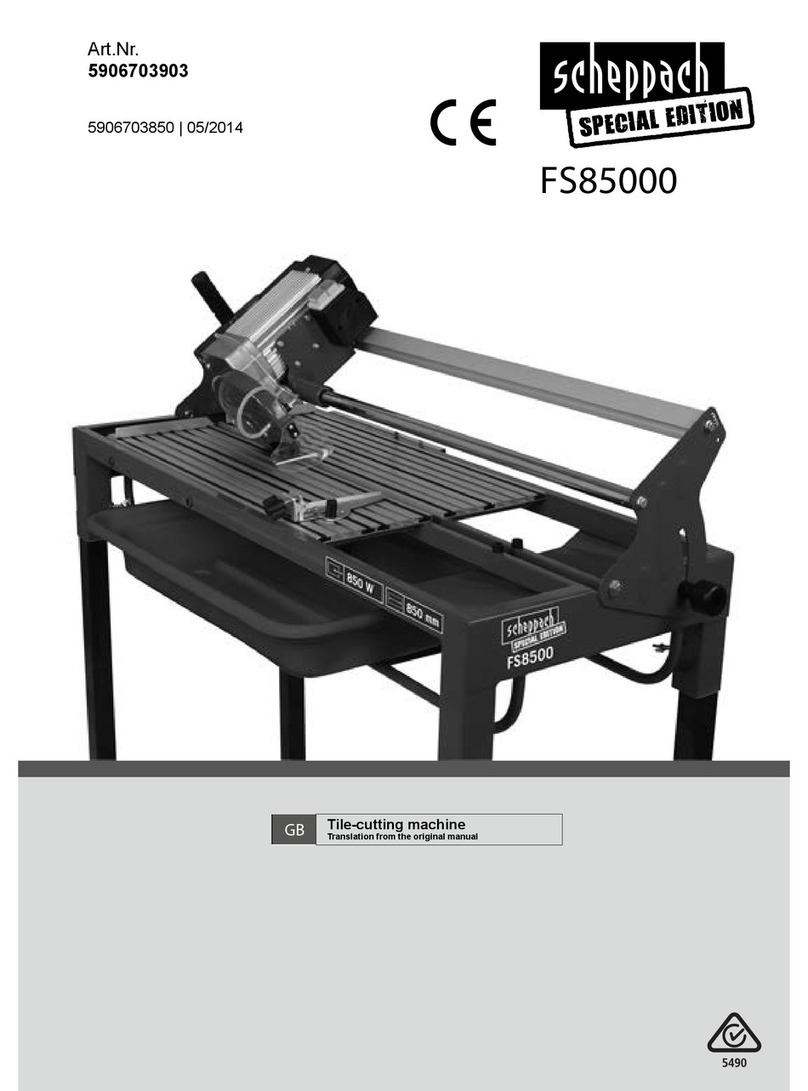

Battipav VIP 850 User manual

IT ISTRUZIONI PER L’USO DELLA

TAGLIERINA ELETTRICA

GB OPERATING INSTRUCTIONS

TILE CUTTING MACHINE

FMODE D’EMPLOI MACHINE

à DéCOUPER LES CARREAUX

DBEDIENUNGSANLEITUNG

FLIESENSCHNEIDMASCHINE

EMANUAL DE INSTRUCCIONES

MàqUINA PARA CORTAR BALDOSAS

DK BETjENINGSvEjLEDNING

FLISESAvEMASkINE

PL DOkUMENTACjA TECHNICZNO-

RU

KZ

AR

ORIGINAL MADE IN ITALY

2

Battipav srl

DATI TECNICI - TEchNIcAL DATA - DONNéEs TEchNIquEs - TEchNIschE DATEN - DATOs TécNIcOs

- TEkNIskE DATA - DANE TEchNIczNE -

ART.

845 450 mm. 318 x 318 mm. 40 mm. 40 mm. 200 / 25,4

mm 1,3hP/1,0kW 960x570x

500 mm. 31 Kg.

850 600 mm. 424 x 424 mm. 40 mm. 40 mm. 200 / 25,4

mm 1,3hP/1,0kW 960x570x

500 mm. 34 Kg.

855 900 mm. 636 x 636 mm. 40 mm. 40 mm. 200 / 25,4

mm 1,3hP/1,0kW 1270x570x

500 mm. 38,5 Kg.

856

1100 mm.

777 x 777 mm. 40 mm. 40 mm. 200 / 25,4

mm 1,3hP/1,0kW 1480x570x

500 mm. 42 Kg.

www.youtube.com/battipav

OFFICIAL CHANNEL

M2

M2

230 V 50 Hz

3 G x 1 RNF

35 W

2800 n

-1

2800 n

1000 W

-1

14 F 400 VL

V ~

v6

170 °C

O

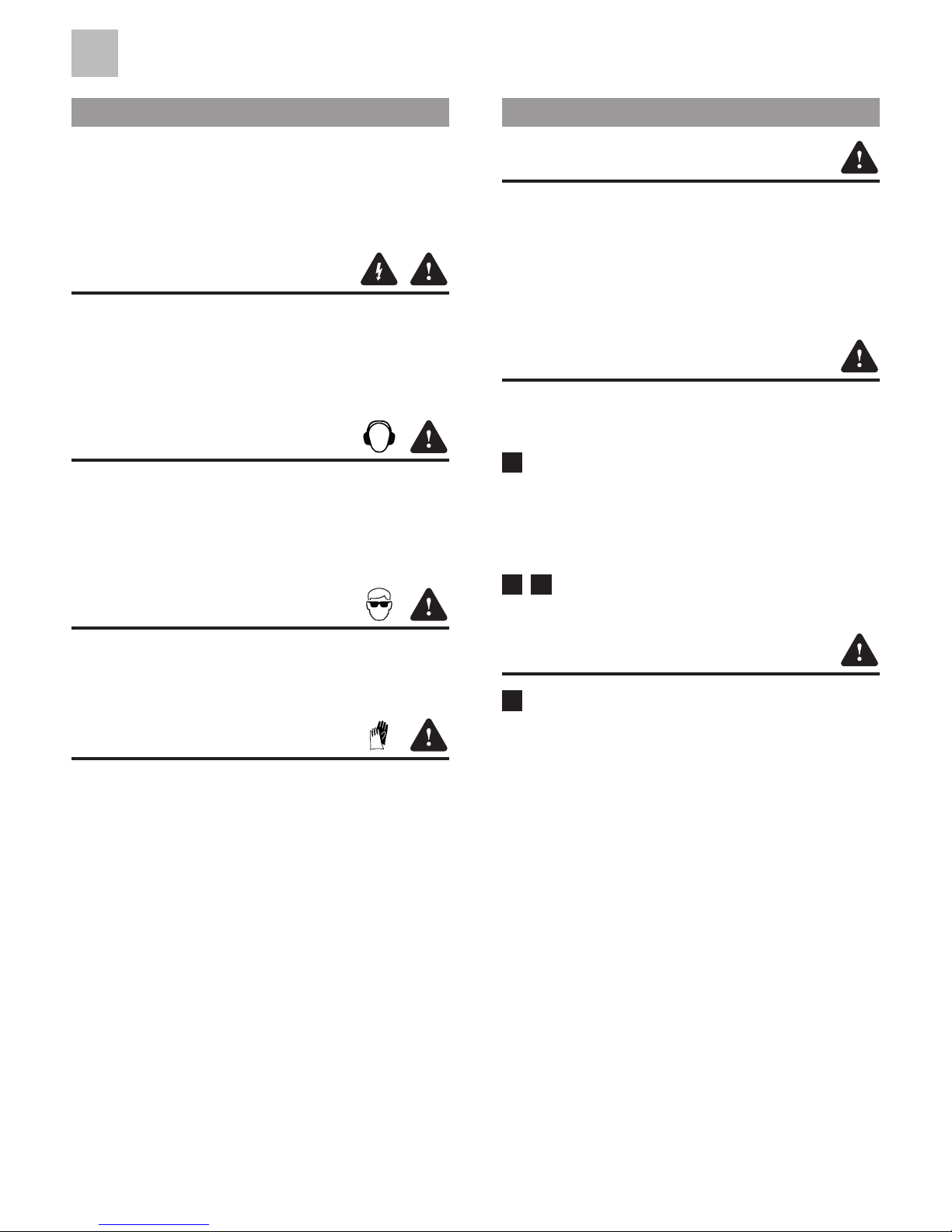

I

SP8500201 7 -

SP81807/2

19

-

SP85001120

-

SP8500211 8 -

SP85002414 -

SP85000711 -

SP0305505

-

SP85003004

SP85000406 -

SP85005201 -

SP85000840 -

SP390245

S03 8 -

SP85000406 -

SP850025

3 3 -

SP850045C31 -

SP855038

SP850001

27

sp_v22

SP390260 12

SP390290 (290)

(245)

(260)

07

(245)

(290)

(260)

SP845001

SP855001 (290)

(260)

(245)

SP850038

08

SP845038

(290)

(260)

(245)

SP850022C23 -

45

45

0606

0

-28 SP90251

-

-SP850065

37

SP07071T

25

(x1) (x1) (x1) (x1) (x1)

SP81807/2

-19 SP81807/2

-

19 SP81807/2

SP845038

SP850038

SP855038

(245)

(260)

(290) 08

(260)

(245)

(290)

SP855005

26 SP850005

SP845005

SP850004

(x1) (x1)

(x1) (x1)

SP850007

-17 SP850020

SP850020

(x1)(x1)

SP850052

(x4)

-24 SP850054

-

04 SP850030

SP850030

(x1) (x1)

SP850033 (245/260/290)

(x1) (x1)

(x1)

16

C

C

B

C

-15 SP850071

SP85007115 - SP850039 -3 6

SP85007115 -

-15 SP850071

SP85007/11C

(x2)

SP85007/11C32 -

B

SP8506002 -

- SP85007335

A

A

(x1)(x1)

SP850077 -03 SP850077

SP85007703 -

SP850080S

(x6)

-30 SP850080S

SP85009329 -

SP85502839 -

-09 SP88071

-15 SP850071

SP8500711 5 -

-15 SP850071

SP85007115 -

-15 SP850071

SP850071 -1 5

-15 SP850071

SP90080 -

34

SP850071

15

-

-

15 SP850071

SP85007115 -

-02 SP85060

SP8506002 -

-02 SP85060

(VITI e DADI PER TESTA MOTORE)

(SCREWS AND NUTS FOR POWER PLANT)

SP85007115 -

-15 SP850071

21-SP850084

SP850071

SP85060

(VITI e DADI PER TELAIO)

(SCREWS AND NUTS FOR FRAME)

-

02 SP85060

(x1)(x1)

SP84025

(x1)

-13 SP84025

SP8506002 -

-

02 SP85060

SP8506002 -

-02 SP85060

SP8506002 -

SP8506002 -

-02 SP85060

SP8506002 -

10-SP85007

I

O

SP845050

22

-

05 SP03055

(x1)

(245)

(x1) (x2)

37 -SP850065

-

SP856033 (2110)

SP3902110 (2110)

(2110)

SP845002

SP850002

SP855002

SP856002

SP856038 (2110)

SP850050

(260)

SP855050

(290)

SP856050

(2110)

SP850033 (245/260/290)

SP856033 (2110)

(2110)SP856005

SP856001 (2110)

SP856038 (2110)

(x5) (x5)

4

Battipav srl

IT GB F D E

DICHIARAZIONE CE

DI CONFORMITÁ

EC DECLARATION

DECLARATION CE

DE CONFORMITE

EG-

kONFORMITÄTSER-

kLÄRUNG

DECLARACIÓN DE

CONFORMIDAD CE

Il sottoscritto,

rappresentante il

seguente costruttore

The undersigned,

representing the following

manufacturer

Le soussigné,

représentant le

constructeur ci-aprés

Der Unterzeichner, der den

nachstehenden Hersteller

vertritt

El abajo rmante, en

representación de

BATTIPAv S.R.L.

dichiara qui di seguito che

la taglierina per ceramica,

monocottura, marmo

herewith declares that

the cutting machine for

ceramic, single-ring

ceramic, marble

déclare par la présente que

le coupe-carreaux pour

céramique, monocuisson,

marbre

erklärt hiermit, daß die

Schneidemaschine für

Keramikiesen, einfach

gebrannten Fliesen,

Marmor

declara que la cortadora

para cerámica,

monococción, mármo

Mod. 845, Mod. 850, Mod. 855, Mod. 856

230V ~ 50 Hz 1000 W S3 50%

2800 min-1

MOTOR CLASS F

risulta in conformità a

quanto previsto dalle

seguenti direttive

comunitarie:

DIRETTIVA 2006/42/CE,

DIRETTIVA 2006/95/CE,

DIRETTIVA 2004/108/CE,

DIRETTIVA 2002/96/CE.

e che sono state

applicate tutte le norme

e/o speciche tecniche

indicate.

is in conformity with the

provisions of the following

EC directives:

2006/42, 2006/95,

2004/108, 2002/96

and that the standards

and/or technical

specications referenced

have been applied.

est conforme aux

dispositions des directives

CE suivantes:

DIRECTIVE 2006/42/CE,

DIRECTIVE 2006/95/CE,

DIRECTIVE 2004/108/CE,

DIRECTIVE 2002/96/CE.

et que les normes et/ou

spécications techniques

ont été appliquées.

in Übereinstimmung ist

mit den Bestimmungen

der nachstehenden EG-

Richtlinien:

EG RICHTLINIE 2006/42,

EG RICHTLINIE 2006/95,

EG RICHTLINIE 2004/108,

EG RICHTLINIE 2002/96.

und daß die Normen

und/oder technischen

Spezikationen, zur

Anwendung gelangt sind.

es conforme con las

disposiciones de las

siguientes directivas CE:

DIRECTIVA 2006/42/CE,

DIRECTIVA 2006/95/CE,

DIRECTIVA 2004/108/CE,

DIRECTIVA 2002/96/CE

y que se han aplicado

las normas y/o

especicaciones técnicas

referenciadas.

EN ISO 12100-1, EN ISO 12100-2, EN ISO 14121-1, EN 61029-1, EN 60335-1, EN 60335-2-41, EN 12418, IEC 1029-2-7,

EN 55014-1, EN 55014-2, EN 610006-1, EN 610006-3, EN 610006-4-2, EN 610006-4-4, EN 610006-4-5, EN 610006-4-6

e autorizzo Zoli Alberto

a costituire il fascicolo

tecnico

and Zoli Alberto is

authorized to compile the

technical le

et Alberto Zoli est autorisé

à constituer le dossier

technique

und Alberto Zoli

ist berechtigt, die

technischen Unterlagen

zusammenzustellen

y Alberto Zoli tiene

autorización para

elaborar el expediente

técnico

Data di costruzione

N° di Serie: Date of manufacture

Series N. Date de fabrication

N° de série Produktionsdatum

Seriennummer Fecha de fabricaciòn

N° de serie:

Direttore Generale

Claudio Tondini

General Manager

Claudio Tondini

Le Directeur Général

Claudio Tondini

Der Generaldirektor

Claudio Tondini

Director General

Claudio Tondini

5

Battipav srl

Dk PL RU kZ AR

EF OvERENSSTEM-

MELSESERkLÆRING

DEkLARACjA

ZGODNOOCI WE

CE

Undertegnede, der

repræsenterer følgende

fabrikant

Niżej podpisany,

reprezentujący rmę: Нижеподписавшийся

представитель

следующего

конструктора

Келесі конструктордың

төмендегі қолқоюшы

өкілі

BATTIPAv S.R.L.

erklærer hermed at

Skæremaskinen for

keramik, enkeltbrændt,

marmor

niniejszym deklaruje, że

przecinarka tarczowa do

ceramiki

Заявляет, что обрезной

станок для

керамики, плиток

монообжига, мрамора

Керамика, мəрмəр,

моноблок тақталар жəне

ұқсасматериалдарды

кесуге арналған

станокың

Mod. 845, Mod. 850, Mod. 855, Mod. 856

230V ~ 50 Hz 1000 W S3 50%

2800 min-1

MOTOR CLASS F

er i overensstemmelse

med bestemmelserne i

følgende EF direktiver:

EF direktiv 2006/42, EF

direktiv 2006/95, EF

direktiv 2004/108, EF

direktiv 2002/96.

og at alle standarder

og/eller tekniske

specikationer er blevet

anvendt.

spełnia wymagania

następujących dyrektyw

Wspólnoty Europejskiej:

2006/42/CE, 2006/95/CE,

2004/108/CE, 2002/96/

CE

oraz, że zastosowano

normy zharmonizowane.

соответствует

следующим

европейским

директивам:

ДИРЕКТИВА 2006/42/

CE, ДИРЕКТИВА

2006/95/CE,

ДИРЕКТИВА 2006/108/

CE, ДИРЕКТИВА

2006/96/CE.

и что при его

производстве были

соблюдены все

нормы и/или указанные

специфические

операции

Келесідей еуропалық

директиваларға

сакелетінін: ДИРЕКТИВА

2006/42/CE,

ДИРЕКТИВА2006/95/

CE, ДИРЕКТИВА

2006/108/

CE,ДИРЕКТИВА

2006/96/CE.жəне оны

өндіріп шығару кезінде

нормаларсақталғанын,

көрсетілген ерекше

ерацияларсақталғанын

:

,CE/2006/42

,CE/2006/95

,CE/2004/108

.CE/2002/96

/

.

EN ISO 12100-1, EN ISO 12100-2, EN ISO 14121-1, EN 61029-1, EN 60335-1, EN 60335-2-41, EN 12418, IEC 1029-2-7,

EN 55014-1, EN 55014-2, EN 610006-1, EN 610006-3, EN 610006-4-2, EN 610006-4-4, EN 610006-4-5, EN 610006-4-6

og Alberto Zoli

bemyndiges til at

udarbejde det tekniske

dossier

i Alberto Zoli jest

upoważniona do

przygotowania

dokumentacji technicznej

Золи и Альберто имеет

право составить

техническую

документацию

Золи жəне Альберто

техникалыққұжаттарды

құруға құқылы

Fremstillingsdato

Serie N.: Data produkcji

Numer seryjny. Дата выпуска

N° серии: Шығарылған күні

Серия № :

Direktør

Claudio Tondini

Dyrektor naczelny

Claudio Tondini

Генеральный директор

Claudio Tondini

орткдире Бас

Claudio Tondini

6

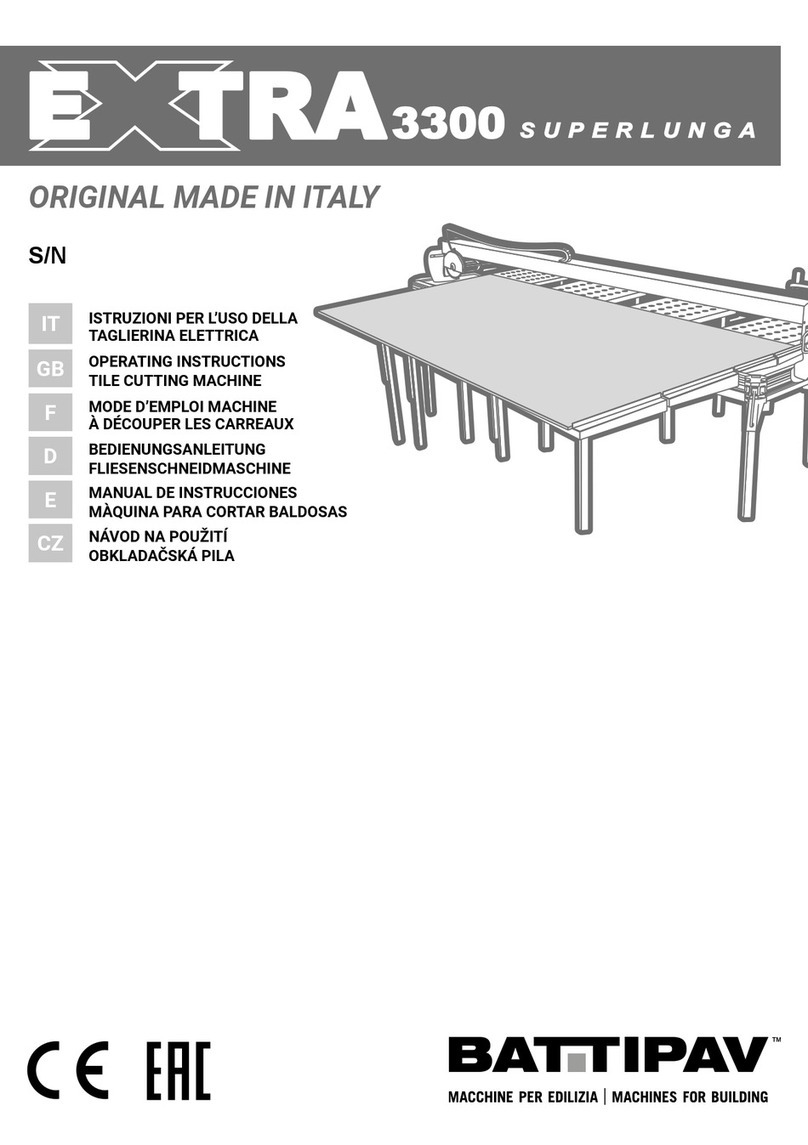

Battipav srl

3

4

5

6

7

8

9

1

2

1.5m1.5m

1.5m

10

7

Battipav srl

11

12

13

14

15

16

17

18

16

GB Battipav srl

“TRANSLATION OF THE ORIGINAL

INSTRUCTIONS”

PURPOSE OF THIS MANUAL

This manual is an integral part of the machine.

It was produced by BATTIPAV S.R.L. to provide

those authorised to work with the machine with the

information required for its foreseeable lifespan.

Before starting to use this machine read the safety

chapter carefully.

Each machine is subjected to a series of tests and

carefully checked before leaving our factory.

BATTIPAV S.R.L. is constantly striving to develop

their machines and therefore reserves the right to

make any change without prior notice. Therefore, no

claims may be made on the basis of the data and

illustrations contained in this manual.

• The manufacturer accepts no responsibility where

theVIPcutterisusedwithanytoolsotherthanthose

specied in the “RECOMMENDED USE” paragraph.

DO NOT USE WOODEN DISCS.

DO NOT USE DRY-CUTTING DISCS.

• VIP is made to operate exclusively under the

conditions indicated under “TYPE OF OPERATION

ALLOWED”, in the “TECHNICAL DATA” paragraph.

• During cutting operations, allow

the machine to rest as indicated.

• VIP is not made for use

with a continuous load.

CAUTION

The following steps are advisable:

• Let the motor run slowly, preventing the disc

from getting locked.

• Ensure that the piece to be cut is properly

supported by the tile clamp.

• Check before each cut that the adjustment knobs

for the cutting angle are tightened.

CAUTION

THE MACHINE IS NOT INTENDED FOR USE IN AN

EXPLOSIVE ENVIRONMENT

CAUTION

START THE MACHINE WHEN THE CUTTING TOOL

Warning! When using electric tools, following

safety precautions should always be followed to

injuries. Read and follow all these instructions

before attempting to operate this product and save

them with care!

SAVE THESE INSTRUCTIONS WITH CARE.

Keep your work area perfectly clean

• Cluttered areas invite injuries.

Consider work area environment

• Don’t expose tools to rain.

• Don’t use tools in damp or wet locations. Keep

work area well lit.

• Don’t use tools in presence of ammable liquids

or gases.

Guard against electric shocks

• Prevent body contact with grounded surfaces.

Keep children away!

• Do not let third parties contact tool or extension

cord. All visitors should be kept away from work

area.

17

Battipav srl GB

Store your tools in a save place

• When not in use, tools should be stored in dry and

save places, out of the reach of children.

Don’t force tool

• It will function better and in a safer way at the rate

for which it was intended.

Use the right tool

• Don’t use low duty tools or accessories to do

the job of a heavy-duty tools. Don’t use tools for

purposes not intended.

Dress properly

• Rubber gloves and non-skid footwear are

recommended when working outdoors. Wear

protective hair covering to contain long hair. Use

safety glasses.

• Use a mask if working operations are dusty.

Don’t abuse cord

• Never carry tool by cord or yank it to disconnect it

from socket.

• Keep cord from heat, oil and sharp edges.

Avoid unsteady positions

• Be sure to work in a safe and balanced position.

Maintain tools with care

• Keep tools sharp and clean for better and safer

performance.

• Follow all maintenance advice and instructions to

replace accessories subject to wear. Inspect tool

cords periodically and, if damaged, have them

repaired by an authorised expert. Check extension

cords periodically and replace them if damaged.

Keep handles dry, clean and free from oil and

grease.

Disconnect tools

• When not in use, before servicing, and when

changing accessories subject to wear.

Remove service keys from tool

• Form the habit of checking to see that keys and

adjusting wrenches are removed from tool before

turning it on.

Avoid unintentional starting

• Be sure that the switch is off when plugging in the

tool.

Extension cords for outdoor works

• When tool is used outdoors, use only extension

cords intended for this particular use and so

marked.

Stay alert

• Watch what you are doing. Use common sense.

Do not operate tool when you are inattentive.

Check tool for damaged parts

• Before further use of the tool, check it and the

safety devices for damages and be sure that

they operate properly. Check for functioning

and binding of moving parts, breakage of parts,

correct mounting, and any other conditions that

may affect the correct operation of the tool.

• Damaged safety devices or other parts should

be properly repaired or replaced by an authorised

Service Centre unless otherwise indicated

elsewhere in this instruction manual.

• Have defective switches replaced by an

authorised Service Centre.

• Do not use tool if its switch cannot be turned on or

off.

Warning

• For your personal safety use only accessories

recommended in this instruction manual or in

the relevant catalogues The use of any other

accessory or attachment other than those

recommended in this instruction manual or in the

relevant catalogue may present a risk of personal

injury.

• This electric appliance is in accordance with

the safety rules in force. Only qualied experts

may carry out repairing of electric appliances

otherwise it may cause considerable danger for

the user.

18

GB Battipav srl

MANUFACTURER AND MACHINE

The nameplate shown is tted directly on the

machine. It indicates all the references and

information necessary for safe operation.

AMachine model MIP Level

BItem NYear of

manufacture

CSerial number OMax tool

diameter

DPower supply

voltage PInternal tool

diameter

EPower supply

frequency QAccessories

FCurrent

absorption RAccessories

GInstalled power

rating SManufacturer’s

name

HTool rotation

speed TManufacturer’s

name and

address

IClass of

protection UCertication

Marks

LStarter capacitor

TYPE N°art.

V~ PHz A

min-1 cl.is

Ø max Ø int.

µF IP YEAR

Made by: BATTIPAV SRL

Via Cavatorta, 6/1 Z.i. 2 - 48010 - Cotignola (RA) ITALY

A B C

D E F G

H

O

QR

S

T

P

I L M N

U

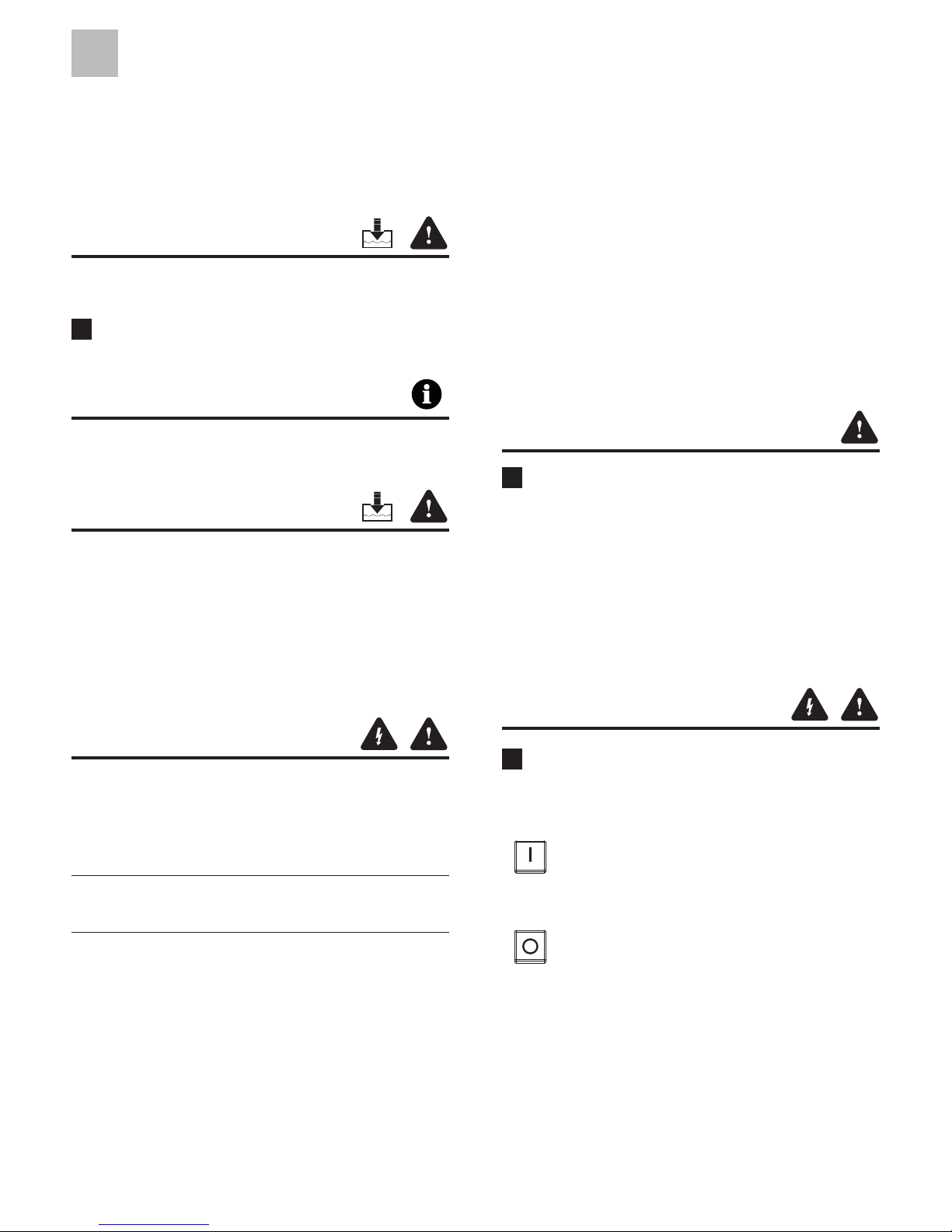

SIGNS

Danger/prohibition stickers are applied to the

machine where necessary. Look at these prior to

using the machine.

A

Use of prescribed PPE

obligatory (Safety

eyewear and earmuffs)

ARead operating

instructions before

each use.

A

Warning!

B

Cut setting 45°

B

Do not use sector discs

BTool diameter

measurements

CRecovery tank water

level

DWarning! Secure the

carriage

A

B

C

D

19

Battipav srl GB

MACHINE DESCRIPTION

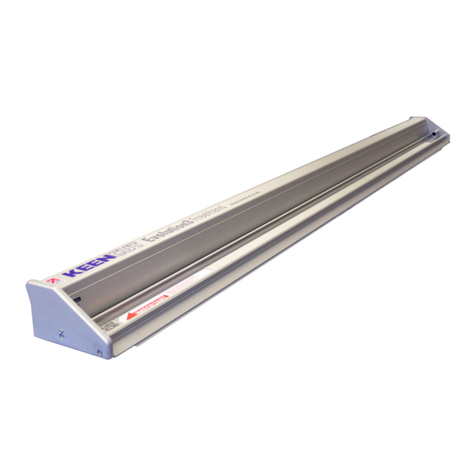

The VIP site cutter is a machine intended specically

for cutting ceramics, single-red items, terracotta,

and marble (Max thickness 20 mm), up to a thickness

of 40 mm.

The machine uses a wet diamond tipped tool cutting

system and is intended for personnel specialized in

the construction sector.

The operator works in front of the narrow side of

the machine, within reach of the operating controls,

and positions the material to be cut on the moving

worktop. He/she starts the machine and moves the

cutting head to bring the tool into contact with the

material.

TECHNICAL DATA

Voltage: 230V 50Hz~

Power absorbed: 1000 W

Admissible working conditions:

INTERMITTENT S3 SERVICE

50% under load running

50% repose

Rotation speed: 2800 min-1

Condenser: 14 µF

Thermal circuit breaker: 170°C

IP Degree: 54

RECOMMENDED USE:

CUTTING TOOL

DIAMOND BLADE WET CUTTING

CONTINUOUS CROWN:

ceramic, single-red ceramic, cotto and marble (max.

thickness 20 mm.)

THE TOOL / MATERIAL TO BE CUT MATCHES ARE

Water recirculation pump: S0 230V 50/60Hz

INSTALLATION

TRANSPORT

The VIP machine is easy to carry by using the

specially provided side handles.

Before carrying the machine make sure that:

• the motor carriage is locked in place with the

two cutting adjustment knobs on the slide rail;

• the motor carriage is completely lowered and

locked with the locking lever;

• the machine is in the 45° (jolly) position and

the inclination adjustment knobs are properly

tightened;

• the tube-holder rod is out of its housing.

3 • the feet are closed with the leg locking pin.

POSITIONING

Place the machine on a stabile surface.

To place the machine in working position, proceed as

follows:

CAUTION

MAKE SURE THAT THE SLIDING CARRIAGE IS

STOPPER.

THE MOTOR SLIDE IS LOCKED IN PLACE WITH

THE TWO CUTTING ADJUSTMENT KNOBS ON

Remove the machine from the packaging with the

aid of the side carrying handles.

To place the machine in working position, proceed as

follows:

41) Remove the machine from the packaging with

the aid of the side carrying handles.

To place the machine in working position,

proceed as follows:

2) Lift the leg making it slide inside the relevant

slot.

53) Repeat the operation for the front part

64) Insert the tube-holder rod in its seat

20

GB Battipav srl

In case of machine disassembly, perform the

opposite operations.

CHECKING BEFORE USE

CAUTION

THE VIP MACHINE HAS BEEN DESIGNED FOR

7Before any cutting operation, make sure that the

water level inside the tank is correct.

CAUTION

Before using the machine, check there is power

supply.

CAUTION

ADJUSTMENT OF COOLING WATER

Through an on-off valve placed on the disk protection,

the water ow can be adjusted according to the type

of material to be cut.

An innovative cooling system makes it possible and

allows the disk to be always wet.

CAUTION

The machine is to be connected to the power supply

by a residual current circuit breaker (RCCB) with the

following characteristics:

RCCB In 6 A Id 30 mA

Transformer 230 V 50 Hz 1500 W

Transformer

N.B. To ensure correct functioning, periodically

push-button on the front of the device.

• Make sure that the section of the power supply

cable cores has been measured according to the

starting current and its length.

For cables up to 50 m long, a section of 2.5 mm2

is enough.

• Before connecting the machine to the power

socket, check that the power supply voltage

corresponds to that shown on the plate on the

machine.

• The machine must be connected to an effective

earth wire.

In case of doubt, do not connect the machine.

Before performing any operation or adjustment,

disconnect the machine from the supply mains.

Loosen both nuts located on the blade cover guard

and remove it.

Remove the blade xing nut using the 19 mm

spanner and the 5 mm Allen wrench.

CAUTION

8THE BLADE FIXING NUT HAS A LEFT-HAND

THREAD.

After dismantling the blade, clean the blade anges

carefully and check them for wear.

Grease any surface with ne oil and install the new

blade. Check for correct direction of rotation as

clearly indicated on the tool.

CONTROL DEVICES

CAUTION

9The VIP machine is equipped with a control

board made up of:

1) START BUTTON (GREEN COLOUR):

Press the button fully to activate machine

starting.

2) REGULAR STOP BUTTON:

Press the button fully to activate machine

stop.

21

Battipav srl GB

3) DEVICE FOR DISCONNECTION FROM THE

MAINS (PLUG):

Machine power supply point.

During the maintenance phases, take out the

device plug in order to disconnect the machine

from the mains.

CUTTING ON THE TABLE

CAUTION

BEFOREPERFORMINGTHE CUTTINGOPERATIONS,

LEANED AGAINST THE TILE STOPPER.

CAUTION

10 BEFORE STARTING THE CUTTING

OPERATIONS, THE OPERATOR MUST MAKE

SURE THAT AT LEAST 150 cm ARE LEFT FREE

AROUND THE MACHINE (Pos. 2).

DO NOT LET OTHER PEOPLE REMAIN NEAR

THE MACHINE DURING THE CUTTING

OPERATIONS.

THE OPERATOR STANDS IN THE WORKING

POSITION (Pos. 1) DURING THE DIFFERENT

MACHINE OPERATION PHASES.

11 Take the disk to the 0° position with the inclination

adjustment knobs.

Position the piece which needs cutting on the

working table and make sure that it is properly

leaned against the tile-stopper. If necessary, a

bearing square can be of help.

CAUTION

THE MILLIMETRE RULER PLACED ON THE

12 In order to carry out any diagonal cutting lean

the tile against the square the way it is shown in

picture 12 and go on with the cutting operation.

CUTTING A SURFACE AT 45°

CAUTION

Before positioning the motor head, make sure that:

CAUTION

12 Take the cutting blade to the 45° position with

the inclination adjustment knobs.

Lock the motor carriage at the max. cutting

depth with the locking lever.

13 Picture 13 shows the proper way the machine

should be used.

With the VIP machine it is also possible to set out:

11 a) the cutting length with the cutting adjustment

knobs.

13 b) the cutting depth with the locking lever.

11 c) the straight cut measurement with the tile

bearing square as well as the ruler placed on

the working table.

d) the cutting adjustment with the specially

provided indicator and ruler placed on the slide

rail.

14 In order to carry out special working it is possible

to set out any cutting inclination ranging from 0°

to 45° as marked on the machine side.

CAUTION

TILE-STOPPER.

22

GB Battipav srl

RESIDUAL RISKS

During the design phase, BATTIPAV SRL paid

particular CAUTION to the aspects that may generate

risks for the safety and health of operators.

In spite of this, there are still some potential risks,

which are described below:

CAUTION

• Danger of presence of electric current.

The machine has an internal electric system:

DIFFERENTIAL PROTECTION AND EFFECTIVE

EARTH WIRE.

CAUTION

• Danger of prolonged exposure to noise:

The continuative use of the machine causes an

exposure to noise levels above 85 dB (A).

OPERATORS MUST USE PROPER EAR

DEFENDERS.

CAUTION

• Danger of exposure to fragments of

materials. OPERATORS MUST WEAR

PROTECTIVE GOGGLES.

CAUTION

• Danger of accidental contact with the moving

tool.

GLOVES

(Pos. 1 picture 10) DURING THE MACHINE

OPERATION PHASES:

• During material loading;

• During material cutting;

• During the cutting tool deceleration following the

machine stop.

MAINTENANCE

CAUTION

ADJUSTMENT, DISCONNECT THE MACHINE FROM

CLEANING

CAUTION

DO NOT WASH THE MACHINE WITH HIGH

PRESSURE WATER JETS

15 It is extremely easy to clean the VIP machine by

loosening the side knobs and dismantling the

working table.

Through the side tap remove any working

residual.

16 17 When necessary clean the sprayer as

shown.

CAUTION

18 MOTOR CARRIAGE ADJUSTMENT

The motor carriage is provided with a register for

the vertical play adjustment.

If any excessive play of the motor carriage

should take place, act as follows:

1) Loosen the register xing nut with a 10 mm

wrench;

2) Screw down the dowel with a 3 mm Allen key until

the play is eliminated.

3) Lock the register again with the xing nut.

23

Battipav srl GB

DISPOSAL

When parts wear out or when the machine is nally

scrapped, waste disposal must be carried out in

compliance with the laws in force.

Electric Motor

Aluminium AL

Steel AC

Copper CU

Polyamide PA

Main Body

Steel AC

Polyamide PA

Submersed pump

Polyamide PA

Steel AC

Aluminium AL

Copper CU

Epoxy Resin

W.E.E.E. IT08020000002803

The European Directive 2002/96/CE

arranges that in the event of scrapping

of electrical equipment, they must not

be disposed of city solid refusals but collected

separately, in order to optimize the level of recovery

and recycling of the materials and above all in order

to prevent damages to health and environment.

To comply with European Directive 2002/96/CE, all

electrical equipments must be marked with crossed

basket symbol.

The packing of the machine will be disposed of in

accordance with the methods laid down by current

legislation.

For further information concerning disposal

of electrical equipment, please refer to public

administration service.

TROUBLESHOOTING

persons using original spare parts, otherwise this may result in considerable danger to the user.

Faul Cause Remedy

The machine does not work. The power supply cable is damaged or

not properly connected.

Press the plug rmly into the power

socket. Check the power supply cable.

No voltage in the socket. Have the socket checked.

Control switch is damaged. Consult local dealer for replacement.

If lubrication does not arrive at the

disk with the pump running.

The sprayer unit is clogged. Dismantle the sprayer assembled inside

the disk cover and remove any possible

residuals.

Motor gives off unpleasant odour. Water may have seeped through inside

the motor

Unplug the power supply cable and

consult local dealer.

Motor bearings are damaged. Unplug the power supply cable and

consult local dealer.

The machine is cutting out of square. The tile supports are not at right angles

with the cutting disc.

Using a square, adjust the tile supports

to 90° in relation to the cutting line of

the disc.

The disc is not suitable for the type of

material to be cut.

Replace the disc with a more suitable

one.

This manual suits for next models

3

Table of contents

Other Battipav Cutter manuals

Battipav

Battipav Extra 3300 Superlunga User manual

Battipav

Battipav Extra 3300 Superlunga User manual

Battipav

Battipav MAGIK User manual

Battipav

Battipav Foragres User manual

Battipav

Battipav Queen 180 User manual

Battipav

Battipav PROFI EVO 6401EV User manual

Battipav

Battipav Super Pro 450 User manual

Battipav

Battipav CLASS plus User manual

Battipav

Battipav Super Pro 450 User manual

Battipav

Battipav SINTESI User manual