“TRANSLATION OF THE ORIGINAL INSTRUCTIONS”

PURPOSE OF THIS MANUAL

This manual is an integral part of the machine.

It was produced by BATTIPAV S.R.L. to provide

those authorised to work with the machine with the

information required for its foreseeable lifespan.

Before starting to use this machine read the safety

chapter carefully.

Each machine is subjected to a series of tests and

carefully checked before leaving our factory.

BATTIPAV S.R.L. is constantly striving to develop

their machines and therefore reserves the right to

make any change without prior notice. Therefore, no

claims may be made on the basis of the data and

illustrations contained in this manual.

SAFETY INFORMATION

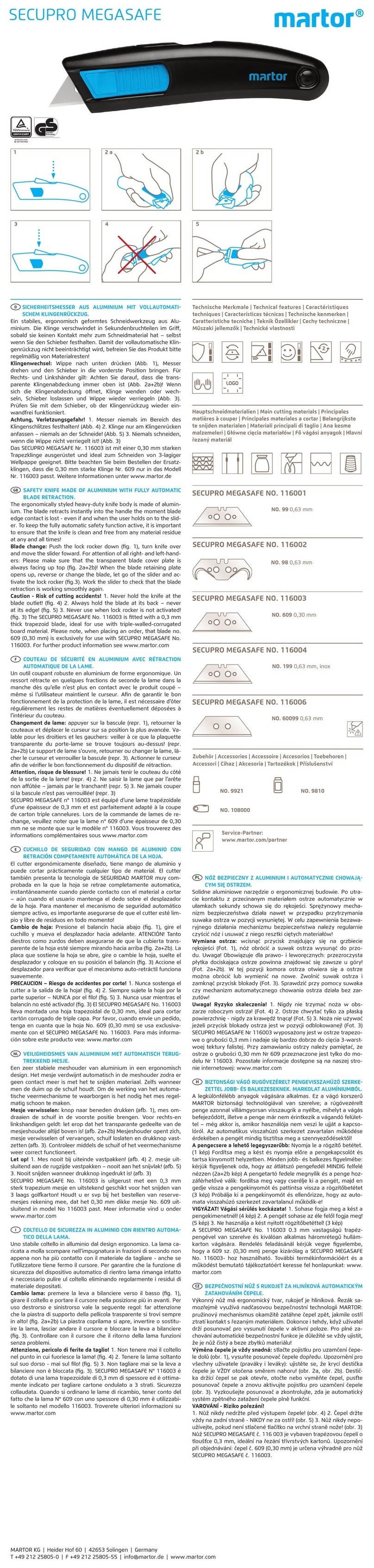

• The manufacturer accepts no responsibility

where the DYNAMIC cutter is used with

any tools other than those specied in

the “RECOMMENDED USE” paragraph.

DO NOT USE WOODEN DISCS.

DO NOT USE DRY-CUTTING DISCS.

• DYNAMIC is made to operate exclusively under the

conditions indicated under “TYPE OF OPERATION

ALLOWED”, in the “TECHNICAL DATA” paragraph.

• During cutting operations, allow the machine to

rest as indicated.

• DYNAMIC is not made for use with a continuous

load.

CAUTION

DO NOT USE DIAMOND TIPPED DISCS OF LOW

QUALITY OR THAT ARE NOT SUITABLE FOR THE

SPECIFIC USE FOR WHICH THE MANUFACTURER

SUPPLIED THEM. THE USE OF POOR QUALITY

DISCS CAN HARM THE OPERATOR AND DAMAGE

THE MACHINE, AS WELL AS SIGNIFICANTLY

SLOWING THE WORK.

CAUTION

THE MACHINE IS NOT INTENDED FOR USE IN AN

EXPLOSIVE ENVIRONMENT

CAUTION

ALWAYS USE INDIVIDUAL PROTECTION DEVICES

TO REDUCE THE RISKS CAUSED BY WORK. NEVER

START THE MACHINE WHEN THE CUTTING TOOL

IS MOVING; WAIT FOR IT TO STOP.

Warning! When using electric tools, following

safety precautions should always be followed to

reduce the risk of re, electric shock and personal

injuries. Read and follow all these instructions

before attempting to operate this product and save

them with care!

SAVE THESE INSTRUCTIONS WITH CARE.

Keep your work area perfectly clean

• Cluttered areas invite injuries.

Consider work area environment

• Don’t expose tools to rain.

• Don’t use tools in damp or wet locations. Keep

work area well lit.

• Don’t use tools in presence of ammable liquids

or gases.

Guard against electric shocks

• Prevent body contact with grounded surfaces.

Keep children away!

• Do not let third parties contact tool or extension

cord. All visitors should be kept away from work

area.

Store your tools in a save place

• When not in use, tools should be stored in dry and

save places, out of the reach of children.

Don’t force tool

• It will function better and in a safer way at the rate

for which it was intended.

Use the right tool

• Don’t use low duty tools or accessories to do

the job of a heavy-duty tools. Don’t use tools for

purposes not intended.