2

Contents

Contents.................................................................................................................................. 2

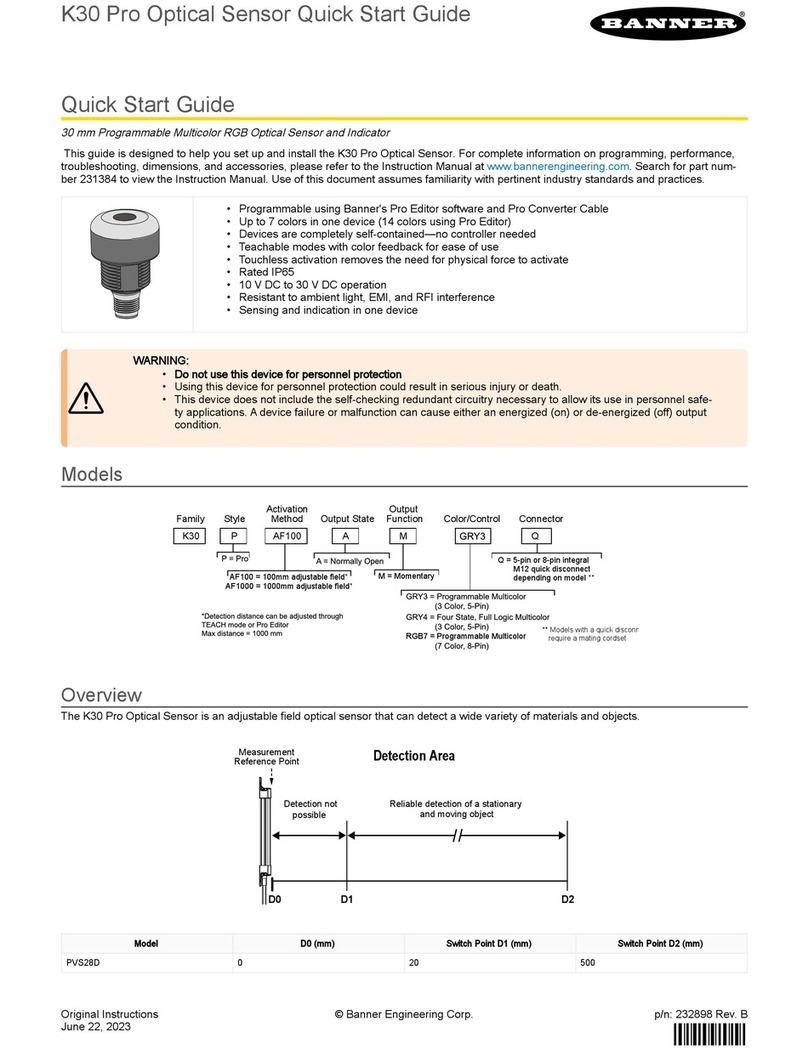

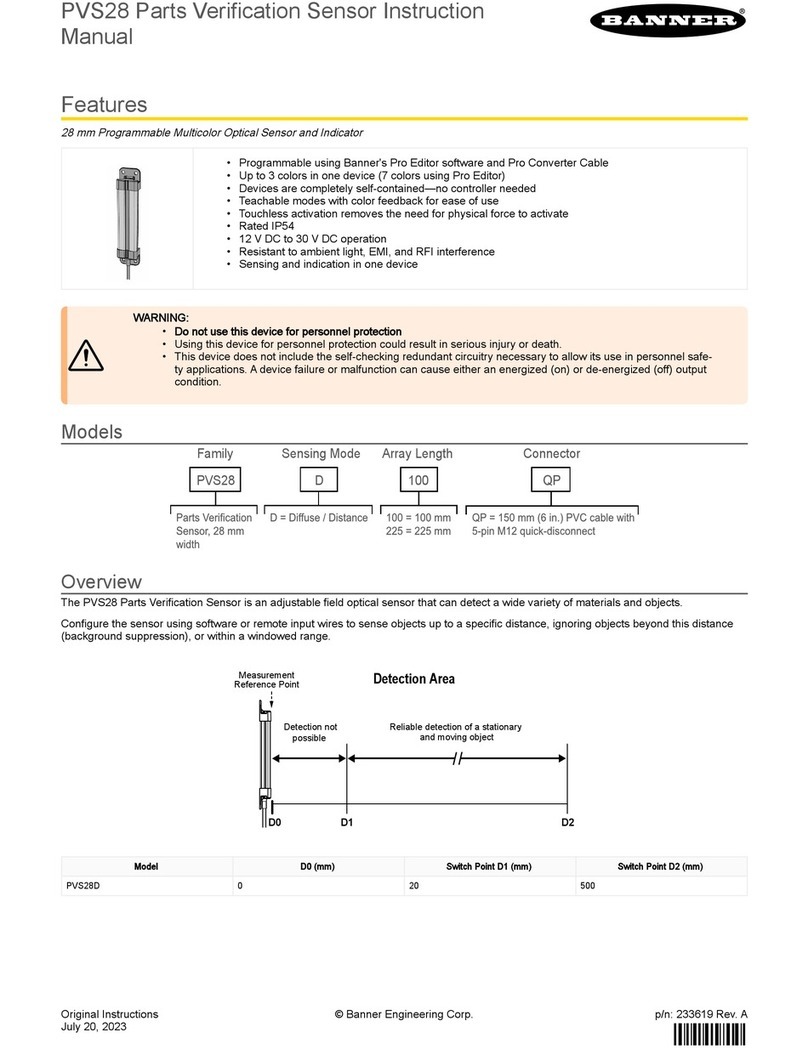

Chapter 1 Product Description

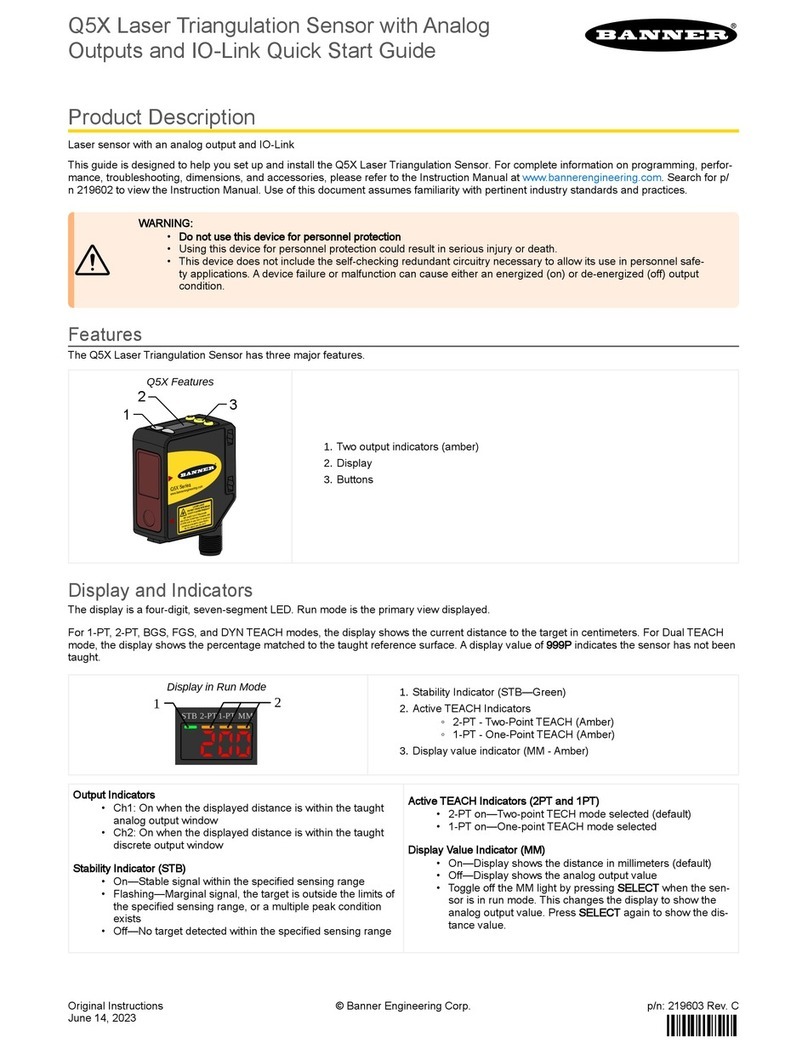

Models .......................................................................................................................................................................................................... 5

Overview...................................................................................................................................................................................................... 5

Class2LaserDescriptionandSafetyInformation ....................................................................................................................................... 6

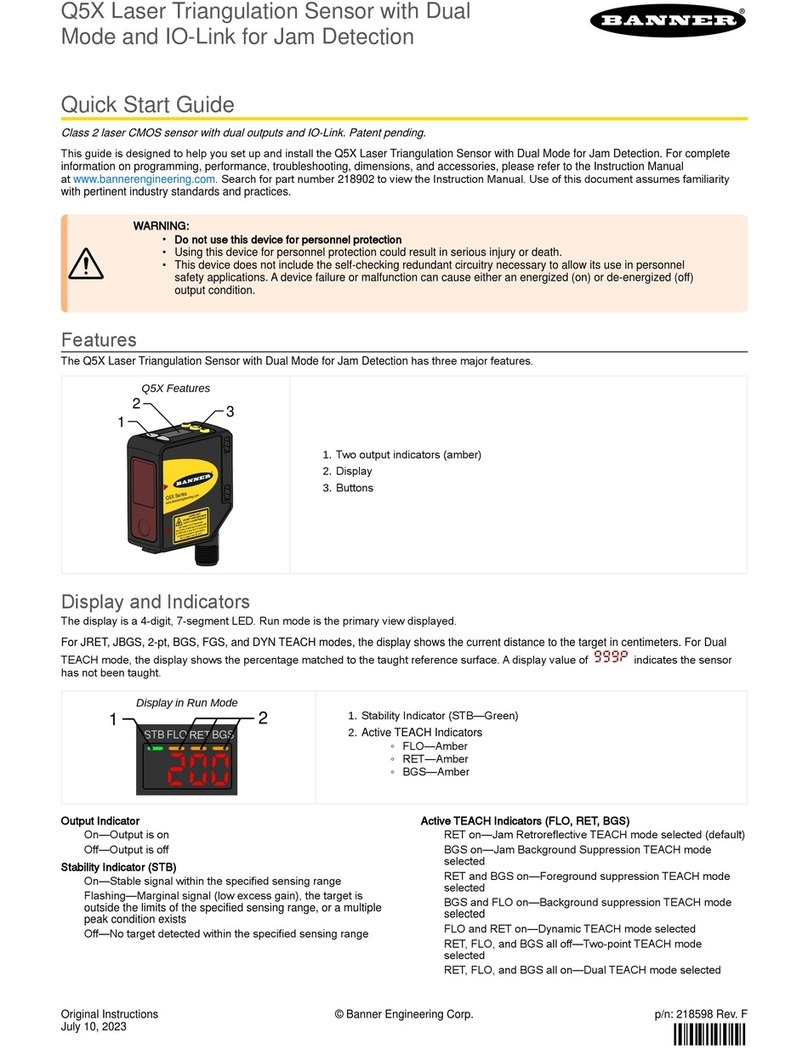

Features ....................................................................................................................................................................................................... 7

Display and Indicators ........................................................................................................................................................................... 7

Buttons.................................................................................................................................................................................................. 7

Chapter 2 Installation

Sensor Orientation........................................................................................................................................................................................ 9

Mount the Device........................................................................................................................................................................................ 10

Wiring Diagrams ......................................................................................................................................................................................... 10

CleaningandMaintenance........................................................................................................................................................................ 10

Button Map from RSD1 to Sensor ............................................................................................................................................................... 11

Chapter 3 Sensor Programming

Channel1andChannel2(CH1/CH2) ....................................................................................................................................................... 13

Setup Mode ................................................................................................................................................................................................ 13

TEACH Procedures (Analog)............................................................................................................................................................... 16

TEACH Mode (Discrete) ...................................................................................................................................................................... 18

LossofSignal(LOS)........................................................................................................................................................................... 24

Input Wire Function (inPt) .................................................................................................................................................................... 25

Trigger (trG) ......................................................................................................................................................................................... 25

Slope (SLPE) ....................................................................................................................................................................................... 26

Output(out2)....................................................................................................................................................................................... 27

Adaptive Tracking (trc2)....................................................................................................................................................................... 27

Window Size (und2)............................................................................................................................................................................. 28

Base Measurement Rate (SPd)........................................................................................................................................................... 28

Averaging............................................................................................................................................................................................ 28

Output Timing Delays .......................................................................................................................................................................... 29

Hysteresis (hYS2)................................................................................................................................................................................ 31

Zero Reference Location (ZEro) .......................................................................................................................................................... 31

Shift the Zero Reference Location after a TEACH (ShFt).................................................................................................................... 32

Offset(oFS1oroFS2)......................................................................................................................................................................... 33

Display View (diSP) ............................................................................................................................................................................. 33

Units (unIt) ........................................................................................................................................................................................... 33

Output Type Polarity (PoL)................................................................................................................................................................... 33

Exit Setup Mode (End)......................................................................................................................................................................... 33

Reset to Factory Defaults .................................................................................................................................................................... 33

ManualAdjustments .................................................................................................................................................................................. 34

Remote Input .............................................................................................................................................................................................. 34

SelecttheTEACHModeUsingtheRemoteInput.............................................................................................................................. 35

ResettoFactoryDefaultsUsingtheRemoteInput ............................................................................................................................ 36

Locking and Unlocking the Sensor Buttons................................................................................................................................................ 36

Button Instructions...................................................................................................................................................................................... 36

Remote Input Instructions........................................................................................................................................................................... 36

SyncMaster/Slave..................................................................................................................................................................................... 37

Chapter 4 IO-Link Interface ................................................................................................. 39

Chapter 5 Specifications

Dimensions................................................................................................................................................................................................. 43

TypicalPerformanceCurves ...................................................................................................................................................................... 43

Chapter 6 Additional Information

Dual (Intensity + Distance) Mode ............................................................................................................................................................... 45

Dual Mode Reference Surface Considerations .......................................................................................................................................... 46

DualModeConsiderationsforClearandTransparentObjectDetection .................................................................................................. 46