Battipav Extra 3300 Superlunga User manual

IT ISTRUZIONI PER L’USO DELLA

TAGLIERINA ELETTRICA

GB OPERATING INSTRUCTIONS

TILE CUTTING MACHINE

FMODE D’EMPLOI MACHINE

À DÉCOUPER LES CARREAUX

DBEDIENUNGSANLEITUNG

FLIESENSCHNEIDMASCHINE

EMANUAL DE INSTRUCCIONES

MÀQUINA PARA CORTAR BALDOSAS E

CZ NÁVOD NA POUŽITÍ

OBKLADAČSKÁ PILA

ORIGINAL MADE IN ITALY

S/N

2

Battipav srl

www.youtube.com/battipav

OFFICIAL CHANNEL

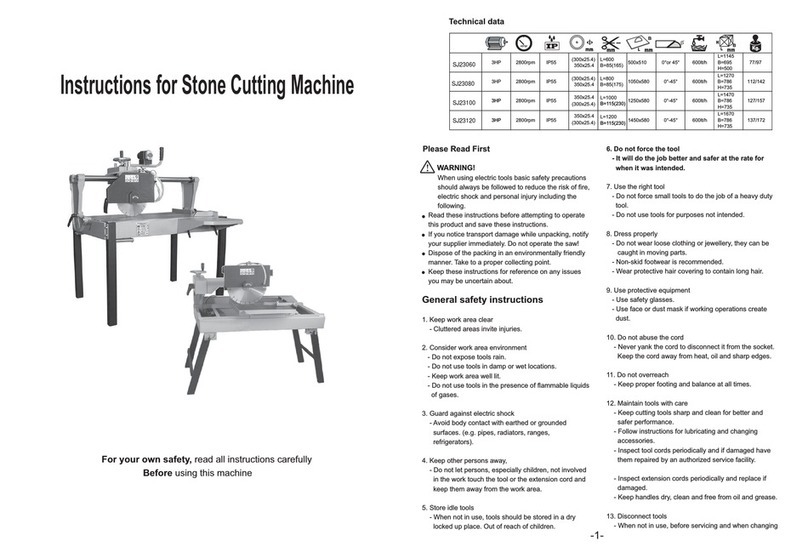

DATI TECNICI - TECHNICAL DATA - DONNÉES TECHNIQUES - TECHNISCHE DATEN - DATOS TÉCNICOS

ART.

6733001 3300 mm 2330 x 2330 mm 40 mm 35 mm 200 /

25,4 mm

1,8 hP/

1,4kW

3950x900x

1260 mm 145 Kg

2M

2800 n

50 W

-1

V ~

2800 n

1400 W

-1

9 A

230V ~ 50Hz

LN

idm1

20 µF 400 VL

°C

XY

M2

sp_v2

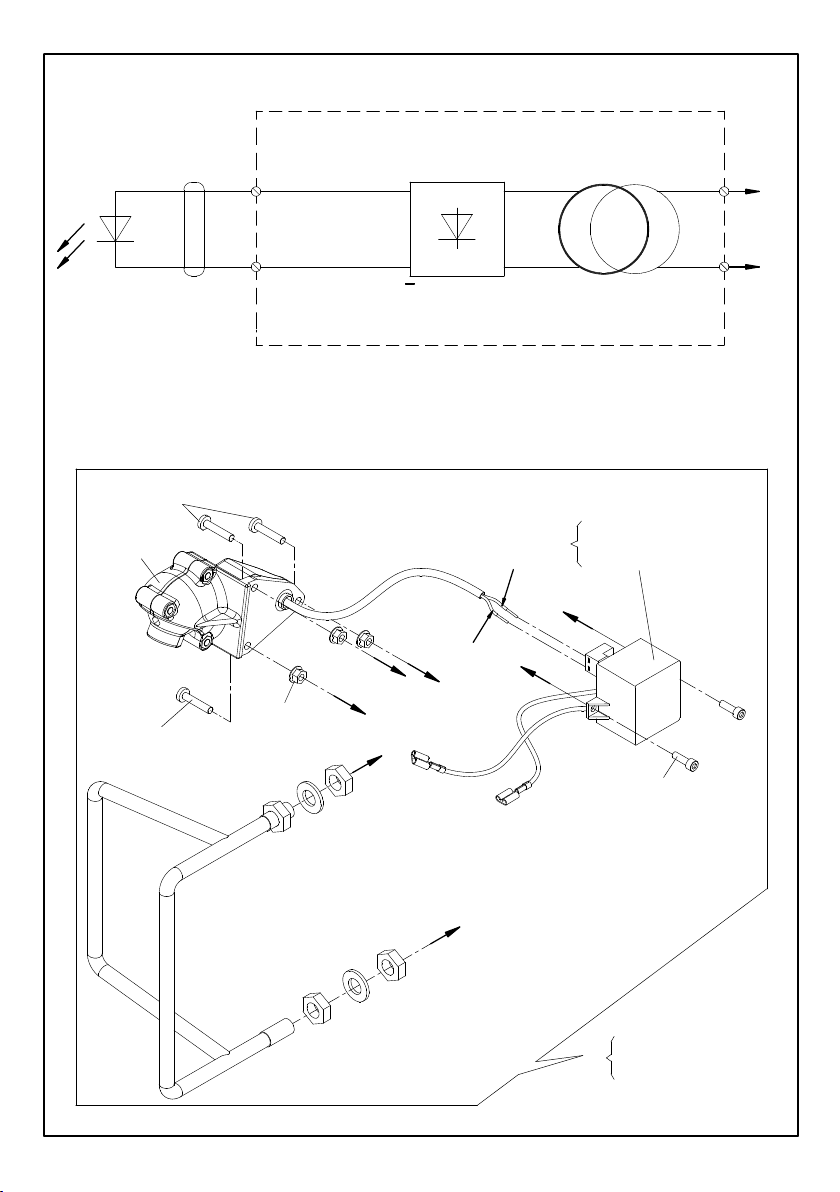

5V D.C.

+

~

~

230V 50/60Hz. (SP90138P)

~

X

Y

HK

LASER

CLASS 3A

635 nm < 5 mW

02 -SP90137

(M3x8)

BLACK (-)

RED (+)

-

+

( )

( )

(M4x20)

(M4x20) C

C

K

90169 (230V-50/60Hz)

SP90138P (230V-50/60Hz)

SP90138P/A (115V-50/60Hz)

03

90169/A (115V-50/60Hz)

01

115V 50/60Hz. (SP90138P/A)

~

7

Battipav srl

IT GB F D E CZ

DICHIARAZIONE CE

DI CONFORMITÀ

EC DECLARATION

OF CONFORMITY

DECLARATION CE

DE CONFORMITE

EG-

KONFORMITÄT-

SERKLÄRUNG

DECLARACIÓN DE

CONFORMIDAD CE

CE PROHLÁŠENÍ O

SHODĚ

Il costruttore: The builder: Le fabricant: Der Hersteller: El fabricante: Výrobce:

BATTIPAV S.R.L. - Z.I.2 Via Cavatorta 6/1 - 48033 Cotignola (RA) ITALY - Tel 0545 40696 - info@battipav.com - www.battipav.com

Dichiara sotto la propria

esclusiva responsabilità che

il prodotto

Declares under your sole

responsibility that the product

Déclare sous votre seule

responsabilité que le produit

Erklärt in alleiniger

Verantwortung, dass das

Produkt

Declara bajo su exclusiva

responsabilidad que el

producto

Potvrzuje a přejímá plnou

zodpovědnost za to, že

produkt

Serie Series Série Baureihe Serie Série

EXTRA SUPERLUNGA

Modello art. Art. Art. Kunst. Art. Označení

Mod. 6733001 - 230V ~ 50 Hz 1400 W S3 40% 2800 min-1 MOTOR CLASS F

Tipo Model Type Typ Tipo

Taglierina da cantiere per

taglio su ceramica, marmo,

granito e gres no ad altezza

di 40mm e lunghezza di

3300mm.

Cutters for ceramic, marble,

granite, gres products up to a

height of 40 mm and a length

of 3300mm.

Coupeur de chantier pour la

coupe de céramique, marbre,

granit et grès jusqu’à une

hauteur de 40 mm et une

longueur de 3300mm.

Baustellenschneider zum

Schneiden von Keramik,

Marmor, Granit und Steinzeug

bis zu einer Höhe von 40

mm und einer Länge von

3300 mm.

Cortador de obra para cortar

cerámica, mármol, granito

y gres hasta una altura de

40 mm y una longitud de

3300 mm.

Pila na keramiku, mramor,

žulu, gresové obklady do

tloušťky 40 mm a délky 3300

mm.

A cui si riferisce la presente

dichiarazione e’ conforme alle

seguenti Direttive

This Declaration relates to the

following Directives

Cette déclaration concerne les

directives suivantes

Diese Erklärung bezieht sich

auf die folgenden Richtlinien

La presente Declaración

se reere a las siguientes

Directivas

Toto prohlášení je v souladu s

následujícím předpisem

2006/42/EC (MD), 2014/35/EU (LVD), 2014/30/EU (EMC), 2011/65/EU (RoHS II)

Riferimento alle pertinenti

norme armonizzate utilizzate Reference to the relevant

harmonized standards used

Référence aux normes

harmonisées pertinentes

utilisées

Bezugnahme auf die

einschlägigen harmonisierten

Normen

Referencia a las normas

armonizadas pertinentes

utilizadas

Odkaz na příslušné použité

normy

EN12418:2000+A1:2009, EN61029-1:2009+A11:2010, EN61029-2-7:1993, EN60335-1:2012+A11:2014,

EN60335-2-41:2003+A1:2004+A2:2010, CEI EN 61000-6-1:2007, CEI EN 61000-6-3:2007+A1:2013, CEI EN 610003-2:2015, CEI EN 61000-3-3:2014

e autorizzo Zoli Alberto a

costituire il fascicolo tecnico

and Zoli Alberto is authorized

to compile the technical le et Alberto Zoli est autorisé à

constituer le dossier technique

und Alberto Zoli ist berechtigt,

die technischen Unterlagen

zusammenzustellen

y Alberto Zoli tiene

autorización para elaborar el

expediente técnico

Zoli Alberto je oprávněn

k sestavení technického

souboru

Data di costruzione N° di Serie: Date of manufacture Series N. Date de fabrication N° de série ProduktionsdatumSeriennummer Fecha de fabricaciòn N° de serie: Datum výroby, sériové číslo

Cotignola,

8

Battipav srl

3

4

5

6

7

8

9

10

9

Battipav srl

11

12

13

14

15

16

17

18

10

Battipav srl

19

20

1

2

1.5m1.5m

1.5m

21

22

23

24

25

26

11

Battipav srl

27

28

29

30

31

32

33

22

GB Battipav srlBattipav srl GB

“TRANSLATION OF THE ORIGINAL

INSTRUCTIONS”

PURPOSE OF THIS MANUAL

This manual is an integral part of the machine.

It was produced by BATTIPAV S.R.L. to provide

those authorised to work with the machine with the

information required for its foreseeable lifespan.

Before starting to use this machine read the safety

chapter carefully.

Each machine is subjected to a series of tests and

carefully checked before leaving our factory.

BATTIPAV S.R.L. is constantly striving to develop

their machines and therefore reserves the right to

make any change without prior notice. Therefore, no

claims may be made on the basis of the data and

illustrations contained in this manual.

SAFETY INFORMATION

• The manufacturer accepts no responsibility

where the EXTRA cutter is used with

any tools other than those specied in

the “RECOMMENDED USE” paragraph.

DO NOT USE WOODEN DISCS.

DO NOT USE DRY-CUTTING DISCS.

• EXTRA is made to operate exclusively under the

conditions indicated under “TYPE OF OPERATION

ALLOWED”, in the “TECHNICAL DATA” paragraph.

• During cutting operations, allow

the machine to rest as indicated.

• EXTRA is not made for use

with a continuous load.

CAUTION

DO NOT USE DIAMOND TIPPED DISCS OF LOW

QUALITY OR THAT ARE NOT SUITABLE FOR THE

SPECIFIC USE FOR WHICH THE MANUFACTURER

SUPPLIED THEM. THE USE OF POOR QUALITY

DISCS CAN HARM THE OPERATOR AND DAMAGE

THE MACHINE, AS WELL AS SIGNIFICANTLY

SLOWING THE WORK.

CAUTION

THE MACHINE IS NOT INTENDED FOR USE IN AN

EXPLOSIVE ENVIRONMENT

CAUTION

ALWAYS USE INDIVIDUAL PROTECTION DEVICES

TO REDUCE THE RISKS CAUSED BY WORK. NEVER

START THE MACHINE WHEN THE CUTTING TOOL

IS MOVING; WAIT FOR IT TO STOP.

Warning! When using electric tools, following

safety precautions should always be followed to

reduce the risk of re, electric shock and personal

injuries. Read and follow all these instructions

before attempting to operate this product and save

them with care!

SAVE THESE INSTRUCTIONS WITH CARE.

Keep your work area perfectly clean

• Cluttered areas invite injuries.

Consider work area environment

• Don’t expose tools to rain.

• Don’t use tools in damp or wet locations. Keep

work area well lit.

• Don’t use tools in presence of ammable liquids

or gases.

Guard against electric shocks

• Prevent body contact with grounded surfaces.

Keep children away!

• Do not let third parties contact tool or extension

cord. All visitors should be kept away from work

area.

23

Battipav srl GB

Store your tools in a save place

• When not in use, tools should be stored in dry and

save places, out of the reach of children.

Don’t force tool

• It will function better and in a safer way at the rate

for which it was intended.

Use the right tool

• Don’t use low duty tools or accessories to do

the job of a heavy-duty tools. Don’t use tools for

purposes not intended.

Dress properly

• Rubber gloves and non-skid footwear are

recommended when working outdoors. Wear

protective hair covering to contain long hair. Use

safety glasses.

• Use a mask if working operations are dusty.

Don’t abuse cord

• Never carry tool by cord or yank it to disconnect it

from socket.

• Keep cord from heat, oil and sharp edges.

Avoid unsteady positions

• Be sure to work in a safe and balanced position.

Maintain tools with care

• Keep tools sharp and clean for better and safer

performance.

• Follow all maintenance advice and instructions to

replace accessories subject to wear. Inspect tool

cords periodically and, if damaged, have them

repaired by an authorised expert. Check extension

cords periodically and replace them if damaged.

Keep handles dry, clean and free from oil and

grease.

Disconnect tools

• When not in use, before servicing, and when

changing accessories subject to wear.

Remove service keys from tool

• Form the habit of checking to see that keys and

adjusting wrenches are removed from tool before

turning it on.

Avoid unintentional starting

• Be sure that the switch is off when plugging in the

tool.

Extension cords for outdoor works

• When tool is used outdoors, use only extension

cords intended for this particular use and so

marked.

Stay alert

• Watch what you are doing. Use common sense.

Do not operate tool when you are inattentive.

Check tool for damaged parts

• Before further use of the tool, check it and the

safety devices for damages and be sure that

they operate properly. Check for functioning

and binding of moving parts, breakage of parts,

correct mounting, and any other conditions that

may affect the correct operation of the tool.

• Damaged safety devices or other parts should

be properly repaired or replaced by an authorised

Service Centre unless otherwise indicated

elsewhere in this instruction manual.

• Have defective switches replaced by an

authorised Service Centre.

• Do not use tool if its switch cannot be turned on or

off.

Warning

• For your personal safety use only accessories

recommended in this instruction manual or in

the relevant catalogues The use of any other

accessory or attachment other than those

recommended in this instruction manual or in the

relevant catalogue may present a risk of personal

injury.

Have tools repaired by qualied personnel

• This electric appliance is in accordance with

the safety rules in force. Only qualied experts

may carry out repairing of electric appliances

otherwise it may cause considerable danger for

the user.

24

GB Battipav srl

MANUFACTURER AND MACHINE

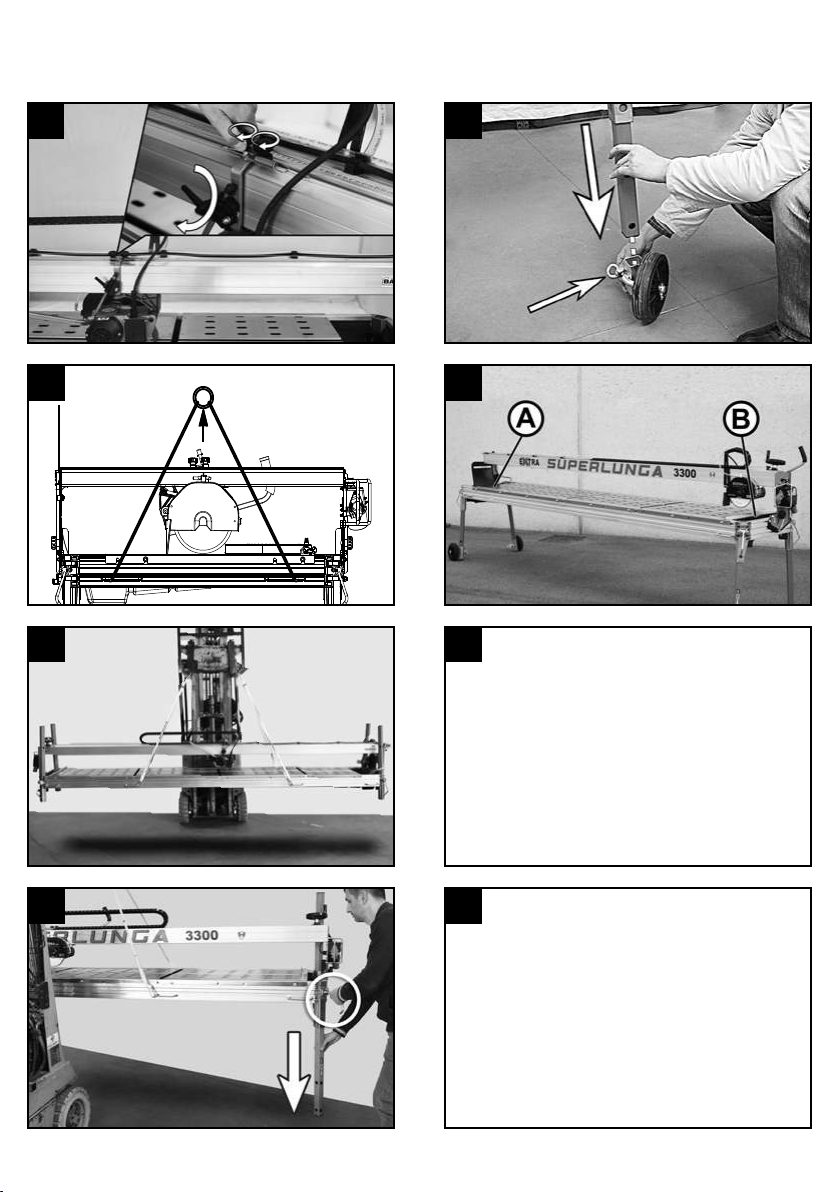

The nameplate shown is tted directly on the

machine. It indicates all the references and

information necessary for safe operation.

1

AMachine model MIP Level

BItem NYear of

manufacture

CSerial number OMax tool

diameter

DPower supply

voltage PInternal tool

diameter

EPower supply

frequency QAccessories

FCurrent

absorption RAccessories

GInstalled power

rating SManufacturer’s

name

HTool rotation

speed T

Manufacturer’s

name and

address

ICLASS of

protection UCertication

Marks

LStarter capacitor

TYPE N°art.

V~ PHz A

min-1 cl.is

Ø max Ø int.

µF IP YEAR

Made by: BATTIPAV SRL

Via Cavatorta, 6/1 Z.i. 2 - 48033 - Cotignola (RA) ITALY

A B C

D E F G

H

O

Q

R

S

T

P

I L M N

U

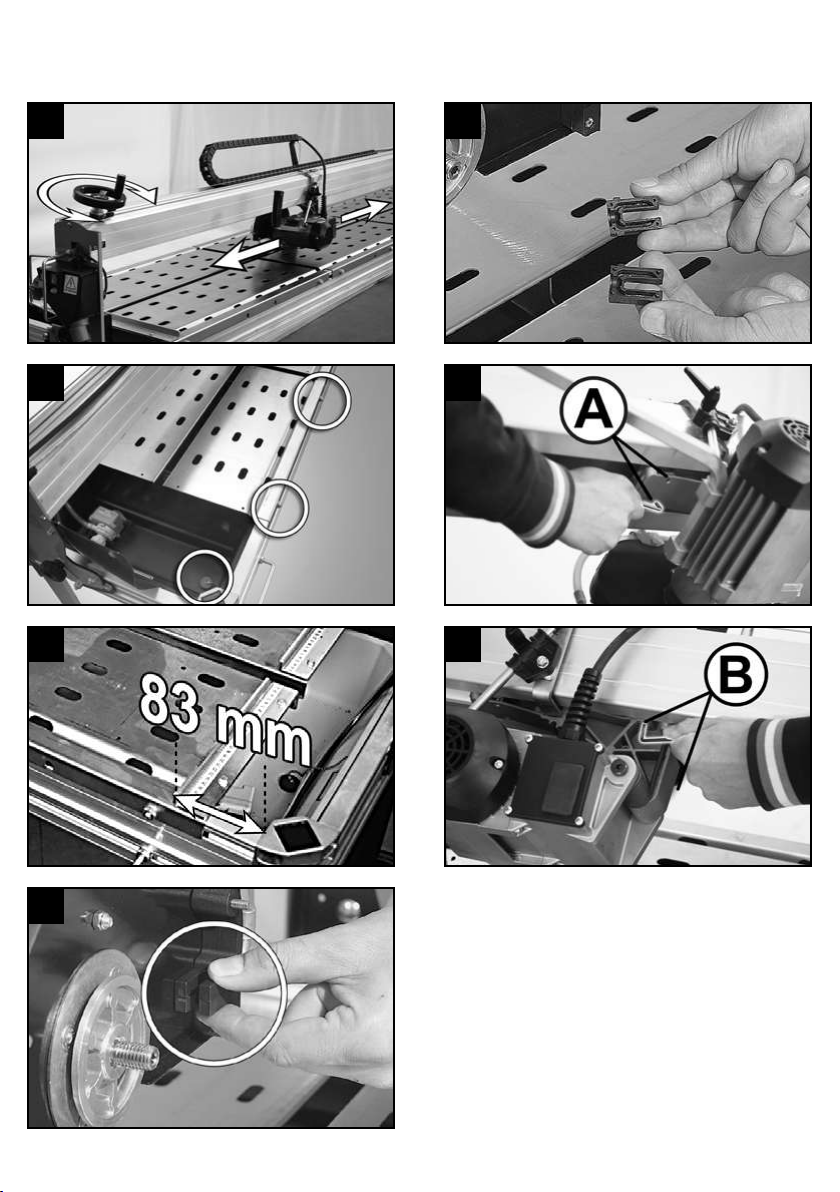

SIGNS

Danger/prohibition stickers are applied to the

machine where necessary. Look at these prior to

using the machine.

A

Use of prescribed PPE

obligatory (Safety

eyewear and earmuffs)

A

Read operating

instructions before each

use.

A

Use of prescribed PPE

obligatory ( Protective

Gloves )

AWarning! Danger of

accidental contact

BDo not use discs for

wood or metal

B

90254

Do not wash with water

under pressure

CRecovery tank water

level

DWarning!

Secure the carriage

EPresence energy

electric

25

Battipav srl GB

A

B

D

E

C

MACHINE DESCRIPTION

The EXTRA site cutter is a machine intended

specically for cutting ceramics, single-red items,

terracotta, and marble (Max thickness 20 mm), up to

a thickness of 65 mm.

The machine uses a wet diamond tipped tool cutting

system and is intended for personnel specialized in

the construction sector.

The operator works in front of the narrow side of

the machine, within reach of the operating controls,

and positions the material to be cut on the moving

worktop. He/she starts the machine and moves the

cutting head to bring the tool into contact with the

material.

TECHNICAL DATA

Voltage: 230V 50Hz~

Power absorbed: 1400 W

Admissible working conditions:

INTERMITTENT S3 SERVICE

30s under load running

30s repose

Rotation speed: 2800 min-1

Condenser: 20 µF

Thermal circuit breaker: 170°C

IP Degree: 54

RECOMMENDED USE:

CUTTING TOOL

DIAMOND BLADE WET CUTTING

CONTINUOUS CROWN:

ceramic, single-red ceramic, cotto and marble

THE TOOL / MATERIAL TO BE CUT MATCHES ARE

PURELY INDICATIVE.

ALWAYS FOLLOW THE INTENDED USE

INDICATIONS PROVIDED BY THE CUTTING TOOL

MANUFACTURER BEFORE ANY APPLICATION.

Water recirculation pump:

S0 230V 50/60Hz

(Art. 66900, 661050)

S1 230V 50/60Hz

(Art. 661350, 661351)

The noise emitted by these machines was

measured on production samples in compliance

with ISO 3745-77 standards.

The machine was positioned on an H800 (mm)

auxiliary table.

The samples comprised 314x314x8 (mm) single

red tiles, mod. P3T287 1200 °C. K = 2, \[ dB ], pr

EN 848 - 1

Sound:

LOADLESS VALUES

Lw 72,4 [dBW(A)] 0,0 [mW(A)]

Lpm 61,5 [dB(A)] 61,5 [dB(C)max]

UNDER LOAD VALUES

Lw 101,5 [dBW(A)] 14,3 [mW(A)]

Lpm 92,0 [dB(A)] 100,7 [dB(C)max]

In working conditions, the machine creates a noise

emission above 85 dB(A).

INSTALLATION

TRANSPORT / HANDLING

Move the EXTRA saw by using the specially provided

side handles.

3Before moving the machine make sure that:

• The motor slide is locked in place at the centre

of the machine with the two cutting adjustment

knobs on the slide rail.

• The motor slide is completely lowered and locked

with the locking lever.

2

26

GB Battipav srl

• The inclination adjustment knobs are properly

tightened.

TO MOVE THE MACHINE

4 Use a 4 (four)-arm tie rod, making use of the

hooks in the transport handles.

5TO MOVE THE MACHINE, USE A FOUR-ARM

TIE ROD WITH THE CAPACITY TO LIFT 200KG

OR AT LEAST 20% MORE THAN THE MACHINE

WEIGHT.

USE LIFTING EQUIPMENT TO MOVE THE MACHINE

POSITIONING

6 Once the machine is raised, lower a leg at a time

and lock it with the specic locking pin. Place the

machine on a stable and perfectly level surface.

CAUTION!

7Fit the transport wheels to the legs on the rear

side.

8Lay the machine onto the surface.

910 Level the machine on both sides

by adjusting the position of the legs

(A and B)

11 Fit the additional working tables supplied

together with the machine:

12 • Use a 17-mm spanner to loosen the side nuts

that fasten the working tables.

13 • Fit the additional working table by inserting the

fastening eyelet on the locking screw.

CAUTION!

14 Bring all the working tables to the same axis

before locking.

Adjust height by acting on the legs.

15 • Lock the table by tightening the screws in the

frame.

16 • Make sure that the tile bearing square of the

additional working table is aligned with those

of the working table of the machine.

CHECKING BEFORE USE

THE EXTRA SAW HAS BEEN DESIGNED FOR

WORKING EXCLUSIVELY WITH WATER.

17 Before any cutting operation, make sure that the

water level inside the tank is correct.

MAKE SURE THAT THE PUMP IS FULLY IMMERSED.

IF IT IS NOT, CHECK THAT THE MACHINE IS

CORRECTLY LEVELLED.

CAUTION!

ADJUSTMENT OF COOLING WATER

18 Through an on-off valve placed on the disk

protection, the water ow can be adjusted

according to the type of material to be cut. An

innovative cooling system makes it possible and

allows the disk to be always wet.

CONNECTING TO POWER SUPPLY

CAUTION

The machine is to be connected to the power supply

by a residual current circuit breaker (RCCB) with the

following characteristics:

RCCB In 10 A Id 30 mA

Transformer 230 V 50 Hz 2000 W

Transformer

N.B. To ensure correct functioning, periodically

check the eciency of RCCBs by pressing the

push-button on the front of the device.

• Make sure that the section of the power supply

cable cores has been measured according to the

starting current and its length.

For cables up to 50 m long, a section of 2.5 mm2

is enough.

• Before connecting the machine to the power

socket, check that the power supply voltage

corresponds to that shown on the plate on the

machine.

• The machine must be connected to an effective

earth wire.

In case of doubt, do not connect the machine.

27

Battipav srl GB

BLADE ASSEMBLY / DISASSEMBLY

Before performing any operation or adjustment,

disconnect the machine from the supply mains.

Loosen both nuts located on the blade cover guard

and remove it.

Remove the blade xing nut using the 19 mm

spanner and the 5 mm Allen wrench.

CAUTION

19 THE BLADE FIXING NUT HAS A LEFT-HAND

THREAD.

After dismantling the blade, clean the blade anges

carefully and check them for wear.

Grease any surface with ne oil and install the new

blade. Check for correct direction of rotation as

clearly indicated on the tool.

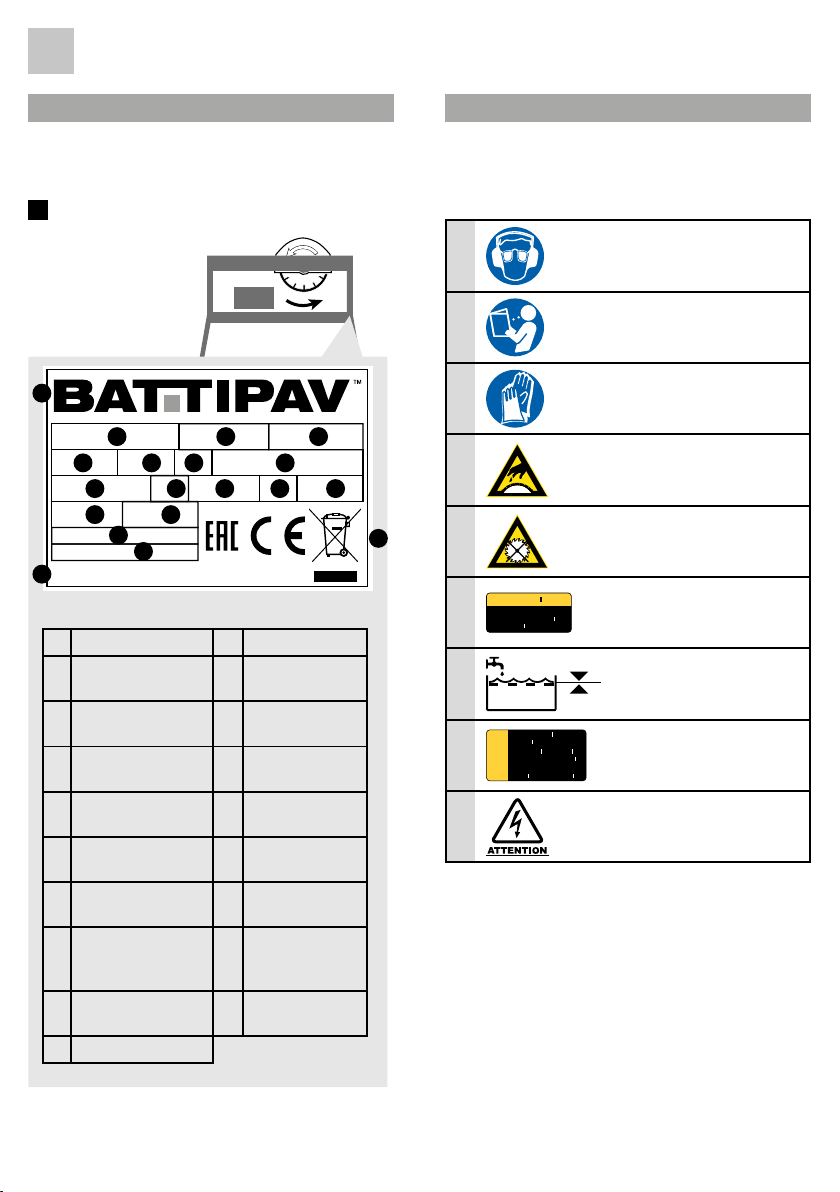

CONTROL DEVICES

CAUTION

20 The EXTRA machine is equipped with a control

board made up of:

1) START BUTTON (GREEN COLOUR):

Press the button fully to activate machine

starting.

2) REGULAR STOP BUTTON:

Press the button fully to activate machine

stop.

3) DEVICE FOR DISCONNECTION FROM THE

MAINS (PLUG):

Machine power supply point.

During the maintenance phases, take out the

device plug in order to disconnect the machine

from the mains.

4) LASER MARKER

It projects the cutting line on the table.

It is enabled when the machine is connected to

the mains.

CUTTING ON THE TABLE

CAUTION

BEFOREPERFORMINGTHECUTTINGOPERATIONS,

MAKE SURE THAT THE MATERIAL IS PROPERLY

LEANED AGAINST THE TILE STOPPER.

CAUTION

21 BEFORE STARTING THE CUTTING

OPERATIONS, THE OPERATOR MUST MAKE

SURE THAT AT LEAST 150 cm ARE LEFT FREE

AROUND THE MACHINE (Pos. 2).

IN ORDER TO WORK IN SAFETY CONDITIONS,

DO NOT LET OTHER PEOPLE REMAIN NEAR

THE MACHINE DURING THE CUTTING

OPERATIONS.

THE OPERATOR STANDS IN THE WORKING

POSITION (Pos. 1) DURING THE DIFFERENT

MACHINE OPERATION PHASES.

22 Different types of cutting are possible thanks to

the high versatility of the EXTRA saw.

Position the piece to be cut on the working

table and make sure that is properly leaned

against the tile stopper.

CAUTION

THE MILLIMETRE RULER PLACED ON THE

WORKING TABLE HELPS ONLY WITH THE

CARRYING OUT OF LINEAR CUTTING.

CUTTING A SURFACE AT 45°

CAUTION

Before positioning the motor head, make sure that:

• the machine is off;

• the cutting tool is not moving;

23 Referring to the graded scale located on the

machine upright, move the motor head to the

JOLLY position and tighten the knobs.

With the locking lever, lower the cutting head until

placing the blade some millimetres below the table

level.

28

GB Battipav srl

CAUTION

BEFORE CUTTING LARGE PIECES, PLEASE CHECK

THE SIZE TO BE CUT (CUT BEGINNING AND END)

COMPARED TO THE DISK.

With the EXTRA machine it is also possible to set out:

a) the cutting length with the cutting adjustment

knobs.

b) the cutting depth with the locking lever.

c) the straight cut measurement with the tile bearing

square as well as the ruler placed on the working

table.

24 In order to carry out special working it is possible

to set out any cutting inclination ranging from 0°

to 45° as marked on the machine side.

LASER MARKER

CAUTION

CLASS I 635 nm, < 5 mW LASER INSTRUMENT

By means of the laser marker accessory, the cutting

operations can be accelerated.

CAUTION

THE LASER MARKER STARTS WORKING ONCE THE

MACHINE IS CONNECTED TO THE POWER SUPPLY.

CUTTING WITH LASER MARKER

• connect the machine to the power supply;

• position the piece to be cut making sure that

the line indicated by the laser marker matches

the reference on the material to be cut;

25 • perform the cutting operation as indicated in

the paragraph: “cutting on the table”

CAUTION

DO NOT MODIFY THE MARKER POSITION BY

TURNING THE BEAM TOWARDS THE OPERATOR’S

EYES.

DO NOT GAZE AT THE BEAM WITH THE NAKED EYE

OR LOOK DIRECTLY WITH OPTICAL INSTRUMENTS.

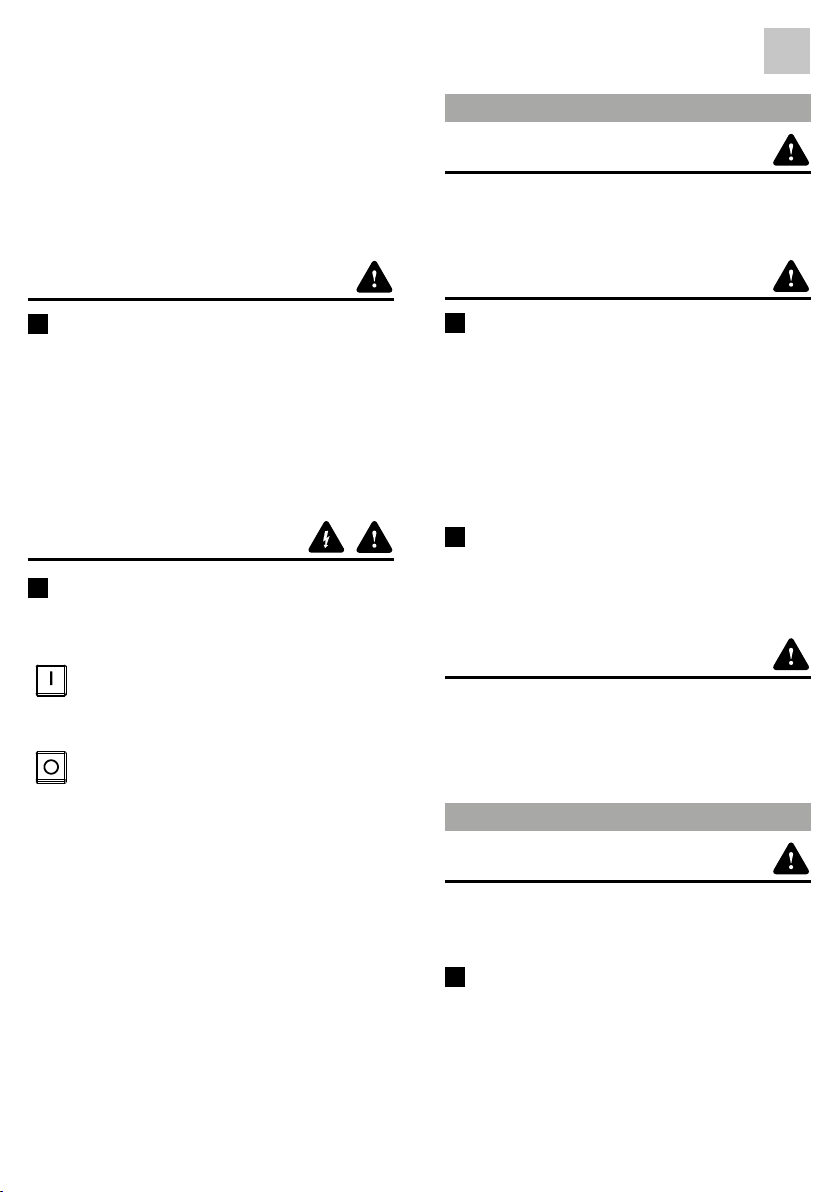

ADJUSTMENT OF THE TRACER

In case the marker is not aligned with the cutting line,

its correct alignment can be adjusted.

In order to correctly position the marker, proceed as

follows:

26 • Loosen the three bulb locking screws so that it

can be moved.

• Position a reference properly on the tool

cutting line.

26 • Insert the 5 mm Allen wrench provided in the

hexagonal slot located on the bulb.

• Using the Allen wrench, turn the bulb until

aligning the mark with the tool cutting line.

CAUTION

DURING THE ADJUSTMENT OPERATIONS, MAKE

SURE THAT THE LINE PRODUCED BY THE MARKER

DOES NOT REACH THE OPERATOR’S EYES.

CAUTION

THE MANUFACTURER DECLINES ANY LIABILITY

FOR THE USE OF THE LASER MARKER IN

APPLICATIONS OTHER THAN THE INDICATED

APPLICATION.

CUTTING PROGRESS SYSTEM

27 The “CUTTING PROGRESS SYSTEM” can be

used to adjust – in a very precise manner and

by means of the hand wheel located on the

machine front upright – the cutting head forward

or backward movement.

CAUTION

GIVEN THE ACCESSORY HIGH SENSITIVITY,

PROCEED WITH CAUTION SO AS NOT TO

ACCIDENTALLY LOCK THE CUTTING TOOL.

RESIDUAL RISKS

During the design phase, BATTIPAV SRL paid

particular CAUTION to the aspects that may generate

risks for the safety and health of operators.

In spite of this, there are still some potential risks,

which are described below:

29

Battipav srl GB

CAUTION

• Danger of presence of electric current.

The machine has an internal electric system:

CONNECT THE MACHINE TO A SYSTEM WITH

DIFFERENTIAL PROTECTION AND EFFECTIVE

EARTH WIRE.

CAUTION

• Danger of prolonged exposure to noise:

The continuative use of the machine causes an

exposure to noise levels above 85 dB (A).

OPERATORS MUST USE PROPER EAR

DEFENDERS.

CAUTION

• Danger of exposure to fragments of

materials. OPERATORS MUST WEAR

PROTECTIVE GOGGLES.

CAUTION

• Danger of accidental contact with the moving

tool.

OPERATORS MUST WEAR HEAVY PROTECTIVE

GLOVES

ALWAYS STAY IN THE WORKING POSITION

(Pos. 1 picture 19) DURING THE MACHINE

OPERATION PHASES:

• During material loading;

• During material cutting;

• During the cutting tool deceleration following the

machine stop.

MAINTENANCE

CAUTION

BEFORE PERFORMING ANY OPERATION OR

ADJUSTMENT, DISCONNECT THE MACHINE FROM

THE SUPPLY MAINS.

CLEANING

CAUTION

DO NOT WASH THE MACHINE WITH HIGH

PRESSURE WATER JETS

28 It is extremely easy to clean the EXTRA saw by

loosening the locking nuts and removing the

working table. Through the side tap remove any

working residual.

CAUTION

29 AFTER THE TANK CLEANING OPERATIONS,

PLACE THE WORKING TABLE BACK IN

POSITION, OBSERVING THE DISTANCE FROM

THE LEG SUPPORT.

30 31 For a greater eciency of the patented

SPRAY SYSTEM lubrication system, clean

it regularly as indicated.

CAUTION

MOTOR CARRIAGE ADJUSTMENT

The motor carriage is provided with a register for the

vertical play adjustment.

For correct adjustment, proceed as follows:

32 • with a 3 mm Allen wrench, screw both front

adjustment dowels (A), until the play is

eliminated.

33 • repeat the operation for both back adjustment

dowels (B).

CAUTION

TIGHTEN THE FOUR REGISTERS EQUALLY IN

ORDER TO OBTAIN SUITABLE SMOOTHNESS.

30

GB Battipav srl

DISPOSAL

When parts wear out or when the machine is nally

scrapped, waste disposal must be carried out in

compliance with the laws in force.

Electric Motor

Aluminium AL

Steel AC

Copper CU

Polyamide PA

Main Body

Steel AC

Polyamide PA

Submersed pump

Polyamide PA

Steel AC

Aluminium AL

Copper CU

Epoxy Resin

The European Directive 2012/19/EU

arranges that in the event of scrapping

of electrical equipment, they must not

be disposed of city solid refusals but collected

separately, in order to optimize the level of recovery

and recycling of the materials and above all in order

to prevent damages to health and environment.

To comply with European Directive 2012/19/EU, all

electrical equipments must be marked with crossed

basket symbol.

The packing of the machine will be disposed of in

accordance with the methods laid down by current

legislation.

For further information concerning disposal

of electrical equipment, please refer to public

administration service.

31

Battipav srl GB

TROUBLESHOOTING

HAVE YOUR TOOL REPAIRED BY A QUALIFIED PERSON

This electric tool complies with the relevant safety rules. Repairs should only be carried out by qualied

persons using original spare parts, otherwise this may result in considerable danger to the user.

Malfunctions not related to a conformity defect that exists at the time of purchase are excluded from the

warranty. Exclusions include:

- Wear of materials (taking into account the average life of the product)

- Failure to comply with the recommendations contained in this manual.

- Maintenance and tampering carried out by unauthorized personnel.

- Use of non-original spare parts.

Faul Cause Remedy

The machine does not work. The power supply cable is not properly

connected.

Press the plug rmly into the power

socket. Check the power supply cable.

No voltage in the socket. Have the socket checked.

Control switch is damaged. Consult local dealer for replacement.

If lubrication does not arrive at the

disk with the pump running.

The sprayer unit is clogged. Dismantle the sprayer assembled inside

the disk cover and remove any possible

residuals.

Motor gives off unpleasant odour. Water may have seeped through inside

the motor

Unplug the power supply cable and

consult local dealer.

Machine is dicult to start. Motor bearings are damaged. Unplug the power supply cable and

consult local dealer.

The machine is cutting out of square. The tile supports are not at right angles

with the cutting disc.

Using a square, adjust the tile supports

to 90° in relation to the cutting line of

the disc.

The disc is not suitable for the type of

material to be cut.

Replace the disc with a more suitable

one.

The laser marker does not work. The laser unit is damaged. Contact your local dealer for a

replacement.

The marker feeder is damaged. Contact your local dealer for a

replacement.

Other manuals for Extra 3300 Superlunga

1

Table of contents

Other Battipav Cutter manuals

Battipav

Battipav Queen 180 User manual

Battipav

Battipav CLASS plus User manual

Battipav

Battipav Super Pro EVO 65 User manual

Battipav

Battipav Queen 180 User manual

Battipav

Battipav PROFI EVO 6401EV User manual

Battipav

Battipav Extra 3300 Superlunga User manual

Battipav

Battipav Foragres User manual

Battipav

Battipav VIP 850 User manual

Battipav

Battipav SINTESI User manual

Battipav

Battipav Super Pro 450 User manual