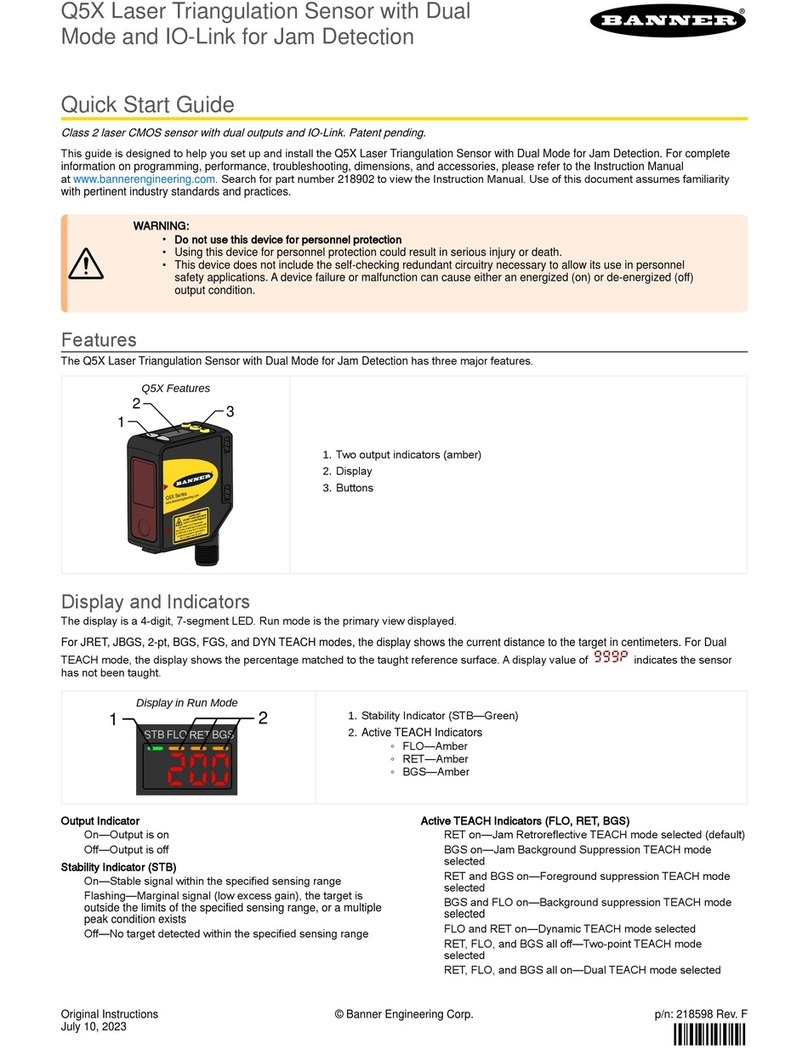

Q5X Laser Triangulation Sensor with Analog Outputs and IO-Link Quick Start Guide

June 14, 2023 page7

•

•

•

•

•

•

•

•

•

•

See the Instruction Manual for detailed instructions and other available TEACH modes. The TEACH modes include:

Two-pointanalogteach2-Pt—Setsthedistancevaluesassociatedwith0Vand10V(4mAand20mA)basedontaughttargetdis-

tances

Onepointanalogteach1-Pt—Setsthe5V(12mA)midpointoftheanalogoutputtocentertheanalogoutputaroundareferencetar-

getposition

Two-pointstaticbackgroundsuppression2-Pt(discrete,channel2only)—Two-pointTEACHsetsasingleswitchpoint.Thesensor

setstheswitchpointbetweentwotaughttargetdistances.

DynamicbackgroundsuppressiondYn(discrete,channel2only)—Dynamic TEACH sets a single switch point during machine run

conditions.Thesensortakesmultiplesamplesandtheswitchpointissetbetweentheminimumandthemaximumsampleddis-

tances.

One-pointwindow(foregroundsuppression)FGS(discrete,channel2only)—One-point window sets a window (two switch points)

centered around the taught target distance.

One-pointbackgroundsuppressionbGS(discrete,channel2only)—One-point background suppression sets a single switch point in

front of the taught target distance. Objects beyond the taught switch point are ignored.

Dualintensity+distanceduAL(discrete,channel2only)—Dualmoderecordsthedistanceandamountoflightreceivedfromtheref-

erencesurface.See"Dual Mode Reference Surface Considerations" on page 11formoreinformationaboutselectingareference

surface. The output switches when an object passing between the sensor and the reference surface changes the perceived distance

oramountofreturnedlight.

ManualAdjustments

Manuallyadjustthesensorswitchpointusingthe+and-buttons.

NOTE: WhenFGSmodeisselected,manualadjustmentmovesbothsidesofthesymmetricalthresholdwindowsimul-

taneously,expandingandcollapsingthewindowsize.Manualadjustmentdoesnotmovethecenterpointofthewin-

dow.

NOTE: When dual mode is selected, after the TEACH process is completed, use the manual adjustment to adjust the

sensitivityofthethresholdsaroundthetaughtreferencepoint.Thetaughtreferencepointisacombinationofthemea-

sured distance and returned signal intensity from the reference target. Manual adjustment does not move the taught

referencepoint,butpressing+increasesthesensitivity,andpressing-decreasesthesensitivity.Whenre-positioning

thesensororchangingthereferencetarget,re-teachthesensor.

Locking and Unlocking the Sensor Buttons

Usethelockandunlockfeaturetopreventunauthorizedoraccidentalprogrammingchanges.

Three settings are available:

—Thesensorisunlockedandallsettingscanbemodified(default).

—Thesensorislockedandnochangescanbemade.

—Theswitchpointvaluecanbechangedbyteachingormanualadjustment,butnosensorsettingscanbechangedthrough

themenu.

WhenthesensorisineitherLocor0Locmode,theactivechannelcanbechangedusing(+)(CH1/CH2).

WheninLocmode,Locdisplayswhenthe(SELECT)(TEACH)buttonispressed.Theswitchpointdisplayswhen(+)(CH1/CH2)or(-)

(MODE)arepressed,butLocdisplaysifthebuttonsarepressedandheld.

Whenin0Locmode,Locdisplayswhen(-)(MODE)ispressedandheld.Toaccessthemanualadjustoptions,brieflypressandre-

lease(+)(CH1/CH2)or(-)(MODE).ToenterTEACHmode,pressthe(SELECT)(TEACH)buttonandholdforlongerthan2seconds.

PressandholdTEACHforlongerthan2secondstostarttheselectedTEACHmode.

Presentthetarget.

PressTEACHtoteachthetarget.Thetargetistaughtandthesensorwaitsforthesecondtarget,ifrequiredbytheselectedTEACH

mode,orreturnstoRunmode.

CompletethesestepsonlyifitisrequiredfortheselectedTEACHmode.

Presentthesecondtarget.

PressTEACHtoteachthetarget.ThetargetistaughtandthesensorreturnstoRunmode.

FromRunmode,presseither+or-onetime.

Theselectedchanneldisplaysbriefly,thenthecurrentswitchpointvalueflashesslowly.

Press+tomovetheswitchpointupor-tomovetheswitchpointdown.

After 1 second of inactivity, the new switch point value flashes rapidly, the new setting is accepted, and the sensor returns to Run

mode.

© Banner Engineering Corp.